-

钙钛矿铁电压电材料具有高介电压电常数和高机电耦合系数等特点, 在工业、消费电子和军事等领域具有广泛的应用, 其压电性能起源的机理及与材料多尺度结构之间的关系一直是凝聚态物理和材料科学领域的研究热点. 铁电材料的压电效应主要来源于本征的场致晶格畸变以及非本征的畴翻转和畴壁运动, 理解并区分这两种压电效应的贡献机制对研究材料压电性能的起源具有重要意义. 本文综述了近年来通过电场原位X射线衍射技术分析电场作用下材料晶格结构和畴结构变化的技术手段和研究方法, 重点介绍了自第三代同步辐射光源和高速探测器获得长足发展以来, 通过时间分辨衍射技术、单双峰拟合、全谱拟合、质心计算等方法开展压电材料本征和非本征贡献, 以及电场诱导相变对其宏观性能影响的研究进展, 期望通过对各类方法的介绍和回顾为多种压电材料的机理分析提供研究方法和技术支持.Ferroelectric/piezoelectric perovskites are an important class of functional material and have broad application prospects in commercial, industrial, military and other areas because of their high dielectric constants, high piezoelectric coefficients, and high electromechanical coupling coefficients. Their structures, applications, and physical mechanisms have been intensively studied in condensed matter physics and material science. The piezoelectric properties of ferroelectric materials mainly originate from the intrinsic field-induced lattice distortion and extrinsic domain inversion and domain wall motion. Therefore, the understanding of and the distinguishing between these mechanisms are important for ascertaining the origin of the high-piezoelectric properties and developing new functional materials. In this article, we review the research progress of technical means and methodology of analyzing the changes of crystal lattices and magnetic domains of materials under the action of an externally applied electric field through the high-energy synchrotron X-ray diffraction experiments. The techniques and analysis methods involved in the review cover the time-resolved X-ray diffraction, single/double-peak analysis, full-pattern refinement, center-of-mass calculation, and field-induced phase transformation analysis, which are used to study the intrinsic and extrinsic contributions to sample’s macroscopic properties. It is expected to provide the research methods, which fulfill the individual experimental requirements, and the technical support for the mechanism analysis of various piezoelectric materials through the introduction and review of various methods.

[1] Berlincourt D 1992 J. Acoust. Soc. Am. 91 3034

Google Scholar

Google Scholar

[2] King T G, Preston M E, Murphy B J M, Cannell D S 1990 Precis. Eng. 12 131

Google Scholar

Google Scholar

[3] Uchino K 2015 Sci. Technol. Adv. Mater. 16 46001

Google Scholar

Google Scholar

[4] Haertling G H 1999 J. Am. Ceram. Soc. 82 797

Google Scholar

Google Scholar

[5] Bellaiche L, Vanderbilt D 1999 Phys. Rev. Lett. 83 1347

Google Scholar

Google Scholar

[6] Li F, Lin D, Chen Z, Cheng Z, Wang J, Li C, Xu Z, Huang Q, Liao X, Chen L Q, Shrout T R, Zhang S 2018 Nat. Mater. 17 349

Google Scholar

Google Scholar

[7] Park S E, Shrout T R 1997 J. Appl. Phys. 82 1804

Google Scholar

Google Scholar

[8] Zhang N, Yokota H, Glazer A M, Ren Z, Keen D A, Keeble D S, Thomas P A, Ye Z G 2014 Nat. Commun. 5 5231

Google Scholar

Google Scholar

[9] Guo R, Cross L E, Park S E, Noheda B, Cox D E, Shirane G 2000 Phys. Rev. Lett. 84 5423

Google Scholar

Google Scholar

[10] Hollenstein E, Davis M, Damjanovic D, Setter N 2005 Appl. Phys. Lett. 87 182905

Google Scholar

Google Scholar

[11] Xu K, Li J, Lv X, Wu J, Zhang X, Xiao D, Zhu J 2016 Adv. Mater. 28 8519

Google Scholar

Google Scholar

[12] Wang X, Wu J, Xiao D, Zhu J, Cheng X, Zheng T, Zhang B, Lou X, Wang X 2014 J. Am. Chem. Soc. 136 2905

Google Scholar

Google Scholar

[13] Wang K, Li J F 2010 Adv. Funct. Mater. 20 1924

Google Scholar

Google Scholar

[14] Saito Y, Takao H, Tani T, Nonoyama T, Takatori K, Homma T, Nagaya T, Nakamura M 2004 Nature 432 84

Google Scholar

Google Scholar

[15] McQuade R R, Dolgos M R 2016 J. Solid State Chem. 242 140

Google Scholar

Google Scholar

[16] Paterson A R, Nagata H, Tan X, Daniels J E, Hinterstein M, Ranjan R, Groszewicz P B, Jo W, Jones J L 2018 MRS Bull. 43 600

Google Scholar

Google Scholar

[17] Du X H, Zheng J, Belegundu U, Uchino K 1998 Appl. Phys. Lett. 72 2421

Google Scholar

Google Scholar

[18] Fu H, Cohen R E 2000 Nature 403 281

Google Scholar

Google Scholar

[19] Noheda B, Cox D E 2006 Phase Transitions 79 5

Google Scholar

Google Scholar

[20] Ye Z G, Noheda B, Dong M, Cox D, Shirane G 2001 Phys. Rev. B 64 184114

Google Scholar

Google Scholar

[21] Li F, Zhang S, Damjanovic D, Chen L Q, Shrout T R 2018 Adv. Funct. Mater. 28 1801504

Google Scholar

Google Scholar

[22] Clegg W 2015 X-ray Crystallography (New York: Oxford University Press) pp1–31

[23] Rietveld H M 1969 J. Appl. Crystallogr. 2 65

Google Scholar

Google Scholar

[24] Hammond C 2009 The Basics of Crystallography and Diffraction Struct. Chem. (New York: Oxford University Press) pp252–267

[25] David W I F, Shankland K, Baerlocher C, McCusker L B 2002 Structure Determination from Powder Diffraction Data (New York: Oxford University Press) pp88–93

[26] Tagantsev A K, Cross L E, Fousek J 2010 Domains in Ferroic Crystals and Thin Films (New York: Springer New York) pp11–74

[27] Viehland D D, Salje E K H 2014 Adv. Phys. 63 267

Google Scholar

Google Scholar

[28] Jones J L, Aksel E, Tutuncu G, Usher T M, Chen J, Xing X, Studer A J 2012 Phys. Rev. B 86 024104

Google Scholar

Google Scholar

[29] Als-Nielsen J, McMorrow D 2011 Elements of Modern X-ray Physics (Chichester: A John Wiley & Sons, Ltd Publication) pp33–42

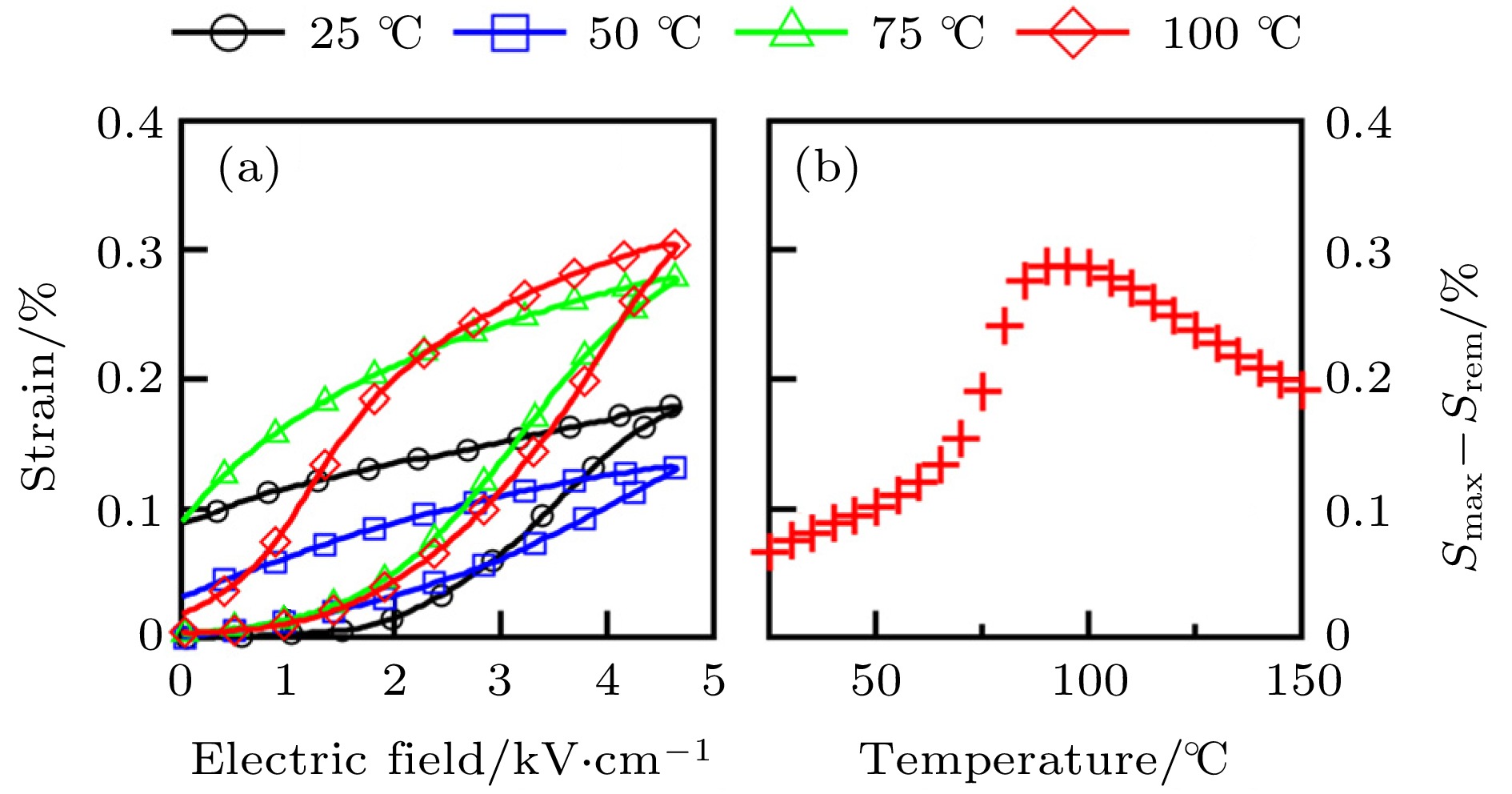

[30] Broennimann C 2008 Acta Crystallogr. Sect. A Found. Crystallogr. 64 C162

Google Scholar

Google Scholar

[31] Daniels J E, Finlayson T R, Studer A J, Hoffman M, Jones J L 2007 J. Appl. Phys. 101 094104

Google Scholar

Google Scholar

[32] Daniels J, Pramanick A, Jones J 2009 IEEE Trans. Ultrason. Ferroelectr. Freq. Control 56 1539

Google Scholar

Google Scholar

[33] Choe H, Bieker J, Zhang N, Glazer A M, Thomas P A, Gorfman S 2018 IUCrJ 5 417

Google Scholar

Google Scholar

[34] Eckold G, Schober H, Nagler S E 2010 Studying Kinetics with Neutrons (Berlin, Heidelberg: Springer Berlin Heidelberg) pp149–173

[35] Jiang A Q, Lee H J, Hwang C S, Scott J F 2012 Adv. Funct. Mater. 22 192

Google Scholar

Google Scholar

[36] Bai F, Wang N, Li J, Viehland D, Gehring P M, Xu G, Shirane G 2004 J. Appl. Phys. 96 1620

Google Scholar

Google Scholar

[37] Ehara Y, Yasui S, Nagata J, Kan D, Anbusathaiah V, Yamada T, Sakata O, Funakubo H, Nagarajan V 2011 Appl. Phys. Lett. 99 182906

Google Scholar

Google Scholar

[38] Rana D S, Kawayama I, Mavani K, Takahashi K, Murakami H, Tonouchi M 2009 Adv. Mater. 21 2881

Google Scholar

Google Scholar

[39] Eckold G, Gibhardt H, Caspary D, Elter P, Elisbihani K 2003 Z. Kristallogr. 218 144

Google Scholar

Google Scholar

[40] Choe H, Heidbrink S, Ziolkowski M, Pietsch U, Dyadkin V, Gorfman S, Chernyshov D 2017 J. Appl. Crystallogr. 50 975

Google Scholar

Google Scholar

[41] Usher T M, Levin I, Daniels J E, Jones J L 2015 Sci. Rep. 5 14678

Google Scholar

Google Scholar

[42] Vergentev T, Bronwald I, Chernyshov D, Gorfman S, Ryding S H M, Thompson P, Cernik R J 2016 J. Appl. Crystallogr. 49 1501

Google Scholar

Google Scholar

[43] Kitanaka Y, Noguchi Y, Miyayama M, Kagawa Y, Moriyoshi C, Kuroiwa Y 2013 Ferroelectrics 443 1

Google Scholar

Google Scholar

[44] Moriyoshi C, Hiramoto S, Ohkubo H, Kuroiwa Y, Osawa H, Sugimoto K, Kimura S, Takata M, Kitanaka Y, Noguchi Y, Miyayama M 2011 Jpn. J. Appl. Phys. 50 09NE05

Google Scholar

Google Scholar

[45] Gorfman S, Keeble D S, Glazer A M, Long X, Xie Y, Ye Z G, Collins S, Thomas P A 2011 Phys. Rev. B 84 020102

Google Scholar

Google Scholar

[46] Gorfman S, Thomas P A 2010 J. Appl. Crystallogr. 43 1409

Google Scholar

Google Scholar

[47] Datta K, Gorfman S, Thomas P A 2009 Appl. Phys. Lett. 95 251901

Google Scholar

Google Scholar

[48] Daymond M R 2004 J. Appl. Phys. 96 4263

Google Scholar

Google Scholar

[49] Pramanick A, Damjanovic D, Daniels J E, Nino J C, Jones J L 2011 J. Am. Ceram. Soc. 94 293

Google Scholar

Google Scholar

[50] Ehmke M C, Khansur N H, Daniels J E, Blendell J E, Bowman K J 2014 Acta Mater. 66 340

Google Scholar

Google Scholar

[51] Jones J L, Slamovich E B, Bowman K J 2005 J. Appl. Phys. 97 034113

Google Scholar

Google Scholar

[52] Jones J L, Hoffman M, Bowman K J 2005 J. Appl. Phys. 98 024115

Google Scholar

Google Scholar

[53] Kungl H, Theissmann R, Knapp M, Baehtz C, Fuess H, Wagner S, Fett T, Hoffmann M J 2007 Acta Mater. 55 1849

Google Scholar

Google Scholar

[54] Hall D A, Steuwer A, Cherdhirunkorn B, Mori T, Withers P J 2004 J. Appl. Phys. 96 4245

Google Scholar

Google Scholar

[55] Fan L, Chen J, Ren Y, Pan Z, Zhang L, Xing X 2016 Phys. Rev. Lett. 116 027601

Google Scholar

Google Scholar

[56] Hinterstein M, Lee K Y, Esslinger S, Glaum J, Studer A J, Hoffman M, Hoffmann M J 2019 Phys. Rev. B 99 174107

Google Scholar

Google Scholar

[57] Matthies S, Lutteroti L, Wenk H R 1997 J. Appl. Crystallogr. 30 31

Google Scholar

Google Scholar

[58] Lutterotti L, Bortolotti M, Ischia G, Lonardelli I, Wenk H R 2007 Z. Kristallogr. Suppl. 26 125

Google Scholar

Google Scholar

[59] Hinterstein M, Hoelzel M, Rouquette J, Haines J, Glaum J, Kungl H, Hoffman M 2015 Acta Mater. 94 319

Google Scholar

Google Scholar

[60] Khansur N H, Hinterstein M, Wang Z, Groh C, Jo W, Daniels J E 2015 Appl. Phys. Lett. 107 242902

Google Scholar

Google Scholar

[61] Zhao C, Hou D, Chung C-C, Zhou H, Kynast A, Hennig E, Liu W, Li S, Jones J L 2018 Acta Mater. 158 369

Google Scholar

Google Scholar

[62] Fu J, Zuo R, Xu Y, Li J F, Shi M 2017 J. Eur. Ceram. Soc. 37 975

Google Scholar

Google Scholar

[63] Ochoa D A, Esteves G, Iamsasri T, Rubio-Marcos F, Fernández J F, García J E, Jones J L 2016 J. Eur. Ceram. Soc. 36 2489

Google Scholar

Google Scholar

[64] Zheng T, Wu H, Yuan Y, Lv X, Li Q, Men T, Zhao C, Xiao D, Wu J, Wang K, Li J F, Gu Y, Zhu J, Pennycook S J 2017 Energy Environ. Sci. 10 528

Google Scholar

Google Scholar

[65] Tutuncu G, Li B, Bowman K, Jones J L 2014 J. Appl. Phys. 115 144104

Google Scholar

Google Scholar

[66] Khansur N H, Rojac T, Damjanovic D, Reinhard C, Webber K G, Kimpton J A, Daniels J E 2015 J. Am. Ceram. Soc. 98 3884

Google Scholar

Google Scholar

[67] Li Y, Chen Y, Zhang Z, Kleppe A, Hall D A 2019 Acta Mater. 168 411

Google Scholar

Google Scholar

[68] Zuo R, Qi H, Fu J, Li J F, Li L 2017 Appl. Phys. Lett. 111 132901

Google Scholar

Google Scholar

[69] Hu C, Meng X, Zhang M H, Tian H, Daniels J E, Tan P, Huang F, Li L, Wang K, Li J F, Lu Q, Cao W, Zhou Z 2020 Sci. Adv. 6 eaay5979

Google Scholar

Google Scholar

[70] Zhang N, Gorfman S, Choe H, Vergentev T, Dyadkin V, Yokota H, Chernyshov D, Wang B, Glazer A M, Ren W, Ye Z G 2018 J. Appl. Crystallogr. 51 1396

Google Scholar

Google Scholar

[71] Hinterstein M, Knapp M, Hölzel M, Jo W, Cervellino A, Ehrenberg H, Fuess H 2010 J. Appl. Crystallogr. 43 1314

Google Scholar

Google Scholar

[72] Kling J, Tan X, Jo W, Kleebe H J, Fuess H, Rödel J 2010 J. Am. Ceram. Soc. 93 2452

Google Scholar

Google Scholar

[73] Daniels J E, Jo W, Rödel J, Honkimäki V, Jones J L 2010 Acta Mater. 58 2103

Google Scholar

Google Scholar

[74] Durbin M K, Jacobs E W, Hicks J C, Park S E 1999 Appl. Phys. Lett. 74 2848

Google Scholar

Google Scholar

[75] Damjanovic D 2005 J. Am. Ceram. Soc. 88 2663

Google Scholar

Google Scholar

[76] Noheda B, Cox D E, Shirane G, Park S E, Cross L E, Zhong Z 2001 Phys. Rev. Lett. 86 3891

Google Scholar

Google Scholar

[77] Fu J, Zuo R, Gao X 2013 Appl. Phys. Lett. 103 182907

Google Scholar

Google Scholar

[78] Li P, Zhai J, Shen B, Zhang S, Li X, Zhu F, Zhang X 2018 Adv. Mater. 30 1705171

Google Scholar

Google Scholar

[79] Yao F Z, Wang K, Jo W, Webber K G, Comyn T P, Ding J X, Xu B, Cheng L Q, Zheng M P, Hou Y D, Li J F 2016 Adv. Funct. Mater. 26 1217

Google Scholar

Google Scholar

[80] Simons H, Daniels J E, Glaum J, Studer A J, Jones J L, Hoffman M 2013 Appl. Phys. Lett. 102 062902

Google Scholar

Google Scholar

[81] Ren P, Liu Z, Liu H, Sun S, Wan Y, Long C, Shi J, Chen J, Zhao G 2019 J. Eur. Ceram. Soc. 39 994

Google Scholar

Google Scholar

[82] Wang G, Fan Z, Murakami S, Lu Z, Hall D A, Sinclair D C, Feteira A, Tan X, Jones J L, Kleppe A K, Wang D, Reaney I M 2019 J. Mater. Chem. A 7 21254

Google Scholar

Google Scholar

[83] Xu G, Zhong Z, Bing Y, Ye Z G, Shirane G 2006 Nat. Mater. 5 134

Google Scholar

Google Scholar

[84] Xu G, Wen J, Stock C, Gehring P M 2008 Nat. Mater. 7 562

Google Scholar

Google Scholar

[85] Paściak M, Welberry T R, Kulda J, Kempa M, Hlinka J 2012 Phys. Rev. B 85 224109

Google Scholar

Google Scholar

[86] Li F, Zhang S, Yang T, Xu Z, Zhang N, Liu G, Wang J, Wang J, Cheng Z, Ye Z G, Luo J, Shrout T R, Chen L Q 2016 Nat. Commun. 7 13807

Google Scholar

Google Scholar

[87] Polinger V, Bersuker I B 2018 Phys. Rev. B 98 214102

Google Scholar

Google Scholar

[88] Bokov A A, Ye Z G 2006 J. Mater. Sci. 41 31

Google Scholar

Google Scholar

[89] Xu G, Zhong Z, Hiraka H, Shirane G 2004 Phys. Rev. B 70 174109

Google Scholar

Google Scholar

[90] Welberry T R 2004 Diffuse X-Ray Scattering and Models of Disorder (New York: Oxford University Press) pp4−20

-

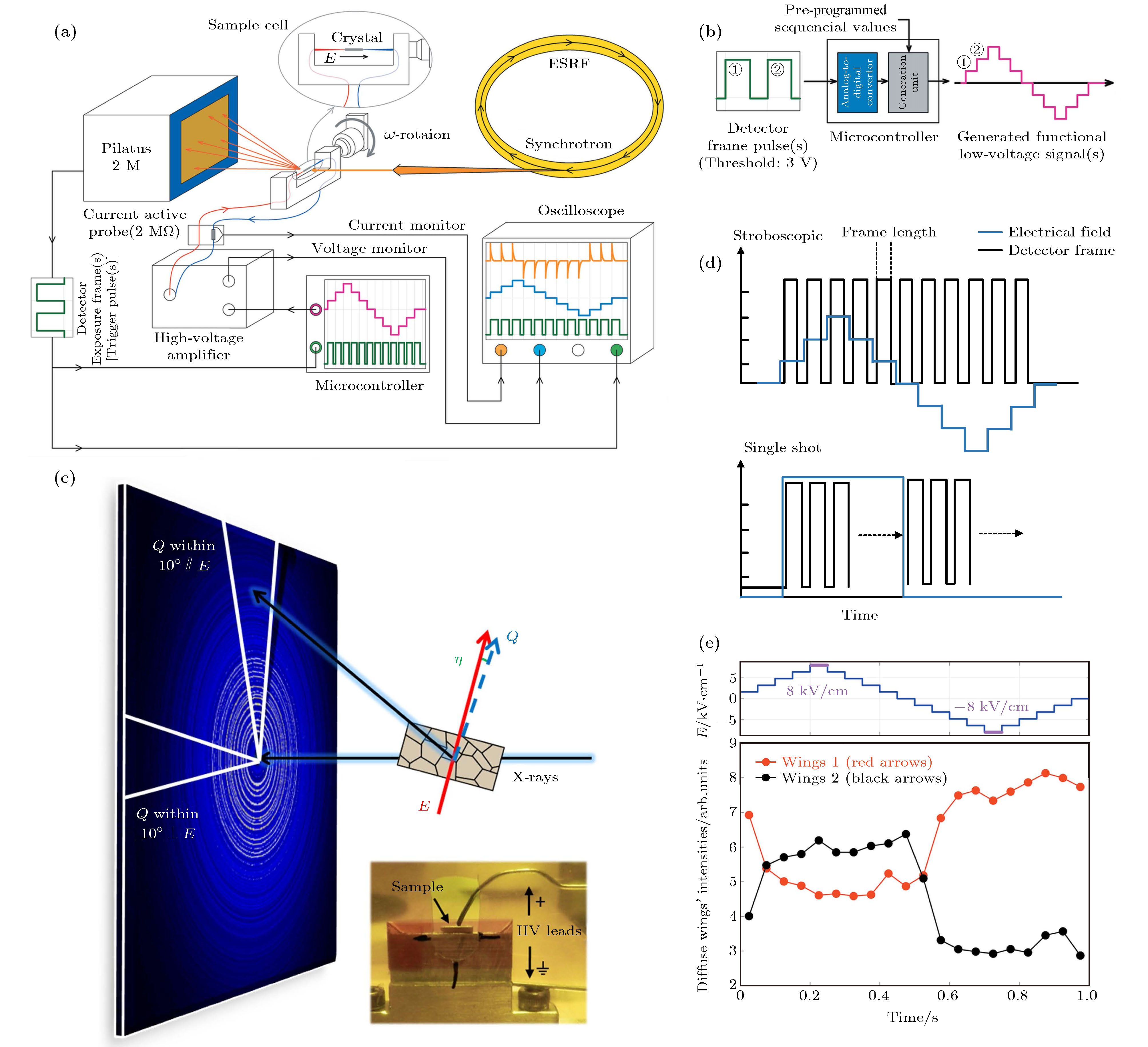

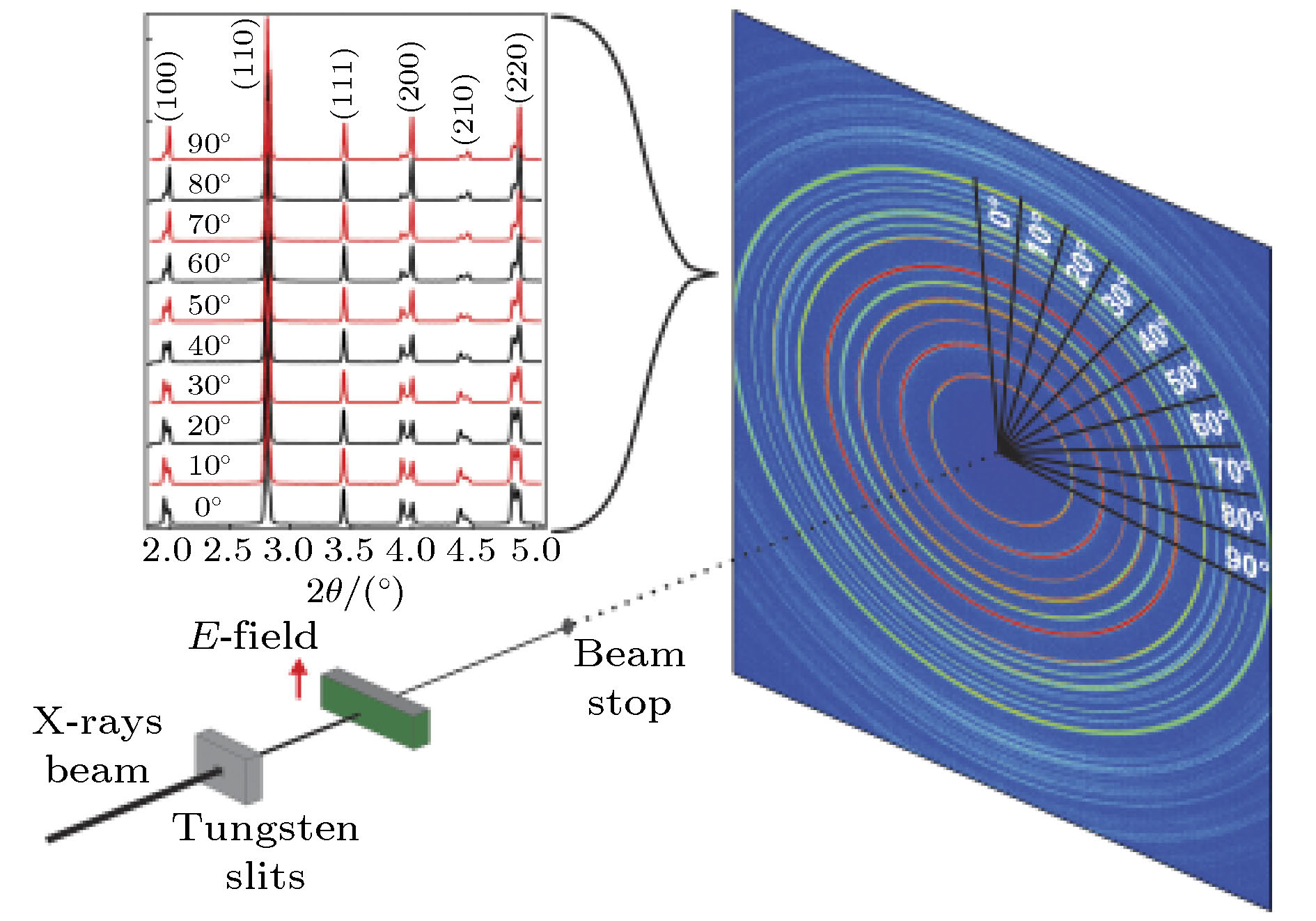

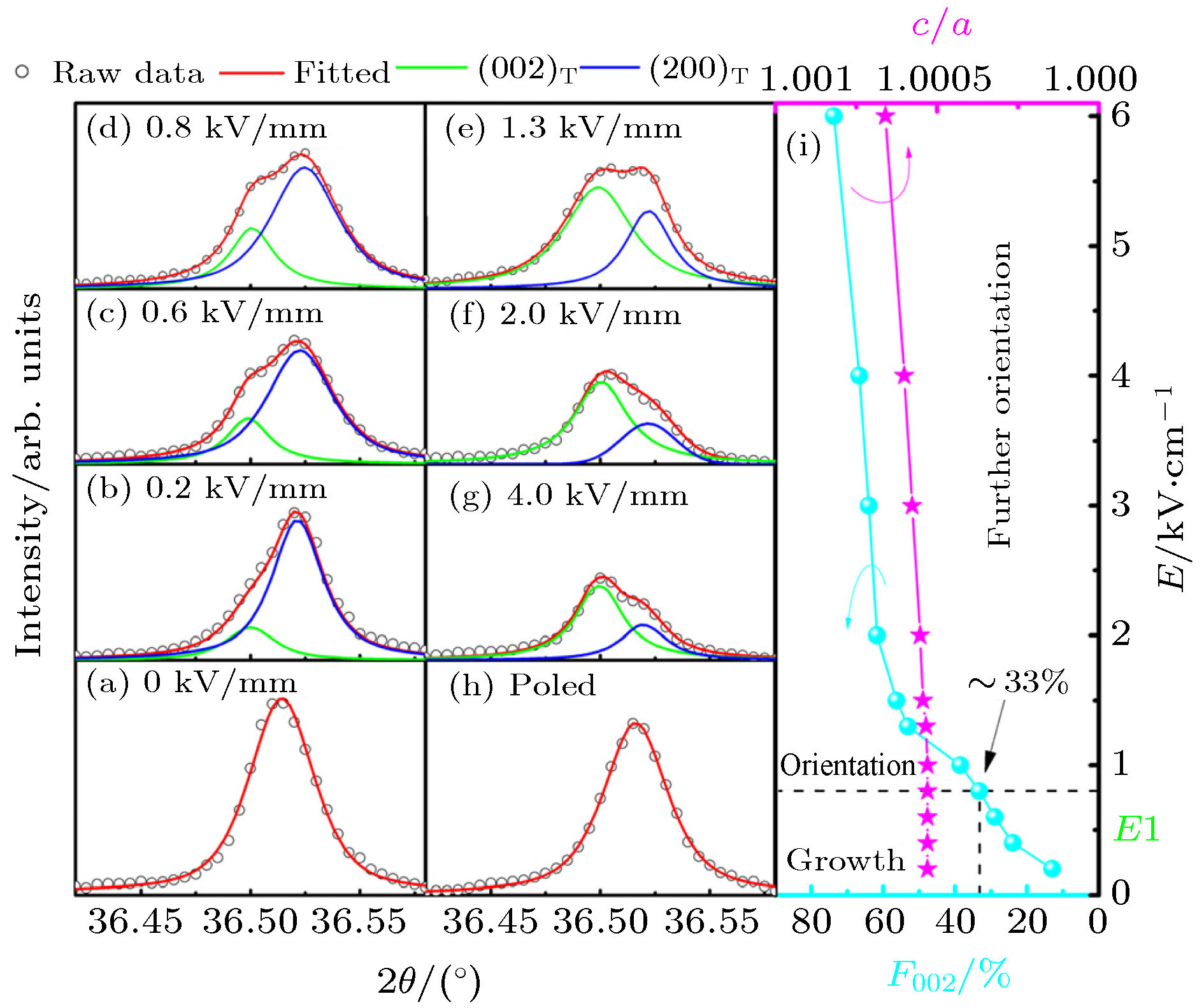

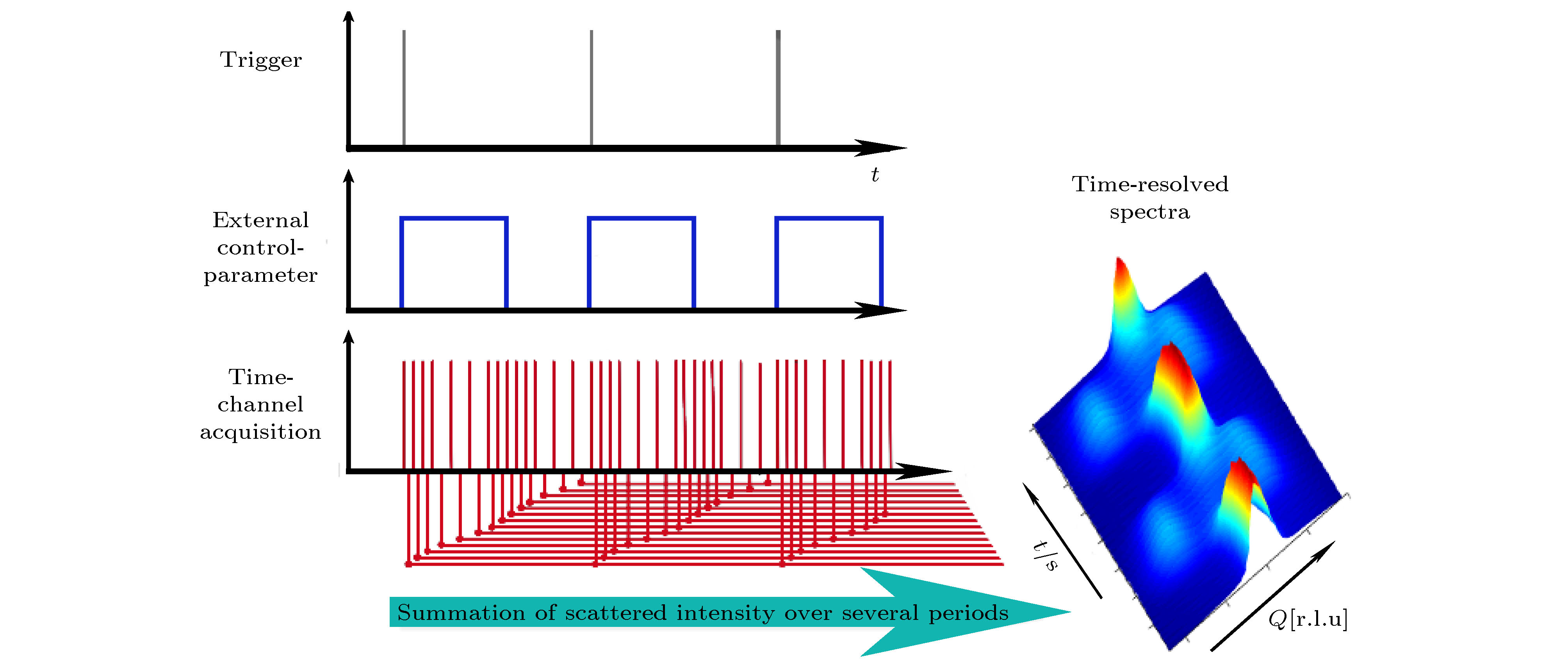

图 2 (a) Choe等[40]的数据采集系统; (b) Choe等[40]的系统中信号同步过程; (c) Daniels等[41]的数据采集系统; (d) Daniels等的系统中数据采集的时间序列; (e)频闪技术中样品所施加电场与时间的关系, 以及相关衍射强度随电场变化趋势[40]

Fig. 2. (a) Data acquisition system by Choe et al.[40]; (b) signal synchronization process in the system of Choe et al.[40]; (c) data acquisition system by Daniels et al.[41]; (d) timing sequences for data acquisition processes in the system of Daniels et al.; (e) time dependence of the AC electric field and the collected intensity of diffraction wings, showing the field-induced intensity exchange between the two wings[40]. (a) (b) (e) Copyright © 2017 International Union of Crystallography. Reproduced with permission of the International Union of Crystallography.

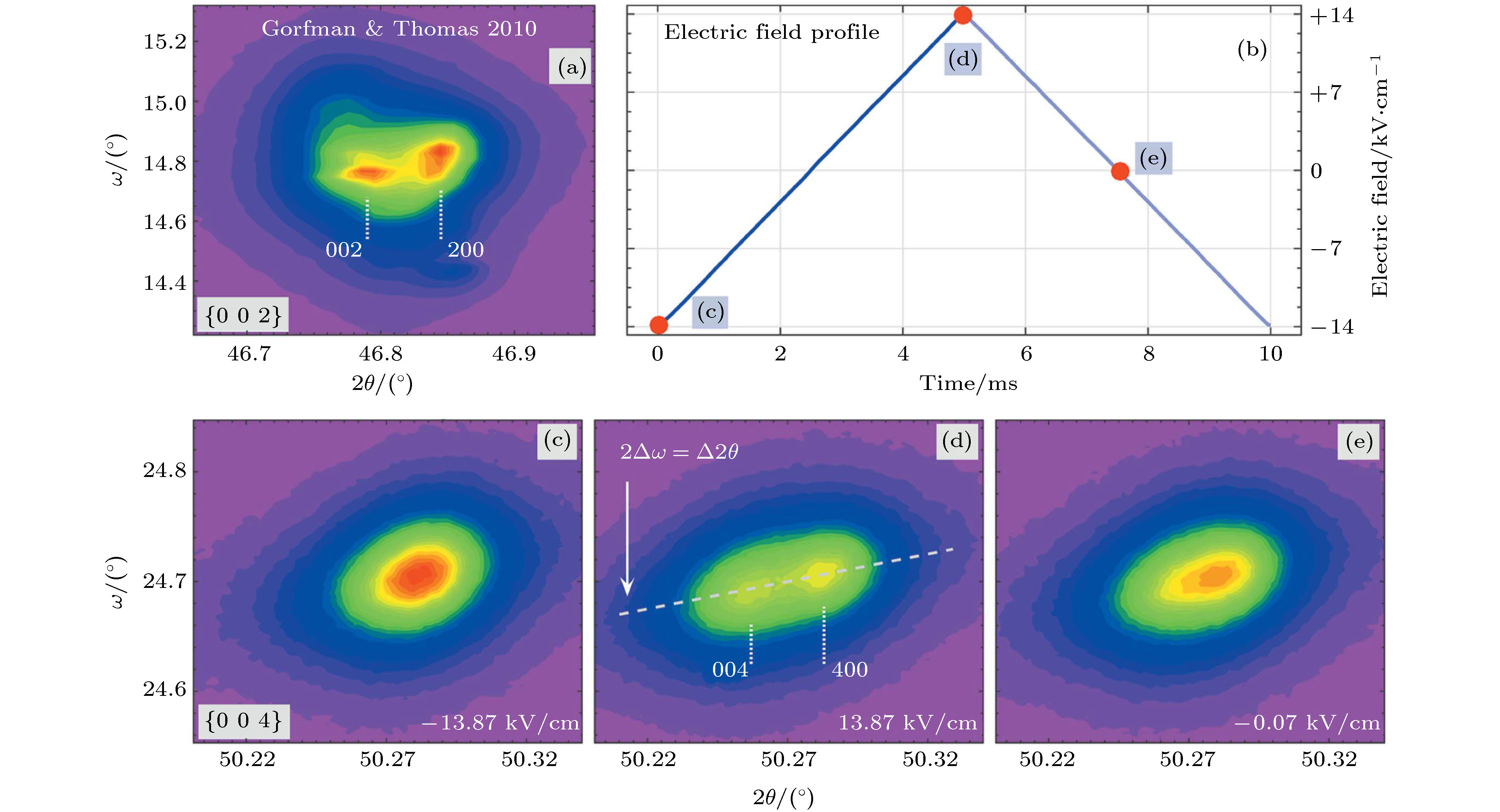

图 3 NBT单晶{00h}衍射峰X-ray衍射峰强度 (a) {002}衍射峰的静态ω-2θ二维衍射图像; (b)外加电场(沿[001]方向)与时间的关系; (c)−(e)使用频闪技术收集到的{004}衍射峰的ω-2θ二维衍射图像, 分别对应不同的时间通道与电场[33]

Fig. 3. Diffraction intensity of the X-ray around the {00h} family of reflections of NBT single crystal: (a) Static ω versus 2θ mesh of the {002} reflections family; (b) the time-dependence of the applied external electric field (along [001]); (c)−(e) stroboscopically collected versus 2θ meshes of the {004} family of reflections, corresponding to different time channels and electric fields[33]

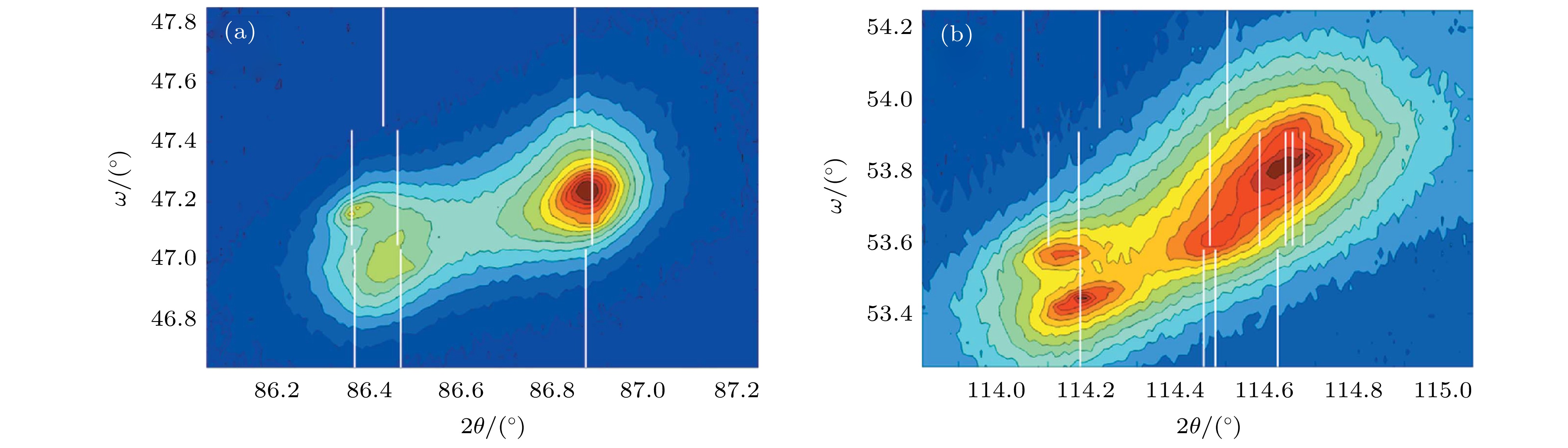

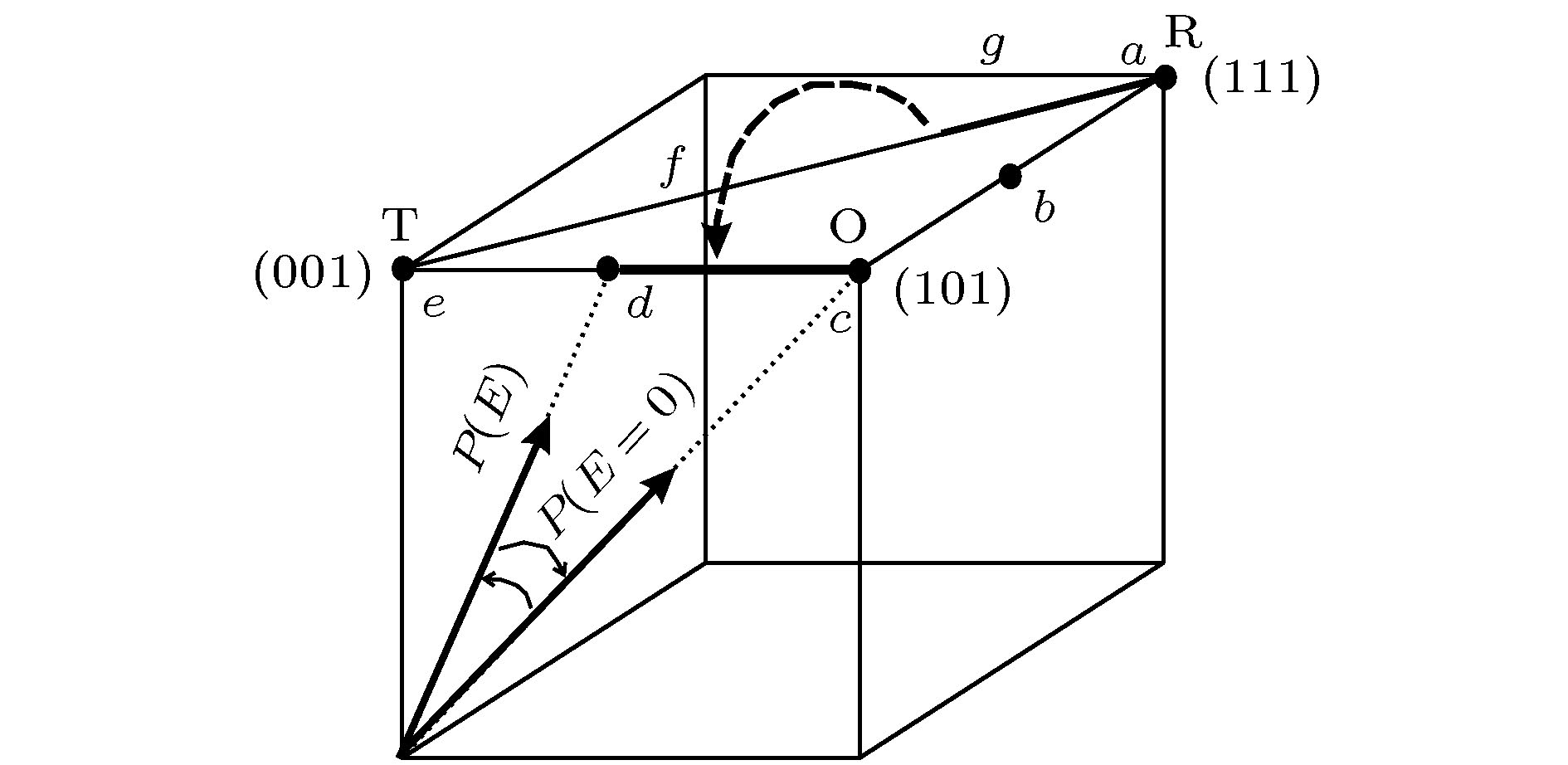

图 4 NBT单晶中不同{hkl}pc衍射峰的ω-2θ二维衍射图像, 其中从上到下的白线表示三方相, 单斜相Cc和三方-四方混合相可能的分峰

$ 2\theta $ 位置 (a) {222}; (b) {114}[46]Fig. 4. Two ω versus 2θ maps for different {hkl}pc of NBT single crystal collected on the high-resolution diffractometer. The lines indicate the simulated position of the scattering angle: from top to bottom, rhombohedral, monoclinic, and a combination of rhombohedral and tetragonal: (a) {222}; (b) {114}[46] (Copyright © 2010 International Union of Crystallography. Reproduced with permission of the International Union of Crystallography)

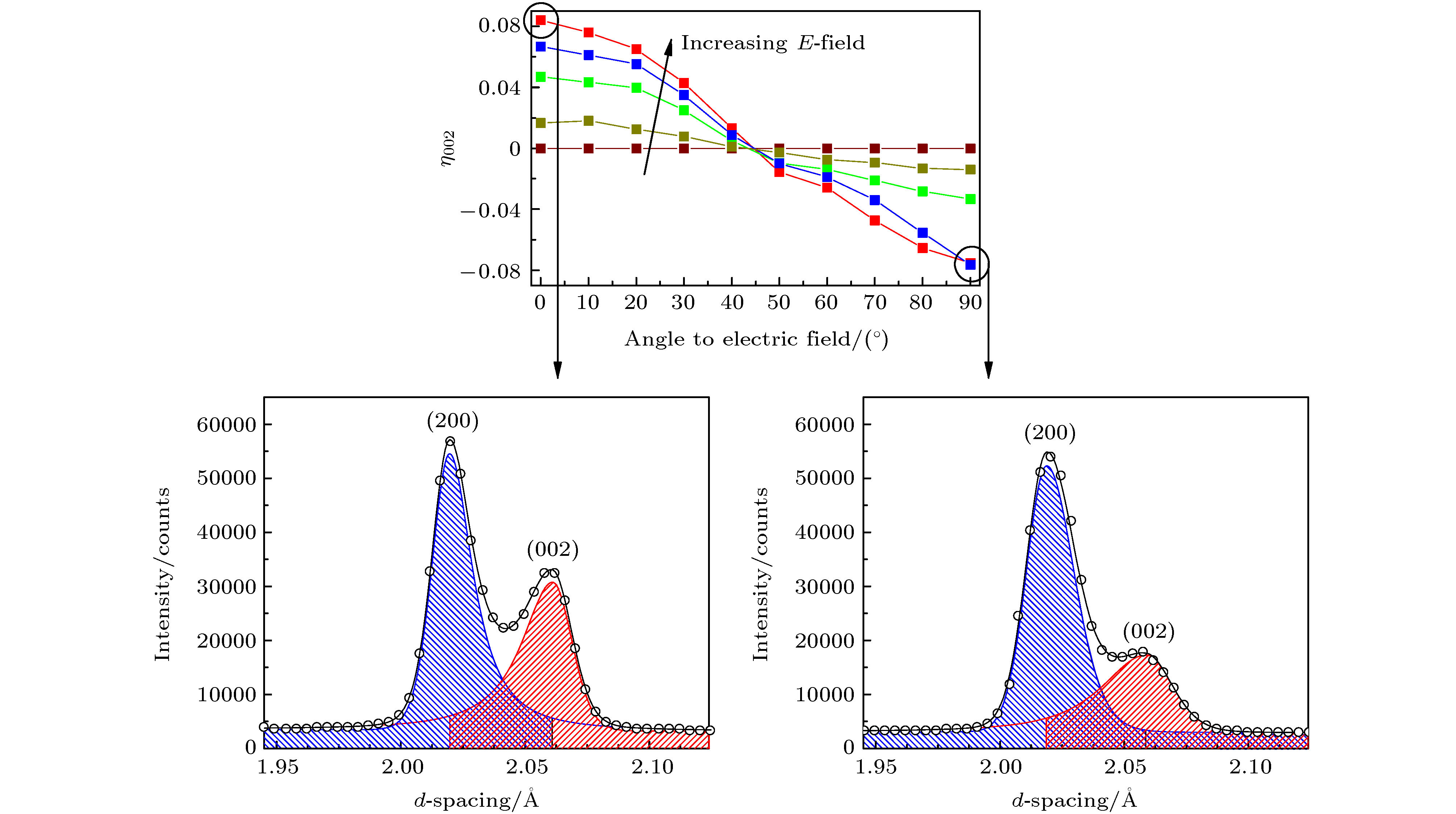

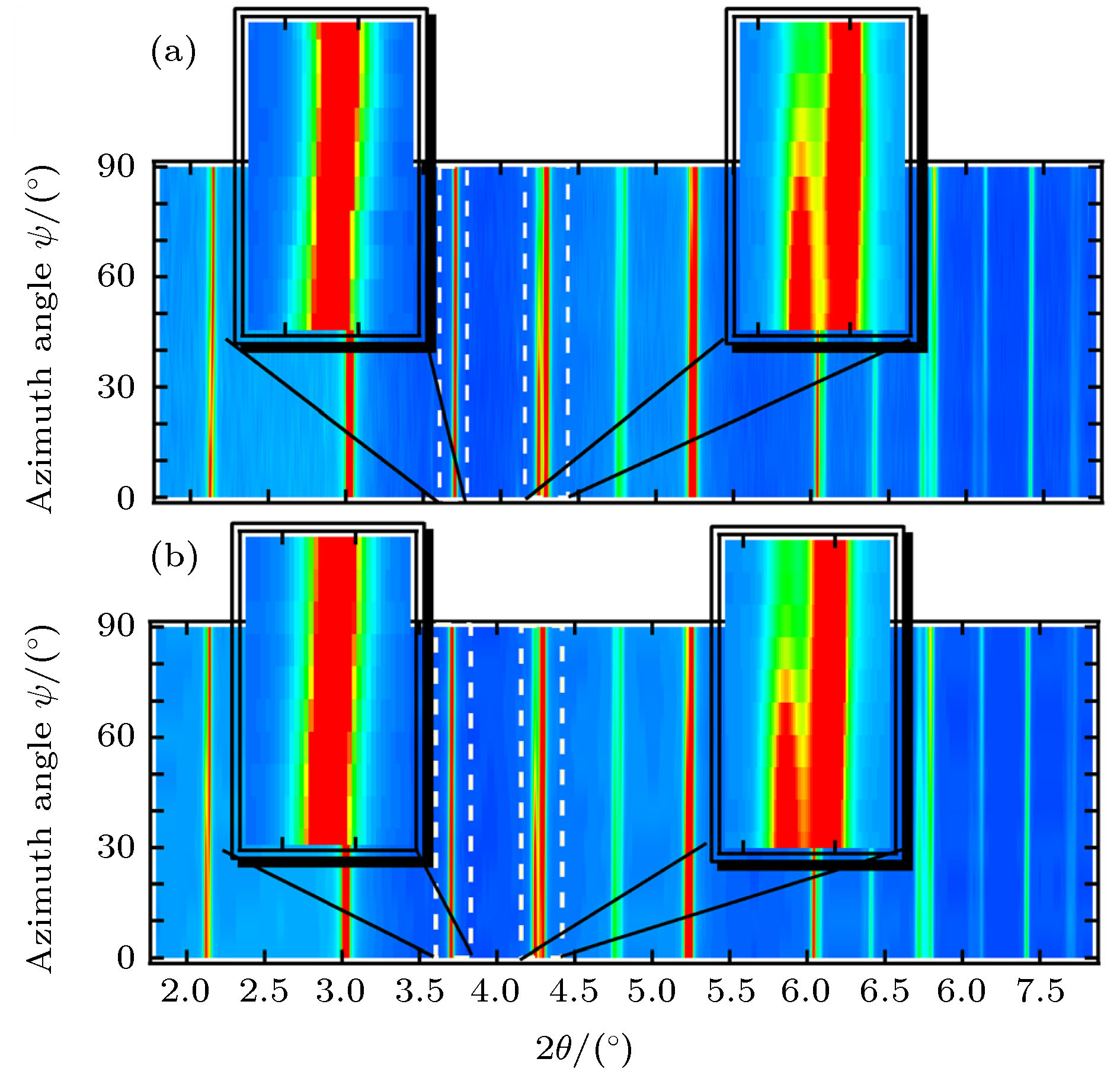

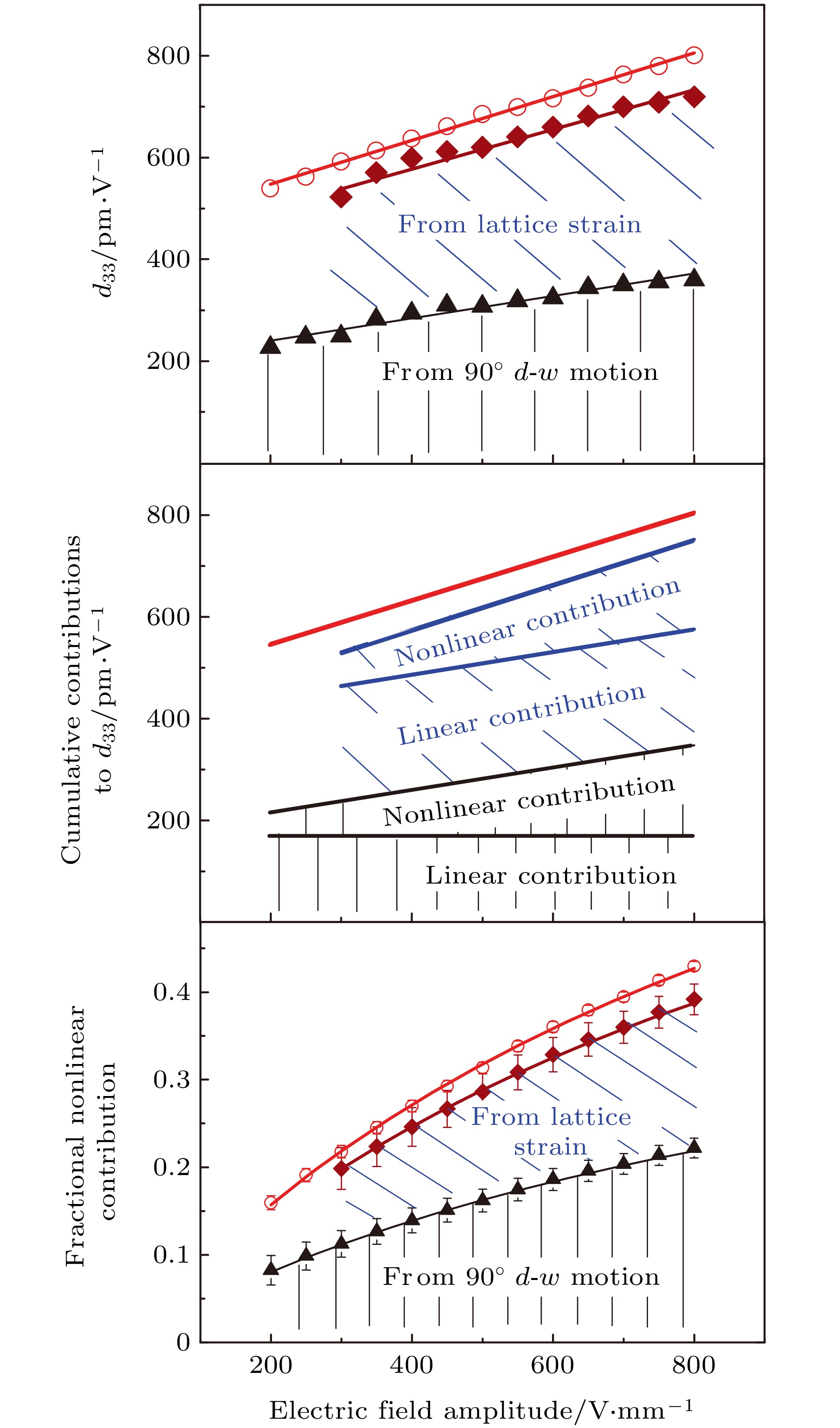

图 6 La掺杂PZT陶瓷中002畴体积分数与电场不同夹角的关系(底图分别显示与电场呈0°与90°条件下(002)与(200)衍射峰体积分数的变化)[49]

Fig. 6. η002 as a function of the field amplitude as well as orientation with respect to the direction of applied field, for an unpoled La-doped tetragonal PZT ceramic under the application of static electric fields. The measured and fitted (002)-type diffraction peaks corresponding to the particular values of η002 (marked by circles and indicated by arrows) are shown in the bottom section of the figure. For the fitted diffraction patterns, the deconvoluted (200) and (002) peaks are shown in black solid lines. The integration of individual (002) and (200) peaks are terminated beyond the peak position of the adjacent peak, as indicated by the color-shaded areas[49] (Copyright © 2011 John Wiley and Sons).

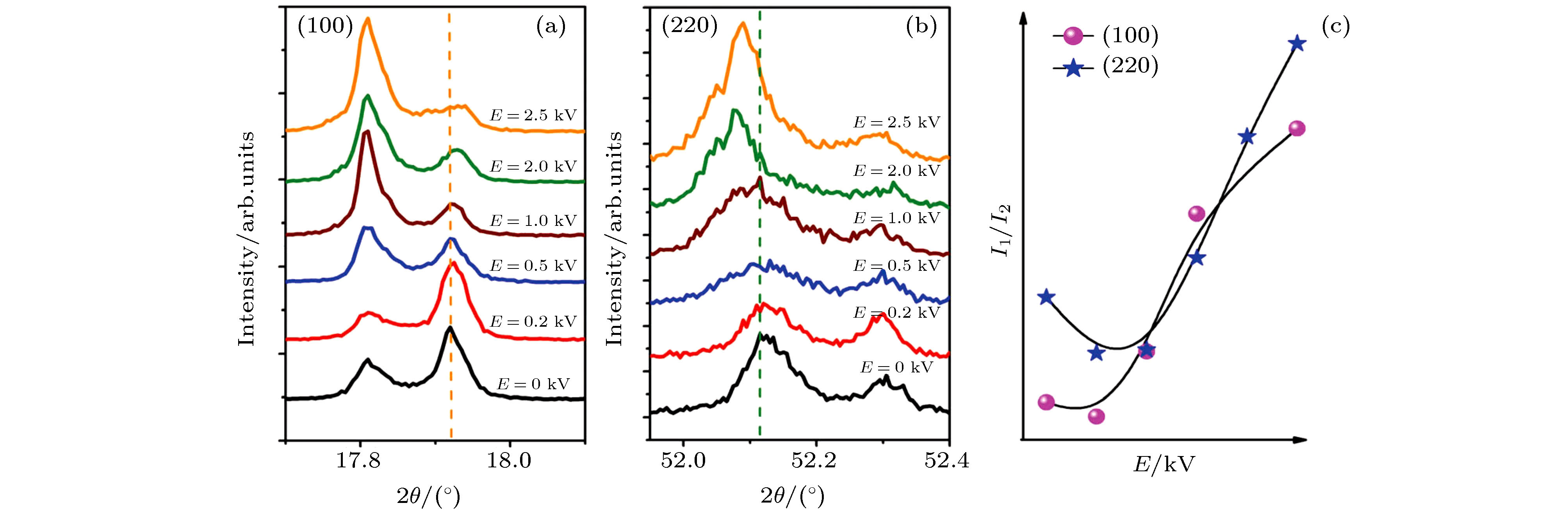

图 9 (1–x)(K1–yNay)(Nb1–zSbz)O3-xBi0.5(Na1–wKw)0.5HfO3 (x = 0.035, y = 0.52, z = 0.05, w = 0.18)陶瓷 (a), (b) (100)和(220)衍射峰随电场的演变过程; (c) (100)和(220)衍射峰中低角度衍射峰与高角度衍射峰的强度之比(I1/I2)随电场的变化[64]

Fig. 9. (1–x)(K1–yNay)(Nb1–zSbz)O3-xBi0.5(Na1–wKw)0.5HfO3 ceramic with x = 0.035, y = 0.52, z = 0.05 and w = 0.18: (a), (b) Evolution of the (100) and (220) pseudocubic reflections as a function of the electric field; (c) ratio of low angle peak intensity to high angle intensity (I1/I2) for (100) and (220) pseudocubic reflections as a function of the electric field[64] (Copyright © 2017 The Royal Society of Chemistry)

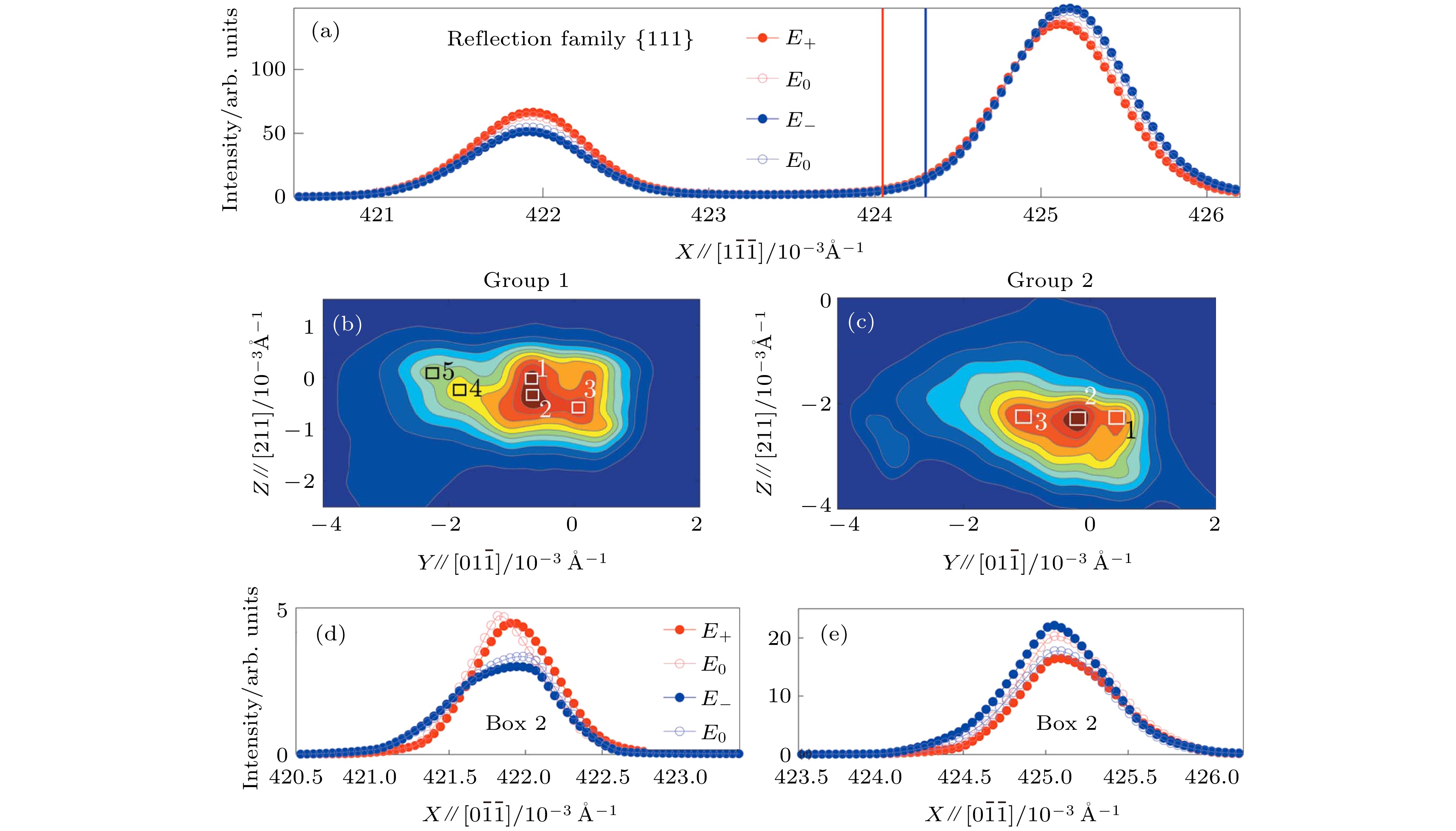

图 11 (a) {111}衍射峰的衍射强度(沿YZ方向积分)与X的关系曲线, 垂直的红蓝线分别对应

$ {E}_{+}\backslash {E}_{-} $ 状态下的质心位置; (b), (c)沿不同X范围积分的二维衍射强度分布图, 分别对应图(a)中的Group 1和Group 2; (d), (e)一个YZ Box范围内积分的衍射强度与X的关系曲线, 其中(d), (e)分别对应Group 1中的Box 2和Group 2中的Box 2 [70]Fig. 11. (a) The X dependence of the diffraction intensity around {111} reflections, integrated within the full YZ range. The vertical red and blue lines mark the center of mass positions corresponding to the E+ and

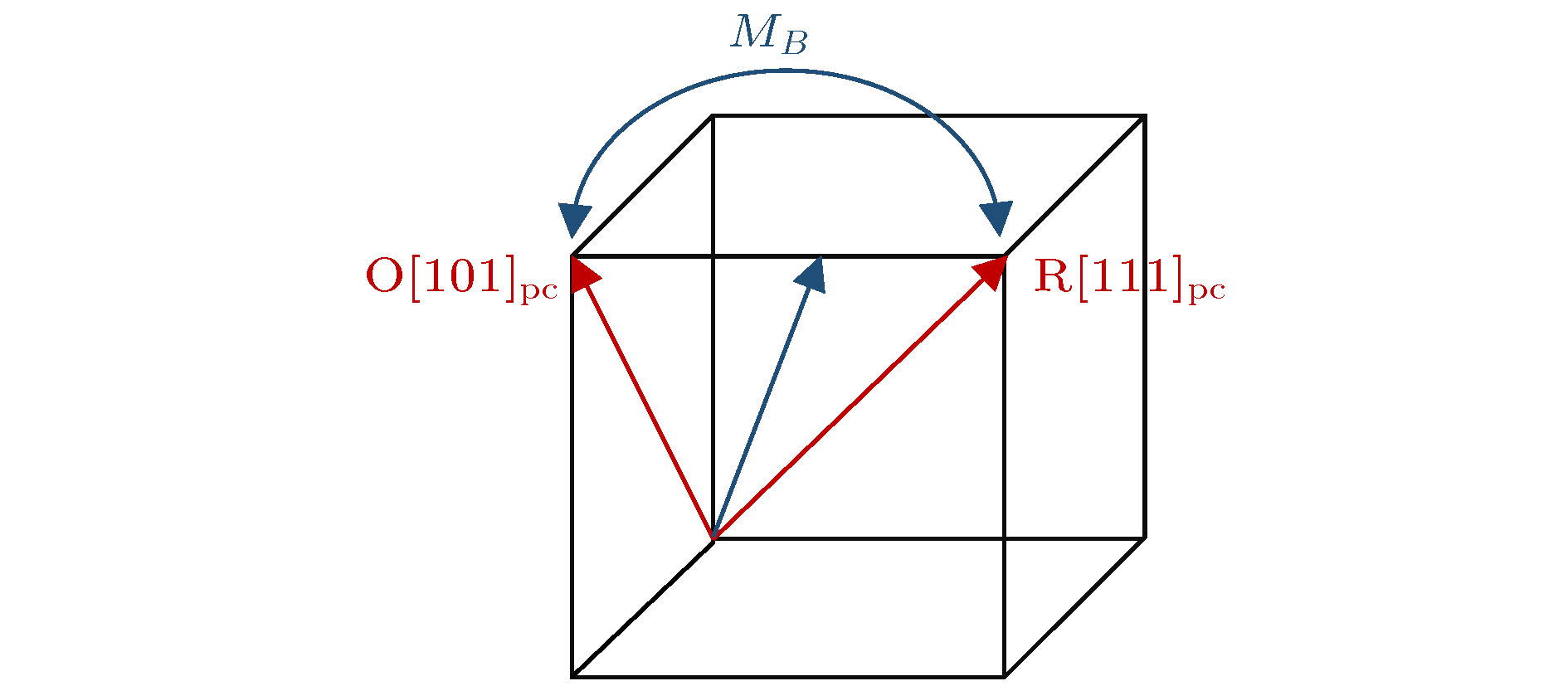

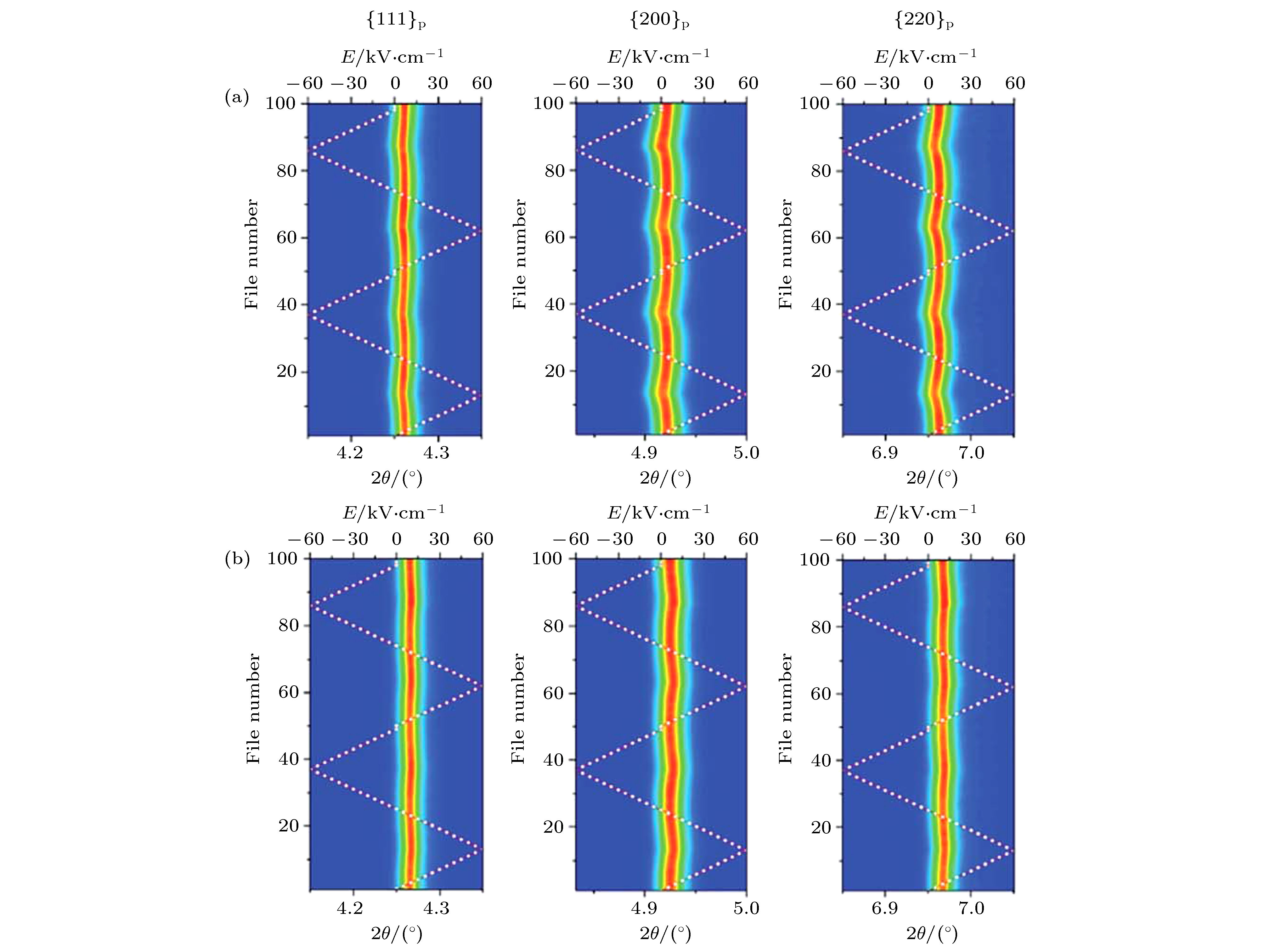

${E_ - } $ states. (b), (c) YZ dependence of the diffraction intensity integrated within two ranges of X, corresponding to Group 1 and Group 2 in panel (a). Several boxes are marked to show the positions of Bragg peak sub-components. (d), (e) Integrated intensities within one YZ box against X under four states of field. (d) Corresponds to Box 2 in Group 1 and (e) to Box 2 in Group 2[70] (Copyright © 2018 International Union of Crystallography. Reproduced with permission of the International Union of Crystallography)图 15 对BF-0.3 BT-0.03 NLN陶瓷在 ± 60 kV/cm的电场下进行了两个电场循环观察到的{111}, {200}和{220}峰的等高线图 (a)平行电场方向; (b)垂直电场方向[82]

Fig. 15. Contour plots of the {111}, {200} and {220} peak profiles for (a)

$ \beta $ = 0° and (b)$ \beta $ = 90° obtained from the in situ X-ray diffraction experiment for BF-0.3 BT-0.03 NLN, with two cycles of electric field poling under ± 60 kV/cm[82] (Copyright © 2019 The Royal Society of Chemistry) -

[1] Berlincourt D 1992 J. Acoust. Soc. Am. 91 3034

Google Scholar

Google Scholar

[2] King T G, Preston M E, Murphy B J M, Cannell D S 1990 Precis. Eng. 12 131

Google Scholar

Google Scholar

[3] Uchino K 2015 Sci. Technol. Adv. Mater. 16 46001

Google Scholar

Google Scholar

[4] Haertling G H 1999 J. Am. Ceram. Soc. 82 797

Google Scholar

Google Scholar

[5] Bellaiche L, Vanderbilt D 1999 Phys. Rev. Lett. 83 1347

Google Scholar

Google Scholar

[6] Li F, Lin D, Chen Z, Cheng Z, Wang J, Li C, Xu Z, Huang Q, Liao X, Chen L Q, Shrout T R, Zhang S 2018 Nat. Mater. 17 349

Google Scholar

Google Scholar

[7] Park S E, Shrout T R 1997 J. Appl. Phys. 82 1804

Google Scholar

Google Scholar

[8] Zhang N, Yokota H, Glazer A M, Ren Z, Keen D A, Keeble D S, Thomas P A, Ye Z G 2014 Nat. Commun. 5 5231

Google Scholar

Google Scholar

[9] Guo R, Cross L E, Park S E, Noheda B, Cox D E, Shirane G 2000 Phys. Rev. Lett. 84 5423

Google Scholar

Google Scholar

[10] Hollenstein E, Davis M, Damjanovic D, Setter N 2005 Appl. Phys. Lett. 87 182905

Google Scholar

Google Scholar

[11] Xu K, Li J, Lv X, Wu J, Zhang X, Xiao D, Zhu J 2016 Adv. Mater. 28 8519

Google Scholar

Google Scholar

[12] Wang X, Wu J, Xiao D, Zhu J, Cheng X, Zheng T, Zhang B, Lou X, Wang X 2014 J. Am. Chem. Soc. 136 2905

Google Scholar

Google Scholar

[13] Wang K, Li J F 2010 Adv. Funct. Mater. 20 1924

Google Scholar

Google Scholar

[14] Saito Y, Takao H, Tani T, Nonoyama T, Takatori K, Homma T, Nagaya T, Nakamura M 2004 Nature 432 84

Google Scholar

Google Scholar

[15] McQuade R R, Dolgos M R 2016 J. Solid State Chem. 242 140

Google Scholar

Google Scholar

[16] Paterson A R, Nagata H, Tan X, Daniels J E, Hinterstein M, Ranjan R, Groszewicz P B, Jo W, Jones J L 2018 MRS Bull. 43 600

Google Scholar

Google Scholar

[17] Du X H, Zheng J, Belegundu U, Uchino K 1998 Appl. Phys. Lett. 72 2421

Google Scholar

Google Scholar

[18] Fu H, Cohen R E 2000 Nature 403 281

Google Scholar

Google Scholar

[19] Noheda B, Cox D E 2006 Phase Transitions 79 5

Google Scholar

Google Scholar

[20] Ye Z G, Noheda B, Dong M, Cox D, Shirane G 2001 Phys. Rev. B 64 184114

Google Scholar

Google Scholar

[21] Li F, Zhang S, Damjanovic D, Chen L Q, Shrout T R 2018 Adv. Funct. Mater. 28 1801504

Google Scholar

Google Scholar

[22] Clegg W 2015 X-ray Crystallography (New York: Oxford University Press) pp1–31

[23] Rietveld H M 1969 J. Appl. Crystallogr. 2 65

Google Scholar

Google Scholar

[24] Hammond C 2009 The Basics of Crystallography and Diffraction Struct. Chem. (New York: Oxford University Press) pp252–267

[25] David W I F, Shankland K, Baerlocher C, McCusker L B 2002 Structure Determination from Powder Diffraction Data (New York: Oxford University Press) pp88–93

[26] Tagantsev A K, Cross L E, Fousek J 2010 Domains in Ferroic Crystals and Thin Films (New York: Springer New York) pp11–74

[27] Viehland D D, Salje E K H 2014 Adv. Phys. 63 267

Google Scholar

Google Scholar

[28] Jones J L, Aksel E, Tutuncu G, Usher T M, Chen J, Xing X, Studer A J 2012 Phys. Rev. B 86 024104

Google Scholar

Google Scholar

[29] Als-Nielsen J, McMorrow D 2011 Elements of Modern X-ray Physics (Chichester: A John Wiley & Sons, Ltd Publication) pp33–42

[30] Broennimann C 2008 Acta Crystallogr. Sect. A Found. Crystallogr. 64 C162

Google Scholar

Google Scholar

[31] Daniels J E, Finlayson T R, Studer A J, Hoffman M, Jones J L 2007 J. Appl. Phys. 101 094104

Google Scholar

Google Scholar

[32] Daniels J, Pramanick A, Jones J 2009 IEEE Trans. Ultrason. Ferroelectr. Freq. Control 56 1539

Google Scholar

Google Scholar

[33] Choe H, Bieker J, Zhang N, Glazer A M, Thomas P A, Gorfman S 2018 IUCrJ 5 417

Google Scholar

Google Scholar

[34] Eckold G, Schober H, Nagler S E 2010 Studying Kinetics with Neutrons (Berlin, Heidelberg: Springer Berlin Heidelberg) pp149–173

[35] Jiang A Q, Lee H J, Hwang C S, Scott J F 2012 Adv. Funct. Mater. 22 192

Google Scholar

Google Scholar

[36] Bai F, Wang N, Li J, Viehland D, Gehring P M, Xu G, Shirane G 2004 J. Appl. Phys. 96 1620

Google Scholar

Google Scholar

[37] Ehara Y, Yasui S, Nagata J, Kan D, Anbusathaiah V, Yamada T, Sakata O, Funakubo H, Nagarajan V 2011 Appl. Phys. Lett. 99 182906

Google Scholar

Google Scholar

[38] Rana D S, Kawayama I, Mavani K, Takahashi K, Murakami H, Tonouchi M 2009 Adv. Mater. 21 2881

Google Scholar

Google Scholar

[39] Eckold G, Gibhardt H, Caspary D, Elter P, Elisbihani K 2003 Z. Kristallogr. 218 144

Google Scholar

Google Scholar

[40] Choe H, Heidbrink S, Ziolkowski M, Pietsch U, Dyadkin V, Gorfman S, Chernyshov D 2017 J. Appl. Crystallogr. 50 975

Google Scholar

Google Scholar

[41] Usher T M, Levin I, Daniels J E, Jones J L 2015 Sci. Rep. 5 14678

Google Scholar

Google Scholar

[42] Vergentev T, Bronwald I, Chernyshov D, Gorfman S, Ryding S H M, Thompson P, Cernik R J 2016 J. Appl. Crystallogr. 49 1501

Google Scholar

Google Scholar

[43] Kitanaka Y, Noguchi Y, Miyayama M, Kagawa Y, Moriyoshi C, Kuroiwa Y 2013 Ferroelectrics 443 1

Google Scholar

Google Scholar

[44] Moriyoshi C, Hiramoto S, Ohkubo H, Kuroiwa Y, Osawa H, Sugimoto K, Kimura S, Takata M, Kitanaka Y, Noguchi Y, Miyayama M 2011 Jpn. J. Appl. Phys. 50 09NE05

Google Scholar

Google Scholar

[45] Gorfman S, Keeble D S, Glazer A M, Long X, Xie Y, Ye Z G, Collins S, Thomas P A 2011 Phys. Rev. B 84 020102

Google Scholar

Google Scholar

[46] Gorfman S, Thomas P A 2010 J. Appl. Crystallogr. 43 1409

Google Scholar

Google Scholar

[47] Datta K, Gorfman S, Thomas P A 2009 Appl. Phys. Lett. 95 251901

Google Scholar

Google Scholar

[48] Daymond M R 2004 J. Appl. Phys. 96 4263

Google Scholar

Google Scholar

[49] Pramanick A, Damjanovic D, Daniels J E, Nino J C, Jones J L 2011 J. Am. Ceram. Soc. 94 293

Google Scholar

Google Scholar

[50] Ehmke M C, Khansur N H, Daniels J E, Blendell J E, Bowman K J 2014 Acta Mater. 66 340

Google Scholar

Google Scholar

[51] Jones J L, Slamovich E B, Bowman K J 2005 J. Appl. Phys. 97 034113

Google Scholar

Google Scholar

[52] Jones J L, Hoffman M, Bowman K J 2005 J. Appl. Phys. 98 024115

Google Scholar

Google Scholar

[53] Kungl H, Theissmann R, Knapp M, Baehtz C, Fuess H, Wagner S, Fett T, Hoffmann M J 2007 Acta Mater. 55 1849

Google Scholar

Google Scholar

[54] Hall D A, Steuwer A, Cherdhirunkorn B, Mori T, Withers P J 2004 J. Appl. Phys. 96 4245

Google Scholar

Google Scholar

[55] Fan L, Chen J, Ren Y, Pan Z, Zhang L, Xing X 2016 Phys. Rev. Lett. 116 027601

Google Scholar

Google Scholar

[56] Hinterstein M, Lee K Y, Esslinger S, Glaum J, Studer A J, Hoffman M, Hoffmann M J 2019 Phys. Rev. B 99 174107

Google Scholar

Google Scholar

[57] Matthies S, Lutteroti L, Wenk H R 1997 J. Appl. Crystallogr. 30 31

Google Scholar

Google Scholar

[58] Lutterotti L, Bortolotti M, Ischia G, Lonardelli I, Wenk H R 2007 Z. Kristallogr. Suppl. 26 125

Google Scholar

Google Scholar

[59] Hinterstein M, Hoelzel M, Rouquette J, Haines J, Glaum J, Kungl H, Hoffman M 2015 Acta Mater. 94 319

Google Scholar

Google Scholar

[60] Khansur N H, Hinterstein M, Wang Z, Groh C, Jo W, Daniels J E 2015 Appl. Phys. Lett. 107 242902

Google Scholar

Google Scholar

[61] Zhao C, Hou D, Chung C-C, Zhou H, Kynast A, Hennig E, Liu W, Li S, Jones J L 2018 Acta Mater. 158 369

Google Scholar

Google Scholar

[62] Fu J, Zuo R, Xu Y, Li J F, Shi M 2017 J. Eur. Ceram. Soc. 37 975

Google Scholar

Google Scholar

[63] Ochoa D A, Esteves G, Iamsasri T, Rubio-Marcos F, Fernández J F, García J E, Jones J L 2016 J. Eur. Ceram. Soc. 36 2489

Google Scholar

Google Scholar

[64] Zheng T, Wu H, Yuan Y, Lv X, Li Q, Men T, Zhao C, Xiao D, Wu J, Wang K, Li J F, Gu Y, Zhu J, Pennycook S J 2017 Energy Environ. Sci. 10 528

Google Scholar

Google Scholar

[65] Tutuncu G, Li B, Bowman K, Jones J L 2014 J. Appl. Phys. 115 144104

Google Scholar

Google Scholar

[66] Khansur N H, Rojac T, Damjanovic D, Reinhard C, Webber K G, Kimpton J A, Daniels J E 2015 J. Am. Ceram. Soc. 98 3884

Google Scholar

Google Scholar

[67] Li Y, Chen Y, Zhang Z, Kleppe A, Hall D A 2019 Acta Mater. 168 411

Google Scholar

Google Scholar

[68] Zuo R, Qi H, Fu J, Li J F, Li L 2017 Appl. Phys. Lett. 111 132901

Google Scholar

Google Scholar

[69] Hu C, Meng X, Zhang M H, Tian H, Daniels J E, Tan P, Huang F, Li L, Wang K, Li J F, Lu Q, Cao W, Zhou Z 2020 Sci. Adv. 6 eaay5979

Google Scholar

Google Scholar

[70] Zhang N, Gorfman S, Choe H, Vergentev T, Dyadkin V, Yokota H, Chernyshov D, Wang B, Glazer A M, Ren W, Ye Z G 2018 J. Appl. Crystallogr. 51 1396

Google Scholar

Google Scholar

[71] Hinterstein M, Knapp M, Hölzel M, Jo W, Cervellino A, Ehrenberg H, Fuess H 2010 J. Appl. Crystallogr. 43 1314

Google Scholar

Google Scholar

[72] Kling J, Tan X, Jo W, Kleebe H J, Fuess H, Rödel J 2010 J. Am. Ceram. Soc. 93 2452

Google Scholar

Google Scholar

[73] Daniels J E, Jo W, Rödel J, Honkimäki V, Jones J L 2010 Acta Mater. 58 2103

Google Scholar

Google Scholar

[74] Durbin M K, Jacobs E W, Hicks J C, Park S E 1999 Appl. Phys. Lett. 74 2848

Google Scholar

Google Scholar

[75] Damjanovic D 2005 J. Am. Ceram. Soc. 88 2663

Google Scholar

Google Scholar

[76] Noheda B, Cox D E, Shirane G, Park S E, Cross L E, Zhong Z 2001 Phys. Rev. Lett. 86 3891

Google Scholar

Google Scholar

[77] Fu J, Zuo R, Gao X 2013 Appl. Phys. Lett. 103 182907

Google Scholar

Google Scholar

[78] Li P, Zhai J, Shen B, Zhang S, Li X, Zhu F, Zhang X 2018 Adv. Mater. 30 1705171

Google Scholar

Google Scholar

[79] Yao F Z, Wang K, Jo W, Webber K G, Comyn T P, Ding J X, Xu B, Cheng L Q, Zheng M P, Hou Y D, Li J F 2016 Adv. Funct. Mater. 26 1217

Google Scholar

Google Scholar

[80] Simons H, Daniels J E, Glaum J, Studer A J, Jones J L, Hoffman M 2013 Appl. Phys. Lett. 102 062902

Google Scholar

Google Scholar

[81] Ren P, Liu Z, Liu H, Sun S, Wan Y, Long C, Shi J, Chen J, Zhao G 2019 J. Eur. Ceram. Soc. 39 994

Google Scholar

Google Scholar

[82] Wang G, Fan Z, Murakami S, Lu Z, Hall D A, Sinclair D C, Feteira A, Tan X, Jones J L, Kleppe A K, Wang D, Reaney I M 2019 J. Mater. Chem. A 7 21254

Google Scholar

Google Scholar

[83] Xu G, Zhong Z, Bing Y, Ye Z G, Shirane G 2006 Nat. Mater. 5 134

Google Scholar

Google Scholar

[84] Xu G, Wen J, Stock C, Gehring P M 2008 Nat. Mater. 7 562

Google Scholar

Google Scholar

[85] Paściak M, Welberry T R, Kulda J, Kempa M, Hlinka J 2012 Phys. Rev. B 85 224109

Google Scholar

Google Scholar

[86] Li F, Zhang S, Yang T, Xu Z, Zhang N, Liu G, Wang J, Wang J, Cheng Z, Ye Z G, Luo J, Shrout T R, Chen L Q 2016 Nat. Commun. 7 13807

Google Scholar

Google Scholar

[87] Polinger V, Bersuker I B 2018 Phys. Rev. B 98 214102

Google Scholar

Google Scholar

[88] Bokov A A, Ye Z G 2006 J. Mater. Sci. 41 31

Google Scholar

Google Scholar

[89] Xu G, Zhong Z, Hiraka H, Shirane G 2004 Phys. Rev. B 70 174109

Google Scholar

Google Scholar

[90] Welberry T R 2004 Diffuse X-Ray Scattering and Models of Disorder (New York: Oxford University Press) pp4−20

计量

- 文章访问数: 13546

- PDF下载量: 424

- 被引次数: 0

下载:

下载: