-

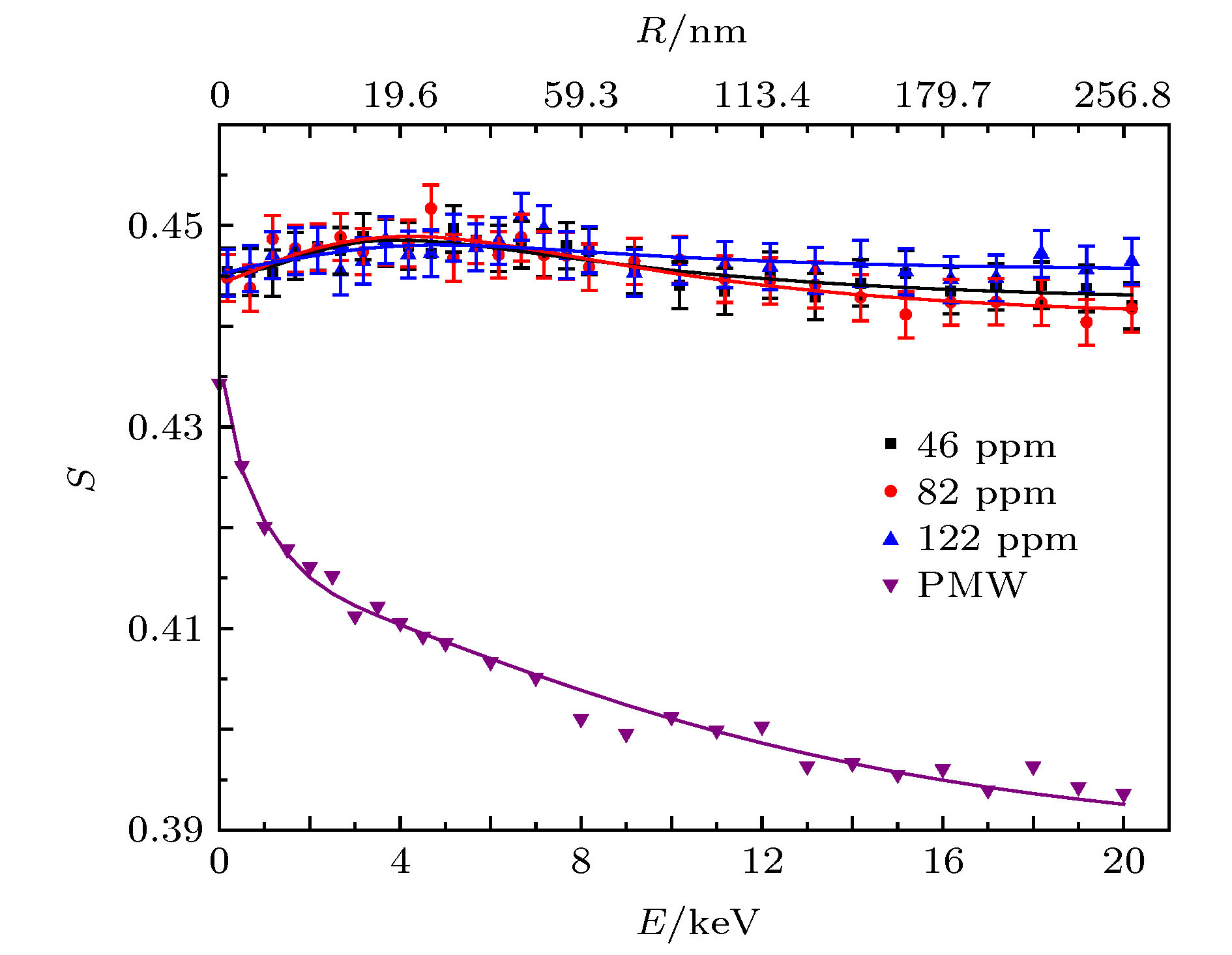

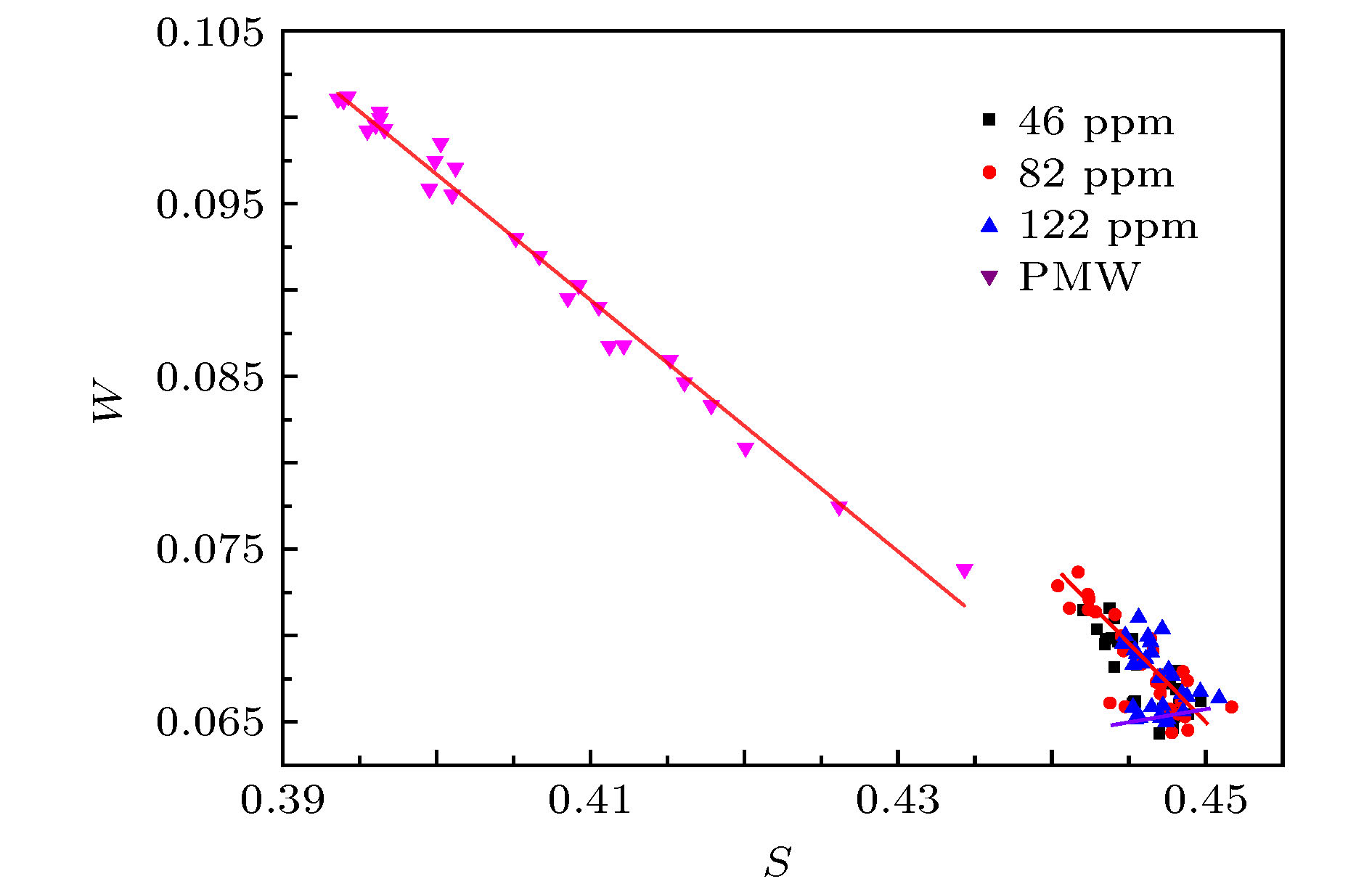

钨合金中钾的掺杂会引入大量的缺陷, 如尺寸几十纳米的钾泡、高密度的位错以及微米量级的晶粒带来的晶界等, 这些缺陷的浓度和分布直接影响合金的服役性能. 本文运用正电子湮没谱学方法研究钾掺杂钨合金中的缺陷信息, 首先模拟计算了合金中各种缺陷的正电子湮没寿命, 发现钾的嵌入对空位团、位错、晶界等缺陷的寿命影响很小; 然后测量了不同钾含量掺杂钨合金样品的正电子湮没寿命谱, 建立三态捕获模型, 发现样品中有高的位错密度和低的空位团簇浓度, 验证了钾对位错的钉扎作用, 阐述了在钾泡形成初期是钾元素与空位团簇结合并逐渐长大的过程; 最后使用慢正电子多普勒展宽谱技术表征了样品中缺陷随深度的均匀分布和大量存在, 通过扩散长度的比较肯定了钾泡、晶界等缺陷的存在.Tungsten alloy is known as a promising plasma-facing material (PFM) in IETR because of high strength, high-temperature stability, low sputtering erosion, low tritium retention, etc. However, tungsten has some disadvantages, such as high ductile-brittle transition temperature, low temperature brittleness, and radiation embrittlement. For the severe environment of PFM, various techniques have been adopted to improve W-based materials, among which the potassium doping is an effective bubble strengthening method, it can bring in nano-sized K bubbles, and enhance the toughness and strength, thermal shock performance, irradiation resistance of the materials. The K bubbles, which can pin grain boundaries (GBs) and dislocations, are the most characteristic defects in W-K alloy and have been widely reported. However, little attention is paid to other defects such as vacancies, GBs and dislocations. In fact, high-density dislocations exist in W-K alloy and vacancies play a considerable role in forming the K bubbles. Thus, positron annihilation technique (including the positron annihilation lifetime spectrum and slow positron beam Doppler broadening spectrum), which is a useful technique for detecting defects in solids, can be used to study these defects in W-K alloy samples. The positron lifetime of potassium bulk is about 376 ps and the positron lifetime of tungsten bulk is about 110 ps. But by simulating positron lifetime of defects in tungsten, it is found that potassium atoms in tungsten lattice do not exhibit the characteristic positron lifetime. Therefore, potassium is not considered in analyzing positron annihilation lifetime spectra of W-K alloy samples with different potassium content (46, 82, 122, 144 ppm). Three-state capture model is established in this paper, the dislocation density and vacancy cluster concentration of these samples are obtained. From the results, the dislocation densities in all samples are very high, but vacancy cluster concentrations are relatively low, and the vacancy cluster concentration in the sample with 82 ppm potassium content is the lowest in all samples. The behavior of potassium atoms in the sintering process is also discussed. Then the slow positron beam Doppler broadening spectra of W-K alloy samples and pure tungsten samples are measured and the obtained data are fitted by VEPFIT. It is noted that the defects in W-K alloy samples are much more than those in pure tungsten sample, and are distributed homogeneously with depth. The positron diffusion length information simultaneously obtained is compared with these values computed by dislocation density and vacancy cluster concentration, confirming the positrons trapped by potassium bubbles and grain boundaries are existent.

-

Keywords:

- potassium doping /

- positron annihilation spectroscopy /

- tungsten alloy

[1] Ueda Y, Coenen J W, De Temmerman G, Doerner R P, Linke J, Philipps V, Tsitrone E 2014 Fusion Eng. Des. 89 901

Google Scholar

Google Scholar

[2] Kang H K 2004 J. Nucl. Mater. 335 1

Google Scholar

Google Scholar

[3] Davis J W, Barabash V R, Makhankov A, Plöchl L, Slattery K T 1998 J. Nucl. Mater. 258 308

[4] Ueda Y, Tobita K, Katoh Y 2003 J. Nucl. Mater. 313-316 32

Google Scholar

Google Scholar

[5] Lisgo S W, Kukushkin A, Pitts R A, Reiter D 2013 J. Nucl. Mater. 438 S580

Google Scholar

Google Scholar

[6] Wurster S, Baluc N, Battabyal M, Crosby T, Du J, García-Rosales C, Hasegawa A, Hoffmann A, Kimura A, Kurishita H, Kurtz R J, Li H, Noh S, Reiser J, Riesch J, Rieth M, Setyawan W, Walter M, You J H, Pippan R 2013 J. Nucl. Mater. 442 S181

Google Scholar

Google Scholar

[7] 王玲 2018 博士论文 (成都: 四川大学)

Wang L 2018 Ph. D. Dissertation (Chengdu: Sichuan University) (in Chinese)

[8] Hirai T, Pintsuk G 2007 Fusion Eng. Des. 82 389

Google Scholar

Google Scholar

[9] Wurster S, Pippan R 2009 Scr. Mater. 60 1083

Google Scholar

Google Scholar

[10] Uytdenhouwen I, Decréton M, Hirai T, Linke J, Pintsuk G, Van Oost G 2007 J. Nucl. Mater. 363 1099

[11] Briant C L 1993 Metall. Trans. A 24 1073

Google Scholar

Google Scholar

[12] Horacsek O, Toth C L, Nagy A 1998 Int. J. Refract. Met. Hard Mater. 16 51

Google Scholar

Google Scholar

[13] Schade P 2010 Int. J. Refract. Met. Hard Mater. 28 648

Google Scholar

Google Scholar

[14] Schade P 1998 Int. J. Refract. Met. Hard Mater. 16 77

Google Scholar

Google Scholar

[15] Dias M, Mateus R, Catarino N, Franco N, Nunes D, Correia J B, Carvalho P A, Hanada K, Sârbu C 2013 J. Nucl. Mater. 442 69

Google Scholar

Google Scholar

[16] Huang B, Tang J, Chen L Q, Yang X L, Lian Y Y, Chen L, Liu X, Cui X D, Gu L, Liu C T 2019 J. Alloys Compd. 782 149

Google Scholar

Google Scholar

[17] Liu G, Zhang G J, Jiang F, Ding X D, Sun Y J, Sun J, Ma E 2013 Nat. Mater. 12 344

Google Scholar

Google Scholar

[18] Xie Z M, Liu R, Miao S, Yang X D, Zhang T, Wang X P, Fang Q F, Liu C S, Luo G N, Lian Y Y, Liu X 2015 Sci. Rep. 5 16014

Google Scholar

Google Scholar

[19] Liu R, Xie Z M, Fang Q F, Zhang T, Wang X P, Hao T, Liu C S, Dai Y 2016 J. Alloys Compd. 657 73

Google Scholar

Google Scholar

[20] Tuomisto F, Makkonen I 2013 Rev. Mod. Phys. 85 1583

Google Scholar

Google Scholar

[21] Wang S J, Chen Z Q, Wang B, Wu Y C, Fang P F, Zhang Y X 2008 Applied Positron Spectroscopy (Wuhan: Hubei Science & Technology Press) p8 (in Chinese) [王少阶, 陈志权, 王波, 吴奕初, 方鹏飞, 张永学 2008 应用正电子谱学 (武汉: 湖北科学技术出版社) 第8页]

[22] Staab T E M, Krause-Rehberg R, Vetter B, Kieback B, Lange G, Klimanek P 1999 J. Phys. Condens. Matter 11 1757

Google Scholar

Google Scholar

[23] Heikinheimo J, Mizohata K, Räisänen J, Ahlgren T, Jalkanen P, Lahtinen A, CatarinoN, Alves E, Tuomisto F 2019 APL Mater. 7 021103

Google Scholar

Google Scholar

[24] Puska M J, Nieminen R M 1983 J. Phys. F: Met. Phys. 13 333

Google Scholar

Google Scholar

[25] Puska M J, Seitsonen A P, Nieminen R M 1995 Phys. Rev. B 52 10947

Google Scholar

Google Scholar

[26] Robles J M C, Ogando E, Plazaola F 2007 J. Phys. Condens. Matter 19 176222

Google Scholar

Google Scholar

[27] Huang B, Chen L Q, Qiu W B, Yang X L, Shi K, Lian Y Y, Liu X, Tang J 2019 J. Nucl. Mater. 520 6

Google Scholar

Google Scholar

[28] Jin S, Zhang P, Lu E, Guo L, Wang B, Cao X 2016 Acta Mater. 103 658

Google Scholar

Google Scholar

[29] Troev T, Popov E, MStaikov P, Nankov N, Yoshiie T 2009 Nucl. Instrum. Meth. B 267 535

Google Scholar

Google Scholar

[30] Puska M J, Lanki P, Nieminen R M 1989 J. Phys. Condens. Matter 1 6081

Google Scholar

Google Scholar

[31] Kuriplach J, Melikhova O, Hou M, Van Petegem S, Zhurkin E, Šob M 2007 Phys. Stat. Sol. 4 3461

[32] Würschum R, Seeger A 1996 Philos. Mag. 73 1489

Google Scholar

Google Scholar

[33] Oberdorfer B, Würschum R 2009 Phys. Rev. B 79 184103

Google Scholar

Google Scholar

[34] Hautojärvi P, Corbel C 1995 Positron Spectroscopy of Solids (Amsterdam: IOS Press) p491

[35] Corbel C, Pierre F, Saarinew K, Hautojarvi P, Moser P 1992 Phys. Rev. B 45 3386

Google Scholar

Google Scholar

[36] Vehanen A, Lynn K G, Schultz P J, Cartier E, Güntherodt H J, Parkin D M 1984 Phys. Rev. B 29 2371

Google Scholar

Google Scholar

[37] Staab T E M, Krause-Rehberg R, Kieback B 1999 J. Mater. Sci. 34 3833

Google Scholar

Google Scholar

[38] Schultz P J, Lynn K G 1988 Rev. Mod. Phys. 60 701

Google Scholar

Google Scholar

[39] Puska M J, Nieminen R M 1994 Rev. Mod. Phys. 66 841

Google Scholar

Google Scholar

[40] Veen A van, Schut H, Vries J de, Hakvoort R A, Ijpma M R 1991 AIP Conf. Proc. 218 171

[41] Esteban G A, Perujo A, Sedano L A, Douglas K 2001 J. Nucl. Mater. 295 49

Google Scholar

Google Scholar

[42] Li Y, Deng A H, Zhou Y L, Zhou B, Wang K, Hou Q, Shi L Q, Qin X B, Wang B Y 2012 Chin. Phys. Lett. 29 047801

Google Scholar

Google Scholar

-

图 2 正电子湮没区域分布 (a) 9 × 9 × 9的BCC钨晶格超胞中存在一个空位; (b) W-GB-1超胞中只有晶界一种缺陷; (c) W-GB-1超胞中晶界处存在一个空位; (d) W-GB-1超胞中晶界处存在一个钾原子

Fig. 2. Distribution of positron annihilation region: (a) 9 × 9 × 9 BCC tungsten lattice supercell with a vacancy; (b) W-GB-1 supercell; (c) W-GB-1 supercell with a vacancy at the GBs; (d) W-GB-1 supercell with a potassium at the GBs.

表 1 正电子湮没寿命计算中建立的晶界和位错模型

Table 1. Grain boundary (GB) and dislocation line (DL) model for positron annihilation lifetime calculation

编号 Σ GB plane GB type Rotation axis Angle/(°) W-GB-1 5 $ \langle 210 \rangle $ twist z (001) 53.15 W-GB-2 13 $ \langle 510 \rangle $ twist z (001) 22.61 W-GB-3 5 $ \{0\bar1 5\} $ tilt x (100) 22.61 W-GB-4 13 $ \{0\bar15\} $ tilt x (100) 53.15 编号 Slip plane(z) Burgers vector[b] Dislocation line[y] Dislocation type b-y Angle/(°) W-DL-1 $ (\bar101) $ (111)/2 $ (\bar 12\bar 1) $ EDGE 90 W-DL-2 $ (\bar101) $ (111)/2 (111) SCREW 0 W-DL-3 $ (\bar101) $ (111)/2 (010) MIX 54.73 表 2 晶界和位错包含空位或钾原子时的正电子湮没寿命值

Table 2. Positron annihilation lifetime of grain boundary and dislocation with vacancies or potassium atoms.

编号 Intact/ps Vac.1/ps Vac.9/ps K1/ps K9/ps W-GB-1 116.6 198.2 297.4 110.6 108.4 W-GB-2 117.9 198.0 297.2 116.4 111.7 W-GB-3 135.2 204.8 304.4 142.3 144.1 W-GB-4 142.2 198.0 317.3 141.0 144.6 W-DL-1 133.9 160.3 309.7 133.9 134.2 W-DL-2 106.5 194.7 324.0 104.7 105.8 W-DL-3 123.4 158.0 315.4 123.4 123.4 表 3 不同钾含量的钨钾合金样品的双组分正电子寿命值

Table 3. Two-component positron lifetime of W-K samples with different potassium content.

钾含量/ppm 编号 ${\tau _{{\rm{1, }}\exp }}$/ps ${I_{1, \exp }}$/% ${\tau _{{\rm{2, }}\exp }}$/ps ${I_{2, \exp }}$/% 平均寿命${\tau _{{\rm{av}}}}$/ps 捕获率$\kappa $/ns–1 计算体寿命$\tau _{\rm{1}}^{{\rm{cal}}}$/ps 46 A1 123.4 74.62 296.2 25.38 167.3 1.1999 97.2 82 B1 123.3 75.68 305.1 24.32 167.5 1.1752 97.4 122 C1 140.1 72.42 332.6 27.58 193.2 1.1395 97.7 144 D1 143.2 77.07 328.3 22.93 185.6 0.9028 100.1 表 4 不同钾含量的钨钾合金样品中位错和空位团簇

Table 4. Dislocation and vacancy clusters in W-K samples with potassium content.

钾含量/ppm 编号 位错捕获率${\kappa _1}$/ps–1 空位团簇捕获率${\kappa _2}$/ps–1 位错密度${C_{{\rm{dis}}}}$/1010 cm2 空位团簇浓度${C_{{\rm{cl}}}}$/10–7 46 A1 0.00912 0.00505 0.8289 1.515 82 B1 0.00895 0.00474 0.8136 1.424 122 C1 0.03359 0.01511 3.0534 4.538 144 D1 0.04400 0.01489 3.9991 4.470 表 5 不同钾含量的钨合金样品的S参数拟合

Table 5. Fitted values of S parameters of W-K samples with different potassium content.

钾含量/ppm 编号 第一层厚度/nm 第一层S1 第二层S2 46 A2 10 0.4521 0.4424 82 B2 11 0.4520 0.4406 122 C2 13 0.4521 0.4455 0 PMW 10 0.4050 0.3880 表 6 不同钾含量的钨合金样品中正电子扩散长度

Table 6. Positron diffusion length in tungsten alloy samples with different potassium content.

钾含量/ppm 编号 寿命谱$L_{{\rm{ +, eff}}}^{{\rm{cal}}}$/nm 编号 第一层$L_{ +, {\rm{eff}}}^1$/nm 第二层$L_{ +, {\rm{eff}}}^2$/nm 46 A1 77.59 A2 2.73 ± 0.89 59.75 ± 9.96 82 B1 78.39 B2 4.98 ± 1.06 58.61 ± 7.86 122 C1 49.22 C2 1.65 ± 1.56 37.44 ± 7.72 0 PMW 6.50 ± 0.29 109.32 ± 5.46 -

[1] Ueda Y, Coenen J W, De Temmerman G, Doerner R P, Linke J, Philipps V, Tsitrone E 2014 Fusion Eng. Des. 89 901

Google Scholar

Google Scholar

[2] Kang H K 2004 J. Nucl. Mater. 335 1

Google Scholar

Google Scholar

[3] Davis J W, Barabash V R, Makhankov A, Plöchl L, Slattery K T 1998 J. Nucl. Mater. 258 308

[4] Ueda Y, Tobita K, Katoh Y 2003 J. Nucl. Mater. 313-316 32

Google Scholar

Google Scholar

[5] Lisgo S W, Kukushkin A, Pitts R A, Reiter D 2013 J. Nucl. Mater. 438 S580

Google Scholar

Google Scholar

[6] Wurster S, Baluc N, Battabyal M, Crosby T, Du J, García-Rosales C, Hasegawa A, Hoffmann A, Kimura A, Kurishita H, Kurtz R J, Li H, Noh S, Reiser J, Riesch J, Rieth M, Setyawan W, Walter M, You J H, Pippan R 2013 J. Nucl. Mater. 442 S181

Google Scholar

Google Scholar

[7] 王玲 2018 博士论文 (成都: 四川大学)

Wang L 2018 Ph. D. Dissertation (Chengdu: Sichuan University) (in Chinese)

[8] Hirai T, Pintsuk G 2007 Fusion Eng. Des. 82 389

Google Scholar

Google Scholar

[9] Wurster S, Pippan R 2009 Scr. Mater. 60 1083

Google Scholar

Google Scholar

[10] Uytdenhouwen I, Decréton M, Hirai T, Linke J, Pintsuk G, Van Oost G 2007 J. Nucl. Mater. 363 1099

[11] Briant C L 1993 Metall. Trans. A 24 1073

Google Scholar

Google Scholar

[12] Horacsek O, Toth C L, Nagy A 1998 Int. J. Refract. Met. Hard Mater. 16 51

Google Scholar

Google Scholar

[13] Schade P 2010 Int. J. Refract. Met. Hard Mater. 28 648

Google Scholar

Google Scholar

[14] Schade P 1998 Int. J. Refract. Met. Hard Mater. 16 77

Google Scholar

Google Scholar

[15] Dias M, Mateus R, Catarino N, Franco N, Nunes D, Correia J B, Carvalho P A, Hanada K, Sârbu C 2013 J. Nucl. Mater. 442 69

Google Scholar

Google Scholar

[16] Huang B, Tang J, Chen L Q, Yang X L, Lian Y Y, Chen L, Liu X, Cui X D, Gu L, Liu C T 2019 J. Alloys Compd. 782 149

Google Scholar

Google Scholar

[17] Liu G, Zhang G J, Jiang F, Ding X D, Sun Y J, Sun J, Ma E 2013 Nat. Mater. 12 344

Google Scholar

Google Scholar

[18] Xie Z M, Liu R, Miao S, Yang X D, Zhang T, Wang X P, Fang Q F, Liu C S, Luo G N, Lian Y Y, Liu X 2015 Sci. Rep. 5 16014

Google Scholar

Google Scholar

[19] Liu R, Xie Z M, Fang Q F, Zhang T, Wang X P, Hao T, Liu C S, Dai Y 2016 J. Alloys Compd. 657 73

Google Scholar

Google Scholar

[20] Tuomisto F, Makkonen I 2013 Rev. Mod. Phys. 85 1583

Google Scholar

Google Scholar

[21] Wang S J, Chen Z Q, Wang B, Wu Y C, Fang P F, Zhang Y X 2008 Applied Positron Spectroscopy (Wuhan: Hubei Science & Technology Press) p8 (in Chinese) [王少阶, 陈志权, 王波, 吴奕初, 方鹏飞, 张永学 2008 应用正电子谱学 (武汉: 湖北科学技术出版社) 第8页]

[22] Staab T E M, Krause-Rehberg R, Vetter B, Kieback B, Lange G, Klimanek P 1999 J. Phys. Condens. Matter 11 1757

Google Scholar

Google Scholar

[23] Heikinheimo J, Mizohata K, Räisänen J, Ahlgren T, Jalkanen P, Lahtinen A, CatarinoN, Alves E, Tuomisto F 2019 APL Mater. 7 021103

Google Scholar

Google Scholar

[24] Puska M J, Nieminen R M 1983 J. Phys. F: Met. Phys. 13 333

Google Scholar

Google Scholar

[25] Puska M J, Seitsonen A P, Nieminen R M 1995 Phys. Rev. B 52 10947

Google Scholar

Google Scholar

[26] Robles J M C, Ogando E, Plazaola F 2007 J. Phys. Condens. Matter 19 176222

Google Scholar

Google Scholar

[27] Huang B, Chen L Q, Qiu W B, Yang X L, Shi K, Lian Y Y, Liu X, Tang J 2019 J. Nucl. Mater. 520 6

Google Scholar

Google Scholar

[28] Jin S, Zhang P, Lu E, Guo L, Wang B, Cao X 2016 Acta Mater. 103 658

Google Scholar

Google Scholar

[29] Troev T, Popov E, MStaikov P, Nankov N, Yoshiie T 2009 Nucl. Instrum. Meth. B 267 535

Google Scholar

Google Scholar

[30] Puska M J, Lanki P, Nieminen R M 1989 J. Phys. Condens. Matter 1 6081

Google Scholar

Google Scholar

[31] Kuriplach J, Melikhova O, Hou M, Van Petegem S, Zhurkin E, Šob M 2007 Phys. Stat. Sol. 4 3461

[32] Würschum R, Seeger A 1996 Philos. Mag. 73 1489

Google Scholar

Google Scholar

[33] Oberdorfer B, Würschum R 2009 Phys. Rev. B 79 184103

Google Scholar

Google Scholar

[34] Hautojärvi P, Corbel C 1995 Positron Spectroscopy of Solids (Amsterdam: IOS Press) p491

[35] Corbel C, Pierre F, Saarinew K, Hautojarvi P, Moser P 1992 Phys. Rev. B 45 3386

Google Scholar

Google Scholar

[36] Vehanen A, Lynn K G, Schultz P J, Cartier E, Güntherodt H J, Parkin D M 1984 Phys. Rev. B 29 2371

Google Scholar

Google Scholar

[37] Staab T E M, Krause-Rehberg R, Kieback B 1999 J. Mater. Sci. 34 3833

Google Scholar

Google Scholar

[38] Schultz P J, Lynn K G 1988 Rev. Mod. Phys. 60 701

Google Scholar

Google Scholar

[39] Puska M J, Nieminen R M 1994 Rev. Mod. Phys. 66 841

Google Scholar

Google Scholar

[40] Veen A van, Schut H, Vries J de, Hakvoort R A, Ijpma M R 1991 AIP Conf. Proc. 218 171

[41] Esteban G A, Perujo A, Sedano L A, Douglas K 2001 J. Nucl. Mater. 295 49

Google Scholar

Google Scholar

[42] Li Y, Deng A H, Zhou Y L, Zhou B, Wang K, Hou Q, Shi L Q, Qin X B, Wang B Y 2012 Chin. Phys. Lett. 29 047801

Google Scholar

Google Scholar

计量

- 文章访问数: 19172

- PDF下载量: 133

- 被引次数: 0

下载:

下载: