-

本研究通过高真空退火法制备了钾掺杂三(二苯甲酰甲基)铁分子晶体的粉末样品. X-射线衍射测试结果表明, 合成样品与纯三(二苯甲酰甲基)铁的晶体结构明显不同, 平均晶粒尺寸约为20.5 nm. 直流磁化率和交流磁化率的测试结果表明, 合成的样品具有阻塞温度(TB)约为8.0 K的超顺磁性, 这与纯有机物在1.8—300 K整个测试温区的顺磁性存在本质的差异. 根据拉曼光谱测试结果可以确认, 掺杂材料中钾的4 s电子转移到了三(二苯甲酰甲基)铁的苯环上, 引起了拉曼模式的红移, 同时电荷转移也导致苯环上局域磁矩的形成. 本研究工作对碱金属掺杂芳香烃分子晶体的合成和物性研究具有重要的意义, 并为寻找新型的有机铁磁体提供了一条新的途径.

-

关键词:

- 三(二苯甲酰甲基)铁 /

- 钾掺杂 /

- 高真空退火法 /

- 超顺磁

Synthesis and exploration of intriguing physical properties of alkali-metal-doped aromatic hydrocarbons have been the important research topics in the fields of physics, chemistry and materials science. In this work, a powder sample of potassium-doped tris(diphenacyl) iron molecular crystal is prepared by the high-vacuum annealing method. The X-ray diffraction results show that the crystal structure of the synthesized sample is different from that of pristine tris(diphenacyl)iron. The direct current (DC) magnetic susceptibilitiy shows a pronounced hump structure near 8.0 K, which is distinct from the paramagnetism of pristine material in the whole temperature range of 1.8–300 K. The alternating current (AC) magnetic susceptibility shows that the hump has a significant frequency dependence, which can safely rule out the possibility of antiferromagnetism. The combination of the Vogel-Fulcher law, the Néel-Brown model and the critical slowing down model reveals that the hump originates from superparamagnetism with a blocking temperature (TB) of about 8.0 K. According to the results of Raman spectroscopy, it can be confirmed that the 4s electrons of potassium in the doped material are transferred to the benzene ring of tris(diphenacyl)iron, causing the characteristic Raman modes to be red-shifted and the local magnetic moment to form. Our work is of great significance in exploring alkali-metal-doped aromatic hydrocarbons, and provides a new route for searching organic magnetic materials.-

Keywords:

- tris(diphenacyl) iron /

- potassium doped /

- high vacuum annealing method /

- superparamagnetism

[1] 高云, 王仁树, 邬小林, 程佳, 邓天郭, 闫循旺, 黄忠兵 2016 65 077402

Google Scholar

Google Scholar

Gao Y, Wang R S, Wu X L, Cheng J, Deng T G, Yan X W, Huang Z B 2016 Acta Phys. Sin. 65 077402

Google Scholar

Google Scholar

[2] 轩书科 2017 66 237401

Google Scholar

Google Scholar

Xuan S K 2017 Acta Phys. Sin. 66 237401

Google Scholar

Google Scholar

[3] Zhang J L, Whitehead G F S, Manning T D, Stewart D, Hiley C I, Pitcher M J, Jansat S, Prassides K, Rosseinsky M J 2018 J. Am. Chem. Soc. 140 18162

Google Scholar

Google Scholar

[4] Mitsuhashi R, Suzuki Y, Yamanari Y, Mitamura H, Kambe T, Ikeda N, Okamoto H, Fujiwara A, Yamaji M, Kawasaki N, Maniwa Y, Kubozono Y 2010 Nature 464 76

Google Scholar

Google Scholar

[5] Wang X F, Liu R H, Gui Z, Xie Y L, Yan Y J, Ying J J, Luo X G, Chen X H 2012 Nature Commun. 2 507

[6] Xue M Q, Cao T B, Wang D M, Wu Y, Yang H X, Dong X L, He J B, Li F W, Chen G F 2012 Sci. Rep. 2 389

Google Scholar

Google Scholar

[7] Wang X F, Yan Y J, Gui Z, Liu R H, Ying J J, Luo X G, Chen X H 2011 Phys. Rev. B 84 214523

Google Scholar

Google Scholar

[8] Takabayashi Y, Menelaou M, Tamura H, Takemori N, Koretsune T, Štefančič A, Klupp G, Buurma C A J, Nomura Y, Arita R, Arčon D, Rosseinsky M J, Prassides K 2017 Nature Chem. 9 635

Google Scholar

Google Scholar

[9] Štefančič A, Klupp G, Knaflič T, Yufit D S, Tavčar G, Potočnik A, Beeby A, Arčon D 2017 J. Phys. Chem. C 127 14864

[10] Phan Q T N, Heguri S, Tamura H, Nakano T, Nozue Y, Tanigaki K 2016 Phys. Rev. B 93 075130

Google Scholar

Google Scholar

[11] Fu M A, Wang R S, Yang H, Zhang P Y, Zhang C F, Chen X J, Gao Y, Huang Z B 2021 Carbon 173 587

Google Scholar

Google Scholar

[12] Wang R S, Gao Y, Huang Z B, Chen X J 2017 arXiv: 1703.06641v1

[13] Liu W H, Lin H, Kang R Z, Zhang Y, Zhu X Y, Wen H H 2017 Phys. Rev. B 96 224501

Google Scholar

Google Scholar

[14] Wang R S, Cheng J, Wu X L, Yang H, Chen X J, Gao Y, Huang Z B 2018 J. Chem. Phys. 149 144502

Google Scholar

Google Scholar

[15] Wang R S, Yang H, Cheng J, Wu X L, Fu M A, Chen X J, Gao Y, Huang Z B. 2019 J. Phys. Chem. C 123 19105

Google Scholar

Google Scholar

[16] Wang R S, Chen L C, Yang H, Fu M A, Cheng J, Wu X L, Gao Y, Huang Z B, Chen X J 2019 Phys. Chem. Chem. Phys. 21 25976

Google Scholar

Google Scholar

[17] Rostamnejadi A, Salamati H, Kameli P, Ahmadvand H 2009 J. Magn. Magn. Mater. 321 3126

Google Scholar

Google Scholar

[18] Venkateswarlu B, Krishnan R H, Chelvane J A, Babu P D, Kumar N H 2019 J. Alloy. Compd. 777 373

Google Scholar

Google Scholar

[19] Shtrikman S, Wohlfarth E P 1918 Phys. Lett. 85A 467

[20] Goya G F, Berquό T S, Fonseca F C 2003 J. Appl. Phys. 94 3520

Google Scholar

Google Scholar

[21] Dormann J L, Fiorani D, Cherkaoui R, Tronc E, Lucari F, DʹOrazio F, Spinu L, Noguès M, Kachkchi H, Jolivet J P 1999 J. Magn. Magn. Mater. 203 23

Google Scholar

Google Scholar

[22] Sharma S K, Kumar R, Kumar S, Kumar V V S, Knobel M, Reddy V R, Banerjee A, Singh M 2007 Solid State Commun. 141 203

Google Scholar

Google Scholar

[23] Jonason K, Mattsson J, Nordblad P 1996 Phys. Rev. B 53 6507

Google Scholar

Google Scholar

[24] Nam D N H, Jonason K, Nordblad P, Khiem N V, Phuc N X 1999 Phys. Rev. B 59 4189

Google Scholar

Google Scholar

[25] Typek J, Guskos N, Zolnierkiewicz G, Lendzion-Bielun Z, Pachla A, Narkiewicz U 2018 Eur. Phys. J. Appl. Phys. 83 10402

Google Scholar

Google Scholar

[26] 潘峰, 丁斌峰, 法涛, 成枫锋, 周生强, 姚淑德 2011 60 108501

Google Scholar

Google Scholar

Pan F, Ding B F, Fa T, Cheng F F, Zhou S Q, Yao S D 2011 Acta Phys. Sin. 60 108501

Google Scholar

Google Scholar

[27] Carvell J, Ayieta E, Gavrin A, Cheng R H, Shah V R, Sokol P 2010 J. Appl. Phys. 107 103913

Google Scholar

Google Scholar

[28] Nekoei A R, Vakili M, Hakimi-Tabar M, TayyariS F, Afzali R, Kjaergaard H G 2014 Spectrochim. Acta A 128 272

Google Scholar

Google Scholar

-

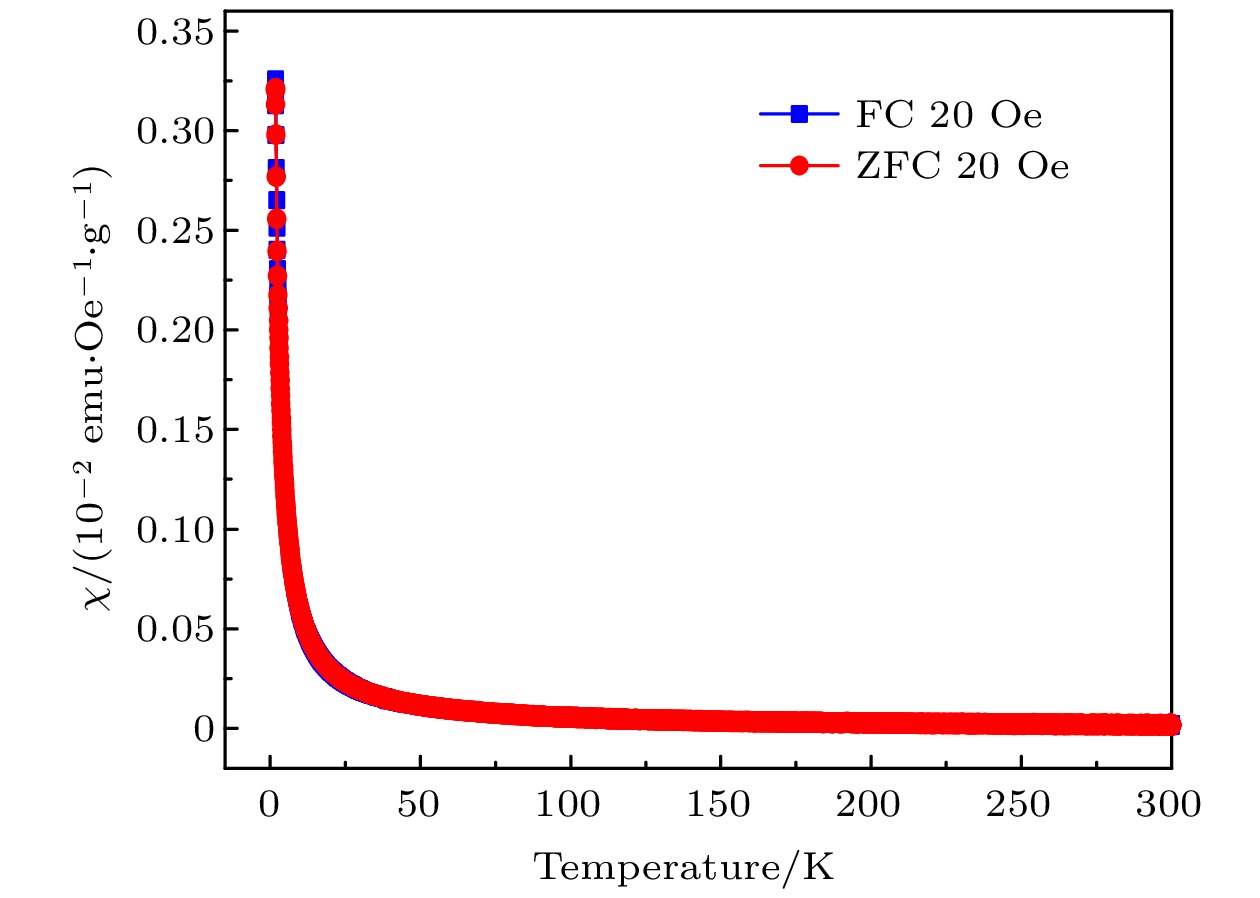

图 4 掺杂样品K3DPF-A的PPMS磁性测试结果 (a) K3DPF-A在外磁场20 Oe下的ZFC和FC直流磁化率测试曲线, 插图为M-H曲线; (b) K3DPF-A在不同磁场下的ZFC曲线; (c) K3DPF-A交流磁化率曲线的实部; (d) K3DPF-A交流磁化率曲线的虚部

Fig. 4. The PPMS magnetic results of the doped sample K3DPF-A: (a) The ZFC and FC DC susceptibility curves of K3DPF-A under an external magnetic field of 20 Oe. The inset is the M-H curve. (b) ZFC curves of K3DPF-A under different magnetic fields. (c) The real part and (d) the imaginary part of AC magnetic susceptibility for K3DPF-A.

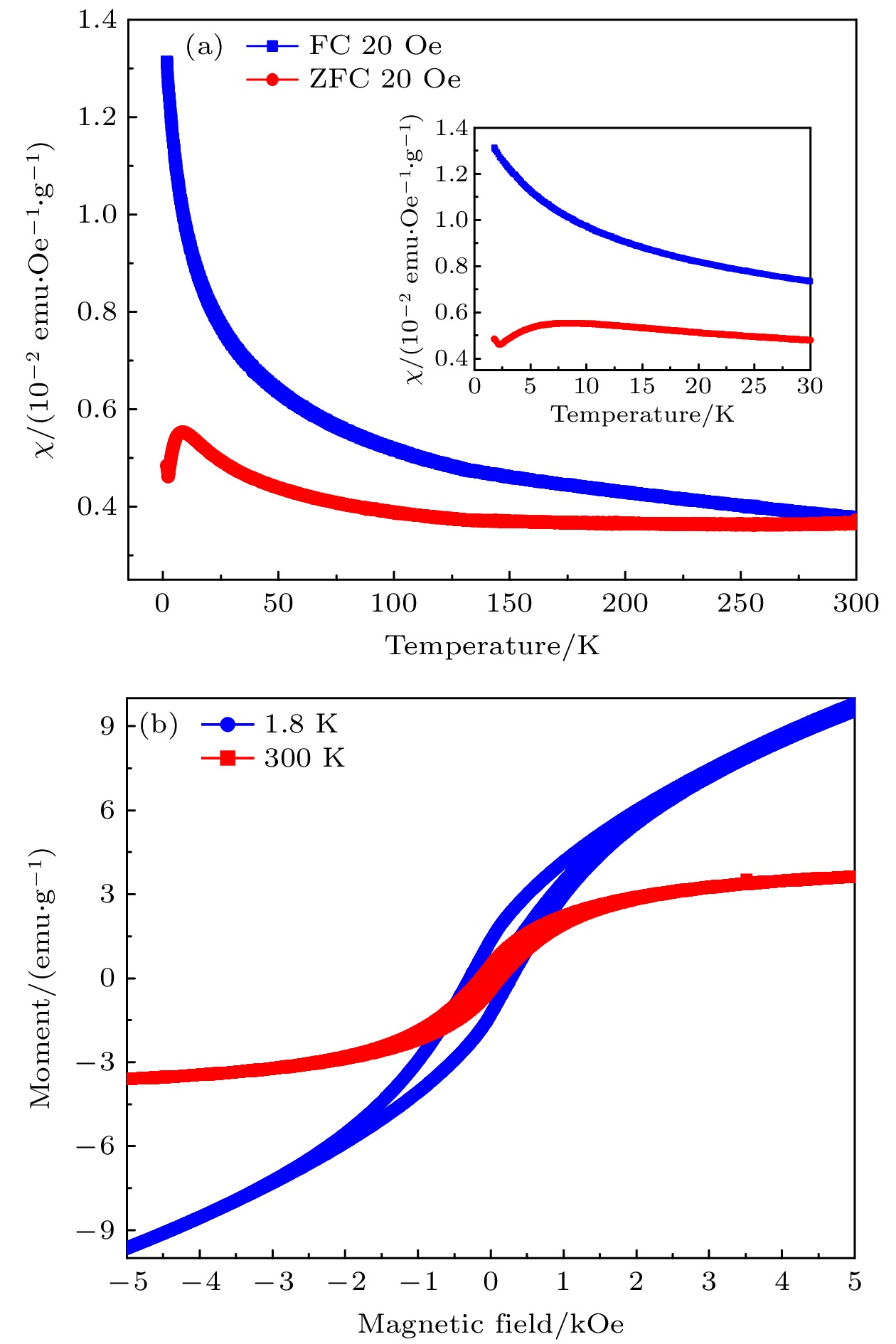

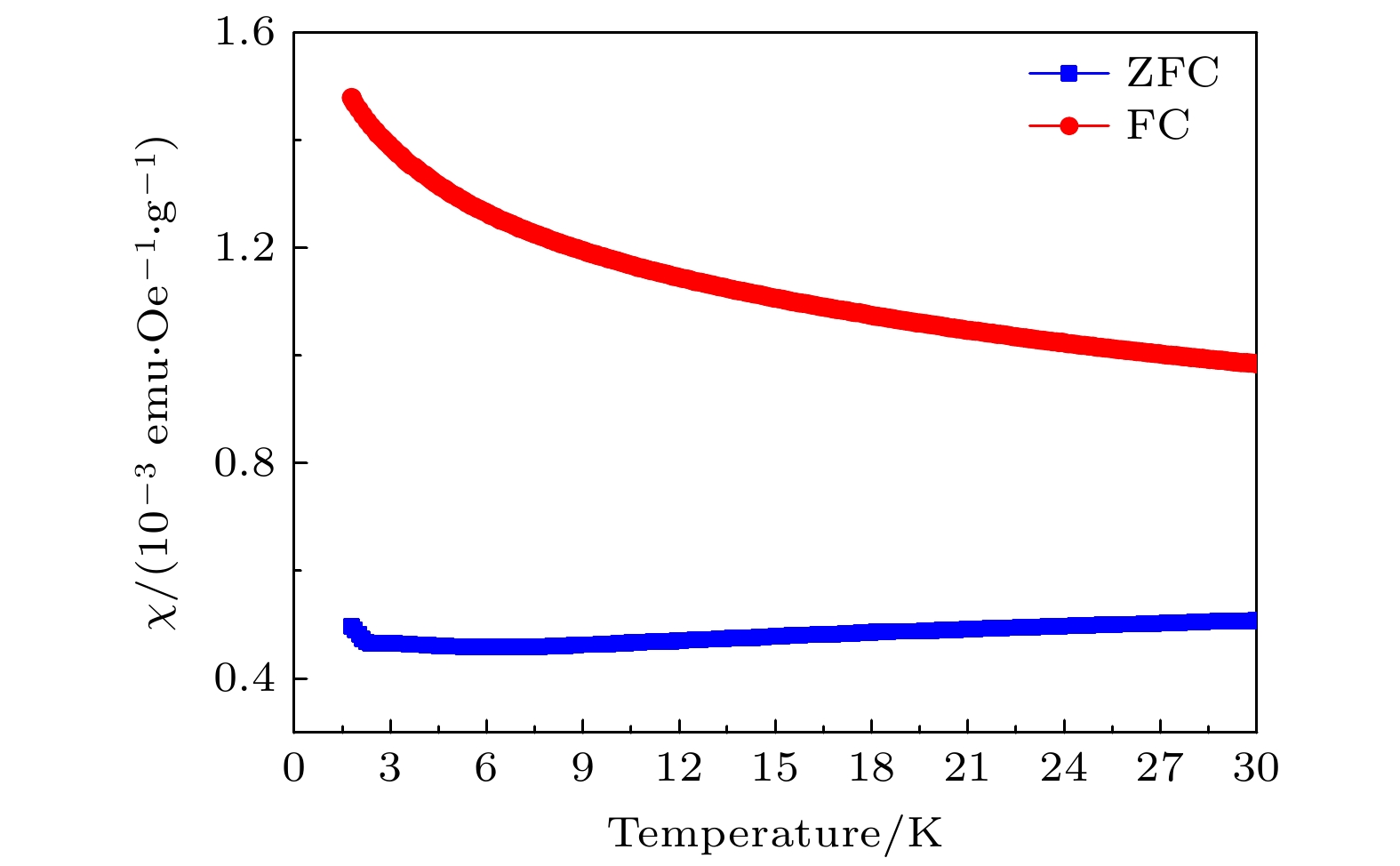

图 5 掺杂样品K3DPF-B的PPMS磁性测试结果 (a) K3DPF-B在外磁场20 Oe下的ZFC和FC直流磁化率测试曲线; (b) K3DPF-B在1.8 K与300 K下的M-H曲线

Fig. 5. The PPMS magnetic results of the doped sample K3DPF-B: (a) The ZFC and FC DC susceptibility curves of K3DPF-B under an external magnetic field of 20 Oe; (b) M-H curves of K3DPF-B at 1.8 and 300 K.

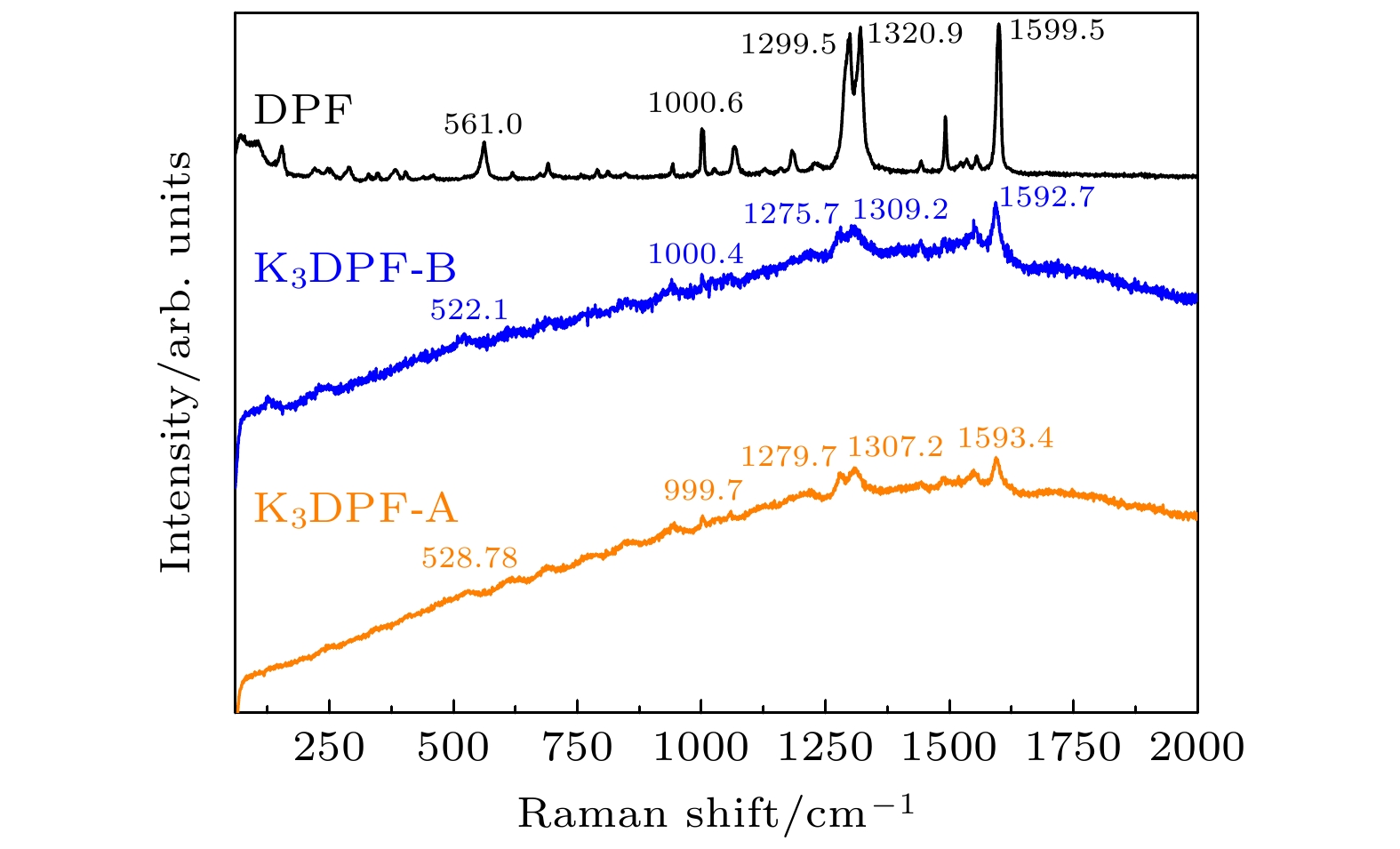

表 1 纯DPF和钾掺杂DPF相应的拉曼模式频率的峰位及对比

Table 1. Comparison of Raman modes of pure DPF and potassium-doped tris(diphenacyl)iron.

number Assignment $ \omega /{\text{c}}{{\text{m}}^{ - 1}} $(DPF) $ \omega /{\text{c}}{{\text{m}}^{ - 1}} $ (K3DPF) $ \omega /{\text{c}}{{\text{m}}^{ - 1}} $ (Cu-DBM) $ \omega /{\text{c}}{{\text{m}}^{ - 1}} $ (CAC) $ \omega /{\text{c}}{{\text{m}}^{ - 1}} $(KCAC) 1 υ(s)Fe(—O)2 561.0 522.1 567.0 2 υ(s)C—C—C 1000.6 1000.4 1002.0 996.4 987.2 3 υ(s)C—C—C 1299.5 1275.7 1290.0 1295.1 1289.6 4 υ(s)C—C—C 1320.9 1309.2 1317.0 1328.9 1322.0 5 υ(s)C—C—C 1491.6 1488.1 1492.0 1491.7 1483.1 6 υ(s)C =O 1599.5 1592.8 1596.0 1606.1 1588.1 -

[1] 高云, 王仁树, 邬小林, 程佳, 邓天郭, 闫循旺, 黄忠兵 2016 65 077402

Google Scholar

Google Scholar

Gao Y, Wang R S, Wu X L, Cheng J, Deng T G, Yan X W, Huang Z B 2016 Acta Phys. Sin. 65 077402

Google Scholar

Google Scholar

[2] 轩书科 2017 66 237401

Google Scholar

Google Scholar

Xuan S K 2017 Acta Phys. Sin. 66 237401

Google Scholar

Google Scholar

[3] Zhang J L, Whitehead G F S, Manning T D, Stewart D, Hiley C I, Pitcher M J, Jansat S, Prassides K, Rosseinsky M J 2018 J. Am. Chem. Soc. 140 18162

Google Scholar

Google Scholar

[4] Mitsuhashi R, Suzuki Y, Yamanari Y, Mitamura H, Kambe T, Ikeda N, Okamoto H, Fujiwara A, Yamaji M, Kawasaki N, Maniwa Y, Kubozono Y 2010 Nature 464 76

Google Scholar

Google Scholar

[5] Wang X F, Liu R H, Gui Z, Xie Y L, Yan Y J, Ying J J, Luo X G, Chen X H 2012 Nature Commun. 2 507

[6] Xue M Q, Cao T B, Wang D M, Wu Y, Yang H X, Dong X L, He J B, Li F W, Chen G F 2012 Sci. Rep. 2 389

Google Scholar

Google Scholar

[7] Wang X F, Yan Y J, Gui Z, Liu R H, Ying J J, Luo X G, Chen X H 2011 Phys. Rev. B 84 214523

Google Scholar

Google Scholar

[8] Takabayashi Y, Menelaou M, Tamura H, Takemori N, Koretsune T, Štefančič A, Klupp G, Buurma C A J, Nomura Y, Arita R, Arčon D, Rosseinsky M J, Prassides K 2017 Nature Chem. 9 635

Google Scholar

Google Scholar

[9] Štefančič A, Klupp G, Knaflič T, Yufit D S, Tavčar G, Potočnik A, Beeby A, Arčon D 2017 J. Phys. Chem. C 127 14864

[10] Phan Q T N, Heguri S, Tamura H, Nakano T, Nozue Y, Tanigaki K 2016 Phys. Rev. B 93 075130

Google Scholar

Google Scholar

[11] Fu M A, Wang R S, Yang H, Zhang P Y, Zhang C F, Chen X J, Gao Y, Huang Z B 2021 Carbon 173 587

Google Scholar

Google Scholar

[12] Wang R S, Gao Y, Huang Z B, Chen X J 2017 arXiv: 1703.06641v1

[13] Liu W H, Lin H, Kang R Z, Zhang Y, Zhu X Y, Wen H H 2017 Phys. Rev. B 96 224501

Google Scholar

Google Scholar

[14] Wang R S, Cheng J, Wu X L, Yang H, Chen X J, Gao Y, Huang Z B 2018 J. Chem. Phys. 149 144502

Google Scholar

Google Scholar

[15] Wang R S, Yang H, Cheng J, Wu X L, Fu M A, Chen X J, Gao Y, Huang Z B. 2019 J. Phys. Chem. C 123 19105

Google Scholar

Google Scholar

[16] Wang R S, Chen L C, Yang H, Fu M A, Cheng J, Wu X L, Gao Y, Huang Z B, Chen X J 2019 Phys. Chem. Chem. Phys. 21 25976

Google Scholar

Google Scholar

[17] Rostamnejadi A, Salamati H, Kameli P, Ahmadvand H 2009 J. Magn. Magn. Mater. 321 3126

Google Scholar

Google Scholar

[18] Venkateswarlu B, Krishnan R H, Chelvane J A, Babu P D, Kumar N H 2019 J. Alloy. Compd. 777 373

Google Scholar

Google Scholar

[19] Shtrikman S, Wohlfarth E P 1918 Phys. Lett. 85A 467

[20] Goya G F, Berquό T S, Fonseca F C 2003 J. Appl. Phys. 94 3520

Google Scholar

Google Scholar

[21] Dormann J L, Fiorani D, Cherkaoui R, Tronc E, Lucari F, DʹOrazio F, Spinu L, Noguès M, Kachkchi H, Jolivet J P 1999 J. Magn. Magn. Mater. 203 23

Google Scholar

Google Scholar

[22] Sharma S K, Kumar R, Kumar S, Kumar V V S, Knobel M, Reddy V R, Banerjee A, Singh M 2007 Solid State Commun. 141 203

Google Scholar

Google Scholar

[23] Jonason K, Mattsson J, Nordblad P 1996 Phys. Rev. B 53 6507

Google Scholar

Google Scholar

[24] Nam D N H, Jonason K, Nordblad P, Khiem N V, Phuc N X 1999 Phys. Rev. B 59 4189

Google Scholar

Google Scholar

[25] Typek J, Guskos N, Zolnierkiewicz G, Lendzion-Bielun Z, Pachla A, Narkiewicz U 2018 Eur. Phys. J. Appl. Phys. 83 10402

Google Scholar

Google Scholar

[26] 潘峰, 丁斌峰, 法涛, 成枫锋, 周生强, 姚淑德 2011 60 108501

Google Scholar

Google Scholar

Pan F, Ding B F, Fa T, Cheng F F, Zhou S Q, Yao S D 2011 Acta Phys. Sin. 60 108501

Google Scholar

Google Scholar

[27] Carvell J, Ayieta E, Gavrin A, Cheng R H, Shah V R, Sokol P 2010 J. Appl. Phys. 107 103913

Google Scholar

Google Scholar

[28] Nekoei A R, Vakili M, Hakimi-Tabar M, TayyariS F, Afzali R, Kjaergaard H G 2014 Spectrochim. Acta A 128 272

Google Scholar

Google Scholar

计量

- 文章访问数: 7309

- PDF下载量: 108

- 被引次数: 0

下载:

下载: