-

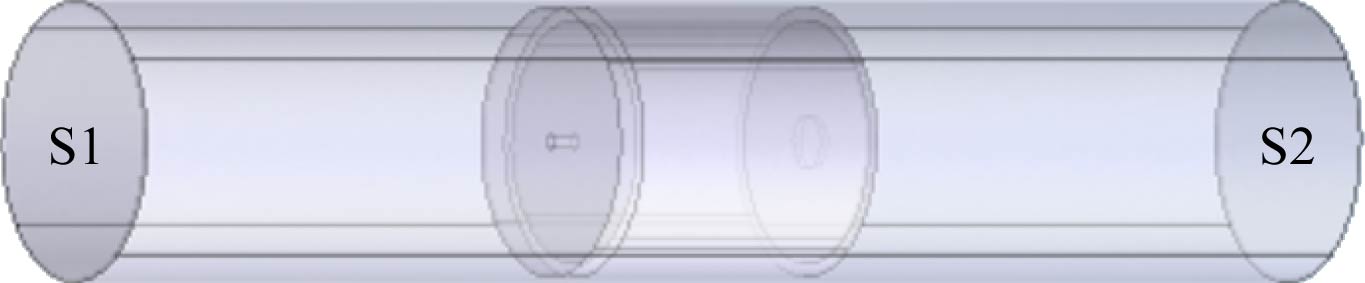

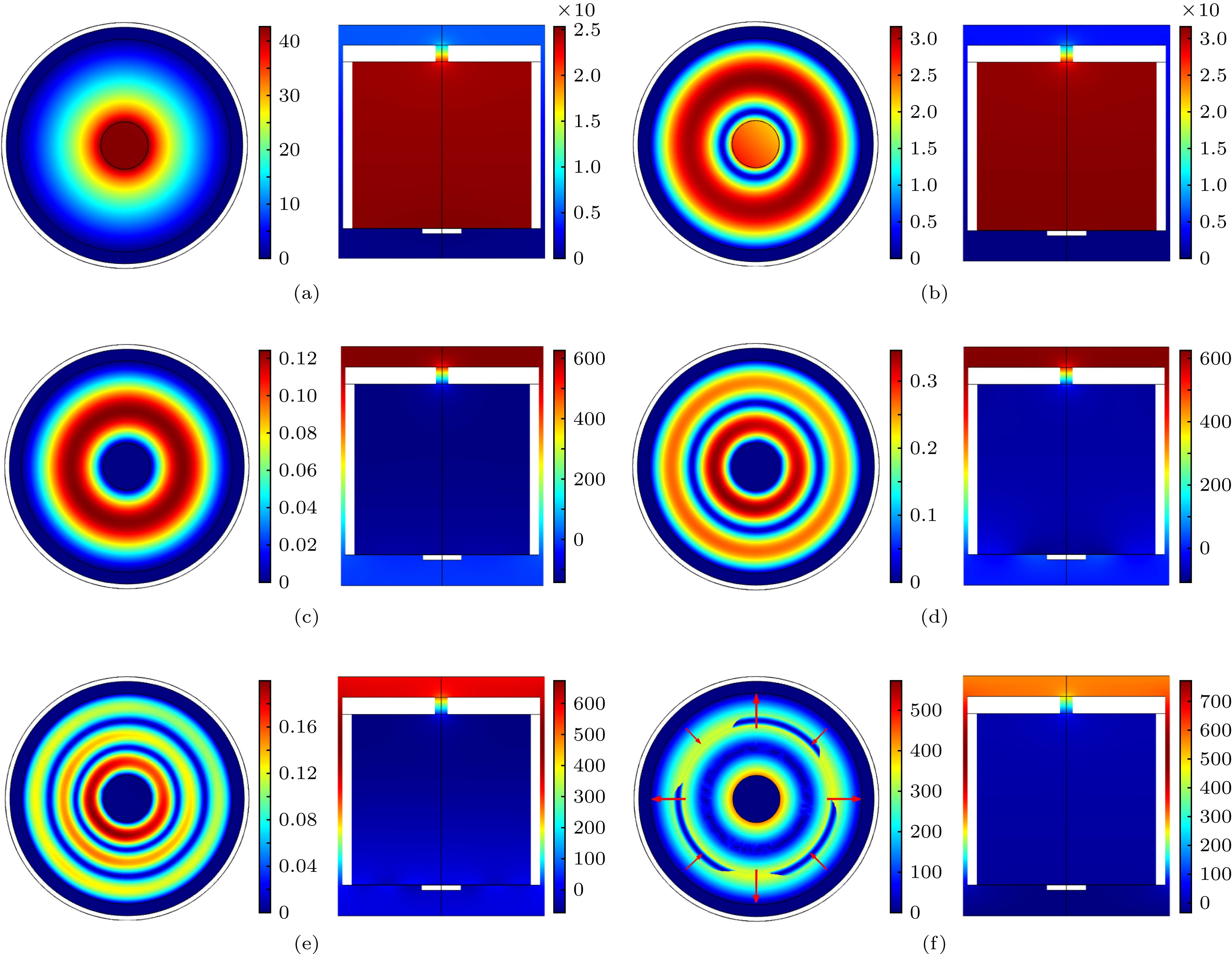

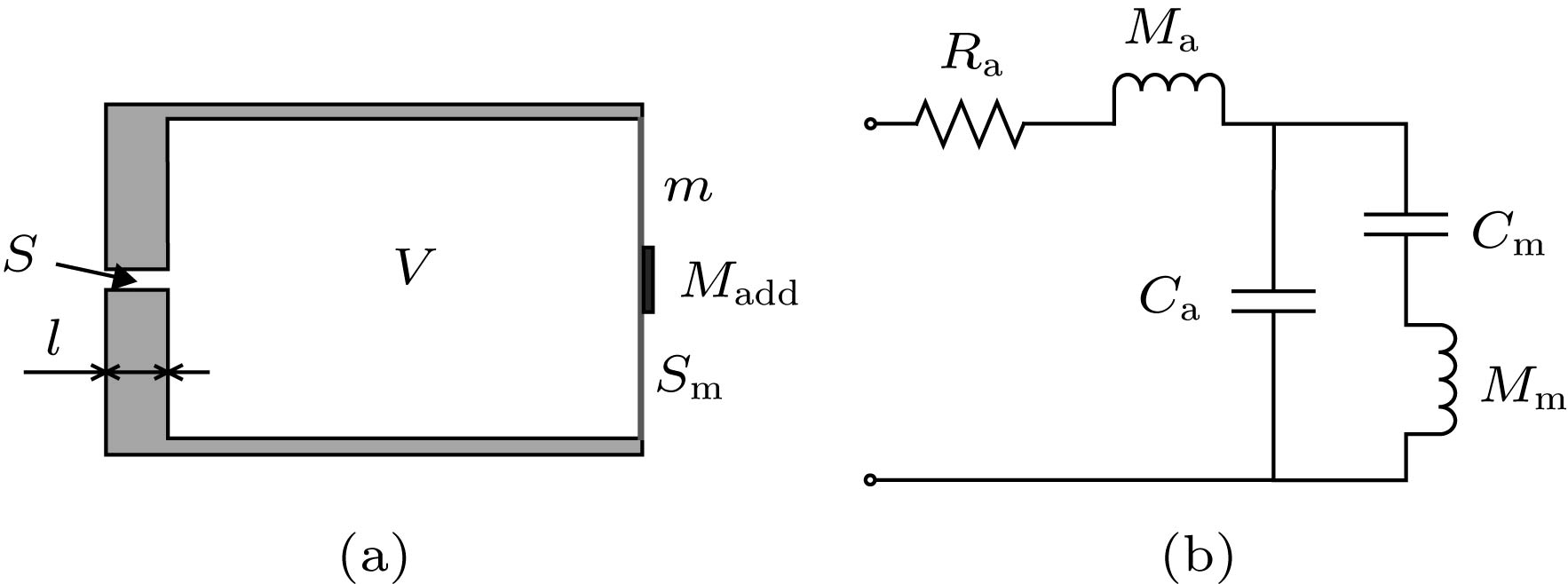

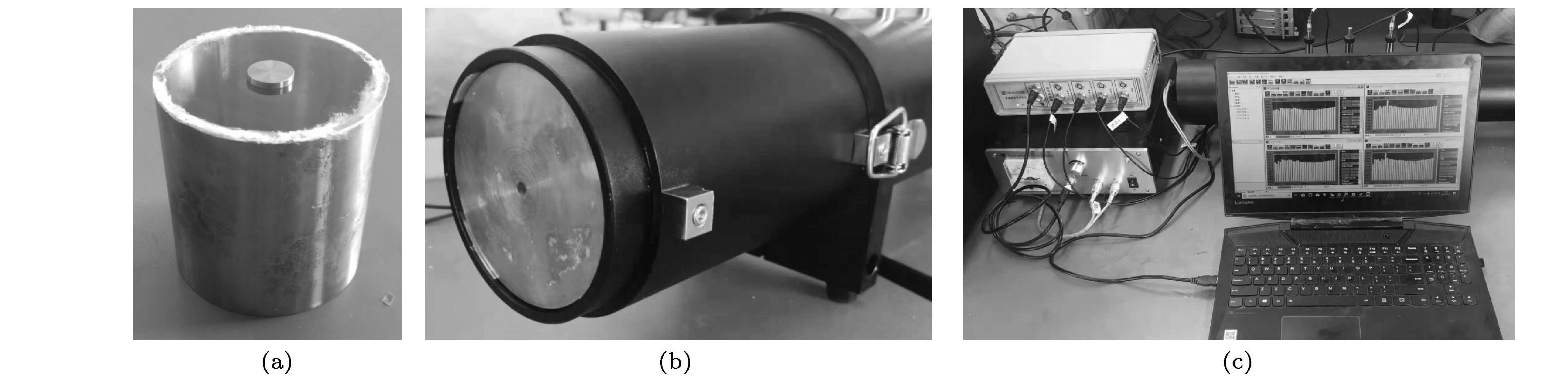

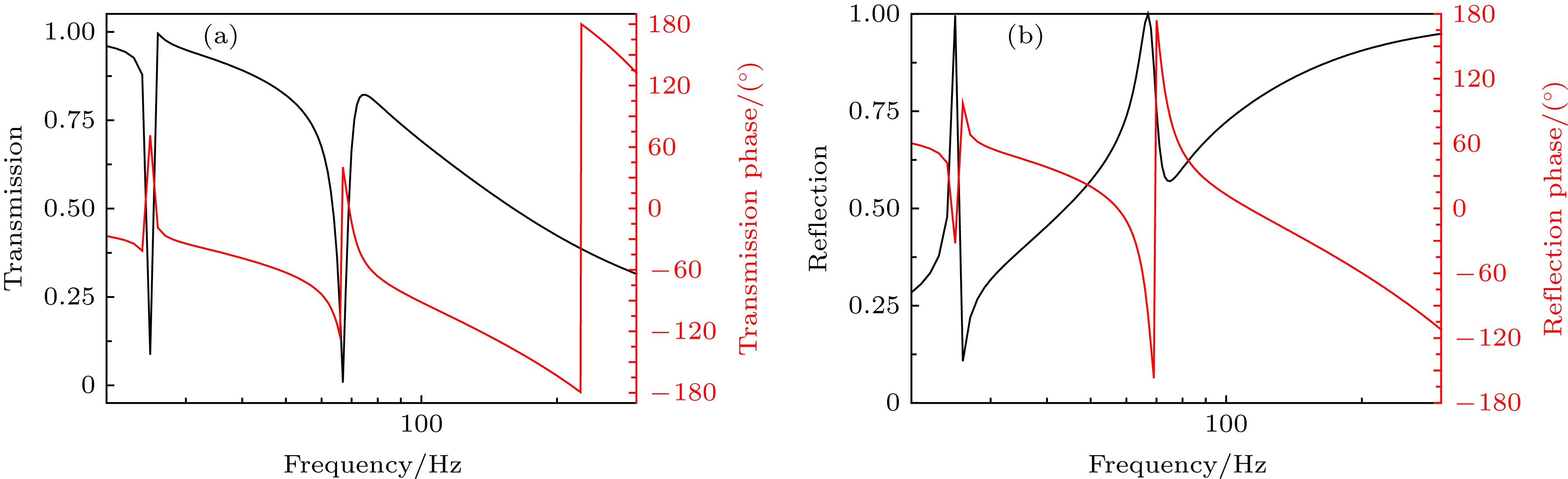

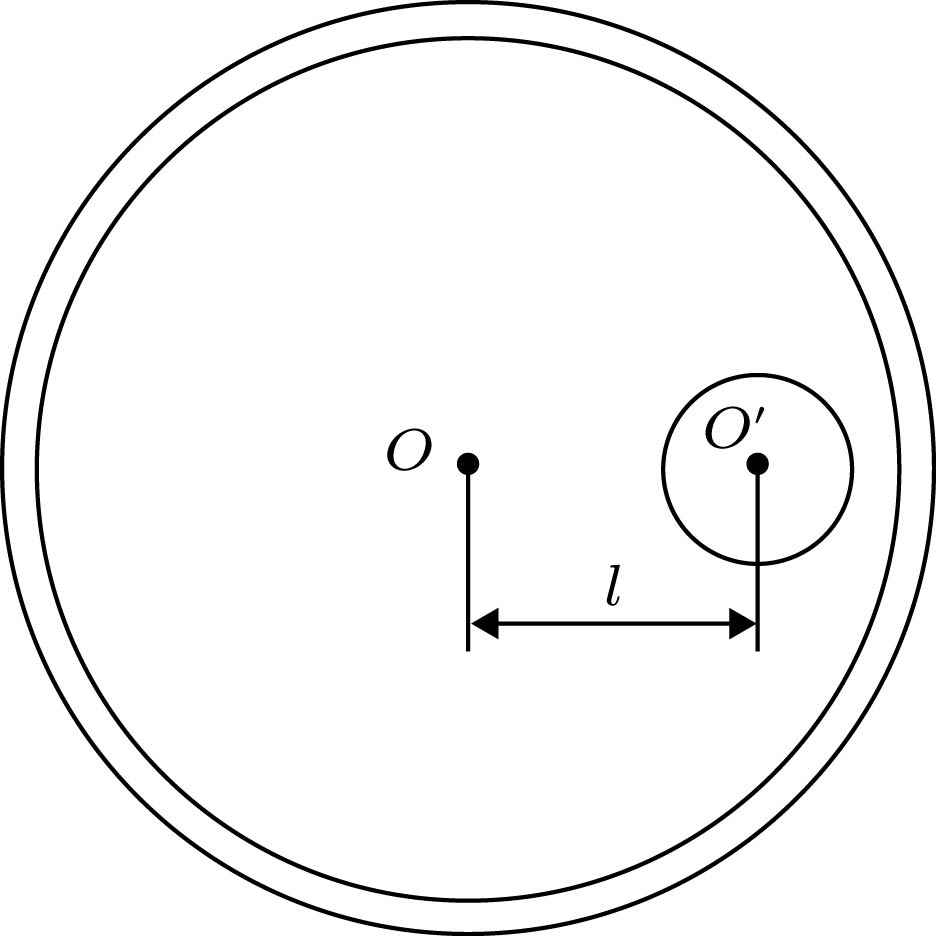

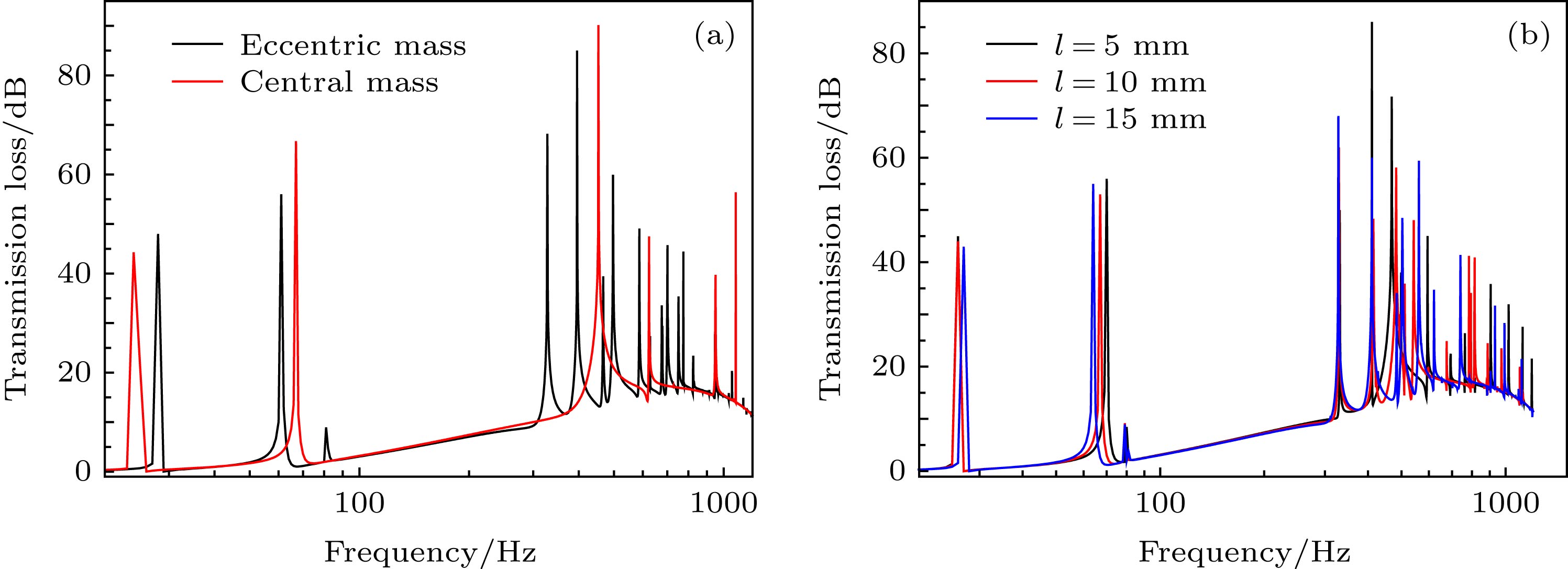

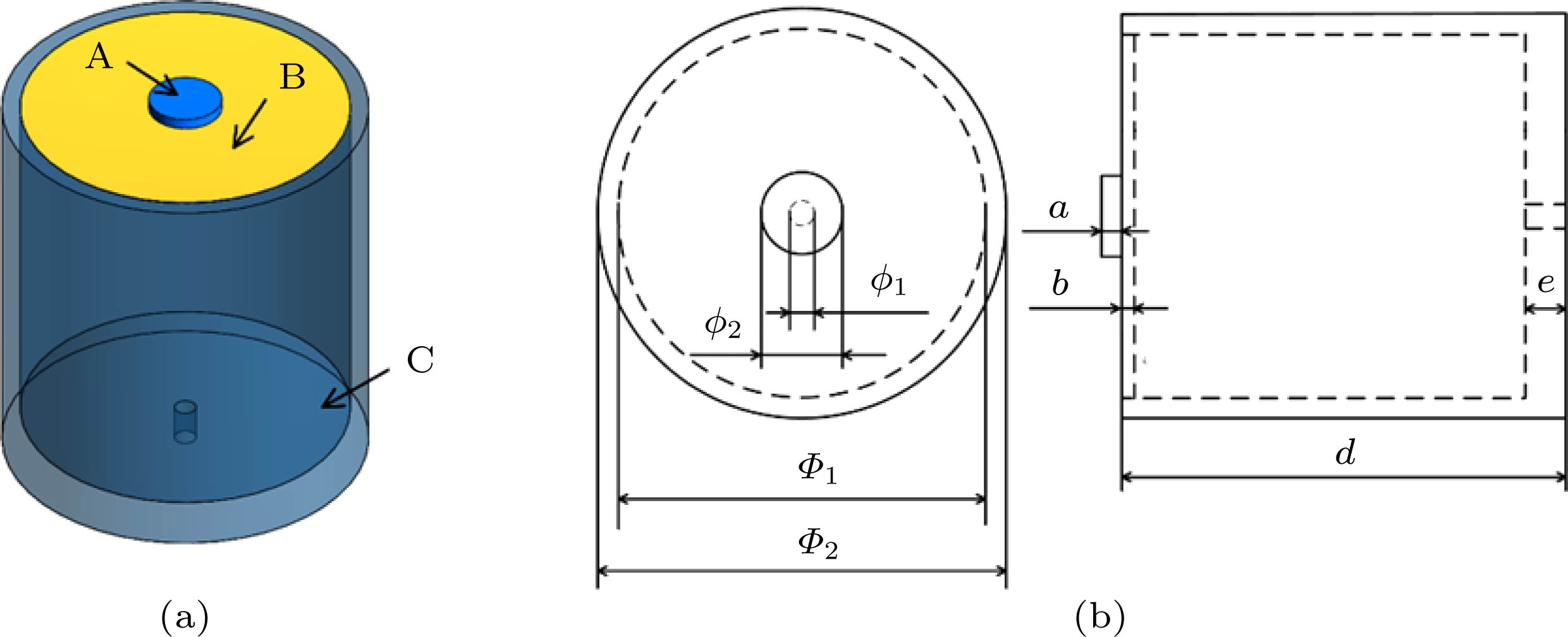

针对低频噪声的隔离问题, 设计了一种薄膜底面Helmholtz腔声学超材料, 该超材料由薄膜底面Helmholtz腔附加质量单元构成. 使用有限元法, 计算了超材料在20—1200 Hz频段内的传输损失曲线与各阶共振频率, 并在实验中验证了数值计算的真实性. 研究结果表明, 超材料在20—1200 Hz频段内隔声性能良好, 出现了6个隔声峰, 其中100 Hz以下的2个隔声峰传输损失分别高达44.29 dB与67.43 dB, 整个频段内的最高传递损失为90.18 dB. 相较于单一的Helmholtz腔、薄膜声学超材料或传统材料, 本超材料的隔声性能有了较大提升. 结合共振频率与隔声峰处的振动模式图, 进一步分析了超材料的隔声机理. 计算了超材料的透射系数与反射系数, 使用等效参数提取法, 得到了超材料的等效模量与等效密度, 在隔声峰处发现了负等效密度, 同时发现其等效模量接近于零, 并由能量角度进一步分析了异常等效参数的产生机理. 通过等效电路法, 得到了超材料的声阻抗, 较精确地计算了超材料的首阶共振频率, 并分析了产生误差的原因. 研究了附加偏心质量单元对超材料隔声性能的影响, 发现附加偏心质量单元可以抑制反对称共振模态的出现, 同时大大增加了超材料的隔声峰数量, 在实验中这一说法得以验证.

-

关键词:

- Helmholtz腔 /

- 薄膜声学超材料 /

- 有限元法 /

- 隔声性能 /

- 负参数

Aiming at the isolation of low-frequency noise, an acoustic metamaterial is designed based on Helmholtz cavity and thin film structure. It consists of a Helmholtz cavity with film bottom and the mass block attached to the cavity. By the finite element method, the transmission losses and resonance frequencies of metamaterials in a frequency range of 20-1200 Hz are calculated and also verified experimentally. The results show that the metamaterial has great sound insulation performance in the frequency range. There are six sound insulation peaks, of which the two sound insulation peaks below 100 Hz have the transmission losses of 44.29 dB and 67.43 dB, respectively. The maximum transmission loss in the whole frequency range is 90.18 dB. Comparing with the normal Helmholtz cavity or thin film acoustic metamaterial or traditional material, the sound insulation performance of the metamaterial is improved greatly. By analyzing the resonance and vibration mode diagram at the sound insulation peaks comprehensively, the sound insulation mechanism of the metamaterial is further explored. The results show that many resonance modes have no effect on transmission loss only when the resonance mode can be coupled with the incident wave and is not an antisymmetric mode which can affect the transmission loss. The transmission and reflection coefficient of the metamaterial are calculated by the finite element method, and through the method for retrieving effective properties, the effective mass density and effective modulus are obtained. It is found that there is a negative effective mass density at the sound insulation peak, meanwhile the effective modulus is close to zero. The generation mechanism of abnormal equivalent parameters is analyzed from the energy view point. The acoustic impedance of the metamaterial is obtained by an equivalent circuit method, through which the first resonance frequency is calculated relatively accurately. According to the results of the previous study on sound insulation mechanism, the effect of the eccentric mass unit on the sound insulation performance of metamaterial is studied. It is found that the eccentric mass can greatly reduce the antisymmetric resonance mode and increase the sound insulation peak of the structure, which is also verified experimentally. The results provide a reference for designing the acoustic metamaterials.-

Keywords:

- Helmholtz cavity /

- thin film acoustic metamaterials /

- finite element method /

- sound insulation performance /

- negative parameter

[1] William B A, Lisa M M, Kelsey B, Stephen B, John L A 2019 Environ. Sci. Technol. 53 7126

Google Scholar

Google Scholar

[2] 周榕 2017 硕士学位论文 (南京: 江苏大学)

Zhou Y 2017 M. S. Thesis (Nanjing: Jiangsu University) (in Chinese)

[3] Wu J H, Ma F Y, Zhang S W, Shen L 2006 J. Mech. Eng. 52 68

[4] 丁昌林, 董仪宝, 赵晓鹏 2018 67 194301

Ding C L, Dong Y B, Zhao X P 2018 Acta Phys. Sin. 67 194301

[5] Lee S H, Park C M, Seo Y M, Wang Z G, Kim C K 2010 Phys. Rev. Lett. 104 054301

Google Scholar

Google Scholar

[6] 沈惠杰, 郁殿龙, 汤智胤, 苏永生, 李雁飞, 刘江伟 2019 68 144301

Shen H J, Yu D L, Tang Z Y, Su Y S, Li Y F, Liu J W 2019 Acta Phys. Sin. 68 144301

[7] Chen H J, Zhai S L, Ding C L, Liu S, Luo C R, Zhao X P 2015 J. Appl. Phys. 118 094901

Google Scholar

Google Scholar

[8] Mei J, Ma G C, Yang M, Yang Z Y, Wen W J, Sheng P 2012 Nat. Commun. 3 756

Google Scholar

Google Scholar

[9] Nemat-Nasser S, Willis J R, Srivastava A, Amirkhizi A V 2011 Phys. Rev. B 83 104103

Google Scholar

Google Scholar

[10] 丁昌林, 赵晓鹏 2009 58 6351

Google Scholar

Google Scholar

Ding C L, Zhao X P 2009 Acta Phys. Sin. 58 6351

Google Scholar

Google Scholar

[11] Liu Z, Zhang X X, Chan C T, Sheng P 2000 Science 289 1734

Google Scholar

Google Scholar

[12] 贺子厚, 赵静波, 姚宏, 蒋娟娜, 张帅, 陈鑫 2018 硅酸盐学报 47 983

He Z H, Zhao J B, Yao H, Jiang J N, Zhang S Chen X 2018 J. Chin. Ceramic Soc. 47 983

[13] 高南沙, 侯宏 2018 材料导报 32 322

Google Scholar

Google Scholar

Gao N S, Hou H 2018 Mater. Rev. 32 322

Google Scholar

Google Scholar

[14] 王莎, 林书玉 2019 68 024303

Wang S, Lin S Y 2019 Acta Phys. Sin. 68 024303

[15] 刘娇, 侯志林, 傅秀军 2015 64 154302

Liu J, Hou Z L, Fu X J 2015 Acta Phys. Sin. 64 154302

[16] Cheng Y, Xu J Y, Liu X J 2008 Appl. Phys. Lett. 92 051913

Google Scholar

Google Scholar

[17] 贾晓珍 2018 硕士学位论文 (西安: 陕西师范大学)

Jia X Z 2018 M. S. Thesis (Xi′an: Shaanxi Normal Univer-sity) (in Chinese)

[18] Chen Y, Huang G, Zhou X, Hu G, Sun C 2014 J. Acoust. Soc. Am. 136 969

Google Scholar

Google Scholar

[19] Fang N, Xi D J, Xu J Y, Ambati M, Srituravanich W, Sun C, Zhang X 2006 Nature Mater. 5 452

Google Scholar

Google Scholar

[20] 姜久龙, 姚宏, 杜军, 赵静波, 邓涛 2017 66 064301

Jiang J L, Yao H, Du J, Zhao J B, Deng T 2017 Acta Phys. Sin. 66 064301

[21] Naify C J, Chang C M, Mcknight G, Nutt S 2011 J. Appl. Phys. 110 751

[22] 梅军, 马冠聪, 杨旻, 杨志宇, 温维佳, 沈平 2012 物理 41 425

Mei J, Ma G C, Yang M, Yang Z Y, Wen W J, Shen P 2012 Physics 41 425

[23] Cheng Y, Zhou C, Yuan B G, Wu D J, Wei Q, Liu X J 2015 Nature Mater. 14 1013

Google Scholar

Google Scholar

[24] 周榕, 吴卫国, 闻轶凡 2017 声学技术 36 297

Zhou Y, Wu W G, Wen Y F 2017 Tech. Acoust. 36 297

[25] Abbad A 2016 SAE International 9th International Styrian Noise, Vibration & Harshness Congress Warrendale, United States, June 22, 2016 p2011

[26] Long H, Cheng Y, Liu X 2018 Sci. Rep. 8 15678

Google Scholar

Google Scholar

[27] 陈鑫, 姚宏, 赵静波, 张帅, 贺子厚, 蒋娟娜 2019 68 084302

Chen X, Yao H, Zhao J B, Zhang S, He Z H, Jiang J N 2019 Acta Phys. Sin. 68 084302

[28] 杜功焕, 朱哲民, 龚秀芬 2012 声学基础 (南京: 南京大学出版社) 第84页

Du G H, Zhu Z M, Gong X F 2012 Acoustic Basis (Nanjing: Nanjing University Press) p84

[29] Fokin V, Ambati M, Sun C, Zhang X 2007 Phys. Rev. B 76 144302

Google Scholar

Google Scholar

[30] 贺子厚, 赵静波, 姚宏, 张帅, 蒋娟娜, 陈鑫 2019 68 134302

Google Scholar

Google Scholar

He Z H, Zhao J B, Yao H, Zhang S, Jiang J N, Chen X 2019 Acta Phys. Sin. 68 134302

Google Scholar

Google Scholar

-

表 1 材料参数

Table 1. Material parameters.

Material ρ/kg·m–3 E/1010 Pa Possion rate Tungsten 19100 35.41 0.35 Silastic 1300 1.175 × 10–5 0.469 Steel 7780 21.06 0.3 -

[1] William B A, Lisa M M, Kelsey B, Stephen B, John L A 2019 Environ. Sci. Technol. 53 7126

Google Scholar

Google Scholar

[2] 周榕 2017 硕士学位论文 (南京: 江苏大学)

Zhou Y 2017 M. S. Thesis (Nanjing: Jiangsu University) (in Chinese)

[3] Wu J H, Ma F Y, Zhang S W, Shen L 2006 J. Mech. Eng. 52 68

[4] 丁昌林, 董仪宝, 赵晓鹏 2018 67 194301

Ding C L, Dong Y B, Zhao X P 2018 Acta Phys. Sin. 67 194301

[5] Lee S H, Park C M, Seo Y M, Wang Z G, Kim C K 2010 Phys. Rev. Lett. 104 054301

Google Scholar

Google Scholar

[6] 沈惠杰, 郁殿龙, 汤智胤, 苏永生, 李雁飞, 刘江伟 2019 68 144301

Shen H J, Yu D L, Tang Z Y, Su Y S, Li Y F, Liu J W 2019 Acta Phys. Sin. 68 144301

[7] Chen H J, Zhai S L, Ding C L, Liu S, Luo C R, Zhao X P 2015 J. Appl. Phys. 118 094901

Google Scholar

Google Scholar

[8] Mei J, Ma G C, Yang M, Yang Z Y, Wen W J, Sheng P 2012 Nat. Commun. 3 756

Google Scholar

Google Scholar

[9] Nemat-Nasser S, Willis J R, Srivastava A, Amirkhizi A V 2011 Phys. Rev. B 83 104103

Google Scholar

Google Scholar

[10] 丁昌林, 赵晓鹏 2009 58 6351

Google Scholar

Google Scholar

Ding C L, Zhao X P 2009 Acta Phys. Sin. 58 6351

Google Scholar

Google Scholar

[11] Liu Z, Zhang X X, Chan C T, Sheng P 2000 Science 289 1734

Google Scholar

Google Scholar

[12] 贺子厚, 赵静波, 姚宏, 蒋娟娜, 张帅, 陈鑫 2018 硅酸盐学报 47 983

He Z H, Zhao J B, Yao H, Jiang J N, Zhang S Chen X 2018 J. Chin. Ceramic Soc. 47 983

[13] 高南沙, 侯宏 2018 材料导报 32 322

Google Scholar

Google Scholar

Gao N S, Hou H 2018 Mater. Rev. 32 322

Google Scholar

Google Scholar

[14] 王莎, 林书玉 2019 68 024303

Wang S, Lin S Y 2019 Acta Phys. Sin. 68 024303

[15] 刘娇, 侯志林, 傅秀军 2015 64 154302

Liu J, Hou Z L, Fu X J 2015 Acta Phys. Sin. 64 154302

[16] Cheng Y, Xu J Y, Liu X J 2008 Appl. Phys. Lett. 92 051913

Google Scholar

Google Scholar

[17] 贾晓珍 2018 硕士学位论文 (西安: 陕西师范大学)

Jia X Z 2018 M. S. Thesis (Xi′an: Shaanxi Normal Univer-sity) (in Chinese)

[18] Chen Y, Huang G, Zhou X, Hu G, Sun C 2014 J. Acoust. Soc. Am. 136 969

Google Scholar

Google Scholar

[19] Fang N, Xi D J, Xu J Y, Ambati M, Srituravanich W, Sun C, Zhang X 2006 Nature Mater. 5 452

Google Scholar

Google Scholar

[20] 姜久龙, 姚宏, 杜军, 赵静波, 邓涛 2017 66 064301

Jiang J L, Yao H, Du J, Zhao J B, Deng T 2017 Acta Phys. Sin. 66 064301

[21] Naify C J, Chang C M, Mcknight G, Nutt S 2011 J. Appl. Phys. 110 751

[22] 梅军, 马冠聪, 杨旻, 杨志宇, 温维佳, 沈平 2012 物理 41 425

Mei J, Ma G C, Yang M, Yang Z Y, Wen W J, Shen P 2012 Physics 41 425

[23] Cheng Y, Zhou C, Yuan B G, Wu D J, Wei Q, Liu X J 2015 Nature Mater. 14 1013

Google Scholar

Google Scholar

[24] 周榕, 吴卫国, 闻轶凡 2017 声学技术 36 297

Zhou Y, Wu W G, Wen Y F 2017 Tech. Acoust. 36 297

[25] Abbad A 2016 SAE International 9th International Styrian Noise, Vibration & Harshness Congress Warrendale, United States, June 22, 2016 p2011

[26] Long H, Cheng Y, Liu X 2018 Sci. Rep. 8 15678

Google Scholar

Google Scholar

[27] 陈鑫, 姚宏, 赵静波, 张帅, 贺子厚, 蒋娟娜 2019 68 084302

Chen X, Yao H, Zhao J B, Zhang S, He Z H, Jiang J N 2019 Acta Phys. Sin. 68 084302

[28] 杜功焕, 朱哲民, 龚秀芬 2012 声学基础 (南京: 南京大学出版社) 第84页

Du G H, Zhu Z M, Gong X F 2012 Acoustic Basis (Nanjing: Nanjing University Press) p84

[29] Fokin V, Ambati M, Sun C, Zhang X 2007 Phys. Rev. B 76 144302

Google Scholar

Google Scholar

[30] 贺子厚, 赵静波, 姚宏, 张帅, 蒋娟娜, 陈鑫 2019 68 134302

Google Scholar

Google Scholar

He Z H, Zhao J B, Yao H, Zhang S, Jiang J N, Chen X 2019 Acta Phys. Sin. 68 134302

Google Scholar

Google Scholar

计量

- 文章访问数: 13700

- PDF下载量: 286

- 被引次数: 0

下载:

下载: