-

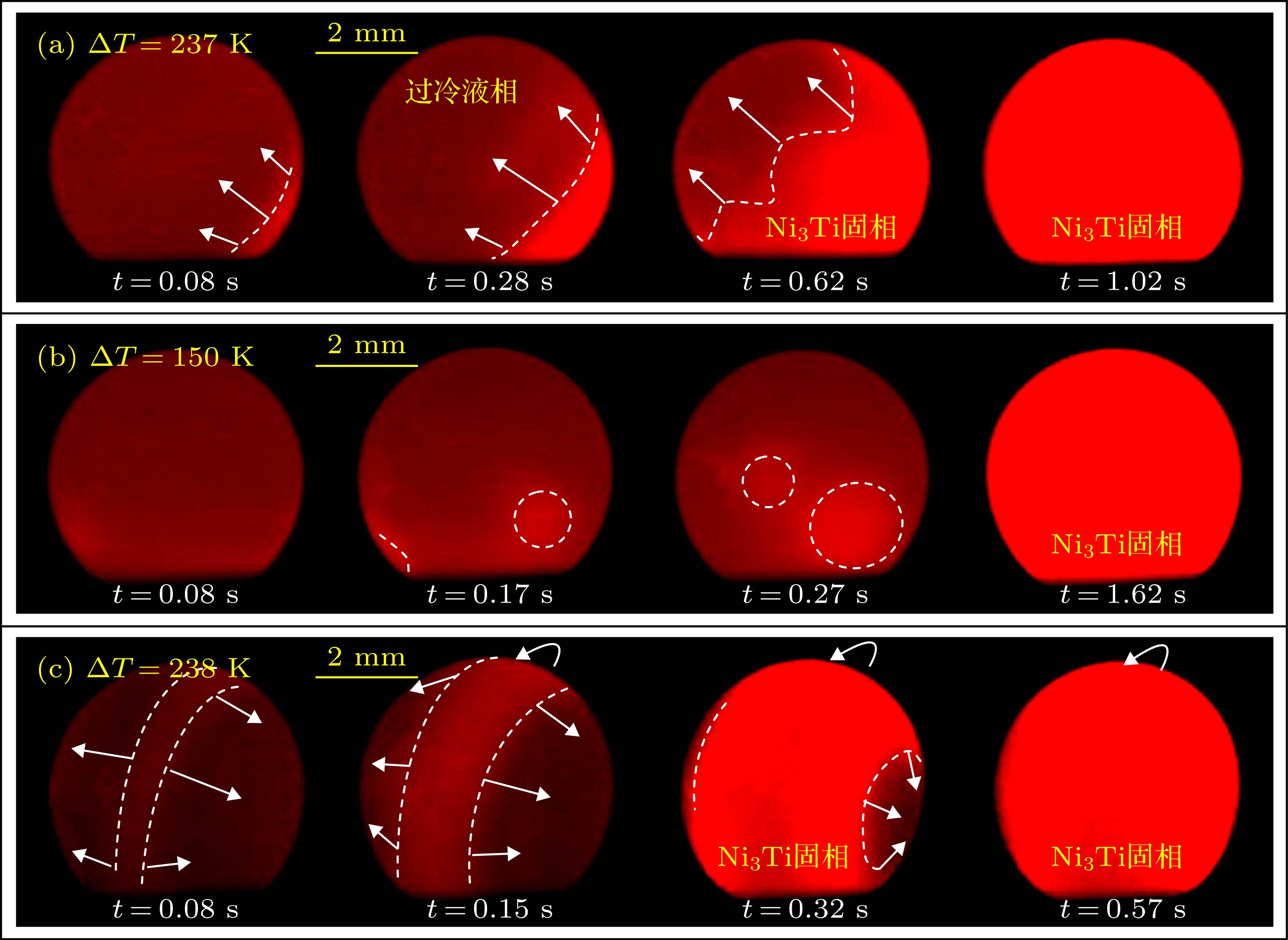

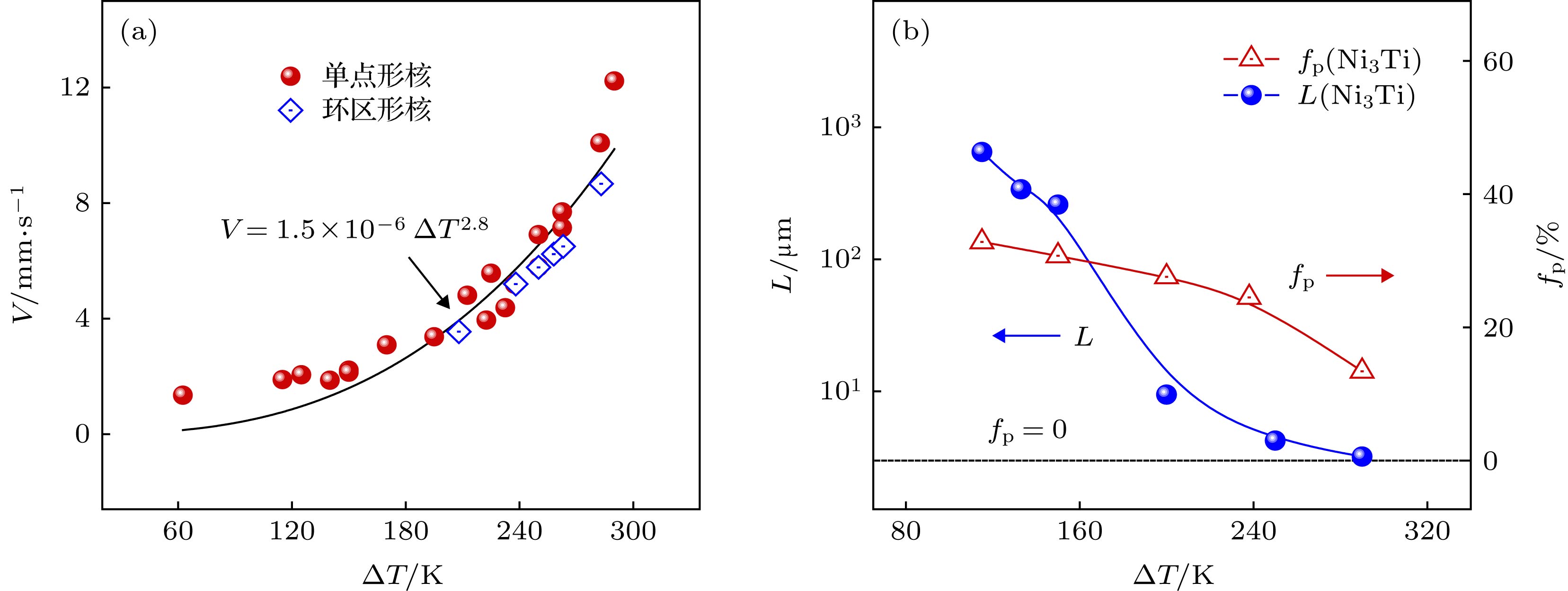

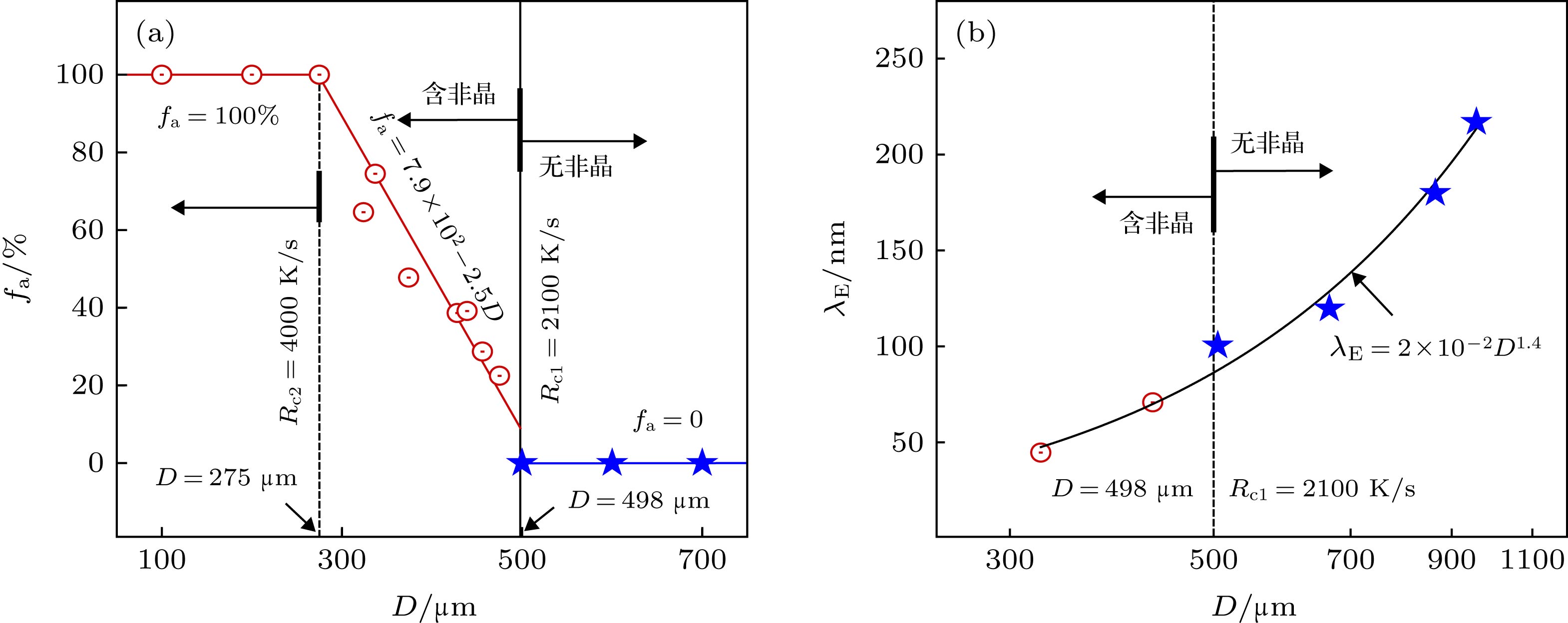

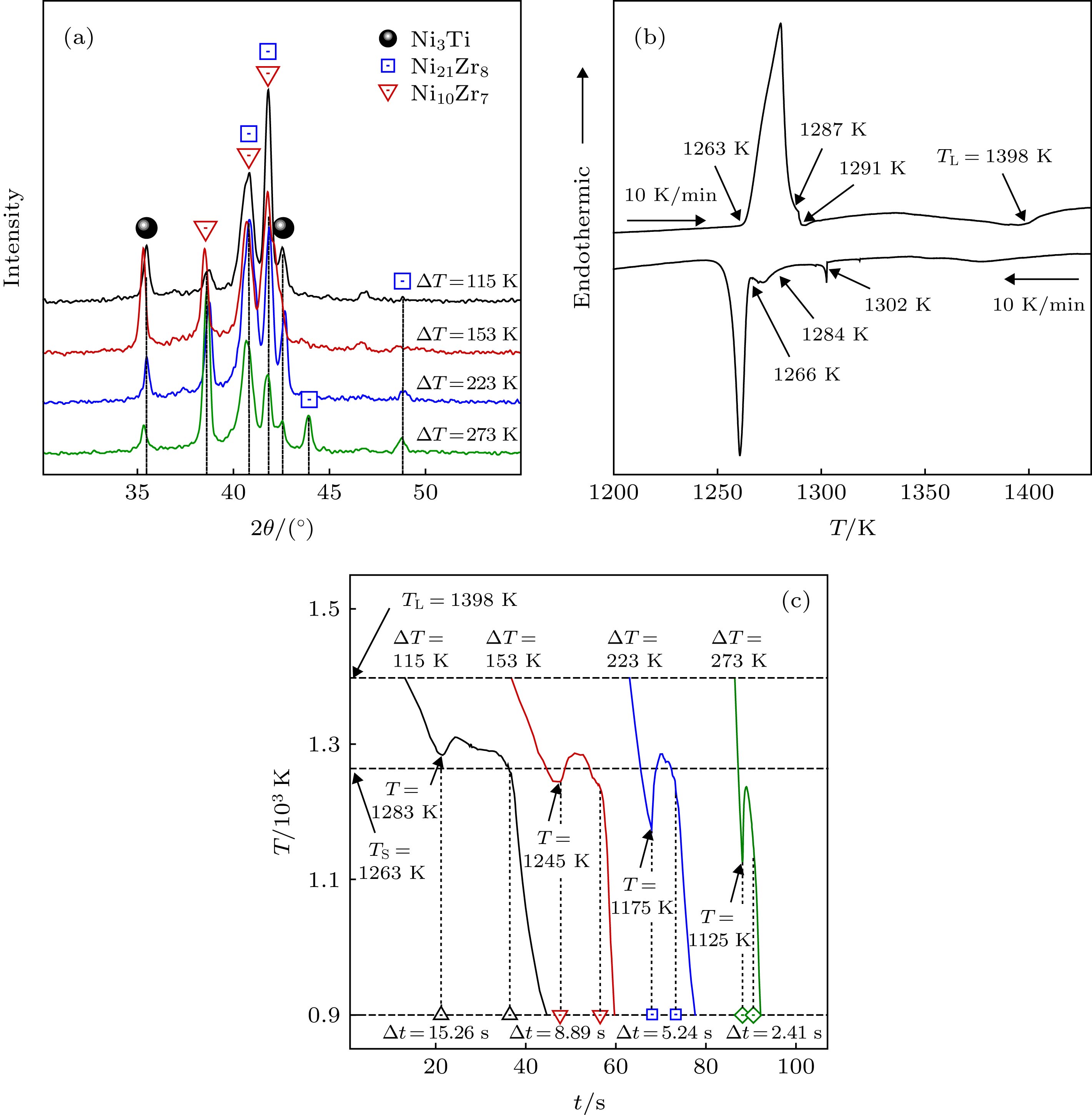

采用电磁悬浮和自由落体两种无容器熔凝技术, 并借助高速摄影实时分析方法, 研究了液态五元Ni40Zr28.5Ti16.5Al10Cu5合金的深过冷能力和快速凝固机制. 在电磁悬浮条件下, 液态合金的过冷度可达290 K (0.21TL). 当深过冷熔体快速凝固时, 高速摄影观察发现悬浮液滴表面呈现点状和环状两种区域形核方式. 合金的快速凝固组织由初生Ni3Ti相、次生Ni10Zr7相和(Ni10Zr7+Ni21Zr8)共晶组成. 初生Ni3Ti相以枝晶方式生长, 枝晶生长速度随熔体过冷度的增大以幂函数关系单调递增, 最高可达12 mm/s, 同时其体积分数逐渐减小至13.4%, 并发生显著组织细化. 在自由落体条件下, 尽管合金液滴凝固组织的相组成并未发生变化, 但随着过冷度的增大, 初生Ni3Ti相的生长被抑制, 凝固组织由晶态向非晶态转变, 且非晶相的体积分数线性增大. 当直径小于275 μm时, 合金液滴实现了完全非晶态凝固.

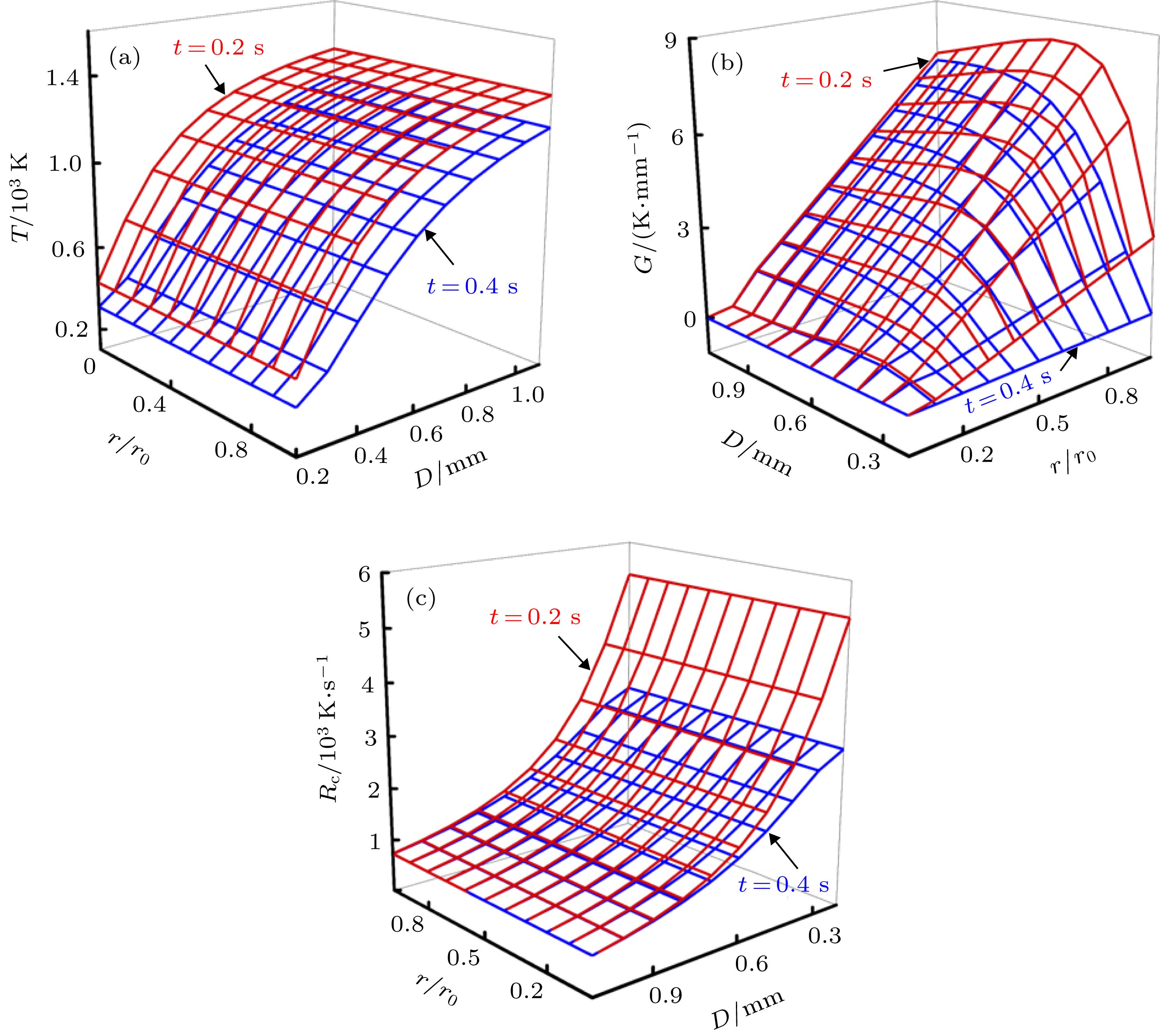

The ability to undercool and solidification mechanism of liquid quinary Ni40Zr28.5Ti16.5Al10Cu5 alloy are investigated by electromagnetic levitation (EML) and drop tube (DT) technique. Under the EML condition, the maximum undercooling of levitated alloy can reach up to 290 K (0.21TL). Under the DT condition, the alloy achieves higher undercooling than EML, and solidifies finally into metallic glass. At lower undercooling, the solidification structure of the alloy is composed of primary Ni3Ti phase, secondary Ni10Zr7 phase and eutectic (Ni10Zr7+Ni21Zr8) phase. With the rise of undercooling, the solidification structure displays the following evolution events: phase morphology refinement, primary phase inhibition, phase number reduction, and amorphous phase formation. By using the high-speed cinematography technique, three nucleation modes are distinctly observed on the levitated alloy melt surface at the beginning of solidification, that is, single-point nucleation, multi-point nucleation and annular nucleation. The levitation state corresponding to single-point mode nucleation is relatively stable, and the alloy undercooling is also relatively low. The annular nucleation only occursin the case with high rotation speed, and the undercooling is greater than 208 K. The discrepancy between nucleation modes is due to the He gas flow for forced cooling. The theoretical calculations indicate that the alloy droplets achieve high undercoolingand large cooling rate under the DT condition. The experimental results show that when the droplet diameter decreases to 498 μm, the amorphous phase begins to appear in the alloy particles. It is noteworthy that the amorphous phase is preferentially formed inside the droplet, but not on the outer surface. The morphology of solidification structure reveals that different regions of the droplet have various local undercoolings, which result in the distribution characteristics of amorphous phase. The volume fraction of amorphous phase increases linearly with the decrease of particle diameter. When the droplet diameter decreases to 275 μm, the alloy droplets are completely frozen into glassy particles. The average eutecticspacing values are also measured at different alloy undercoolings. Compared with the classical binary eutectic growth model, the experimental eutectic growth law exhibits a large deviation in index. This indicates that the eutectic growth in multicomponent alloys displays more complex kinetic characteristics. -

Keywords:

- electromagnetic levitation /

- drop tube /

- undercooling /

- rapid solidification

[1] Zhao P, Heinrich J C, Poirier D R 2005 Int. J. Numer. Meth. Fluids 49 233

Google Scholar

Google Scholar

[2] Sánchez Lamazares J L, Sanchez T, Santos J D, Pérez M J, Sanchez M L, Hernando B 2008 Appl. Phys. Lett. 92 4358

[3] Wu M, Liu T, Dong M, Sun J M, Dong S L, Qiang W 2017 J. Appl. Phys. 121 064901

Google Scholar

Google Scholar

[4] Lü P, Wang H P 2017 Scr. Mater. 137 31

Google Scholar

Google Scholar

[5] Chen F, Zhang T Q, Wang J, Zhang L T, Zhou G F 2015 J. Alloy. Compd. 640 375

[6] 翟秋亚, 杨扬, 徐锦锋, 郭学锋 2007 56 6118

Google Scholar

Google Scholar

Zhai Q Y, Yang Y, Xu J F, Guo X F 2007 Acta Phys. Sin. 56 6118

Google Scholar

Google Scholar

[7] Haein C Y, Xu D H, William L J 2003 Appl. Phys. Lett. 82 1030

Google Scholar

Google Scholar

[8] Duwez P, Willens R H, Klement J W 1960 J. Appl. Phys. 31 1137

[9] 沙莎, 王伟丽, 吴宇昊, 魏炳波 2018 67 046402

Google Scholar

Google Scholar

Sha S, Wang W L, Wu Y H, Wei B 2018 Acta Phys. Sin. 67 046402

Google Scholar

Google Scholar

[10] Greaves G N, Wilding M C, Fearn S, Langstaff D, Kargl F, Cox S, Vu Van Q, Majérus O, Benmore C J, Weber R, Martin C M, Hennet L 2008 Science 322 566

Google Scholar

Google Scholar

[11] Kavouras A, Krammer G 2003 Rev. Sci. Instrum. 74 4468

Google Scholar

Google Scholar

[12] Baer S, Andrade M A, Esen C, Adamowski J C, Schweiger G, Ostendorf A 2011 Rev. Sci. Instrum. 82 105111

Google Scholar

Google Scholar

[13] Wall J J, Weber R, Kim J, Liaw P K, Choo H 2007 Mater. Sci. Eng. A 445 219

[14] Skinner L B, Benmore C J, Weber J K R, Du J, Neuefeind J, Tumber S K, Parise1 J B 2014 Phys. Rev. Lett. 112 157801

Google Scholar

Google Scholar

[15] Lan S, Blodgett M, Kelton K F, Ma J L, Fan J, Wang X L 2016 Appl. Phys. Lett. 108 831

[16] 杨尚京, 王伟丽, 魏炳波 2015 64 056401

Google Scholar

Google Scholar

Yang S J, Wang W L, Wei B 2015 Acta Phys. Sin. 64 056401

Google Scholar

Google Scholar

[17] Royer Z L, Tackes C, Lesar R, Napolitano R E 2013 J. Appl. Phys. 113 214901

Google Scholar

Google Scholar

[18] Lee J, Rodriguez J E, Hyers R W, Matson D M 2015 Metall. Mater. Trans. B 46 2470

Google Scholar

Google Scholar

[19] Cao L, Cochrane R F, Mullis A M 2015 Intermetallics 60 33

Google Scholar

Google Scholar

[20] Xu D, Duan G, Johnson W L, Garland C 2004 Acta Mater. 52 3493

Google Scholar

Google Scholar

[21] Lee E S, Ahn S 1994 Acta Metall. Mater. 42 3231

Google Scholar

Google Scholar

[22] Wang W L, Li Z Q, Wei B 2011 Acta Mater. 59 5482

Google Scholar

Google Scholar

[23] Alford T L, Gale W F, Totemeir T C 2015 Smithells Metals Reference Book (Elsevier) 8−2

[24] Inoue A 2000 Acta Mater. 48 279

Google Scholar

Google Scholar

[25] Jackson K A, Hunt J D 1988 Dyna. Curv. Front. 236363

[26] Kurz W, Trivedi R 1991 Metall. Trans. A 22 3051

Google Scholar

Google Scholar

-

图 8 自由落体条件下不同直径合金液滴的凝固组织形貌 (a) 957 μm直径; (b) A区放大; (c) B区放大(d) 428 μm直径; (e) C区放大; (f) D区放大

Fig. 8. Microstructural morphology of solidified alloy droplets with different diameters.(a) 957 μm diameter; (b) Enlarged A in (a); (c) Enlarged B in (a)(d) 428 μm diameter; (b) Enlarged C in (d); (c) Enlarged D in (d)

表 1 理论计算用热物性参数[23]

Table 1. Physical parameters used in calculations

物理参数 数值 初始温度, T0/K 1500 环境温度, Ti/K 298 热导率, κ/W·m–1·K–1 65.4 液相线温度, TL/K 1400 Stefan-Boltzmann常数, σSB/W·m–1·K–1 5.67 × 10–8 熔体密度, ρ/kg·m–3 6.15 × 103 位置参数, r/r0 0.1—1.0 熔体热辐射系数, εh 0.2 熔体比热, Cp, /J·kg–1·K–1 601 -

[1] Zhao P, Heinrich J C, Poirier D R 2005 Int. J. Numer. Meth. Fluids 49 233

Google Scholar

Google Scholar

[2] Sánchez Lamazares J L, Sanchez T, Santos J D, Pérez M J, Sanchez M L, Hernando B 2008 Appl. Phys. Lett. 92 4358

[3] Wu M, Liu T, Dong M, Sun J M, Dong S L, Qiang W 2017 J. Appl. Phys. 121 064901

Google Scholar

Google Scholar

[4] Lü P, Wang H P 2017 Scr. Mater. 137 31

Google Scholar

Google Scholar

[5] Chen F, Zhang T Q, Wang J, Zhang L T, Zhou G F 2015 J. Alloy. Compd. 640 375

[6] 翟秋亚, 杨扬, 徐锦锋, 郭学锋 2007 56 6118

Google Scholar

Google Scholar

Zhai Q Y, Yang Y, Xu J F, Guo X F 2007 Acta Phys. Sin. 56 6118

Google Scholar

Google Scholar

[7] Haein C Y, Xu D H, William L J 2003 Appl. Phys. Lett. 82 1030

Google Scholar

Google Scholar

[8] Duwez P, Willens R H, Klement J W 1960 J. Appl. Phys. 31 1137

[9] 沙莎, 王伟丽, 吴宇昊, 魏炳波 2018 67 046402

Google Scholar

Google Scholar

Sha S, Wang W L, Wu Y H, Wei B 2018 Acta Phys. Sin. 67 046402

Google Scholar

Google Scholar

[10] Greaves G N, Wilding M C, Fearn S, Langstaff D, Kargl F, Cox S, Vu Van Q, Majérus O, Benmore C J, Weber R, Martin C M, Hennet L 2008 Science 322 566

Google Scholar

Google Scholar

[11] Kavouras A, Krammer G 2003 Rev. Sci. Instrum. 74 4468

Google Scholar

Google Scholar

[12] Baer S, Andrade M A, Esen C, Adamowski J C, Schweiger G, Ostendorf A 2011 Rev. Sci. Instrum. 82 105111

Google Scholar

Google Scholar

[13] Wall J J, Weber R, Kim J, Liaw P K, Choo H 2007 Mater. Sci. Eng. A 445 219

[14] Skinner L B, Benmore C J, Weber J K R, Du J, Neuefeind J, Tumber S K, Parise1 J B 2014 Phys. Rev. Lett. 112 157801

Google Scholar

Google Scholar

[15] Lan S, Blodgett M, Kelton K F, Ma J L, Fan J, Wang X L 2016 Appl. Phys. Lett. 108 831

[16] 杨尚京, 王伟丽, 魏炳波 2015 64 056401

Google Scholar

Google Scholar

Yang S J, Wang W L, Wei B 2015 Acta Phys. Sin. 64 056401

Google Scholar

Google Scholar

[17] Royer Z L, Tackes C, Lesar R, Napolitano R E 2013 J. Appl. Phys. 113 214901

Google Scholar

Google Scholar

[18] Lee J, Rodriguez J E, Hyers R W, Matson D M 2015 Metall. Mater. Trans. B 46 2470

Google Scholar

Google Scholar

[19] Cao L, Cochrane R F, Mullis A M 2015 Intermetallics 60 33

Google Scholar

Google Scholar

[20] Xu D, Duan G, Johnson W L, Garland C 2004 Acta Mater. 52 3493

Google Scholar

Google Scholar

[21] Lee E S, Ahn S 1994 Acta Metall. Mater. 42 3231

Google Scholar

Google Scholar

[22] Wang W L, Li Z Q, Wei B 2011 Acta Mater. 59 5482

Google Scholar

Google Scholar

[23] Alford T L, Gale W F, Totemeir T C 2015 Smithells Metals Reference Book (Elsevier) 8−2

[24] Inoue A 2000 Acta Mater. 48 279

Google Scholar

Google Scholar

[25] Jackson K A, Hunt J D 1988 Dyna. Curv. Front. 236363

[26] Kurz W, Trivedi R 1991 Metall. Trans. A 22 3051

Google Scholar

Google Scholar

计量

- 文章访问数: 11513

- PDF下载量: 128

- 被引次数: 0

下载:

下载: