-

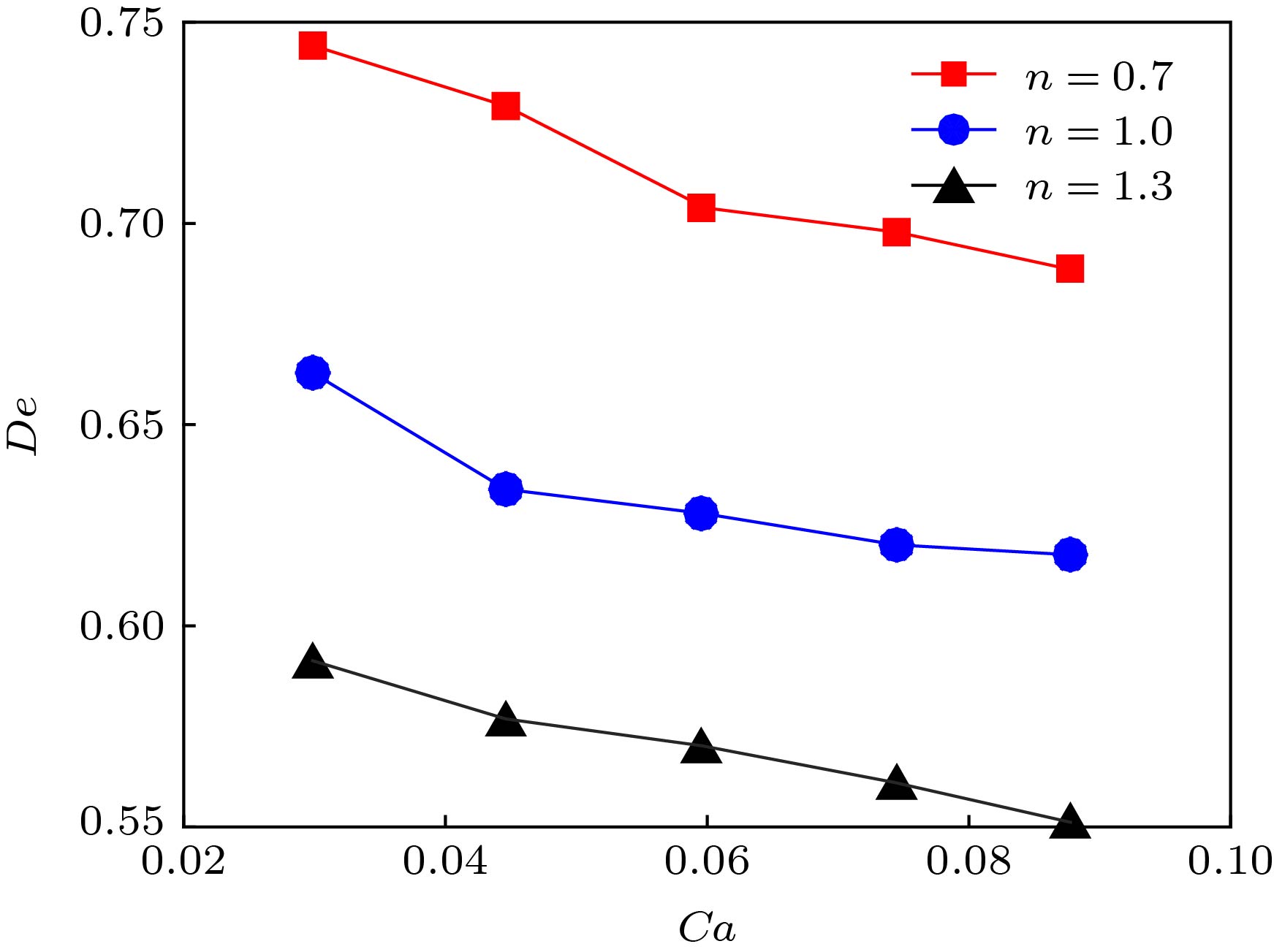

基于不可压格子玻尔兹曼气-液两相流模型, 建立了一个新的非牛顿幂律流体气-液两相流模型, 并采用该模型研究了多孔介质内牛顿气体驱替非牛顿幂律流体液体的驱替问题, 主要探究了Ca数、动力黏度比M、固体表面润湿性θ、多孔结构几何类型及幂律指数n对驱替过程的影响. 研究发现: 不论被驱替液体为剪切变稀流体、牛顿流体还是剪切变稠流体都有随着Ca数增加, 驱替速度越快, 指进现象越明显, 驱替效率越低. 然而对于不同的幂率指数n, 驱替效率随Ca数的增加而减小的速率不同: n越大驱替效率随着Ca数增加而减小的速率越慢. 另一方面, 随着黏性比M增加, 驱替效率减小, 且幂律指数n越小, M对驱替效率的影响越大. 此外, 固体表面接触角θ对驱替过程的影响也和被驱替流体的幂率指数n相关, 虽然对于n > 1和 n < 1的情况都有随着多孔介质固体表面接触角θ增加, 驱替过程受到的阻力越小, 指进越来越不明显, 驱替完成时间和驱替效率增加, 然而当n > 1时, 随着n的增加, 接触角对驱替过程的影响越来越小. 还研究了孔隙率相同的情况下, 孔隙几何类型不同时的驱替过程, 从数值结果可以发现与多孔结构为圆形和方形障碍物相比, 当多孔结构的几何类型为三角形时, 指进现象最明显, 驱替效率最低.

-

关键词:

- 幂律两相流体 /

- 格子Boltzmann模型 /

- 不混溶驱替 /

- 多孔介质

A new incompressible gas-liquid two-phase flow model for non-Newtonian power-law fluid is proposed based on an incompressible lattice Boltzmann model. And the fundamental physical mechanism of Newtonian fluid displacing non-Newtonian power-law fluid liquid in porous medium is studied by using the proposed model. The effects of capillary number Ca, dynamic viscosity ratio M, surface wettability θ, porous medium geometry, and power law index n on the displacement process are investigated. The comprehensive results show that with the increase of capillary number, the displacement process turns faster, the fingering phenomenon becomes more obvious and the displacement efficiency decreases. However, for different values of power-law index n, the effects of the Ca on the displacement process have some differences. Specially, the decrease rate of displacement efficiency becomes slow if the displaced fluid is shear thickening fluid as compared with that if the displaced fluid is shear thinning fluid. On the other hand, the displacement efficiency decreases as dynamic viscosity ratio M increases. And the effect of the viscosity ratio on the displacement process becomes more obvious for the low value of the power-law index n. Moreover, the effect of the surface wettability of the porous medium on the displacement process is also related to the size of the power-law index. With the increase of the contact angle of the porous medium, the fingering phenomenon turns less obvious, and the displacement efficiency increases. However, with the increase of power-law index n, the influence of the contact angle on the displacement process decreases. Besides, the displacement processes with different geometric types of the porous media are also studied in the work. The results show that comparing with the case of porous medium denoted by circle shape and square shape, the fingering phenomenon obtained by the case of triangular shape is most obvious, and the displacement efficiency is lowest.-

Keywords:

- power-law two-phase fluid /

- lattice Boltzmann model /

- immiscible displacement /

- porous media

[1] Santvoort J V, Golombok M 2018 J. Pet. Sci. Eng. 167 28

Google Scholar

Google Scholar

[2] Fang T M, Wang M H, Gao Y, Zhang Y N, Yan Y G, Zhang J 2019 Chem. Eng. Sci. 197 204

Google Scholar

Google Scholar

[3] Xu X F, Zhang J, Liu F X, Wang X J, Wei W, Liu Z J 2017 Int. J. Multiphase Flow. 95 84

Google Scholar

Google Scholar

[4] Du W, Fu T T, Duan Y F, Zhu C Y, Ma Y G, Li H Z 2018 Chem. Eng. Sci. 176 66

Google Scholar

Google Scholar

[5] Fu T T, Ma Y G, Li H Z 2015 Chem. Eng. Process. 97 38

Google Scholar

Google Scholar

[6] Salehi M S, Esfidani M T, Afshin H, Firoozabadi B 2018 Exp. Therm. Fluid Sci. 94 148

Google Scholar

Google Scholar

[7] Sontti S G, Atta A 2017 Chem. Eng. J. 330 245

Google Scholar

Google Scholar

[8] 娄钦, 李涛, 杨茉 2018 67 234701

Google Scholar

Google Scholar

Lou Q, Li T, Yang M 2018 Acta Phys. Sin. 67 234701

Google Scholar

Google Scholar

[9] 臧晨强, 娄钦 2017 66 134701

Google Scholar

Google Scholar

Zang C Q, Lou Q 2017 Acta Phys. Sin. 66 134701

Google Scholar

Google Scholar

[10] Lou Q, Guo Z L, Shi B C 2012 Europhys. Lett. 99 64005

Google Scholar

Google Scholar

[11] Lou Q, Guo Z L 2015 Phys. Rev. E 91 013302

Google Scholar

Google Scholar

[12] 娄钦, 李涛, 李凌 2018 上海理工大学学报 40 13

Lou Q, Li T, Li L 2018 J. Univ. Shanghai Sci. Technol. 40 13

[13] 谢驰宇, 张建影, 王沫然 2016 计算物理 33 147

Google Scholar

Google Scholar

Xie C Y, Zhang J Y, Wang M R 2016 Chin. J. Computat. Phys. 33 147

Google Scholar

Google Scholar

[14] Swift M R, Osborn W R, Yeomans J M 1995 Phys. Rev. Lett. 75 830

Google Scholar

Google Scholar

[15] Shi Y, Tang G H 2014 Comput. Math. Appl. 68 1279

Google Scholar

Google Scholar

[16] Fakhari A, Rahimian M H 2010 Phys. Rev. E 81 036707

Google Scholar

Google Scholar

[17] Shi Y, Tang G H 2016 J. Non-Newtonian Fluid Mech. 229 86

Google Scholar

Google Scholar

[18] Ba Y, Wang N N, Liu H H, Li Q, He G Q 2018 Phys. Rev. E 97 033307

Google Scholar

Google Scholar

[19] Halliday I, Law R, Care C M, Hollis A 2006 Phys. Rev. E 73 056708

Google Scholar

Google Scholar

[20] Halliday I, Hollis A P, Care C M 2007 Phys. Rev. E 76 026708

Google Scholar

Google Scholar

[21] 闵琪, 段远源, 王晓东, 吴莘馨 2013 热科学与技术 12 335

Min Q, Duan Y Y, Wang X D, Wu X X 2013 J. Therm. Sci. Technol. 12 335

[22] Shan X W, Chen H D 1994 Phys. Rev. E 49 2941

Google Scholar

Google Scholar

[23] Shan X W, Chen H D 1993 Phys. Rev. E 47 1815

Google Scholar

Google Scholar

[24] Nourgaliev R R, Dinh T N, Theofanous T G, Joseph D 2003 Int. J. Multiphase Flow. 29 117

Google Scholar

Google Scholar

[25] Huang H B, Sukop M, Lu X Y 2015 Multiphase Lattice Boltzmann Methods: Theory and Application (USA: WILEY Blackwell) pp7−10

[26] Yu Z, Fan L S 2009 J. Comput. Phys. 228 6456

Google Scholar

Google Scholar

[27] He X Y, Chen S Y, Zhang R Y 1999 J. Comput. Phys. 152 642

Google Scholar

Google Scholar

[28] Fakhari A, Bolster D 2017 J. Comput. Phys. 334 620

Google Scholar

Google Scholar

[29] Fakhari A, Rahimian M H 2011 Comput. Fluids 40 156

Google Scholar

Google Scholar

[30] Lou Q, Guo Z L, Shi B C 2013 Phys. Rev. E 87 063301

Google Scholar

Google Scholar

[31] Sadeghi R, Shadloo M S 2017 Numer. Heat Transfer Part A 71 560

Google Scholar

Google Scholar

[32] Kano Y, Sato T 2017 Energy Procedia 114 3385

Google Scholar

Google Scholar

[33] Ye F, Di Q F, Wang W C, Chen F, Chen H J, Hua S 2018 J. Appl. Math. Mech. 39 513

Google Scholar

Google Scholar

[34] Huang H B, Huang J J, Lu X Y 2014 J. Comput. Phys. 269 386

Google Scholar

Google Scholar

[35] Chao J H, Mei R W, Singh R, Shyy W 2011 Int. J. Numer. Methods Fluids 66 622

Google Scholar

Google Scholar

[36] Chen Y P, Deng Z L 2017 J. Fluid Mech. 819 401

Google Scholar

Google Scholar

[37] Fu Y H, Bai L, Jin Y, Cheng Y 2017 Phys. Fluids 29 032003

Google Scholar

Google Scholar

[38] 郭照立, 郑楚光 2008 格子Boltzmann方法的原理及应用 (北京: 科学出版社) 第244页

Guo Z L, Zheng C G 2008 Theory and Applications of Lattice Boltzmann Method (Beijing: Science Press) p244 (in Chinese)

[39] Guo Z L, Zheng C G, Shi B C 2011 Phys. Rev. E 83 036707

Google Scholar

Google Scholar

[40] Davies A R, Summers J L, Wilson M C T 2006 Int. J. Comput. Fluid. D 20 415

Google Scholar

Google Scholar

[41] Shi Y, Tang G H 2015 Commun. Comput. Phys. 17 1056

Google Scholar

Google Scholar

[42] Ansarinasab J, Jamialahmadi M 2017 J. Pet. Sci. Eng. 156 748

Google Scholar

Google Scholar

[43] Basirat F, Yang Z B, Niemi A 2017 Adv. Water Resour. 109 181

[44] Zheng X L, Mahabadi N, Yun T S, Jang J 2017 J. Geophys. Res.: Solid Earth 122 1634

Google Scholar

Google Scholar

[45] Xu Z Y, Liu H H, Valocchi A J 2017 Water Resources Res. 53 3770

Google Scholar

Google Scholar

[46] Soulaine C, Roman S, Kovscek A, Tchelepi H A 2018 J. Fluid Mech. 855 616

Google Scholar

Google Scholar

[47] 黄海波 2009 第六届全国流体力学青年研讨会 中国杭州 2009年10月10日 第27页

Huang H B 2009 The 6th National Youth Workshop on Fluid Mechanics Hangzhou, China October 10, 2009 p27 (in Chinese)

[48] Shiri Y, HassaniH,Nazari M, Sharifi M 2018 Mol. Simul. 44 708

Google Scholar

Google Scholar

[49] Liu H H, ValocchiAJ, Kang Q J, Werth C 2013 Transp. Porous Media 99 555

Google Scholar

Google Scholar

[50] Dong B, YanY Y, Li W Z, Song Y C 2010 Comput. Fluids 39 768

Google Scholar

Google Scholar

[51] Ferer M, Anna S L,Tortora P, Kadambi J R, Oliver M, Bromhal G S, Smith D H 2011 Transp. Porous Media 86 243

Google Scholar

Google Scholar

[52] Dong B, YanY Y, Li W Z, Song Y C 2011 J. Bionic. Eng. 7 267

Google Scholar

Google Scholar

-

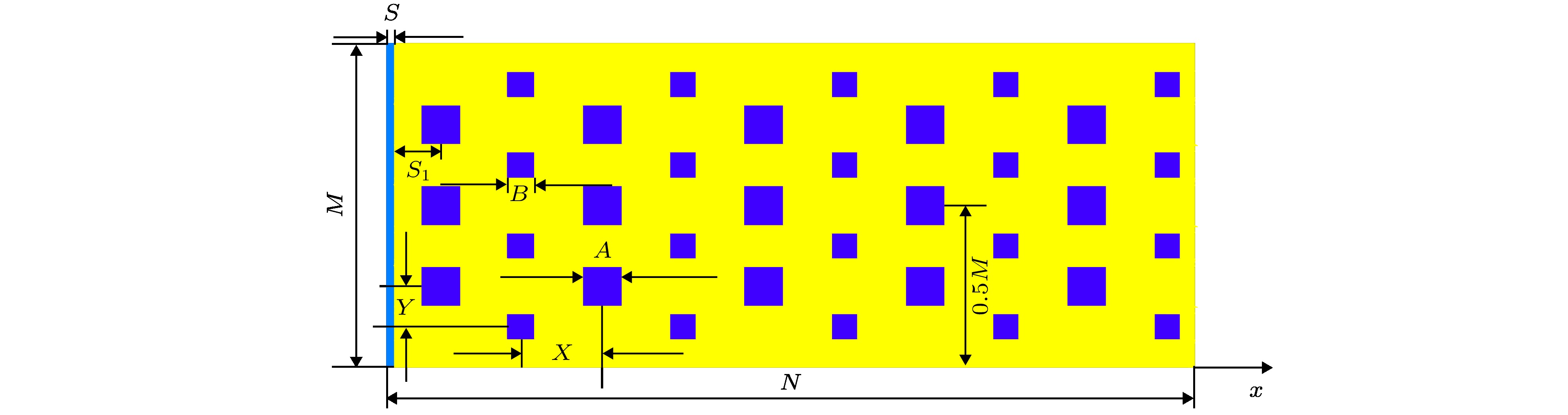

图 2 不同初始静态接触角

${\theta _{{\rm{eq}}}}$ 时得到的稳态接触角$\theta $ (a)${\theta _{{\rm{eq}}}}{\rm{ = }}{60^{\rm{o}}}$ ; (b)${\theta _{{\rm{eq}}}}{\rm{ = }}{90^{\rm{o}}};$ (c)${\theta _{{\rm{eq}}}}={120^{\rm{o}}}$ Fig. 2. Steady state contact angles

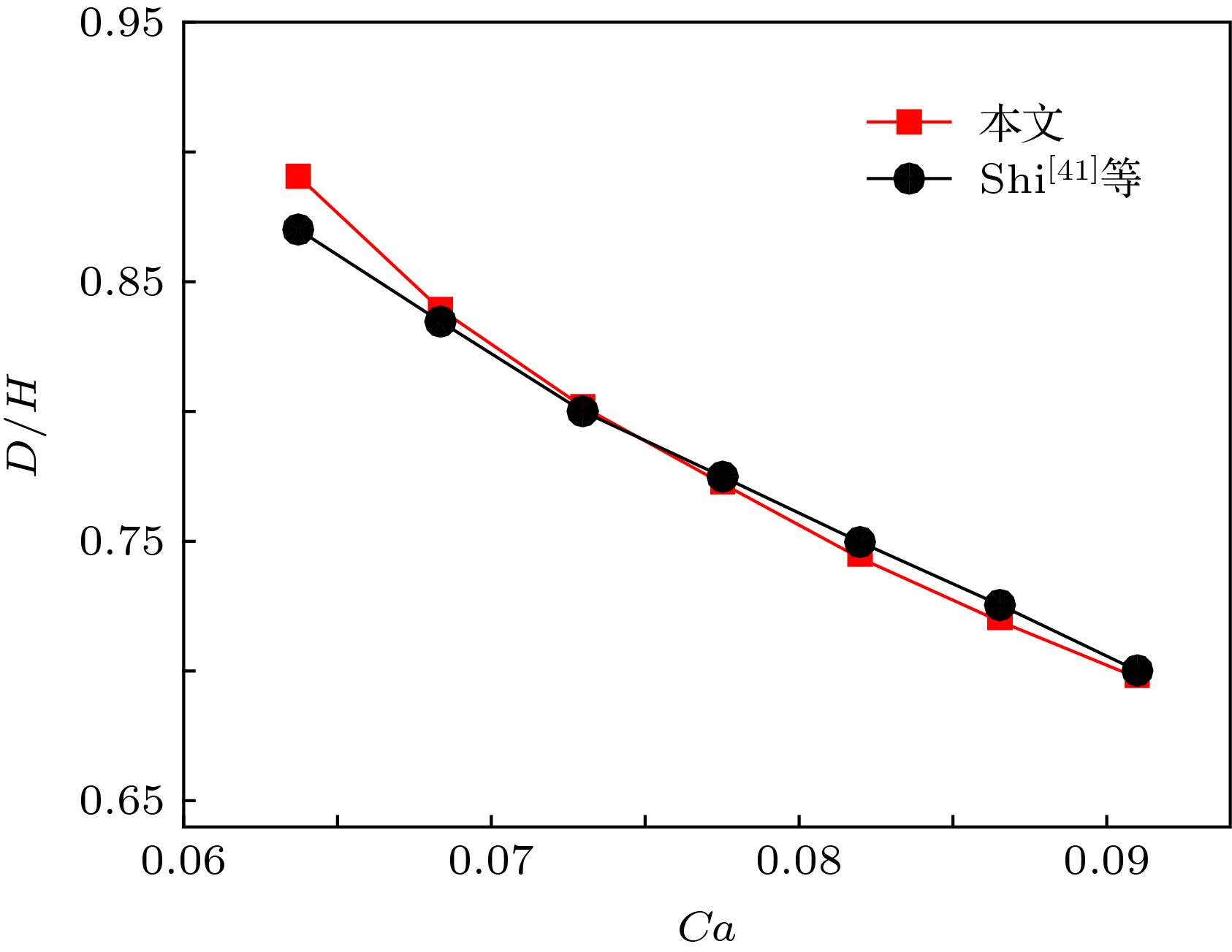

$\theta $ obtained with the different values of static contact angles${\theta _{{\rm{eq}}}}$ : (a)${\theta _{{\rm{eq}}}}{\rm{ = }}{60^{\rm{o}}}$ ; (b)${\theta _{{\rm{eq}}}}{\rm{ = }}{90^{\rm{o}}};$ (c)${\theta _{{\rm{eq}}}}{\rm{ = }}{120^{\rm{o}}}$ .图 5 不同Ca数对应的液滴形态 (a) Ca = 0.06370; (b) Ca = 0.06835; (c) Ca = 0.07300; (d) Ca = 0.07750; (e) Ca = 0.0820; (f) Ca = 0.08650; (g) Ca = 0.0910

Fig. 5. Droplet morphology obtained under various values of Ca: (a) Ca = 0.06370; (b) Ca = 0.06835; (c) Ca = 0.07300; (d) Ca = 0.07750; (e) Ca = 0.0820; (f) Ca = 0.08650; (g) Ca = 0.0910.

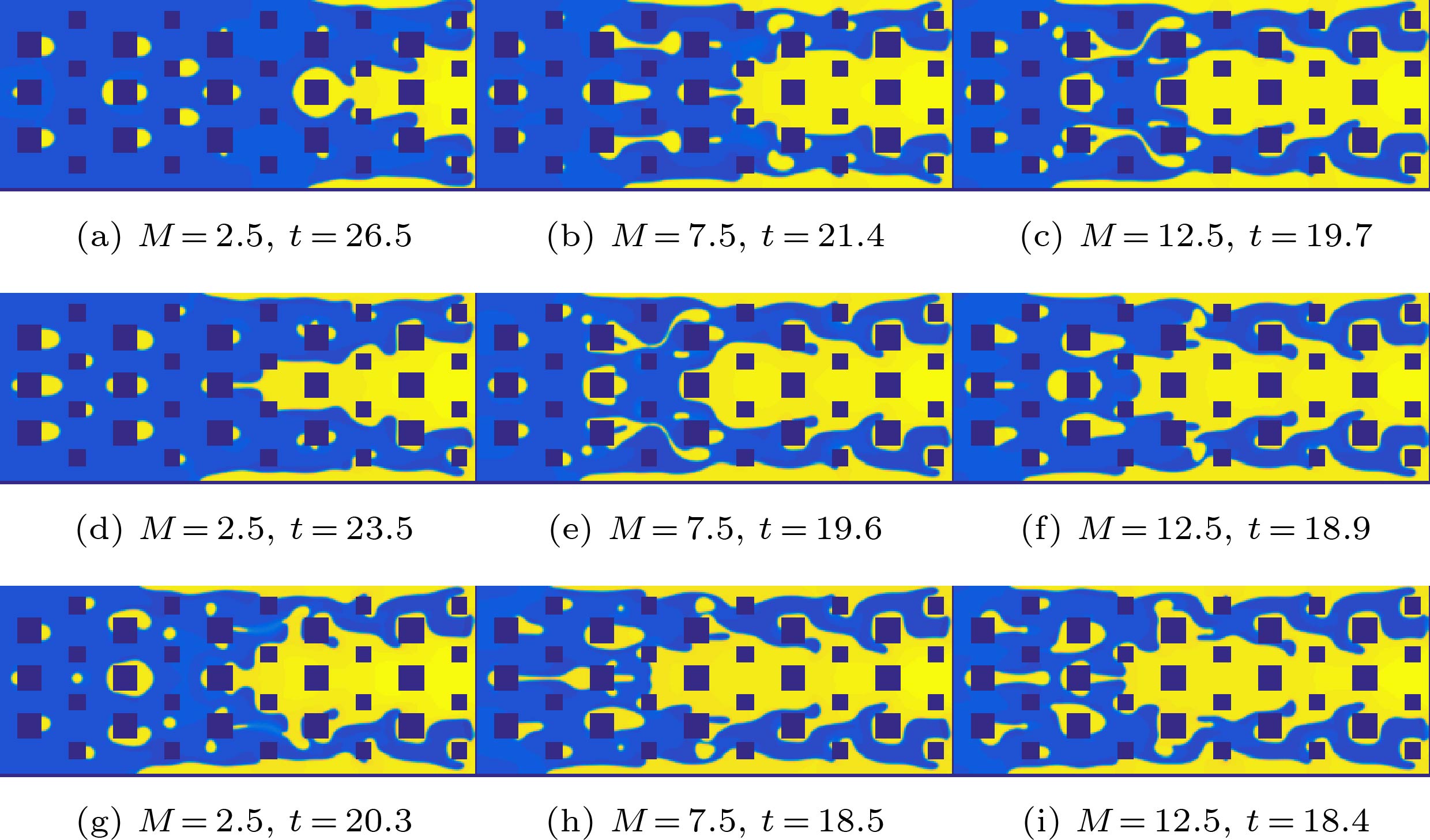

图 13 不同的润湿性角度

$\theta $ 下, 被驱替液为剪切变稀、牛顿与剪切变稠流体时得到的指进形态图 (a)−(c)$\theta = {45^{\circ}}$ ; (d)− (f)$\theta = {60^{\circ}}$ ; (g)−(i)$\theta = {120^{\circ}}$ ; (j)−(l)$\theta = {135^{\circ}}$ Fig. 13. Final finger patterns obtained under different values of contact angles

$\theta $ for shear thinning, Newtonian and shear thickening fluids: (a)−(c)$\theta = {45^{\circ}}$ ; (d)-(f)$\theta = {60^{\circ}}$ ; (g)−(i)$\theta = {120^{\circ}}$ ; (j)−(l)$\theta = {135^{\circ}}$ .图 15 不同的障碍物几何类型, 被驱替液为剪切变稀、牛顿与剪切变稠流体时驱得到的指进形态图 (a)−(c) n = 0.4; (d)− (f) n = 0.7; (g)−(i) n = 1.0; (j)−(l) n = 1.3, (m)−(o) n = 1.6

Fig. 15. Final finger patterns obtained under different geometric type for shear thinning, Newtonian and shear thickening fluids: (a)− (c) n = 0.4; (d)−(f) n = 0.7; (g)−(i) n = 1.0; (j)−(l) n = 1.3; (m)−(o) n = 1.6.

-

[1] Santvoort J V, Golombok M 2018 J. Pet. Sci. Eng. 167 28

Google Scholar

Google Scholar

[2] Fang T M, Wang M H, Gao Y, Zhang Y N, Yan Y G, Zhang J 2019 Chem. Eng. Sci. 197 204

Google Scholar

Google Scholar

[3] Xu X F, Zhang J, Liu F X, Wang X J, Wei W, Liu Z J 2017 Int. J. Multiphase Flow. 95 84

Google Scholar

Google Scholar

[4] Du W, Fu T T, Duan Y F, Zhu C Y, Ma Y G, Li H Z 2018 Chem. Eng. Sci. 176 66

Google Scholar

Google Scholar

[5] Fu T T, Ma Y G, Li H Z 2015 Chem. Eng. Process. 97 38

Google Scholar

Google Scholar

[6] Salehi M S, Esfidani M T, Afshin H, Firoozabadi B 2018 Exp. Therm. Fluid Sci. 94 148

Google Scholar

Google Scholar

[7] Sontti S G, Atta A 2017 Chem. Eng. J. 330 245

Google Scholar

Google Scholar

[8] 娄钦, 李涛, 杨茉 2018 67 234701

Google Scholar

Google Scholar

Lou Q, Li T, Yang M 2018 Acta Phys. Sin. 67 234701

Google Scholar

Google Scholar

[9] 臧晨强, 娄钦 2017 66 134701

Google Scholar

Google Scholar

Zang C Q, Lou Q 2017 Acta Phys. Sin. 66 134701

Google Scholar

Google Scholar

[10] Lou Q, Guo Z L, Shi B C 2012 Europhys. Lett. 99 64005

Google Scholar

Google Scholar

[11] Lou Q, Guo Z L 2015 Phys. Rev. E 91 013302

Google Scholar

Google Scholar

[12] 娄钦, 李涛, 李凌 2018 上海理工大学学报 40 13

Lou Q, Li T, Li L 2018 J. Univ. Shanghai Sci. Technol. 40 13

[13] 谢驰宇, 张建影, 王沫然 2016 计算物理 33 147

Google Scholar

Google Scholar

Xie C Y, Zhang J Y, Wang M R 2016 Chin. J. Computat. Phys. 33 147

Google Scholar

Google Scholar

[14] Swift M R, Osborn W R, Yeomans J M 1995 Phys. Rev. Lett. 75 830

Google Scholar

Google Scholar

[15] Shi Y, Tang G H 2014 Comput. Math. Appl. 68 1279

Google Scholar

Google Scholar

[16] Fakhari A, Rahimian M H 2010 Phys. Rev. E 81 036707

Google Scholar

Google Scholar

[17] Shi Y, Tang G H 2016 J. Non-Newtonian Fluid Mech. 229 86

Google Scholar

Google Scholar

[18] Ba Y, Wang N N, Liu H H, Li Q, He G Q 2018 Phys. Rev. E 97 033307

Google Scholar

Google Scholar

[19] Halliday I, Law R, Care C M, Hollis A 2006 Phys. Rev. E 73 056708

Google Scholar

Google Scholar

[20] Halliday I, Hollis A P, Care C M 2007 Phys. Rev. E 76 026708

Google Scholar

Google Scholar

[21] 闵琪, 段远源, 王晓东, 吴莘馨 2013 热科学与技术 12 335

Min Q, Duan Y Y, Wang X D, Wu X X 2013 J. Therm. Sci. Technol. 12 335

[22] Shan X W, Chen H D 1994 Phys. Rev. E 49 2941

Google Scholar

Google Scholar

[23] Shan X W, Chen H D 1993 Phys. Rev. E 47 1815

Google Scholar

Google Scholar

[24] Nourgaliev R R, Dinh T N, Theofanous T G, Joseph D 2003 Int. J. Multiphase Flow. 29 117

Google Scholar

Google Scholar

[25] Huang H B, Sukop M, Lu X Y 2015 Multiphase Lattice Boltzmann Methods: Theory and Application (USA: WILEY Blackwell) pp7−10

[26] Yu Z, Fan L S 2009 J. Comput. Phys. 228 6456

Google Scholar

Google Scholar

[27] He X Y, Chen S Y, Zhang R Y 1999 J. Comput. Phys. 152 642

Google Scholar

Google Scholar

[28] Fakhari A, Bolster D 2017 J. Comput. Phys. 334 620

Google Scholar

Google Scholar

[29] Fakhari A, Rahimian M H 2011 Comput. Fluids 40 156

Google Scholar

Google Scholar

[30] Lou Q, Guo Z L, Shi B C 2013 Phys. Rev. E 87 063301

Google Scholar

Google Scholar

[31] Sadeghi R, Shadloo M S 2017 Numer. Heat Transfer Part A 71 560

Google Scholar

Google Scholar

[32] Kano Y, Sato T 2017 Energy Procedia 114 3385

Google Scholar

Google Scholar

[33] Ye F, Di Q F, Wang W C, Chen F, Chen H J, Hua S 2018 J. Appl. Math. Mech. 39 513

Google Scholar

Google Scholar

[34] Huang H B, Huang J J, Lu X Y 2014 J. Comput. Phys. 269 386

Google Scholar

Google Scholar

[35] Chao J H, Mei R W, Singh R, Shyy W 2011 Int. J. Numer. Methods Fluids 66 622

Google Scholar

Google Scholar

[36] Chen Y P, Deng Z L 2017 J. Fluid Mech. 819 401

Google Scholar

Google Scholar

[37] Fu Y H, Bai L, Jin Y, Cheng Y 2017 Phys. Fluids 29 032003

Google Scholar

Google Scholar

[38] 郭照立, 郑楚光 2008 格子Boltzmann方法的原理及应用 (北京: 科学出版社) 第244页

Guo Z L, Zheng C G 2008 Theory and Applications of Lattice Boltzmann Method (Beijing: Science Press) p244 (in Chinese)

[39] Guo Z L, Zheng C G, Shi B C 2011 Phys. Rev. E 83 036707

Google Scholar

Google Scholar

[40] Davies A R, Summers J L, Wilson M C T 2006 Int. J. Comput. Fluid. D 20 415

Google Scholar

Google Scholar

[41] Shi Y, Tang G H 2015 Commun. Comput. Phys. 17 1056

Google Scholar

Google Scholar

[42] Ansarinasab J, Jamialahmadi M 2017 J. Pet. Sci. Eng. 156 748

Google Scholar

Google Scholar

[43] Basirat F, Yang Z B, Niemi A 2017 Adv. Water Resour. 109 181

[44] Zheng X L, Mahabadi N, Yun T S, Jang J 2017 J. Geophys. Res.: Solid Earth 122 1634

Google Scholar

Google Scholar

[45] Xu Z Y, Liu H H, Valocchi A J 2017 Water Resources Res. 53 3770

Google Scholar

Google Scholar

[46] Soulaine C, Roman S, Kovscek A, Tchelepi H A 2018 J. Fluid Mech. 855 616

Google Scholar

Google Scholar

[47] 黄海波 2009 第六届全国流体力学青年研讨会 中国杭州 2009年10月10日 第27页

Huang H B 2009 The 6th National Youth Workshop on Fluid Mechanics Hangzhou, China October 10, 2009 p27 (in Chinese)

[48] Shiri Y, HassaniH,Nazari M, Sharifi M 2018 Mol. Simul. 44 708

Google Scholar

Google Scholar

[49] Liu H H, ValocchiAJ, Kang Q J, Werth C 2013 Transp. Porous Media 99 555

Google Scholar

Google Scholar

[50] Dong B, YanY Y, Li W Z, Song Y C 2010 Comput. Fluids 39 768

Google Scholar

Google Scholar

[51] Ferer M, Anna S L,Tortora P, Kadambi J R, Oliver M, Bromhal G S, Smith D H 2011 Transp. Porous Media 86 243

Google Scholar

Google Scholar

[52] Dong B, YanY Y, Li W Z, Song Y C 2011 J. Bionic. Eng. 7 267

Google Scholar

Google Scholar

计量

- 文章访问数: 11976

- PDF下载量: 140

- 被引次数: 0

下载:

下载: