-

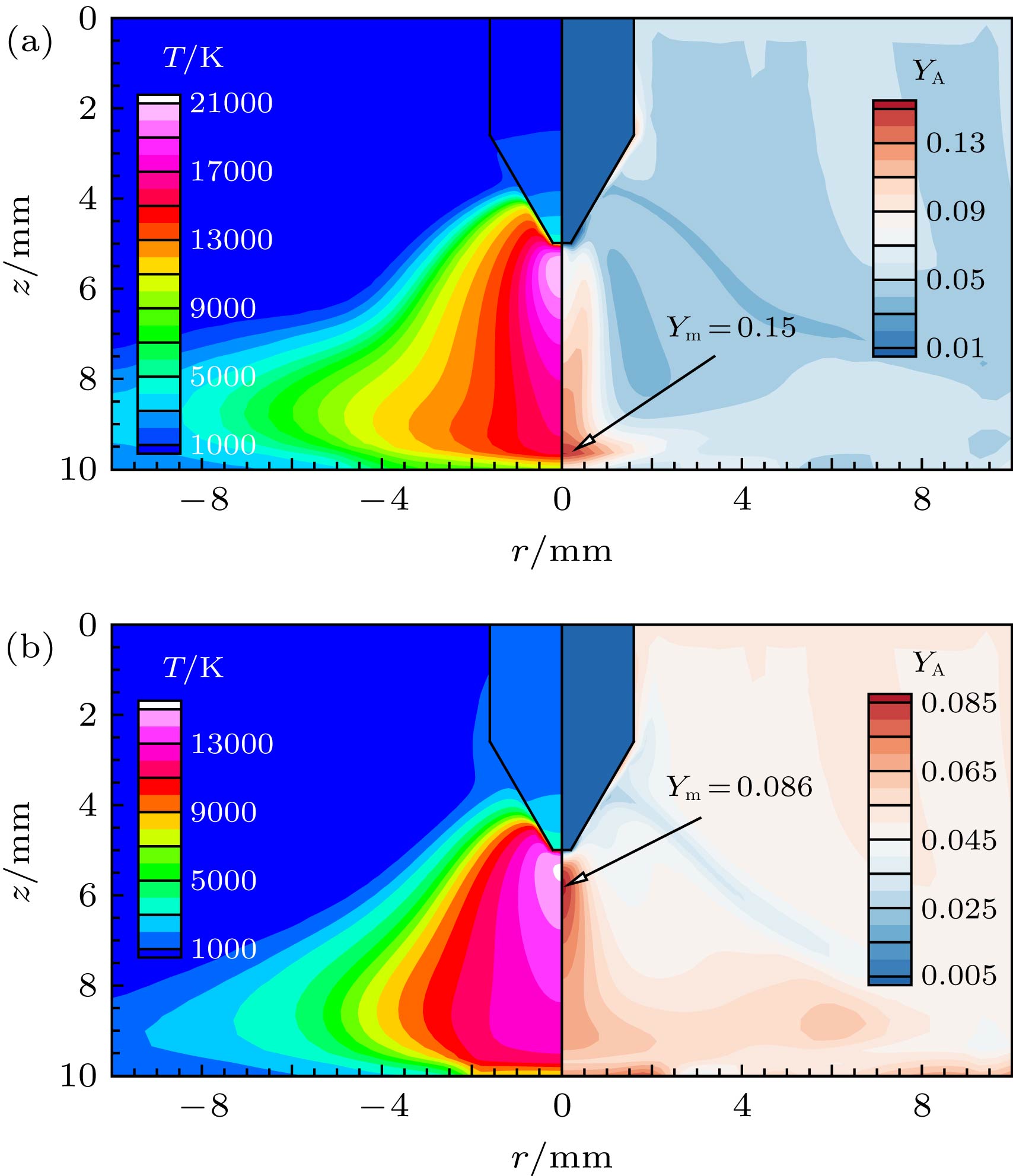

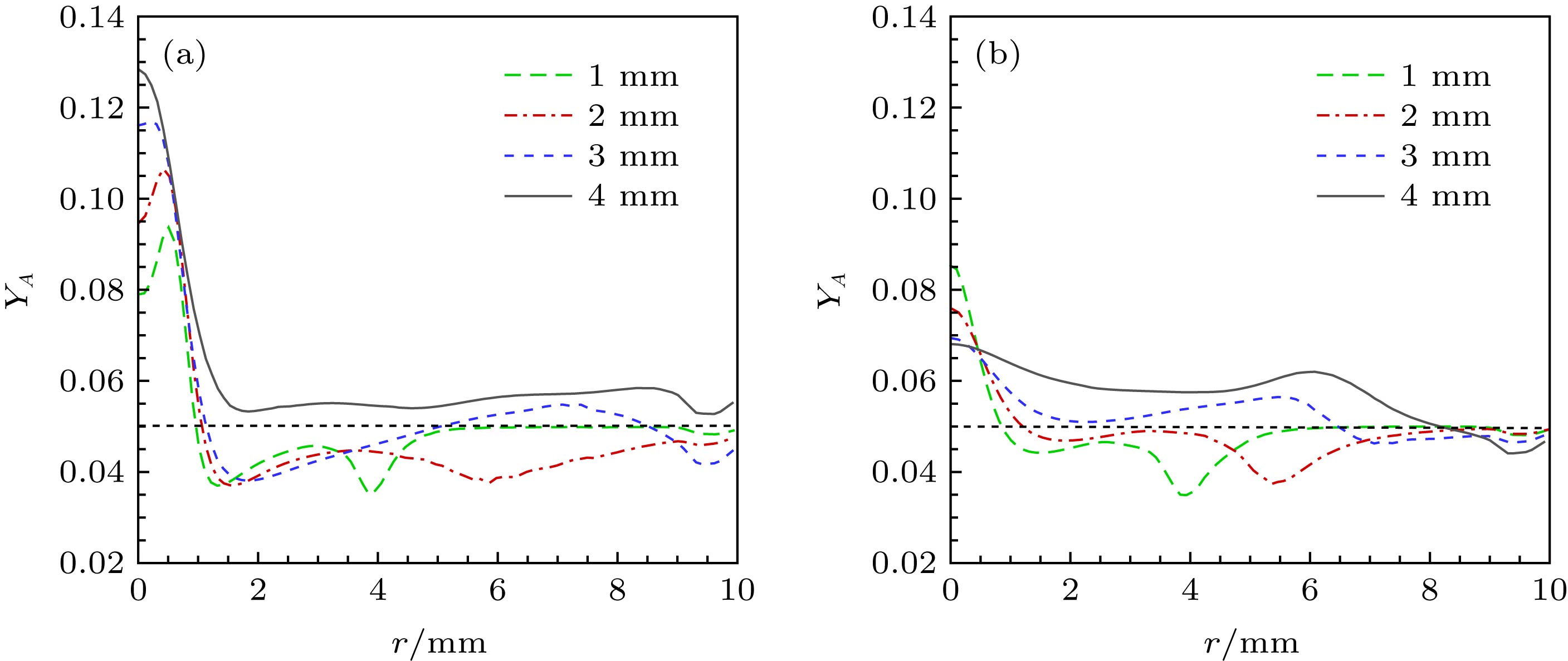

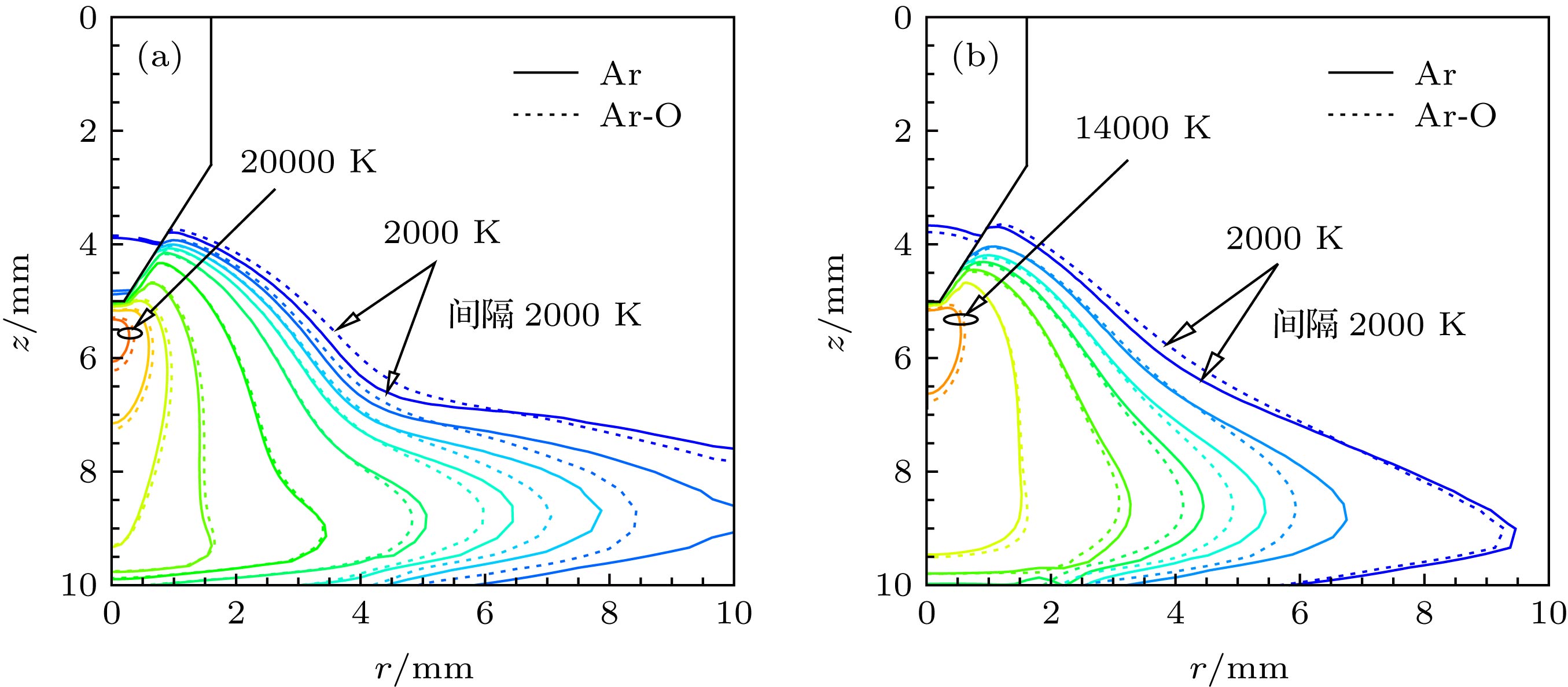

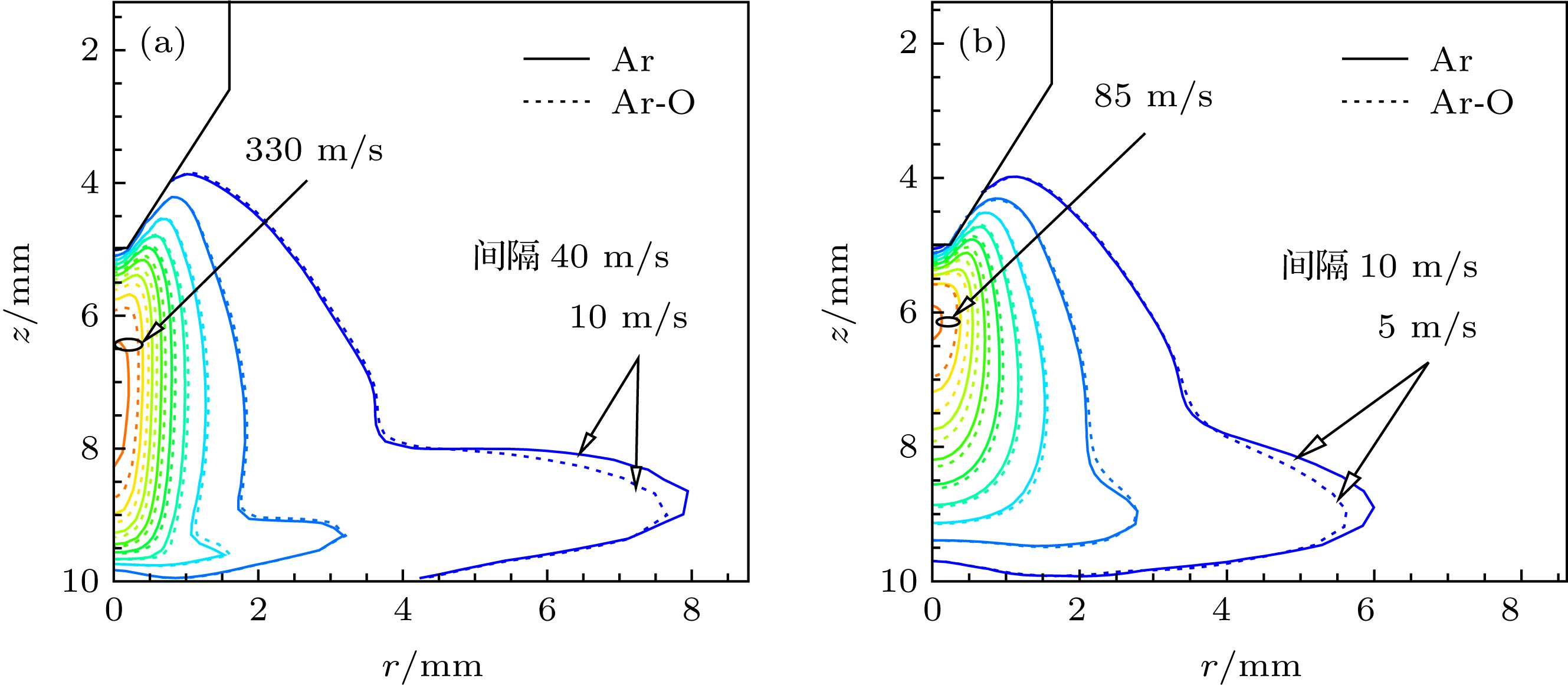

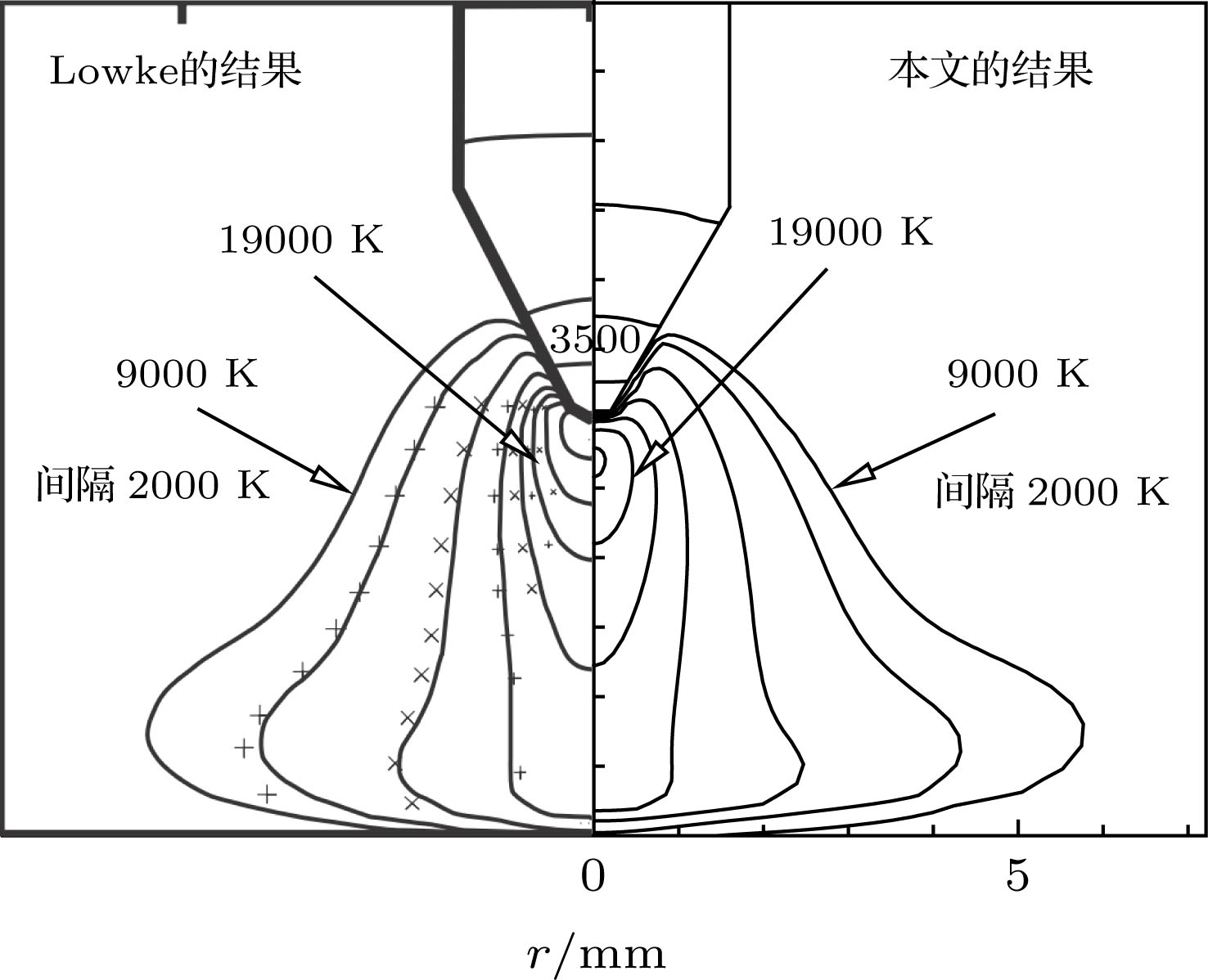

混合气体电弧被广泛地应用于焊接制造领域, 为了深入理解混合气体电弧的传热和传质特性, 本文建立了Ar-O2混合气体电弧的二维稳态数学模型. 模型基于局域热平衡假设, 混合气体电弧的热力学参数和输运系数是温度和氧浓度的函数, 分别采用组合普通扩散系数和组合温度扩散系数描述氧和氩两种组分之间的扩散行为, 研究了不同电流条件下的氧分布及其对电弧温度场和流场的影响. 结果表明, 对于Ar-5%O2的混合气体电弧, 氧在电弧中呈现极不均匀的分布, 在电弧中心轴线附近和靠近两极的区域, 氧浓度高于混合气体浓度, 而在其他区域则明显小于混合气体浓度. 在小电流时, 氧集中分布于阴极和阳极附近, 且在阴极附近出现峰值; 而在大电流时, 氧的分布明显向阳极集中, 且在阳极中心附近出现峰值. 两种情形下, 氧在距离阳极表面0.1 mm的区域分布都不均匀. 与纯Ar保护相比, 混入5%的O2使电弧出现一定程度的收缩, 温度和等离子体流速升高.Mixture gas arcs are used extensively in welding manufacturing. A two-dimensional steady mathematical model for Ar-O2 mixture gas arc is developed to understand further the heat and mass transfer of the mixture gas arc. The model is based on the assumption of local thermodynamic equilibrium, and the thermodynamic parameters and transport coefficients are dependent on both the temperature and the oxygen content. In the present model, the diffusion between the argon species and oxygen species is depicted by the approach of the combined diffusion coefficient, i. e. the mixture gas arc is simplified into two different species, and the diffusion between them is formulated by combined ordinary diffusion coefficient and combined temperature diffusion coefficient; the oxygen distribution and its influence on the temperature and flow field of the arc are investigated for two different current conditions. It is shown that the oxygen species presents significant non-uniform distribution for argon gas mixed with 5% oxygen; the oxygen content is higher than that in mixed shielding gas in the regions close to the electrodes and arc axis, while its content is lower than that of the mixed shielding gas in other regions. For high current, oxygen concentrates more to the flat anode, while it concentrates more to tungsten cathode for low current. For both cases, oxygen content is inhomogeneous in the region 0.1 mm above the anode. The 5% oxygen mixed in argon constricts the arc plasma to some extent and thus raises the arc temperature as well as the plasma flow velocity.

-

Keywords:

- mixture gas /

- arc /

- numerical simulation

[1] Murphy A B, Tanaka M, Tashiro S, Sato T, Lowke J J 2009 J. Phys. D: Appl. Phys. 42 115205

Google Scholar

Google Scholar

[2] Pires I, Quintino L, Miranda R M 2007 Mater. Design 28 1623

Google Scholar

Google Scholar

[3] Lones L A, Eagar T W, Lang J H 1998 J. Phys. D: Appl. Phys. 31 107

Google Scholar

Google Scholar

[4] Lu S P, Fujii H, Nogi K, Sato T 2007 Sci. Technol. Weld. Joi. 12 689

Google Scholar

Google Scholar

[5] Palmer T A, DebRoy T 1998 Sci. Technol. Weld. Joi. 3 190

Google Scholar

Google Scholar

[6] Fujii H, Sato T, Lu S P, Nogi K 2008 Mater. Sci. Eng. 495 29

[7] Church J G, Imaizumi H 1990 IIW/IIS Doc. XII-1199-90

[8] 张建晓, 樊丁, 黄勇 2017 焊接学报 38 47

Google Scholar

Google Scholar

Zhang J X, Fan, D, Huang Y 2017 Trans. China Weld. Inst. 38 47

Google Scholar

Google Scholar

[9] Wang X, Fan D, Huang J, Huang Y 2014 J. Phys. D: Appl. Phys. 47 275202

Google Scholar

Google Scholar

[10] Hsu K C, Mtemadi K, Pfender E 1983 J. Appl. Phys. 54 1293

[11] Fan D, Ushio M, Matsuda F 1986 Trans. JWRI 15 1

[12] Lowke J J, Morrow R, Haidar J 1997 J. Phys. D: Appl. Phys. 30 2033

Google Scholar

Google Scholar

[13] Kim W H, Fan H G, Na S J 1997 Metall. Mater. Trans. B 28B 679

[14] Choo R T C, Szekely J, Westhoff R C 1992 Metall. Mater. Trans. B 23B 57

[15] Murphy A B, Tanaka M, Yamamoto K, Tashiro S , Sato T, Lowke J J 2009 J. Phys. D: Appl. Phys. 42 194006

Google Scholar

Google Scholar

[16] Tanaka M, Terasaki H, Ushio M, Lowke J J 2003 Plasma Chem. Plasma Process. 23 585

Google Scholar

Google Scholar

[17] 袁行球, 李辉, 赵太泽, 王飞, 俞国扬, 郭文康, 须平 2004 53 3806

Google Scholar

Google Scholar

Yuan X Q, Li H, Zhao T Z, Wang F, Yu G Y, Guo W K, Xu P 2004 Acta Phys. Sin. 53 3806

Google Scholar

Google Scholar

[18] 石玗, 郭朝博, 黄健康, 樊丁 2011 60 048102

Google Scholar

Google Scholar

Shi Y, Guo C B, Huang J K, Fan D 2011 Acta Phys. Sin. 60 048102

Google Scholar

Google Scholar

[19] 王新鑫, 樊丁, 黄健康, 黄勇 2013 62 228101

Google Scholar

Google Scholar

Wang X X, Fan D, Huang J K, Huang Y 2013 Acta Phys. Sin. 62 228101

Google Scholar

Google Scholar

[20] Bini R, Monno M, Boulos M I 2006 J. Phys. D: Appl. Phys. 39 3253

Google Scholar

Google Scholar

[21] Hsu K C, Pfender E 1983 J. Appl. Phys. 54 4359

Google Scholar

Google Scholar

[22] Konishi K, Shigeta M, Tanaka M, Murata A, Murata T, Murphy A B 2017 Weld. World 61 197

Google Scholar

Google Scholar

[23] 黄勇, 刘林, 王新鑫, 陆肃中 2017 焊接学报 39 6

Google Scholar

Google Scholar

Huang Y, Liu L, Wang X X, Lu S Z 2017 Trans. China Weld. Inst. 39 6

Google Scholar

Google Scholar

[24] Baeva M, Kozakov R, Gorchakov S, Uhrlandt D 2012 Plasma Sources Sci. Technol. 21 055027

Google Scholar

Google Scholar

[25] Baeva M 2017 Plasma Chem. Plasma Process. 37 513

Google Scholar

Google Scholar

[26] 钱海洋, 吴彬 2011 核聚变与等离子体物理 31 186

Qian H Y, Wu B 2011 Nucl. Fusion Plasma Phys. 31 186

[27] Li H P, Benilov M S 2007 J. Phys. D: Appl. Phys. 40 2010

Google Scholar

Google Scholar

[28] Wei F Z, Wang H X, Murphy A B, Sun W P, Liu Y 2013 J. Phys. D: Appl. Phys. 46 505205

Google Scholar

Google Scholar

[29] Zhang X N, Li H P, Murphy A B, Xia W D 2013 Phys. Plasmas 20 033508

Google Scholar

Google Scholar

[30] Li H P, Zhang X N, Xia W D 2013 Phys. Plasmas 20 033509

Google Scholar

Google Scholar

[31] Zhao G Y, Dassanayake M, Etemadi K 1990 Plasma Chem. Plasma Process. 10 87

Google Scholar

Google Scholar

[32] Tanaka M, Yamamoto K, Tashiro S, Nakata K, Yamamoto E, Yamazaki K, Suzuki K, Murphy A B, Lowke J J 2010 J. Phys. D: Appl. Phys. 43 434009

Google Scholar

Google Scholar

[33] Schnick M, Füssel U, Hertel M, Spille-Kohoff A, Murphy A B 2010 J. Phys. D: Appl. Phys. 43 022001

Google Scholar

Google Scholar

[34] Wang X, Luo Y, Wu G, Chi L, Fan D 2018 Plasma Chem. Plasma Process. 38 1095

Google Scholar

Google Scholar

[35] 菅晓霞, 武传松 2016 金属学报 52 1467

Jian X X, Wu C S 2016 Acta Metall. Sin. 52 1467

[36] Savas A, Ceyhun V 2012 Comp. Mater. Sci. 51 53

[37] Wang L L, Lu F G, Wang H P, Murphy A B, Tang X H 2014 J. Phys. D: Appl. Phys. 47 465202

Google Scholar

Google Scholar

[38] Rao Z H, Liao S M, Tsai H L 2010 J. Appl. Phys. 107 044902

Google Scholar

Google Scholar

[39] Murphy A B 1994 Phys. Rev. Lett. 73 1797

Google Scholar

Google Scholar

[40] Murphy A B 1997 Phys. Rev. E 55 7473

[41] Murphy A B, Hiraoka K 2000 J. Phys. D: Appl. Phys. 33 2183

Google Scholar

Google Scholar

[42] Bitharas I, McPherson N A, McGhie W, Roy D, Moore A J 2018 J. Mater. Process. Tech. 255 451

Google Scholar

Google Scholar

[43] 黄勇, 陆肃中, 王新鑫, 李慧 2016 焊接学报 37 36

Huang Y, Lu S Z, Wang X X, Li H 2016 China Weld. Inst. 37 36

[44] Chen J, Xu H, Wei X, Lv H, Song Z, Chen Z 2017 Vacuum 145 77

Google Scholar

Google Scholar

[45] 杨郁, 唐成双, 赵一帆, 虞一青, 辛煜 2017 66 185202

Google Scholar

Google Scholar

Yang Y, Tang C S, Zhao Y F, Yu Y Q, Xin Y 2017 Acta Phys. Sin. 66 185202

Google Scholar

Google Scholar

[46] Murphy A B 1993 Phys. Rev. E 48 3594

Google Scholar

Google Scholar

[47] Murphy A B 1993 J. Chem. Phys. 99 1340

Google Scholar

Google Scholar

[48] 查普曼, 考林 著 (刘大有, 王伯懿 译) 1985 非均匀气体的数学理论 (第三版) (北京: 科学出版社) 第178−191, 343−344页

Chapman S, Cowling T G (translated by Liu D Y, Wang B Y 1970 The Mathematical Theory of Non-Uniform Gases (3rd ed.) (Beijing: Science Press) pp178−191, 343−344 (in Chinese)

[49] Murphy A B 1996 J. Phys. D: Appl. Phys. 29 1922

Google Scholar

Google Scholar

[50] Murphy A B 1998 J. Phys. D: Appl. Phys. 31 3383

Google Scholar

Google Scholar

[51] Murphy A B, Arundell C J 1994 Plasma Chem. Plasma Process. 14 451

Google Scholar

Google Scholar

[52] Cram L E 1985 J. Phys. D: Appl. Phys. 18 40

[53] Choquet I, Shirvan J A, Nilsson H 2012 J. Phys. D: Appl. Phys. 45 205203

Google Scholar

Google Scholar

[54] Tanaka M, Terasaki H, Ushio M, Lowke J J 2002 Metall. Mater. Trans. A 33 2043

Google Scholar

Google Scholar

[55] Wang X, Huang J, Huang Y, Fan D, Guo Y 2017 Appl. Therm. Eng. 113 27

Google Scholar

Google Scholar

[56] 陆善平, 董文超, 李殿中, 李依依 2009 58 94

Lu S, Dong W, Li D, Li Y 2009 Acta Phys. Sin. 58 94

[57] 黄勇, 王艳磊, 张治国 2014 光谱学与光谱分析 34 1168

Google Scholar

Google Scholar

Huang Y, Wang Y L, Zhang Z G 2014 Spectrsc. Spect. Anal. 34 1168

Google Scholar

Google Scholar

-

图 1 扩散系数 (a) 组合普通扩散系数

$\overline {D_{{\rm{Ar,}}{{\rm{O}}_{\rm{2}}}}^x} $ ; (b) 组合温度扩散系数$\overline {D_{{\rm{Ar,}}{{\rm{O}}_{\rm{2}}}}^T} $ Fig. 1. Diffusion coefficients: (a) Combined ordinary diffusion coefficient

$\overline {D_{{\rm{Ar,}}{{\rm{O}}_{\rm{2}}}}^x} $ ; (b) combined temperature diffusion coefficient$\overline {D_{{\rm{Ar,}}{{\rm{O}}_{\rm{2}}}}^T} $ 表 1 边界条件

Table 1. Boundary conditions.

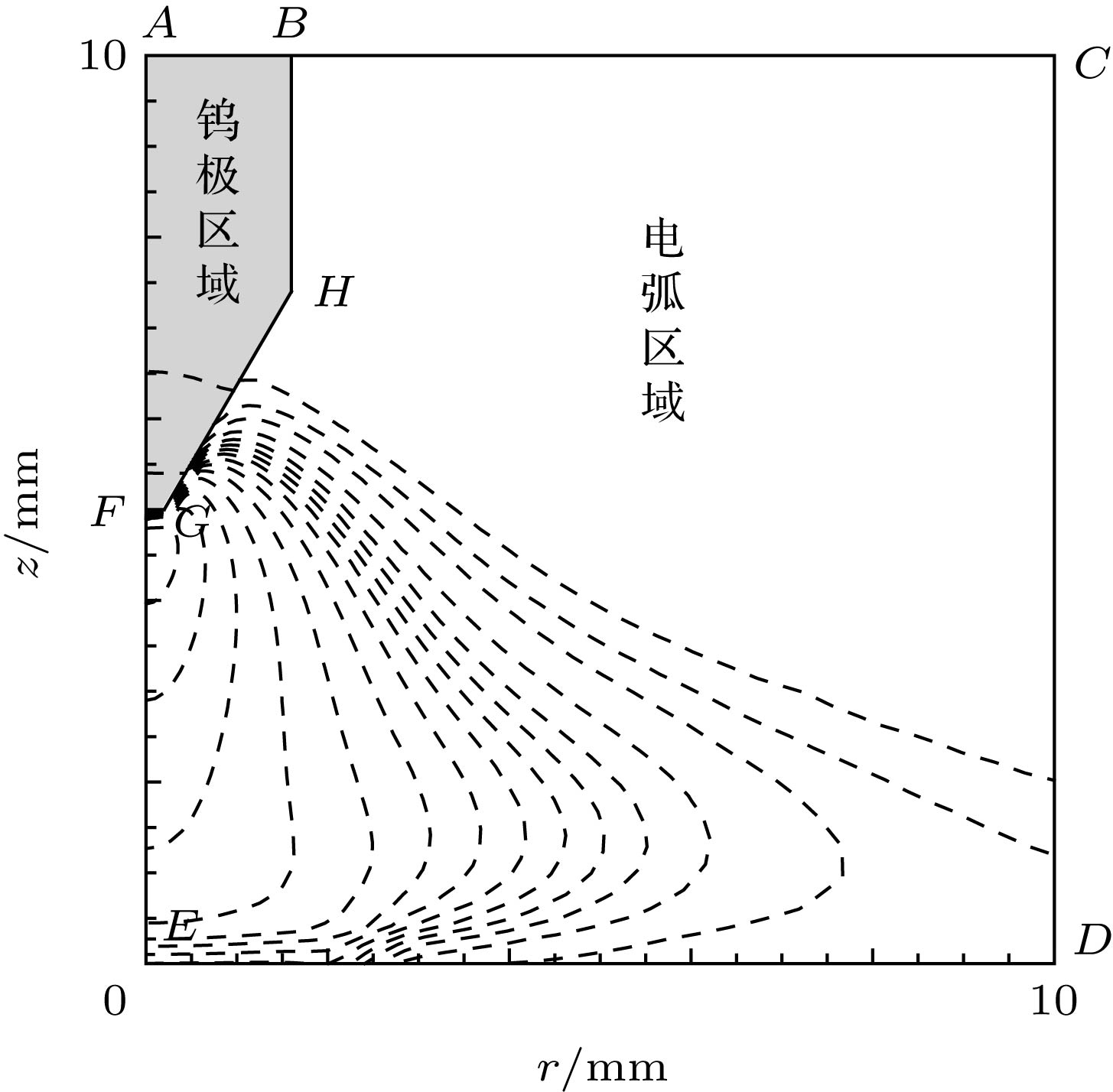

边界 v/m·s–1 T/K Φ/V A/Wb·m–1 YA AB — 1000 jz $\partial$A/$\partial$n=0 — BC vgiv 500 $\partial$Φ/$\partial$n=0 $\partial$A/$\partial$n=0 0.05 CD $\partial$v/$\partial$n=0 500 $\partial$Φ/$\partial$n=0 A=0 0.05 DE — 2000 0 $\partial$A/$\partial$n=0 $\partial$YA/$\partial$n=0 EA $\partial$v/$\partial$n=0 $\partial$T/$\partial$n=0 $\partial$Φ/$\partial$n=0 $\partial$A/$\partial$n=0 $\partial$YA/$\partial$n=0 BF Non-slip (12)式 Coupled Coupled YAgiv -

[1] Murphy A B, Tanaka M, Tashiro S, Sato T, Lowke J J 2009 J. Phys. D: Appl. Phys. 42 115205

Google Scholar

Google Scholar

[2] Pires I, Quintino L, Miranda R M 2007 Mater. Design 28 1623

Google Scholar

Google Scholar

[3] Lones L A, Eagar T W, Lang J H 1998 J. Phys. D: Appl. Phys. 31 107

Google Scholar

Google Scholar

[4] Lu S P, Fujii H, Nogi K, Sato T 2007 Sci. Technol. Weld. Joi. 12 689

Google Scholar

Google Scholar

[5] Palmer T A, DebRoy T 1998 Sci. Technol. Weld. Joi. 3 190

Google Scholar

Google Scholar

[6] Fujii H, Sato T, Lu S P, Nogi K 2008 Mater. Sci. Eng. 495 29

[7] Church J G, Imaizumi H 1990 IIW/IIS Doc. XII-1199-90

[8] 张建晓, 樊丁, 黄勇 2017 焊接学报 38 47

Google Scholar

Google Scholar

Zhang J X, Fan, D, Huang Y 2017 Trans. China Weld. Inst. 38 47

Google Scholar

Google Scholar

[9] Wang X, Fan D, Huang J, Huang Y 2014 J. Phys. D: Appl. Phys. 47 275202

Google Scholar

Google Scholar

[10] Hsu K C, Mtemadi K, Pfender E 1983 J. Appl. Phys. 54 1293

[11] Fan D, Ushio M, Matsuda F 1986 Trans. JWRI 15 1

[12] Lowke J J, Morrow R, Haidar J 1997 J. Phys. D: Appl. Phys. 30 2033

Google Scholar

Google Scholar

[13] Kim W H, Fan H G, Na S J 1997 Metall. Mater. Trans. B 28B 679

[14] Choo R T C, Szekely J, Westhoff R C 1992 Metall. Mater. Trans. B 23B 57

[15] Murphy A B, Tanaka M, Yamamoto K, Tashiro S , Sato T, Lowke J J 2009 J. Phys. D: Appl. Phys. 42 194006

Google Scholar

Google Scholar

[16] Tanaka M, Terasaki H, Ushio M, Lowke J J 2003 Plasma Chem. Plasma Process. 23 585

Google Scholar

Google Scholar

[17] 袁行球, 李辉, 赵太泽, 王飞, 俞国扬, 郭文康, 须平 2004 53 3806

Google Scholar

Google Scholar

Yuan X Q, Li H, Zhao T Z, Wang F, Yu G Y, Guo W K, Xu P 2004 Acta Phys. Sin. 53 3806

Google Scholar

Google Scholar

[18] 石玗, 郭朝博, 黄健康, 樊丁 2011 60 048102

Google Scholar

Google Scholar

Shi Y, Guo C B, Huang J K, Fan D 2011 Acta Phys. Sin. 60 048102

Google Scholar

Google Scholar

[19] 王新鑫, 樊丁, 黄健康, 黄勇 2013 62 228101

Google Scholar

Google Scholar

Wang X X, Fan D, Huang J K, Huang Y 2013 Acta Phys. Sin. 62 228101

Google Scholar

Google Scholar

[20] Bini R, Monno M, Boulos M I 2006 J. Phys. D: Appl. Phys. 39 3253

Google Scholar

Google Scholar

[21] Hsu K C, Pfender E 1983 J. Appl. Phys. 54 4359

Google Scholar

Google Scholar

[22] Konishi K, Shigeta M, Tanaka M, Murata A, Murata T, Murphy A B 2017 Weld. World 61 197

Google Scholar

Google Scholar

[23] 黄勇, 刘林, 王新鑫, 陆肃中 2017 焊接学报 39 6

Google Scholar

Google Scholar

Huang Y, Liu L, Wang X X, Lu S Z 2017 Trans. China Weld. Inst. 39 6

Google Scholar

Google Scholar

[24] Baeva M, Kozakov R, Gorchakov S, Uhrlandt D 2012 Plasma Sources Sci. Technol. 21 055027

Google Scholar

Google Scholar

[25] Baeva M 2017 Plasma Chem. Plasma Process. 37 513

Google Scholar

Google Scholar

[26] 钱海洋, 吴彬 2011 核聚变与等离子体物理 31 186

Qian H Y, Wu B 2011 Nucl. Fusion Plasma Phys. 31 186

[27] Li H P, Benilov M S 2007 J. Phys. D: Appl. Phys. 40 2010

Google Scholar

Google Scholar

[28] Wei F Z, Wang H X, Murphy A B, Sun W P, Liu Y 2013 J. Phys. D: Appl. Phys. 46 505205

Google Scholar

Google Scholar

[29] Zhang X N, Li H P, Murphy A B, Xia W D 2013 Phys. Plasmas 20 033508

Google Scholar

Google Scholar

[30] Li H P, Zhang X N, Xia W D 2013 Phys. Plasmas 20 033509

Google Scholar

Google Scholar

[31] Zhao G Y, Dassanayake M, Etemadi K 1990 Plasma Chem. Plasma Process. 10 87

Google Scholar

Google Scholar

[32] Tanaka M, Yamamoto K, Tashiro S, Nakata K, Yamamoto E, Yamazaki K, Suzuki K, Murphy A B, Lowke J J 2010 J. Phys. D: Appl. Phys. 43 434009

Google Scholar

Google Scholar

[33] Schnick M, Füssel U, Hertel M, Spille-Kohoff A, Murphy A B 2010 J. Phys. D: Appl. Phys. 43 022001

Google Scholar

Google Scholar

[34] Wang X, Luo Y, Wu G, Chi L, Fan D 2018 Plasma Chem. Plasma Process. 38 1095

Google Scholar

Google Scholar

[35] 菅晓霞, 武传松 2016 金属学报 52 1467

Jian X X, Wu C S 2016 Acta Metall. Sin. 52 1467

[36] Savas A, Ceyhun V 2012 Comp. Mater. Sci. 51 53

[37] Wang L L, Lu F G, Wang H P, Murphy A B, Tang X H 2014 J. Phys. D: Appl. Phys. 47 465202

Google Scholar

Google Scholar

[38] Rao Z H, Liao S M, Tsai H L 2010 J. Appl. Phys. 107 044902

Google Scholar

Google Scholar

[39] Murphy A B 1994 Phys. Rev. Lett. 73 1797

Google Scholar

Google Scholar

[40] Murphy A B 1997 Phys. Rev. E 55 7473

[41] Murphy A B, Hiraoka K 2000 J. Phys. D: Appl. Phys. 33 2183

Google Scholar

Google Scholar

[42] Bitharas I, McPherson N A, McGhie W, Roy D, Moore A J 2018 J. Mater. Process. Tech. 255 451

Google Scholar

Google Scholar

[43] 黄勇, 陆肃中, 王新鑫, 李慧 2016 焊接学报 37 36

Huang Y, Lu S Z, Wang X X, Li H 2016 China Weld. Inst. 37 36

[44] Chen J, Xu H, Wei X, Lv H, Song Z, Chen Z 2017 Vacuum 145 77

Google Scholar

Google Scholar

[45] 杨郁, 唐成双, 赵一帆, 虞一青, 辛煜 2017 66 185202

Google Scholar

Google Scholar

Yang Y, Tang C S, Zhao Y F, Yu Y Q, Xin Y 2017 Acta Phys. Sin. 66 185202

Google Scholar

Google Scholar

[46] Murphy A B 1993 Phys. Rev. E 48 3594

Google Scholar

Google Scholar

[47] Murphy A B 1993 J. Chem. Phys. 99 1340

Google Scholar

Google Scholar

[48] 查普曼, 考林 著 (刘大有, 王伯懿 译) 1985 非均匀气体的数学理论 (第三版) (北京: 科学出版社) 第178−191, 343−344页

Chapman S, Cowling T G (translated by Liu D Y, Wang B Y 1970 The Mathematical Theory of Non-Uniform Gases (3rd ed.) (Beijing: Science Press) pp178−191, 343−344 (in Chinese)

[49] Murphy A B 1996 J. Phys. D: Appl. Phys. 29 1922

Google Scholar

Google Scholar

[50] Murphy A B 1998 J. Phys. D: Appl. Phys. 31 3383

Google Scholar

Google Scholar

[51] Murphy A B, Arundell C J 1994 Plasma Chem. Plasma Process. 14 451

Google Scholar

Google Scholar

[52] Cram L E 1985 J. Phys. D: Appl. Phys. 18 40

[53] Choquet I, Shirvan J A, Nilsson H 2012 J. Phys. D: Appl. Phys. 45 205203

Google Scholar

Google Scholar

[54] Tanaka M, Terasaki H, Ushio M, Lowke J J 2002 Metall. Mater. Trans. A 33 2043

Google Scholar

Google Scholar

[55] Wang X, Huang J, Huang Y, Fan D, Guo Y 2017 Appl. Therm. Eng. 113 27

Google Scholar

Google Scholar

[56] 陆善平, 董文超, 李殿中, 李依依 2009 58 94

Lu S, Dong W, Li D, Li Y 2009 Acta Phys. Sin. 58 94

[57] 黄勇, 王艳磊, 张治国 2014 光谱学与光谱分析 34 1168

Google Scholar

Google Scholar

Huang Y, Wang Y L, Zhang Z G 2014 Spectrsc. Spect. Anal. 34 1168

Google Scholar

Google Scholar

计量

- 文章访问数: 10754

- PDF下载量: 106

- 被引次数: 0

下载:

下载: