-

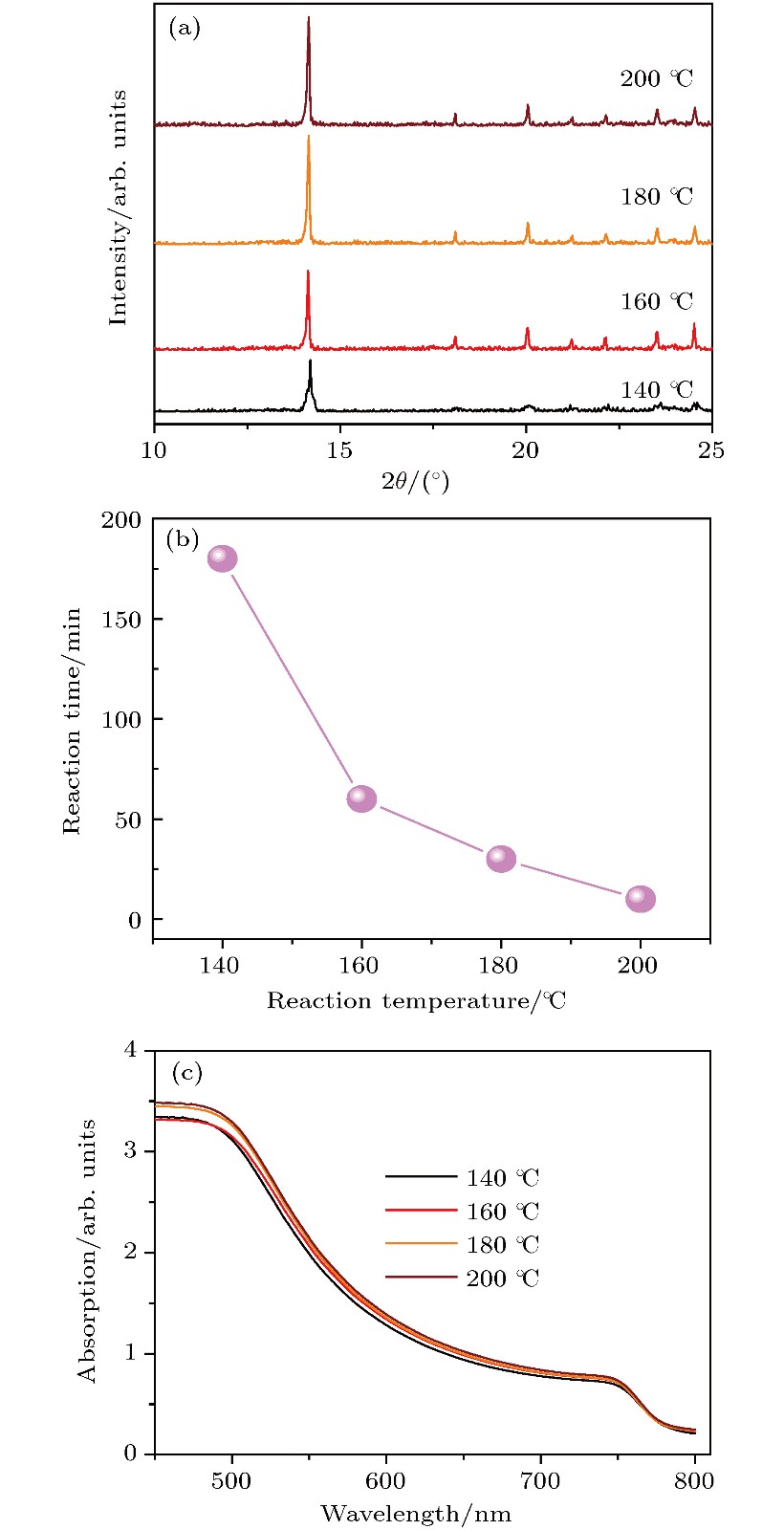

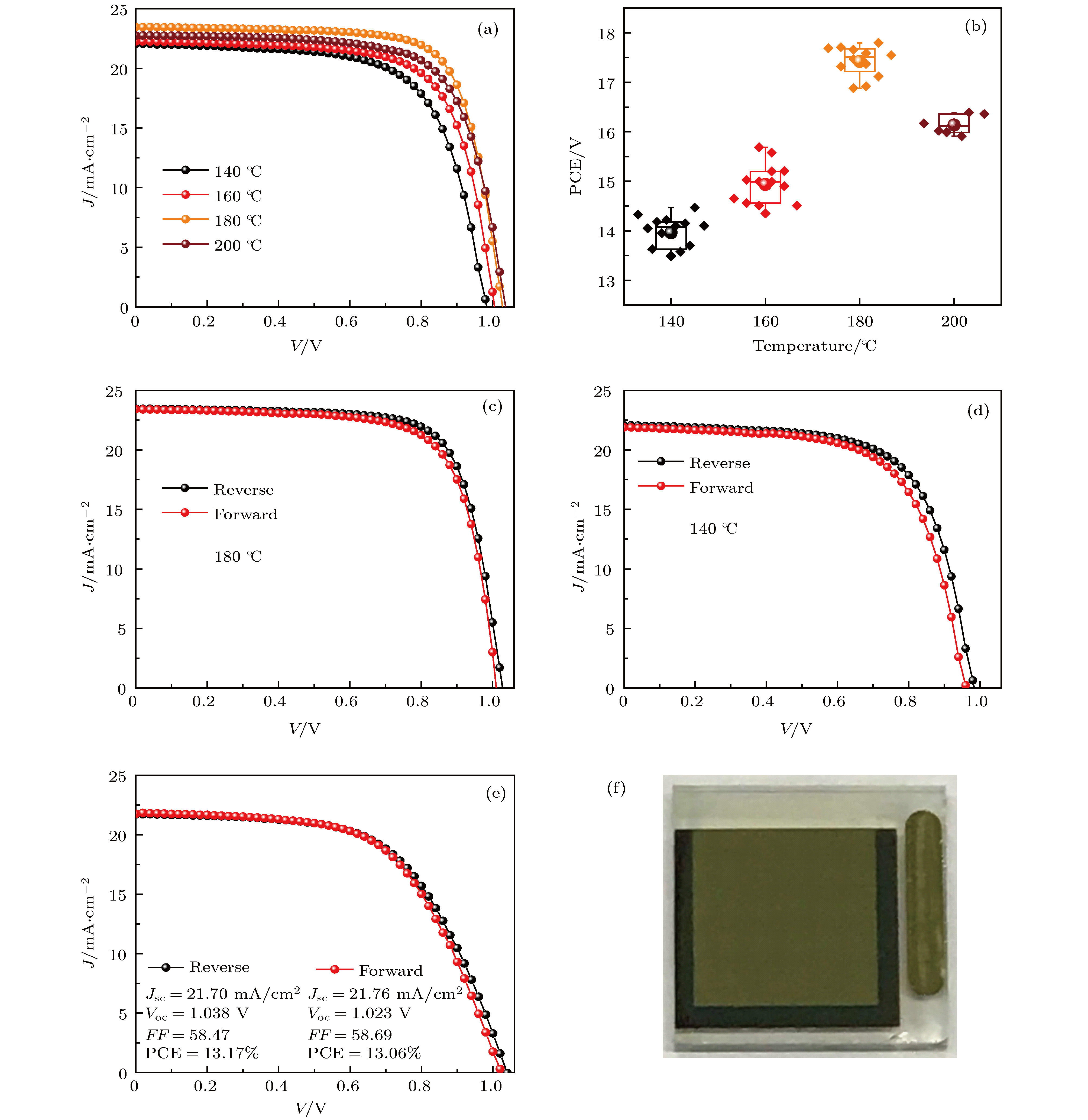

钙钛矿薄膜的气相制备是一种极具潜力的工业化生产工艺, 但薄膜的质量控制目前远落后于溶液制备法. 本文通过建立PbI2薄膜向钙钛矿薄膜完全转化过程中反应时间、晶粒尺寸与温度的关系, 实现了薄膜的质量优化及大面积钙钛矿薄膜的制备, 将薄膜的平均晶粒粒径从0.42

${\text{μm}}$ 优化到0.81${\text{μm}}$ . 基于空间电荷限制电流模型对缺陷密度的研究显示, 钙钛矿薄膜的缺陷密度由5.90 × 1016 cm–3降低到2.66 × 1016 cm–3. 光伏器件(FTO/TiO2/C60/MAPbI3/spiro-OMeTAD/Au结构)测试显示, 面积为0.045 cm2器件的平均光电转换效率从14.00%提升到17.42%, 最佳光电转换效率达到17.80%, 迟滞因子减小至4.04%. 同时, 基于180 ℃制备的1 cm2器件的光电转换效率达到13.17%.Organometal halide perovskite is one of the most promising materials for high efficient thin-film solar cell. Solution fabrication process shows that the recorded power conversion efficiency (PCE) is 23.7%, however, large scale fabrication suffers the inevitable toxic solvent, preventing it from implementing the green commercialization. As one of the matured large-scale fabrication techniques, the vapor deposition is recently found to promise the green fabrication of perovskite thin film without toxic solvent. However, the PCE based on vapor deposition is considerably lower than that based on solution fabrication because of ineffective regulation methods of the perovskite films. So, there is intensive requirement for optimizing the growth of perovskite in vapor deposition for improving PCE, especially, developing a kind of quality regulation method of the perovskite films. In this study, we provide a method of adjusting grain size in vapor deposition method. The grain size optimization of MAPbI3 films is realized by simply modulating the reaction temperature between PbI2 films and MAI vapor. We set the reaction temperature to be 140 ℃, 160 ℃, 180 ℃ and 200 ℃ separately and establish the relationship between reaction time and grain size during the complete conversion of PbI2 film into MAPbI3 film. We find that the average grain size of the film increases first with growth temperature increasing from 140 ℃ to 180 ℃ and then decrease at 200 ℃, giving an average grain size of 0.81 ${\text{μm}}$ and a largest grain size of about 2${\text{μm}}$ at 180 ℃. The defect density of perovskite film is deduced from the space charge limited current model, showing that it decreases from 5.90 × 1016 cm–3 at 140 ℃ to 2.66 × 1016 cm–3 at 180 ℃. Photovoltaic devices with structure FTO/TiO2/C60/MAPbI3/spiro-OMeTAD/Au are fabricated to demonstrate the performance. It is found that the devices with an active area of 0.045 cm2 show that with the increase of grain size, the average PCE increases from 14.00% to 17.42%, and the best device shows that its PCE is 17.80% with 4.04% hysteresis index. To show the possibility of scaling up, we fabricate a uniform perovskite thin film with an area of about 72 cm2, and a device with an active area of 1 cm2, which gives a PCE of 13.17% in reverse scan. In summary, our research provides a method of regulating the grain size for the vapor deposition, which can improve device performance by reducing the trap density in perovskite film for suppressing the carrier recombination in grain boundary. Meanwhile, we prepare high performance devices and large area thin films, showing their potential in large area device fabrication and applications.-

Keywords:

- perovskite solar cells /

- vapor deposition /

- grains size regulation /

- trap density

[1] Yin W J, Shi T, Yan Y 2014 Adv. Mater. 26 4653

Google Scholar

Google Scholar

[2] De Wolf S, Holovsky J, Moon S J, Loper P, Niesen B, Ledinsky M, Haug F J, Yum J H, Ballif C 2014 J. Phys. Chem. Lett. 5 1035

Google Scholar

Google Scholar

[3] Green M A, Ho-Baillie A, Snaith H J 2014 Nature Photon. 8 506

Google Scholar

Google Scholar

[4] Kojima A, Teshima K, Shirai Y, Miyasaka T 2009 J. Am. Chem. Soc. 131 6050

Google Scholar

Google Scholar

[5] Correa-Baena J P, Saliba M, Buonassisi T, Grätzel M, Abate A, Tress W, Hagfeldt A 2017 Sicence 358 739

Google Scholar

Google Scholar

[6] 吴存存, 孙伟海, 陈志坚, 肖立新 2017 科学通报 62 1457

Wu C C, Sun W H, Chen Z J, Xiao L X 2017 Chin. Sci. Bull. 62 1457

[7] 杨旭东, 陈汉, 毕恩兵, 韩礼元 2015 64 038404

Google Scholar

Google Scholar

Yang X D, Chen H, Bi E B, Han L Y 2015 Acta Phys. Sin. 64 038404

Google Scholar

Google Scholar

[8] 杨迎国, 阴广志, 冯尚蕾, 李萌, 季庚午, 宋飞, 文闻, 高兴宇 2017 66 018401

Google Scholar

Google Scholar

Yang Y G, Yin G Z, Feng S L, Li M, Ji G W, Song F, Wen W, Gao X Y 2017 Acta Phys. Sin. 66 018401

Google Scholar

Google Scholar

[9] Liu M, Johnston M B, Snaith H J 2013 Nature 501 395

Google Scholar

Google Scholar

[10] Chen Q, Zhou H P, Hong Z R, Luo S, Duan H S, Wang H H, Liu Y S, Li G, Yang Y 2014 J. Am. Chem. Soc. 136 622

Google Scholar

Google Scholar

[11] Hsiao S Y, Lin H L, Lee W H, Tsai W L, Chiang K M, Liao W Y, Zheng C, Wu R Z, Chen C Y, Lin H W 2016 Adv. Mater. 28 7013

Google Scholar

Google Scholar

[12] Chen C Y, Lin H Y, Chiang K M, Tsai W L, Huang Y C, Tsao C S, Lin H W 2017 Adv. Mater. 29 1605290

Google Scholar

Google Scholar

[13] Long M Z, Zhang T K, Liu M Z, Chen Z F, Wang C, Xie W G, Xie F Y, Chen J, Li G, Xu J B 2018 Adv. Mater. 30 1801562

Google Scholar

Google Scholar

[14] Tong G Q, Li H, Li G P, Zhang T, Li C D, Yu L W, Xu J, Jiang Y, Shi Y, Chen K J 2018 Nano Energy 48 536

Google Scholar

Google Scholar

[15] Zhu X J, Yang D, Yang R X, Yang B, Yang Z, Ren X D, Zhang J, Niu J Z, Feng J S, Liu S Z 2017 Nanoscale 9 12316

Google Scholar

Google Scholar

[16] Niu T Q, Lu J, Munir R, Li J B, Barrit D, Zhang X, Hu H L, Yang Z, Amassian A, Zhao K, Liu S Z 2018 Adv. Mater. 30 1706576

Google Scholar

Google Scholar

[17] Seok S I, Kim E K, Noh J H 2017 Science 356 1376

Google Scholar

Google Scholar

[18] Li X, Chen C C, Cai M, Hua X, Xie F, Liu X, Hua J, Long Y T, Tian H, Han L 2018 Adv. Energy Mater. 8 1800715

Google Scholar

Google Scholar

[19] Han Q, Bai Y, Liu J, Du K Z, Li T, Ji D, Zhou Y, Cao C, Shin D, Ding J, Franklin A D, Glass J T, Hu J, Therien M J, Liu J, Mitzi D B 2017 Energy Environ. Sci. 10 2365

Google Scholar

Google Scholar

[20] 王栋, 朱慧敏, 周忠敏, 王在伟, 吕思刘, 逄淑平, 崔光磊 2015 64 038403

Google Scholar

Google Scholar

Wang D, Zhu H M, Zhou Z M, Wang Z W, Lü S L, Pang S P, Cui G L 2015 Acta Phys. Sin. 64 038403

Google Scholar

Google Scholar

[21] 杜相, 陈思, 林东旭, 谢方艳, 陈建, 谢伟广, 刘彭义 2018 67 098801

Google Scholar

Google Scholar

Du X, Chen S, Lin D X, Xie F Y, Chen J, Xie W G, Liu P Y 2018 Acta Phys. Sin. 67 098801

Google Scholar

Google Scholar

[22] Tavakoli M M, Simchi A, Mo X, Fan Z 2017 Mater. Chem. Front. 1 1520

Google Scholar

Google Scholar

[23] Yue S Z, Liu K, Xu R, Li M C, Azam M, Ren K, Liu J, Sun Y, Wang Z J, Cao D W, Yan X H, Qu S C, Lei Y, Wang Z G 2017 Energy Environ. Sci. 10 2570

[24] Zhang T K, Long M Z, Qin M C, Lu X H, Chen S, Xie F Y, Gong L, Chen J, Chu M, Miao Q, Chen Z F, Xu W Y, Liu P Y, Xie W G, Xu J B 2018 Joule 2 1

Google Scholar

Google Scholar

[25] Zhang T K, Long M Z, Yan K Y, Qin M C, Lu X H, Zeng X L, Cheng C M, Wong K S, Liu P Y, Xie W G, Xu J B 2017 Adv. Energy Mater. 7 1700118

Google Scholar

Google Scholar

[26] Shao Y C, Fang Y J, Li T, Wang Q, Dong Q F, Deng Y H, Yuan Y B, Wei H T, Wang M Y, Gruverman A, Shield J, Huang J S 2016 Energy Environ. Sci. 9 1752

Google Scholar

Google Scholar

-

图 1 钙钛矿薄膜的气相制备流程及效果 (a)两步钙钛矿薄膜气相制备流程示意图; (b)PbI2与MAI气体反应示意图; (c)器件SEM截面图

Fig. 1. Vapor growth of perovskite film: (a) Schematic growth processes of two-step vapor growth of perovskite films; (b) reaction schematic between the PbI2 structure and the MAI molecule; (c) the cross-sectional morphology of the as-prepared device.

图 3 温度对钙钛矿薄膜形态的影响 (a)—(d)反应温度分别为140 ℃, 160 ℃, 180 ℃以及200 ℃时制备的钙钛矿的SEM形貌图(白色线段长度为1

${\text{μm}}$ ); (e)不同反应温度下的钙钛矿薄膜晶体粒径统计; (f)气相法制备面积约72 cm2的MAPbI3薄膜Fig. 3. Reaction temperature effect on the morphology of perovskite film: (a)–(d) SEM images of perovskite films with reaction temperature of (a) 140 ℃, (b) 160 ℃, (c) 180 ℃ and (d) 200 ℃ (the scale bars in the SEM images are 1

${\text{μm}}$ ); (e) statistics of grain size under different reaction temperature; (f) as prepared MAPbI3 film with area about 72 cm2.图 5 钙钛矿光伏器件性能 (a)标准光照下面积为0.045 cm2器件的J-V曲线; (b)多组器件效率的统计结果; (c)面积为0.045 cm2器件180 ℃下制备的器件回滞曲线; (d)面积为0.045 cm2器件140 ℃下制备的器件回滞曲线; (e)面积为1 cm2 器件180 ℃下制备的器件J-V曲线; (f) 1 cm2 器件的光学图片

Fig. 5. Device performance of perovskite photovoltaic devices: (a) 0.045 cm2 device reverse J-V curves under 1 Sun AM 1.5 G; (b) statistical distribution of PCE; reverse and forward J-V curves of devices (0.045 cm2) grown at (c) 180 ℃ and (d) 140 ℃; (e) reverse and forward J-V curves of device (1 cm2) grown at 180 ℃ and (f) corresponding optical image.

表 1 不同反应温度的器件具体性能参数以及统计值

Table 1. Characteristic parameters and statistical result of PSCs.

Sythesis temperature Jsc/mA·cm-2 Voc/V FF/% Champion PCE/% Average PCE/% 140 22.04 0.99 66.31 14.47 14.00 160 22.25 1 70.51 15.69 14.93 180 23.47 1.02 74.35 17.80 17.42 200 22.75 1.03 70.88 16.61 16.13 -

[1] Yin W J, Shi T, Yan Y 2014 Adv. Mater. 26 4653

Google Scholar

Google Scholar

[2] De Wolf S, Holovsky J, Moon S J, Loper P, Niesen B, Ledinsky M, Haug F J, Yum J H, Ballif C 2014 J. Phys. Chem. Lett. 5 1035

Google Scholar

Google Scholar

[3] Green M A, Ho-Baillie A, Snaith H J 2014 Nature Photon. 8 506

Google Scholar

Google Scholar

[4] Kojima A, Teshima K, Shirai Y, Miyasaka T 2009 J. Am. Chem. Soc. 131 6050

Google Scholar

Google Scholar

[5] Correa-Baena J P, Saliba M, Buonassisi T, Grätzel M, Abate A, Tress W, Hagfeldt A 2017 Sicence 358 739

Google Scholar

Google Scholar

[6] 吴存存, 孙伟海, 陈志坚, 肖立新 2017 科学通报 62 1457

Wu C C, Sun W H, Chen Z J, Xiao L X 2017 Chin. Sci. Bull. 62 1457

[7] 杨旭东, 陈汉, 毕恩兵, 韩礼元 2015 64 038404

Google Scholar

Google Scholar

Yang X D, Chen H, Bi E B, Han L Y 2015 Acta Phys. Sin. 64 038404

Google Scholar

Google Scholar

[8] 杨迎国, 阴广志, 冯尚蕾, 李萌, 季庚午, 宋飞, 文闻, 高兴宇 2017 66 018401

Google Scholar

Google Scholar

Yang Y G, Yin G Z, Feng S L, Li M, Ji G W, Song F, Wen W, Gao X Y 2017 Acta Phys. Sin. 66 018401

Google Scholar

Google Scholar

[9] Liu M, Johnston M B, Snaith H J 2013 Nature 501 395

Google Scholar

Google Scholar

[10] Chen Q, Zhou H P, Hong Z R, Luo S, Duan H S, Wang H H, Liu Y S, Li G, Yang Y 2014 J. Am. Chem. Soc. 136 622

Google Scholar

Google Scholar

[11] Hsiao S Y, Lin H L, Lee W H, Tsai W L, Chiang K M, Liao W Y, Zheng C, Wu R Z, Chen C Y, Lin H W 2016 Adv. Mater. 28 7013

Google Scholar

Google Scholar

[12] Chen C Y, Lin H Y, Chiang K M, Tsai W L, Huang Y C, Tsao C S, Lin H W 2017 Adv. Mater. 29 1605290

Google Scholar

Google Scholar

[13] Long M Z, Zhang T K, Liu M Z, Chen Z F, Wang C, Xie W G, Xie F Y, Chen J, Li G, Xu J B 2018 Adv. Mater. 30 1801562

Google Scholar

Google Scholar

[14] Tong G Q, Li H, Li G P, Zhang T, Li C D, Yu L W, Xu J, Jiang Y, Shi Y, Chen K J 2018 Nano Energy 48 536

Google Scholar

Google Scholar

[15] Zhu X J, Yang D, Yang R X, Yang B, Yang Z, Ren X D, Zhang J, Niu J Z, Feng J S, Liu S Z 2017 Nanoscale 9 12316

Google Scholar

Google Scholar

[16] Niu T Q, Lu J, Munir R, Li J B, Barrit D, Zhang X, Hu H L, Yang Z, Amassian A, Zhao K, Liu S Z 2018 Adv. Mater. 30 1706576

Google Scholar

Google Scholar

[17] Seok S I, Kim E K, Noh J H 2017 Science 356 1376

Google Scholar

Google Scholar

[18] Li X, Chen C C, Cai M, Hua X, Xie F, Liu X, Hua J, Long Y T, Tian H, Han L 2018 Adv. Energy Mater. 8 1800715

Google Scholar

Google Scholar

[19] Han Q, Bai Y, Liu J, Du K Z, Li T, Ji D, Zhou Y, Cao C, Shin D, Ding J, Franklin A D, Glass J T, Hu J, Therien M J, Liu J, Mitzi D B 2017 Energy Environ. Sci. 10 2365

Google Scholar

Google Scholar

[20] 王栋, 朱慧敏, 周忠敏, 王在伟, 吕思刘, 逄淑平, 崔光磊 2015 64 038403

Google Scholar

Google Scholar

Wang D, Zhu H M, Zhou Z M, Wang Z W, Lü S L, Pang S P, Cui G L 2015 Acta Phys. Sin. 64 038403

Google Scholar

Google Scholar

[21] 杜相, 陈思, 林东旭, 谢方艳, 陈建, 谢伟广, 刘彭义 2018 67 098801

Google Scholar

Google Scholar

Du X, Chen S, Lin D X, Xie F Y, Chen J, Xie W G, Liu P Y 2018 Acta Phys. Sin. 67 098801

Google Scholar

Google Scholar

[22] Tavakoli M M, Simchi A, Mo X, Fan Z 2017 Mater. Chem. Front. 1 1520

Google Scholar

Google Scholar

[23] Yue S Z, Liu K, Xu R, Li M C, Azam M, Ren K, Liu J, Sun Y, Wang Z J, Cao D W, Yan X H, Qu S C, Lei Y, Wang Z G 2017 Energy Environ. Sci. 10 2570

[24] Zhang T K, Long M Z, Qin M C, Lu X H, Chen S, Xie F Y, Gong L, Chen J, Chu M, Miao Q, Chen Z F, Xu W Y, Liu P Y, Xie W G, Xu J B 2018 Joule 2 1

Google Scholar

Google Scholar

[25] Zhang T K, Long M Z, Yan K Y, Qin M C, Lu X H, Zeng X L, Cheng C M, Wong K S, Liu P Y, Xie W G, Xu J B 2017 Adv. Energy Mater. 7 1700118

Google Scholar

Google Scholar

[26] Shao Y C, Fang Y J, Li T, Wang Q, Dong Q F, Deng Y H, Yuan Y B, Wei H T, Wang M Y, Gruverman A, Shield J, Huang J S 2016 Energy Environ. Sci. 9 1752

Google Scholar

Google Scholar

计量

- 文章访问数: 14518

- PDF下载量: 187

- 被引次数: 0

下载:

下载: