-

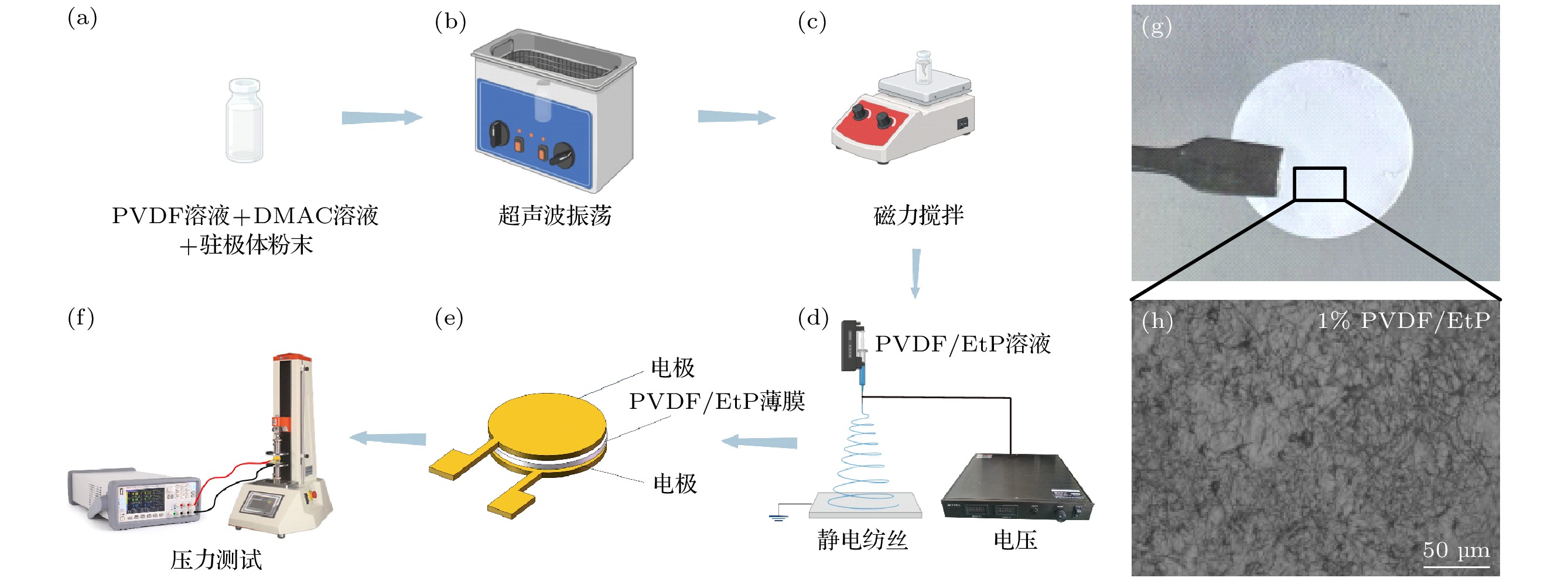

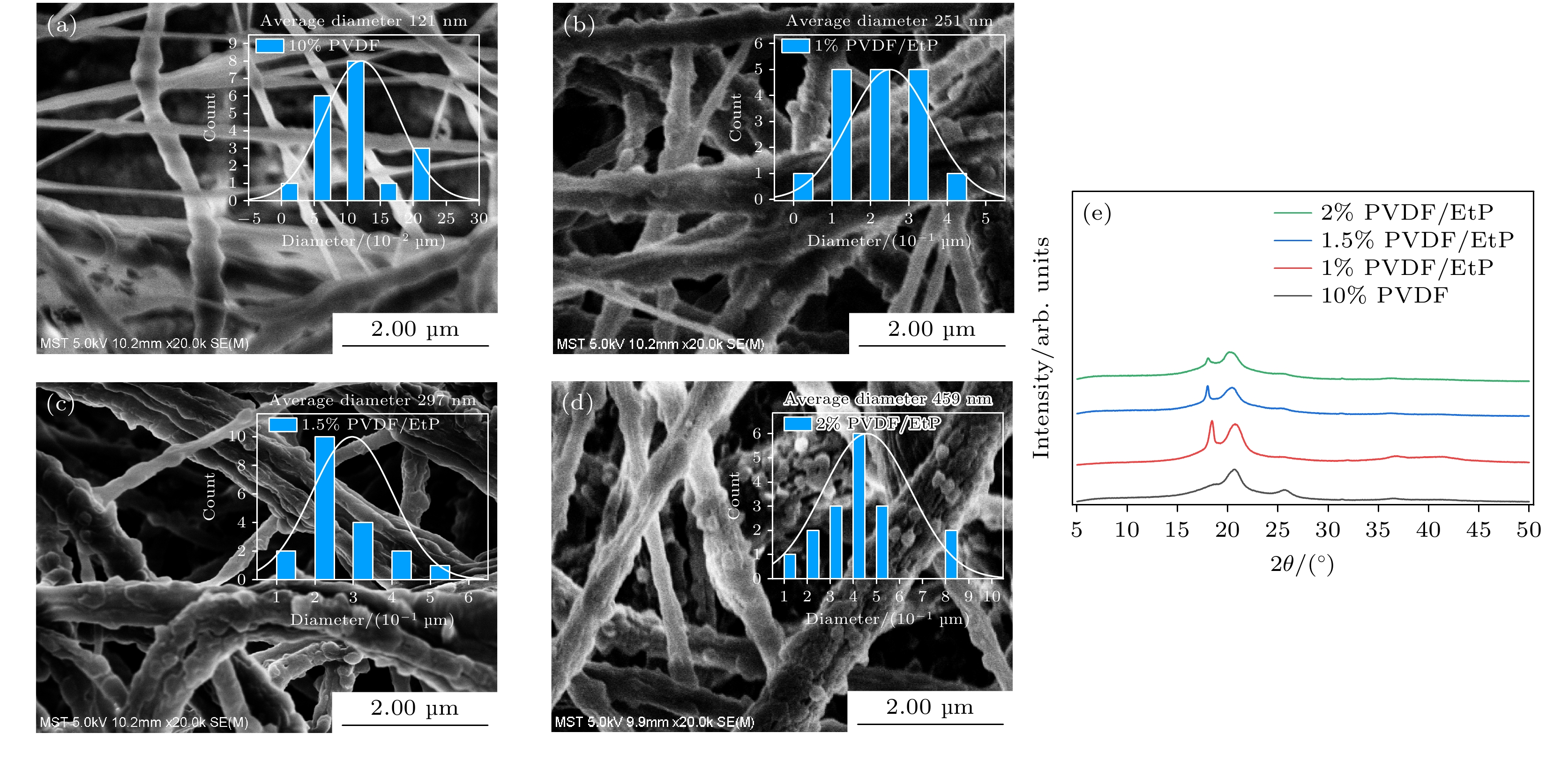

近年来, 聚偏氟乙烯(PVDF)基纳米纤维膜由于其优异的压电性能, 成为了传感器、能量采集器等应用中的重要材料. 然而, PVDF膜的压电性能仍受限于其本身的结构和材料特性, 因此, 本文研究了填料掺杂驻极体纳米颗粒(EtP)对PVDF纳米纤维膜性能的影响. 实验采用静电纺丝技术, 将不同浓度的填料掺杂到PVDF纳米纤维膜中, 发现适量的填料掺杂可以显著提高膜的压电性能. 此外, 填料的加入提高了PVDF纳米纤维膜电输出性能的稳定性. 实验结果表明, 在PVDF溶液中添加不同质量分数的填料, 例如质量分数为1%, 1.5%和2%的驻极体颗粒, 并通过静电纺丝制备纳米复合纳米纤维膜, 可以显著提高其在20 N测试压力下的电输出性能. 此外, 增加膜面积和施加的压力可以进一步提高它们的电输出性能. 本文还提出了一种高效的信号处理方法, 通过FIR数字低通滤波去除高频噪声、平滑先验法消除基线漂移, 并改进AMPD算法精确检测压电信号中的主波峰位置与特性, 从而提高信号的稳定性与特征提取准确性. 结合本文实验, 填料掺杂和静电纺丝技术的结合为提高PVDF纳米纤维膜的性能提供了一种简单有效的方法, 为其在各个领域的应用提供了新的可能性和广阔的前景.In recent years, polyvinylidene fluoride (PVDF)-based nanofiber membranes, as key materials for applications in sensors, energy harvesters, and flexible electronics, have received significant attention due to their excellent piezoelectric properties. However, the research on the piezoelectric performance of PVDF membranes is still limited because of their intrinsic structure and material characteristics. Therefore, in this work, the effects of filler doping on the properties of PVDF nanofiber membranes are investigated to enhance their piezoelectric performance and stability. Using electrospinning technology, electret particles are incorporated into PVDF nanofiber membranes at different concentrations (e.g. 1%, 1.5%, and 2%). Characterization tests of the composite nanofiber membranes, such as scanning electron microscopy (SEM) and X-ray diffraction (XRD), reveal that the doping of electret particles can increase the average fiber diameter and enhance the β-phase content. In the piezoelectric performance tests, the piezoelectric sensors made of nanofiber membranes doped with electric particles show significant improvement in electrical output at a test pressure of 20 N. Furthermore, increasing the membrane area and using higher pressure can further enhance the electrical output. These results show that the piezoelectric properties of PVDF membranes can be effectively improved by appropriately doping electric particles. Stability tests carried out three months after sensor was fabricated shows that the electrical output stability of the piezoelectric sensors containing electric particles has been significantly improved. Additionally, an efficient signal processing method is proposed, with an FIR digital low-pass filter used to remove high-frequency noise. This method is not only a smoothing prior method to eliminate baseline drift, but also an improved AMPD algorithm to accurately detect the peak position and features of the piezoelectric signal. This method can significantly enhance the stability and accuracy of signal feature extraction. All in all, this study presents a simple and effective approach to improving the piezoelectric performance and electrical output stability of PVDF nanofiber membranes through the combination of filler doping and electrospinning technology. This method not only optimizes the performance of PVDF-based composites but also provides new insights into and technical support for their broad applications in energy collection, smart sensors, flexible electronic devices, and other fields.

-

Keywords:

- electrospinning /

- electret particles /

- PVDF nanofiber membranes /

- signal processing

[1] Rasoolzadeh M, Sherafat Z, Vahedi M, Bagherzadeh E 2022 J. Alloys Compd. 917 165505

Google Scholar

Google Scholar

[2] Zhang D D, Zhang X L, Li X J, Wang H P, Sang X D, Zhu G D, Yeung Y H 2022 Eur. Polym. J 166 0014

Google Scholar

Google Scholar

[3] Fu G M, Shi Q S, Liang Y R, He Y Q, Xue R, He S F, Chen Y J 2022 Polyme 254 125087

Google Scholar

Google Scholar

[4] Liang H, Zhang L, Wu T, Song H, Tang C 2022 Nanomaterials 13 102

Google Scholar

Google Scholar

[5] Mirjalali S, Mahdavi A, Abrishami S, Bagherzadeh R, Asadnia M, Huang S 2023 Macromol. Mater. Eng. 308 2200442

Google Scholar

Google Scholar

[6] Zhang M H, Hu K, Meng Q Y, Lan Z Y, Shi S T, Sun Q F, Zhou L, Shen X P 2023 Mater. Opt. Electron 11 4766

Google Scholar

Google Scholar

[7] Leung C M, Chen X, Wang T, Tang Y, Duan Z, Zhao X, Zhou H, Wang F 2022 Mater. 15 1769

Google Scholar

Google Scholar

[8] Tiwari S, Dubey D K, Prakash O, Das S, Maiti P 2023 Energy 275 127492

Google Scholar

Google Scholar

[9] Chen G, Chen G, Pan L, Chen D 2022 Diam. Relat. Mater 129 109358

Google Scholar

Google Scholar

[10] Chen L, Xiao W Q, Yan L, Wu T, Qiu Y S, Lin H L, Bian J, Lu Y 2018 J. Funct. Mater. 49 6064

Google Scholar

Google Scholar

[11] Revathi S, Kennedy L J, Basha S K, Padmanabhan R 2018 J. Nanosci. Nanotechnol. 18 4953

Google Scholar

Google Scholar

[12] Xu J, Yu T, Han D, Guan X L, Lei X P 2019 J. Wuhan Univ. Technol. Mater. Sci. Ed. 34 1279

Google Scholar

Google Scholar

[13] Gregorio Jr R 2006 J. Appl. Polym. Sci. 100 3272

Google Scholar

Google Scholar

[14] Tashiro K 1995 Plast. Eng. 28 63

[15] Mahanty B, Ghosh S K, Lee D W 2023 Nano 24 100421

Google Scholar

Google Scholar

[16] Furukawa T 1989 Phase Transit. 18 143

Google Scholar

Google Scholar

[17] Ramasundaram S, Yoon S, Kim K J, Lee J S 2008 Macromol. Chem. Phys. 209 2516

Google Scholar

Google Scholar

[18] Constantino C J L, Job A E, Simoes R D, Giacometti J A, Zucolotto V, Oliveira O N, Gozzi G, Chinaglia D L 2005 Appl Spectrosc. 59 275

Google Scholar

Google Scholar

[19] He S, Xin B J, Chen Z M, Liu Y 2018 Cellulose 25 3691

Google Scholar

Google Scholar

[20] Gao Q, Cao C, Ao J P, Bi J L, Yao L Y, Guo J J, Sun G Z, Liu W, Zhang Y, Liu F F, Li W 2021 Appl. Surf. Sci. 578 152063

Google Scholar

Google Scholar

[21] Nunes J S, Sencadas V, Wu A, Kholkin A L, Vilarinho P M, Lanceros-Méndez S 2006 MRS Online proc. Libr. 949 0949

Google Scholar

Google Scholar

[22] Chen X, Han M, Chen H, Cheng X, Song Y, Su Z, Jiang Y, Zhang H 2017 Nanoscale 9 1263

Google Scholar

Google Scholar

[23] Kim Y, Wu X, Lee C, Oh J H 2021 ACS Appl. Mater. Interfaces 13 36967

Google Scholar

Google Scholar

[24] 郭欣格 2018 硕士学位论文 (南京: 东南大学)

Guo X G 2018 M. S. Thesis (Nanjing: Southeast University

[25] Wang X Y, Zuo J L, Jiang T L, Xiao J X, Tong J, Huang S Q, Zhang W H 2024 Engergies. 17 3886

Google Scholar

Google Scholar

[26] Kulkarni N D, Kumari P 2023 Mater. Res. Bull. 157 112039

Google Scholar

Google Scholar

[27] Kwon H, Yoo Y W, Park Y, Nam U H, Byon E 2023 J. Asian Ceram. Soc. 11 282

Google Scholar

Google Scholar

[28] Kim M S, Lee D S, Park E C, Jeong S J, Song J S 2007 J. Eur. Ceram. Soc. 27 13

Google Scholar

Google Scholar

[29] Haily E, Bih L, Bouari A E, Lahmar A, Elmarssi M, Manoun B 2020 Mater. Chem. Phys. 241 122434

Google Scholar

Google Scholar

[30] Song G L, Chen L, Xing L Y, Zhang K, Wu Z Y, Yang H G, Zhang N 2021 Physica B 621 413308

Google Scholar

Google Scholar

[31] Wang Q P, Jiang S L, Zhang Y Y, Zhang G Z, Xiong L Y 2011 J. Mater. Sci-Mater. El. 22 849

Google Scholar

Google Scholar

-

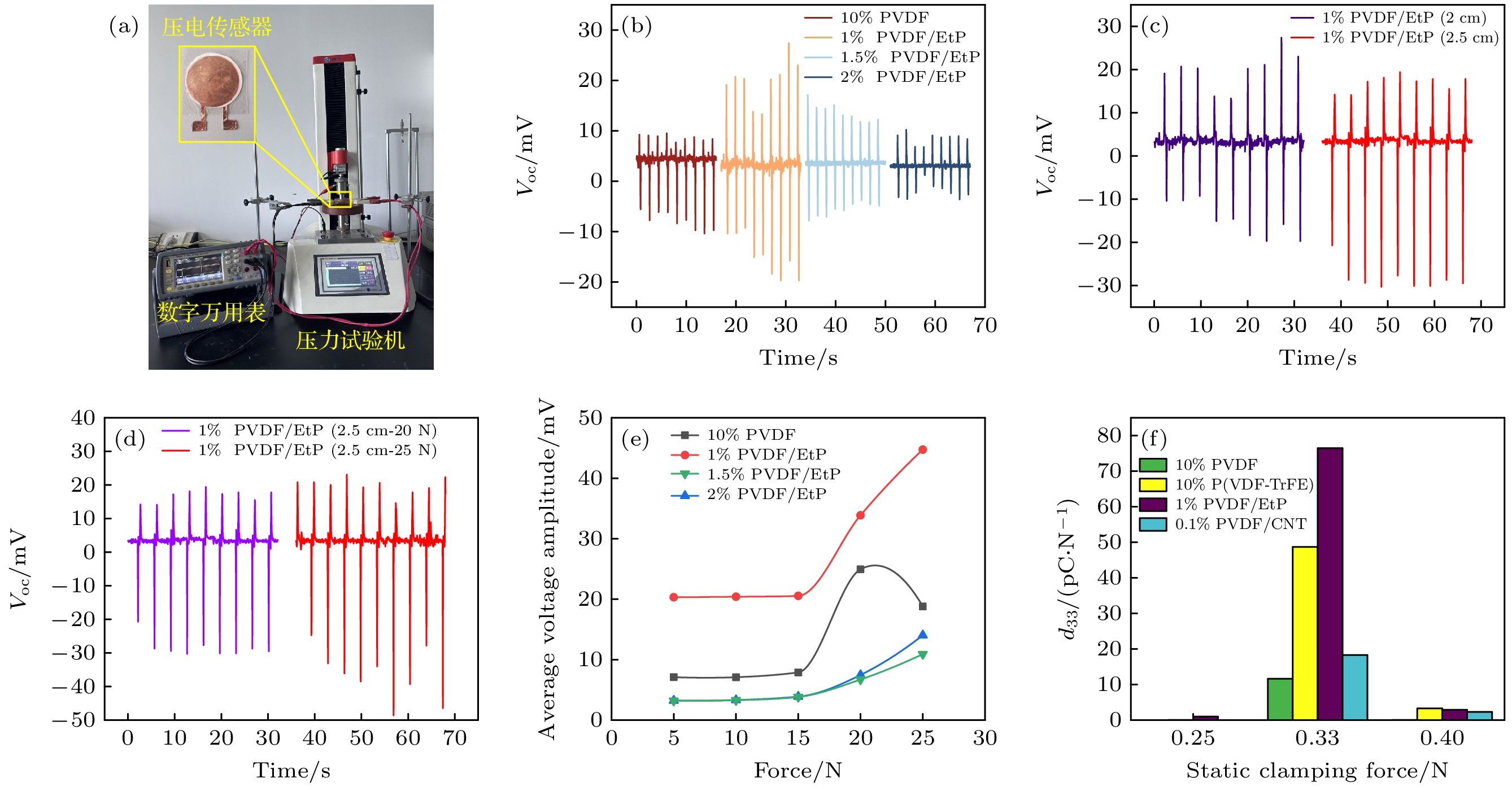

图 5 (a) 压电传感器的测试系统和传感器样品; (b) 不同PVDF/EtP浓度传感器的输出电压测试; (c) 输出电压与传感器尺寸之间的关系; (d) 输出电压与施加力之间的关系; (e) 制备传感器在不同施加力下的平均输出电压幅度; (f)压电系数测试

Fig. 5. (a) Testing system of the piezoelectric sensors and a sensor sample; (b) the output voltage testing of the sensors with various PVDF/EtP concentration; (c) relationship between the output voltage and the sensor size; (d) relationship between the output voltage and the applied force; (e) the average output voltage magnitude of fabricated sensors under different force; (f) piezoelectric coefficient test.

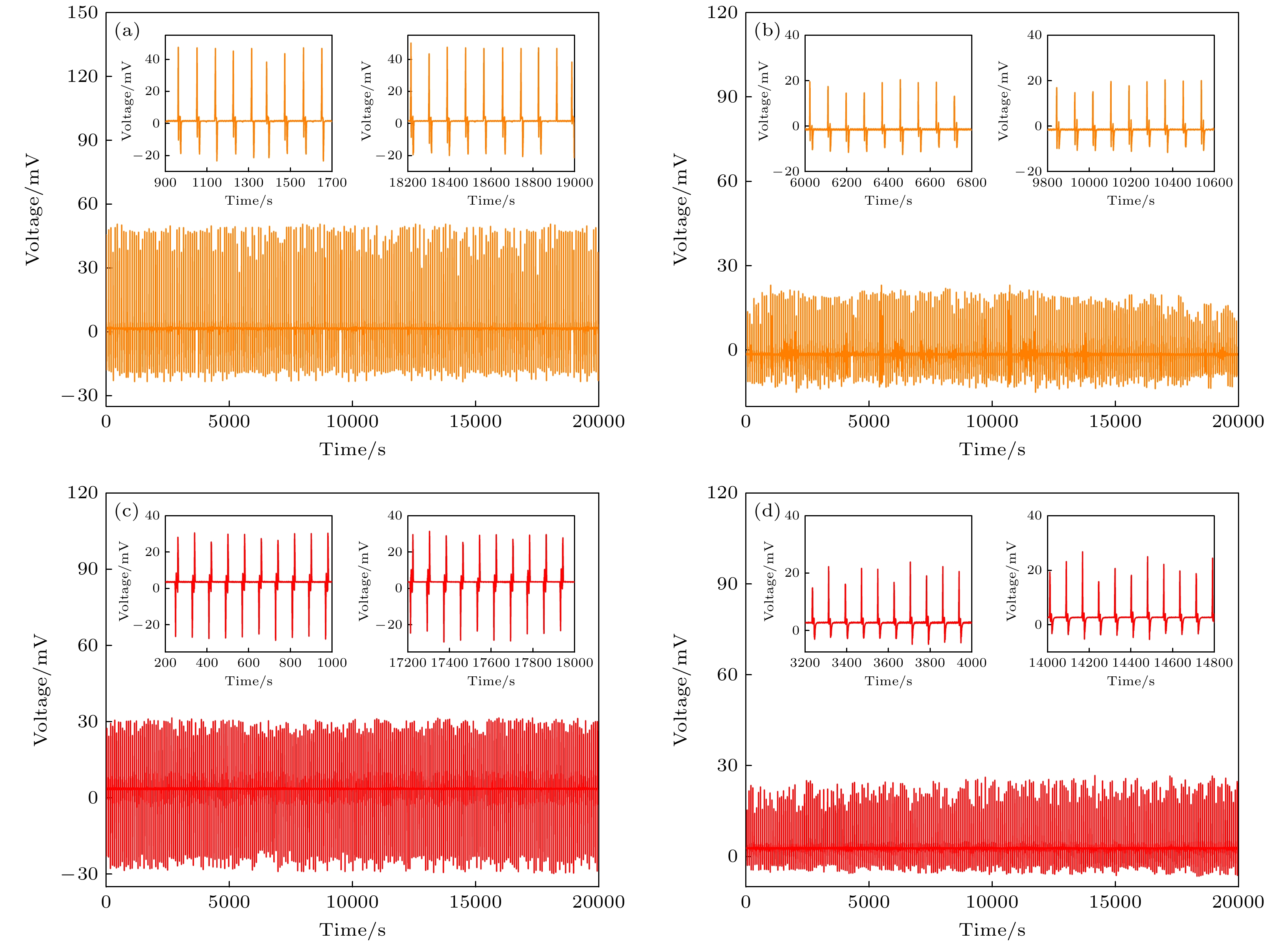

图 6 传感器在20000次振动循环下的长期稳定性, 插图显示了不同循环周期下的信号, 新制备传感器的重复性测试 (a) 1% PVDF/EtP; (b) 10% PVDF. 制备3个月后传感器的重复性测试 (c) 1% PVDF/EtP; (d) 10% PVDF

Fig. 6. The long-term stability of the sensor under 20000 vibration cycles is shown in the illustration, which displays the signals at different cycle periods, repeatability testing of newly fabricated sensors: (a) 1% PVDF/EtP; (b) 10% PVDF. Repeatability testing of sensors fabricated three months before: (a) 1% PVDF/EtP; (b) 10% PVDF.

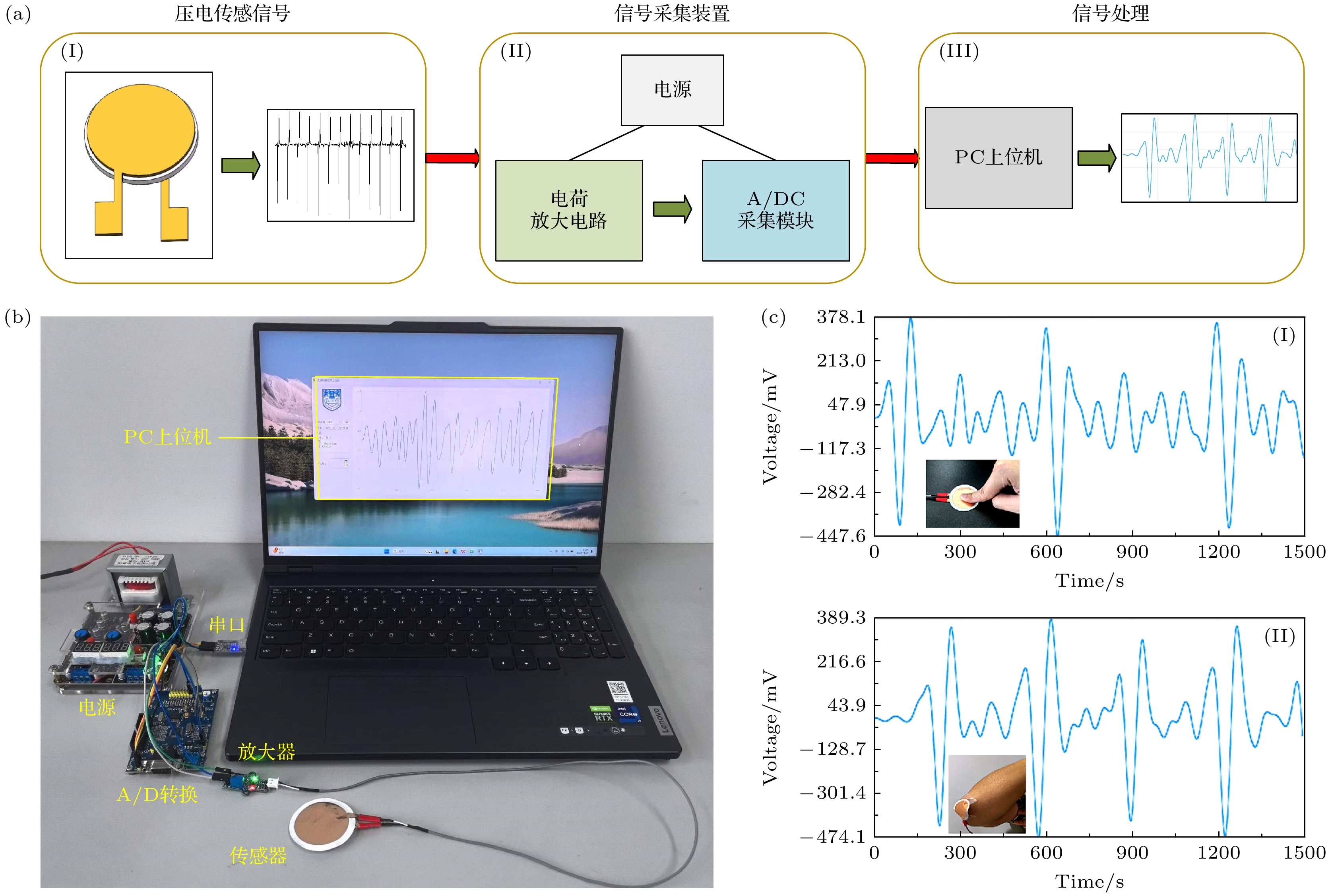

图 7 (a) 基于PVDF/EtP纳米纤维压电传感器的系统工作流程; (b) 硬件系统照片; (c) 基于PVDF/EtP纳米纤维的压电传感器用于检测, 其中(I)为手指按压; (II)为肘部弯曲

Fig. 7. (a) System workflow based on PVDF/EtP nanofiber piezoelectric sensor; (b) hardware system photos; (c) a piezoelectric sensor based on PVDF/EtP nanofibers is used for detecting, where (I) represents finger pressure; (II) represents bend the elbow.

-

[1] Rasoolzadeh M, Sherafat Z, Vahedi M, Bagherzadeh E 2022 J. Alloys Compd. 917 165505

Google Scholar

Google Scholar

[2] Zhang D D, Zhang X L, Li X J, Wang H P, Sang X D, Zhu G D, Yeung Y H 2022 Eur. Polym. J 166 0014

Google Scholar

Google Scholar

[3] Fu G M, Shi Q S, Liang Y R, He Y Q, Xue R, He S F, Chen Y J 2022 Polyme 254 125087

Google Scholar

Google Scholar

[4] Liang H, Zhang L, Wu T, Song H, Tang C 2022 Nanomaterials 13 102

Google Scholar

Google Scholar

[5] Mirjalali S, Mahdavi A, Abrishami S, Bagherzadeh R, Asadnia M, Huang S 2023 Macromol. Mater. Eng. 308 2200442

Google Scholar

Google Scholar

[6] Zhang M H, Hu K, Meng Q Y, Lan Z Y, Shi S T, Sun Q F, Zhou L, Shen X P 2023 Mater. Opt. Electron 11 4766

Google Scholar

Google Scholar

[7] Leung C M, Chen X, Wang T, Tang Y, Duan Z, Zhao X, Zhou H, Wang F 2022 Mater. 15 1769

Google Scholar

Google Scholar

[8] Tiwari S, Dubey D K, Prakash O, Das S, Maiti P 2023 Energy 275 127492

Google Scholar

Google Scholar

[9] Chen G, Chen G, Pan L, Chen D 2022 Diam. Relat. Mater 129 109358

Google Scholar

Google Scholar

[10] Chen L, Xiao W Q, Yan L, Wu T, Qiu Y S, Lin H L, Bian J, Lu Y 2018 J. Funct. Mater. 49 6064

Google Scholar

Google Scholar

[11] Revathi S, Kennedy L J, Basha S K, Padmanabhan R 2018 J. Nanosci. Nanotechnol. 18 4953

Google Scholar

Google Scholar

[12] Xu J, Yu T, Han D, Guan X L, Lei X P 2019 J. Wuhan Univ. Technol. Mater. Sci. Ed. 34 1279

Google Scholar

Google Scholar

[13] Gregorio Jr R 2006 J. Appl. Polym. Sci. 100 3272

Google Scholar

Google Scholar

[14] Tashiro K 1995 Plast. Eng. 28 63

[15] Mahanty B, Ghosh S K, Lee D W 2023 Nano 24 100421

Google Scholar

Google Scholar

[16] Furukawa T 1989 Phase Transit. 18 143

Google Scholar

Google Scholar

[17] Ramasundaram S, Yoon S, Kim K J, Lee J S 2008 Macromol. Chem. Phys. 209 2516

Google Scholar

Google Scholar

[18] Constantino C J L, Job A E, Simoes R D, Giacometti J A, Zucolotto V, Oliveira O N, Gozzi G, Chinaglia D L 2005 Appl Spectrosc. 59 275

Google Scholar

Google Scholar

[19] He S, Xin B J, Chen Z M, Liu Y 2018 Cellulose 25 3691

Google Scholar

Google Scholar

[20] Gao Q, Cao C, Ao J P, Bi J L, Yao L Y, Guo J J, Sun G Z, Liu W, Zhang Y, Liu F F, Li W 2021 Appl. Surf. Sci. 578 152063

Google Scholar

Google Scholar

[21] Nunes J S, Sencadas V, Wu A, Kholkin A L, Vilarinho P M, Lanceros-Méndez S 2006 MRS Online proc. Libr. 949 0949

Google Scholar

Google Scholar

[22] Chen X, Han M, Chen H, Cheng X, Song Y, Su Z, Jiang Y, Zhang H 2017 Nanoscale 9 1263

Google Scholar

Google Scholar

[23] Kim Y, Wu X, Lee C, Oh J H 2021 ACS Appl. Mater. Interfaces 13 36967

Google Scholar

Google Scholar

[24] 郭欣格 2018 硕士学位论文 (南京: 东南大学)

Guo X G 2018 M. S. Thesis (Nanjing: Southeast University

[25] Wang X Y, Zuo J L, Jiang T L, Xiao J X, Tong J, Huang S Q, Zhang W H 2024 Engergies. 17 3886

Google Scholar

Google Scholar

[26] Kulkarni N D, Kumari P 2023 Mater. Res. Bull. 157 112039

Google Scholar

Google Scholar

[27] Kwon H, Yoo Y W, Park Y, Nam U H, Byon E 2023 J. Asian Ceram. Soc. 11 282

Google Scholar

Google Scholar

[28] Kim M S, Lee D S, Park E C, Jeong S J, Song J S 2007 J. Eur. Ceram. Soc. 27 13

Google Scholar

Google Scholar

[29] Haily E, Bih L, Bouari A E, Lahmar A, Elmarssi M, Manoun B 2020 Mater. Chem. Phys. 241 122434

Google Scholar

Google Scholar

[30] Song G L, Chen L, Xing L Y, Zhang K, Wu Z Y, Yang H G, Zhang N 2021 Physica B 621 413308

Google Scholar

Google Scholar

[31] Wang Q P, Jiang S L, Zhang Y Y, Zhang G Z, Xiong L Y 2011 J. Mater. Sci-Mater. El. 22 849

Google Scholar

Google Scholar

计量

- 文章访问数: 4648

- PDF下载量: 123

- 被引次数: 0

下载:

下载: