-

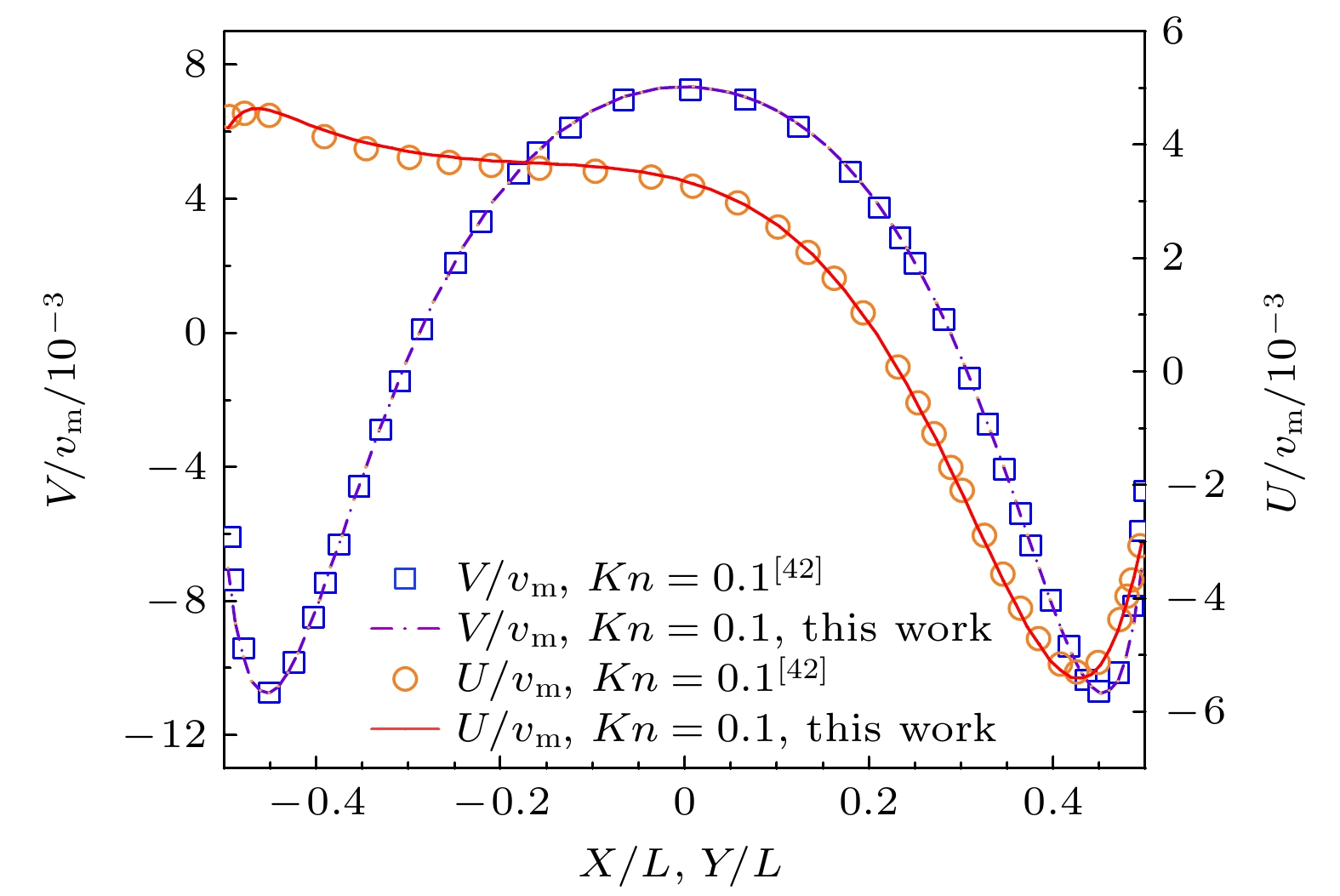

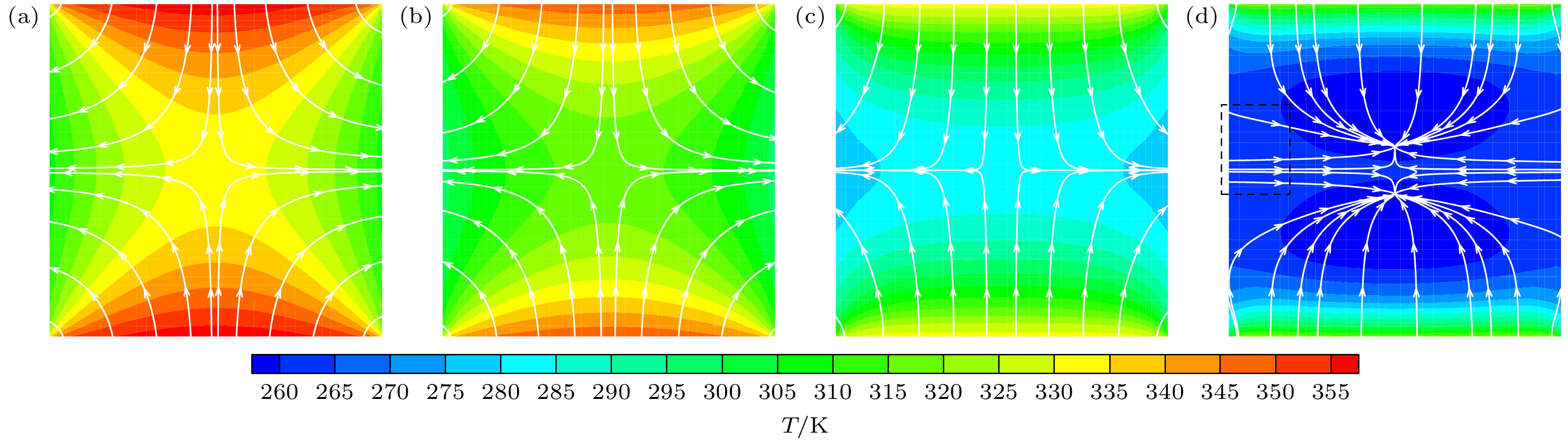

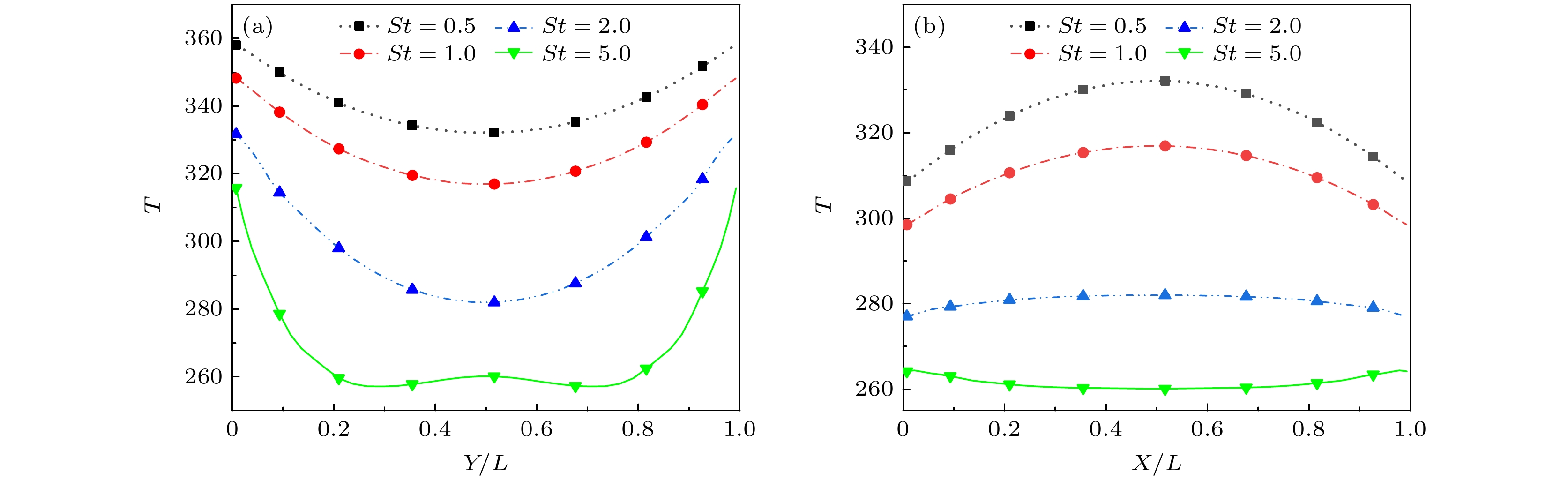

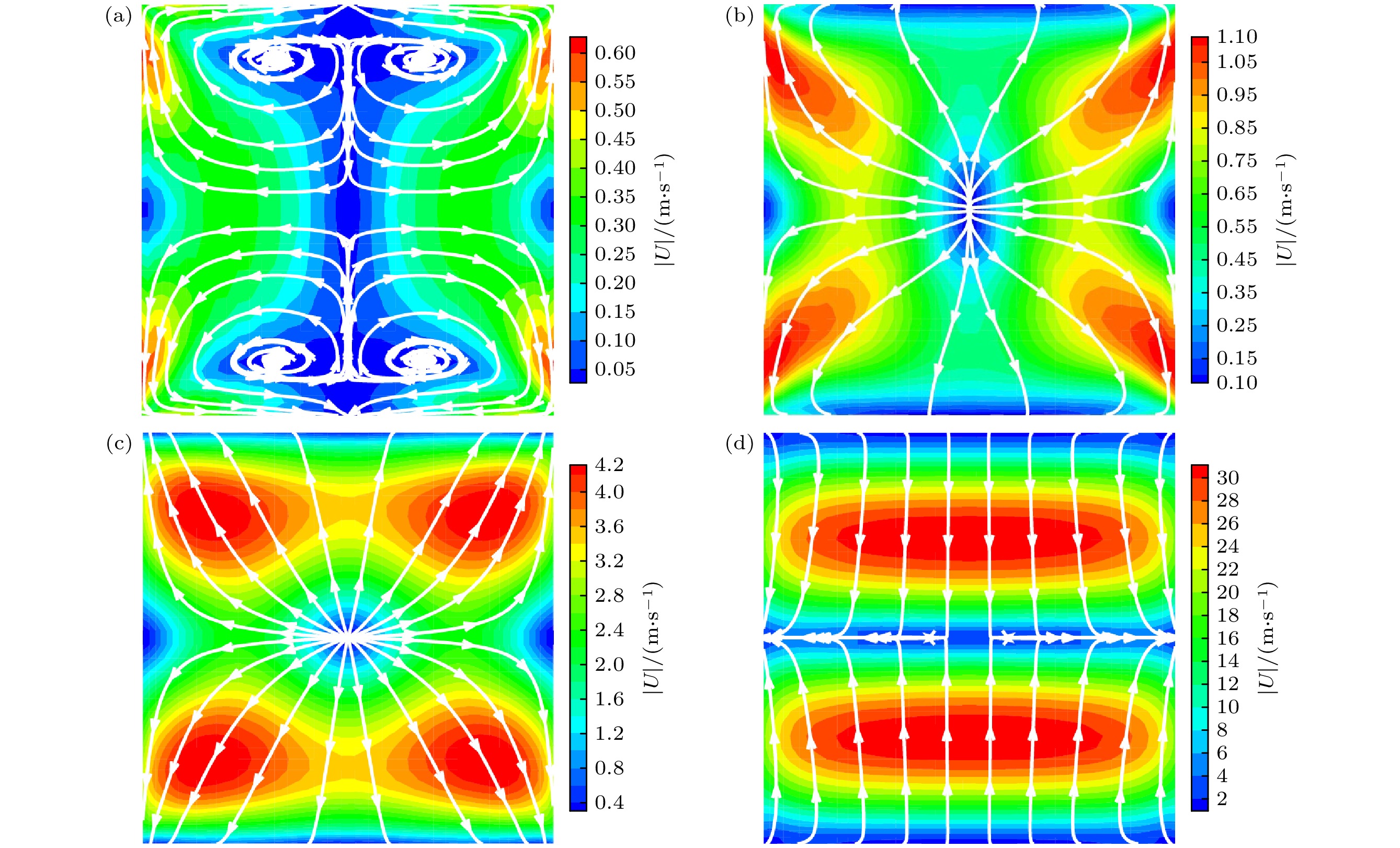

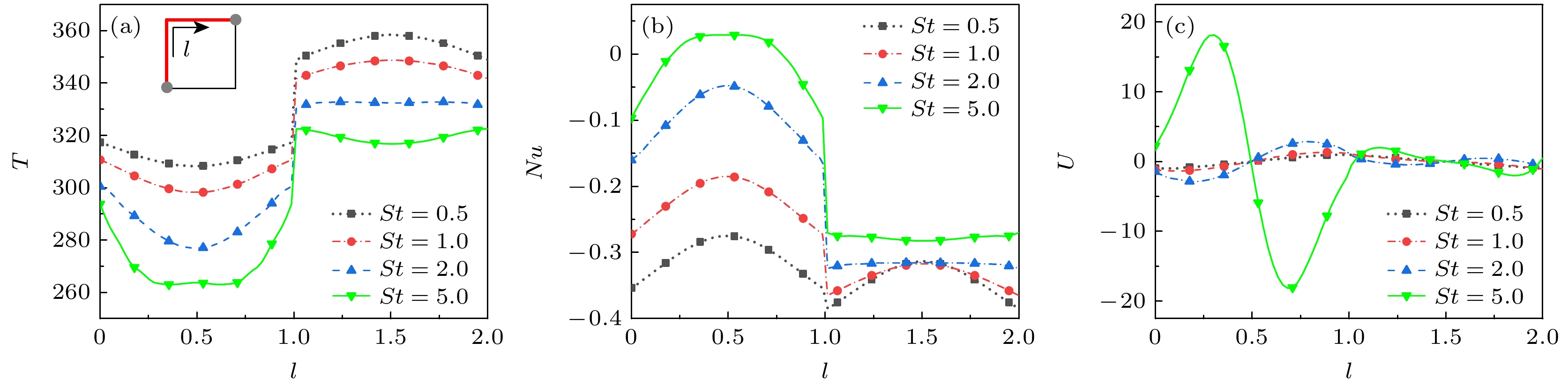

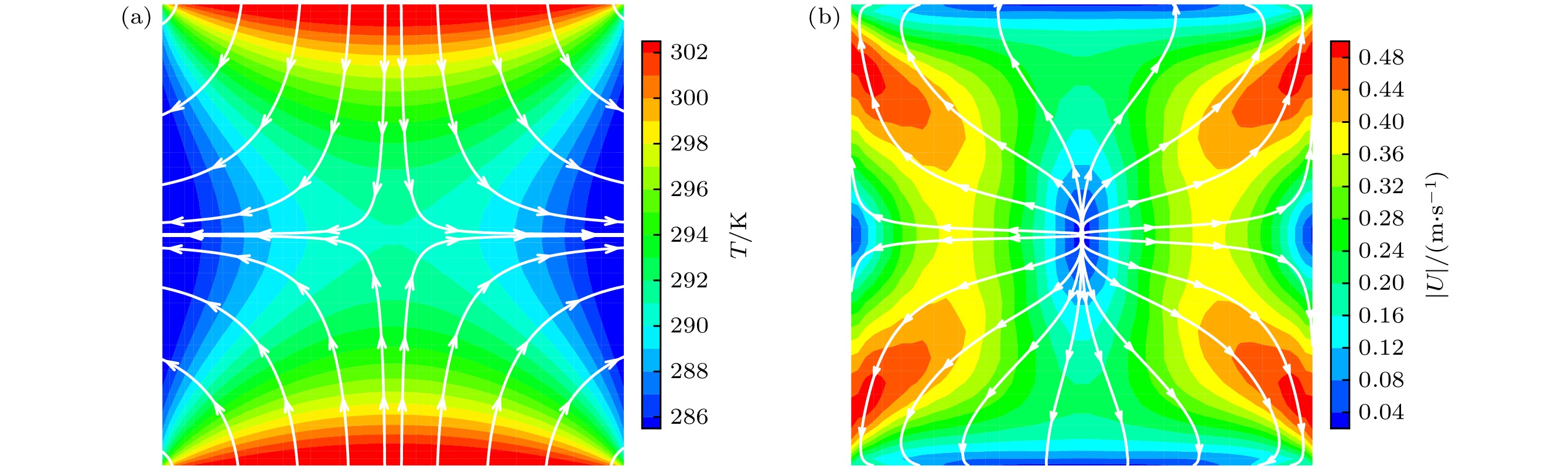

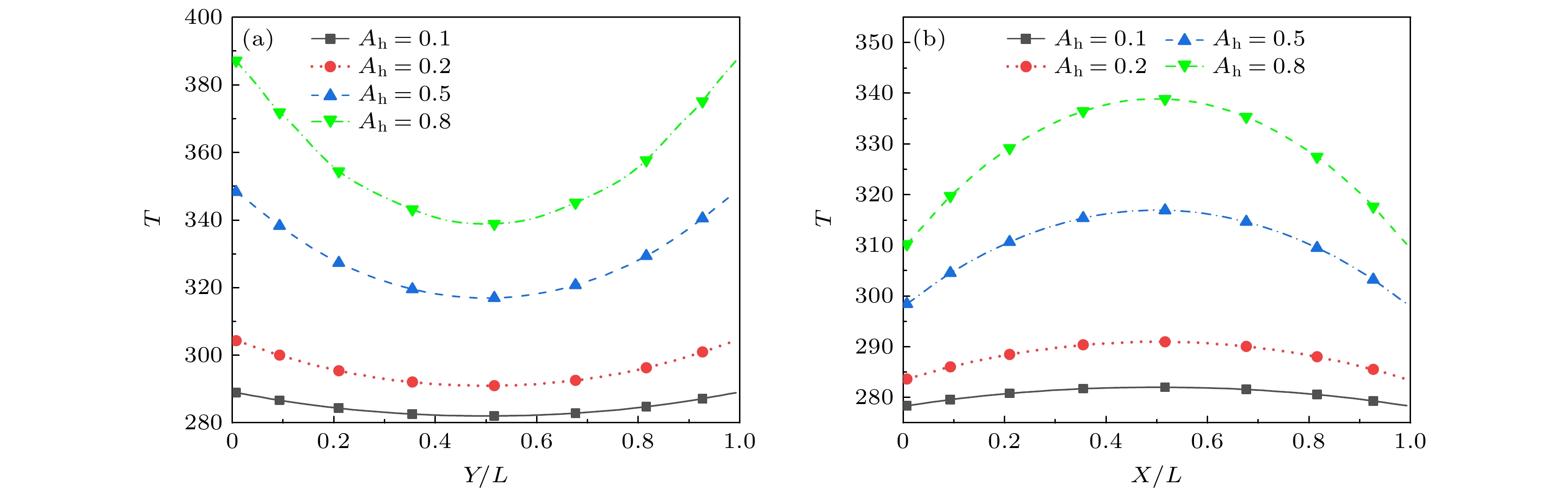

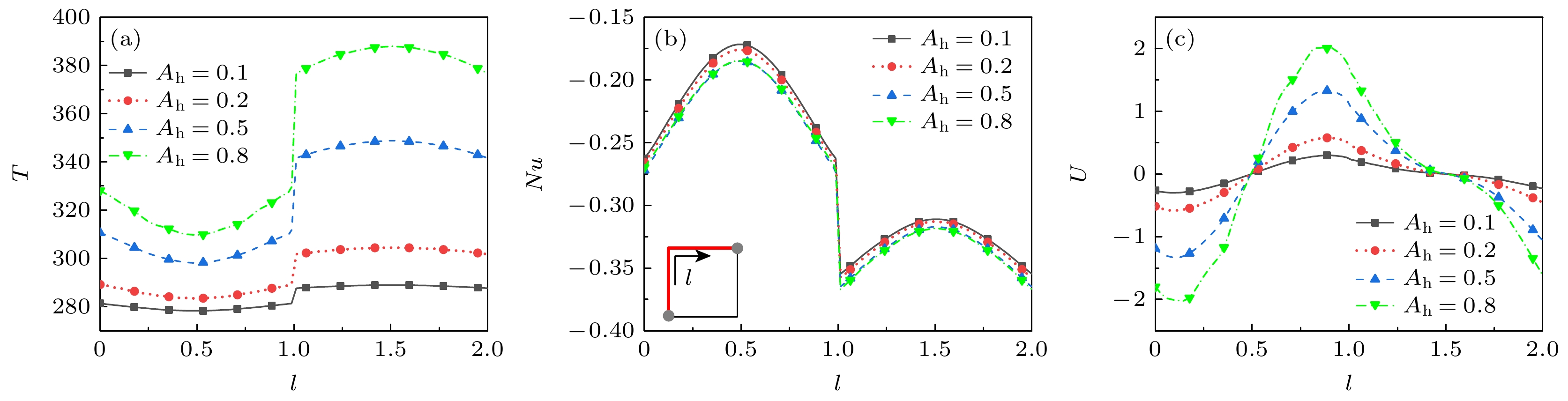

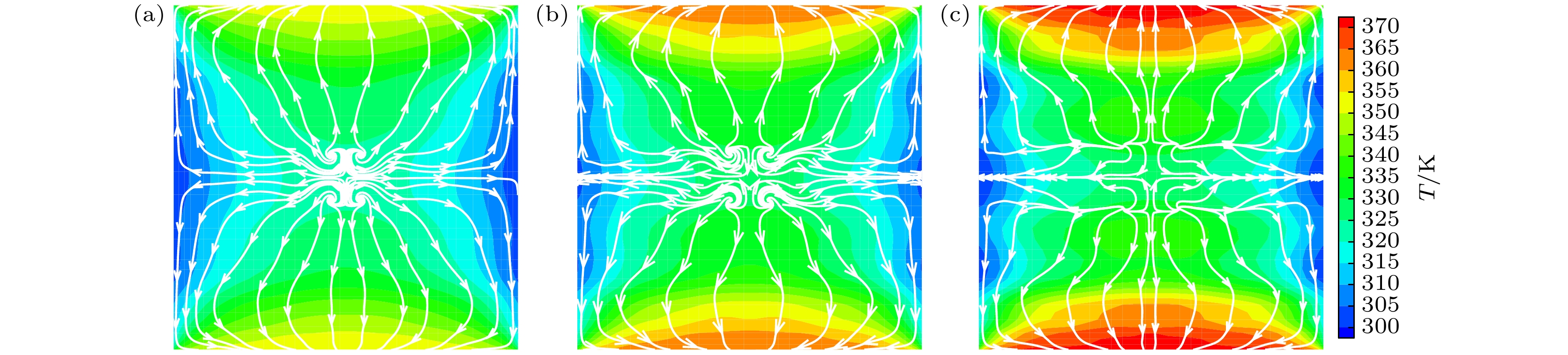

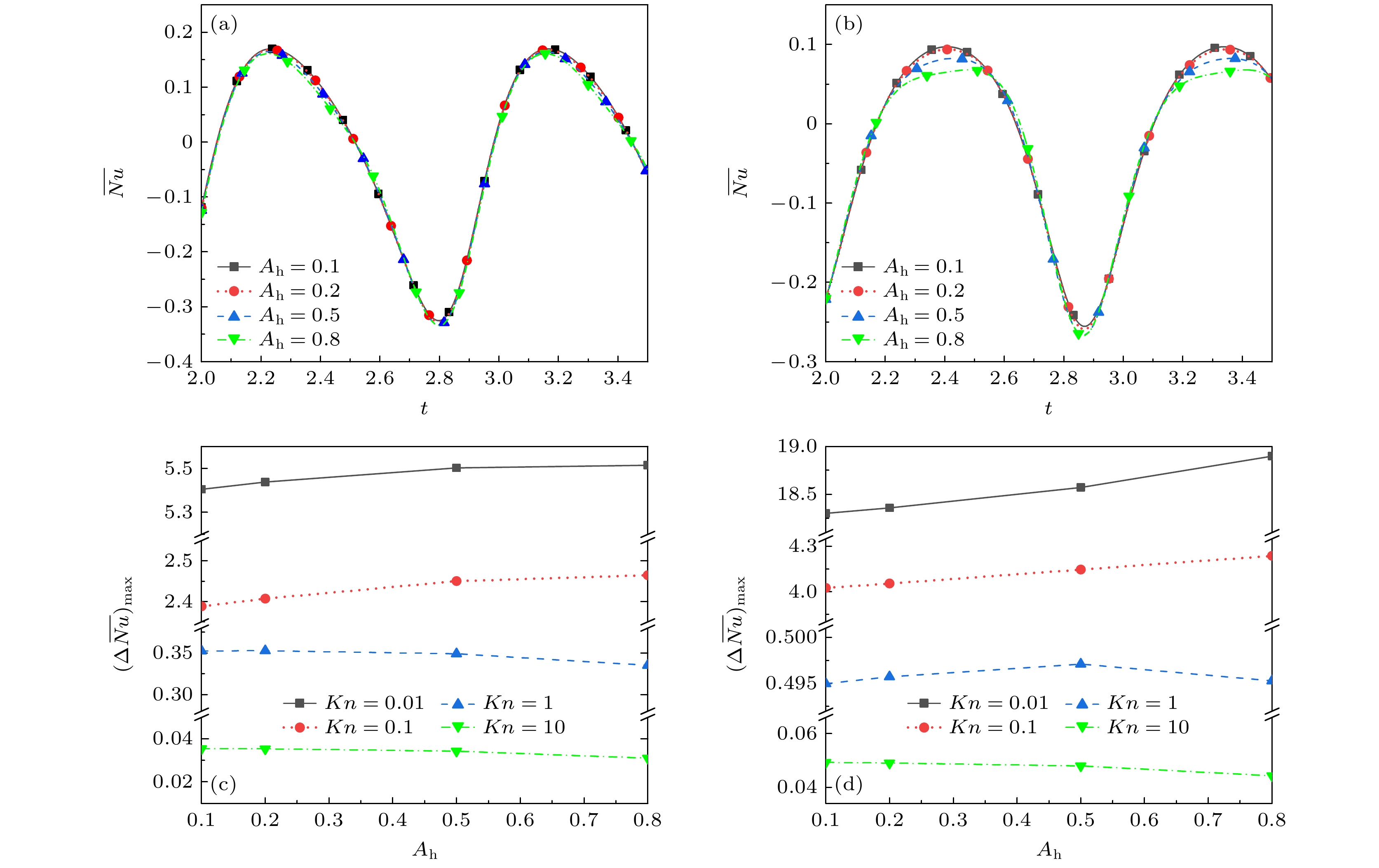

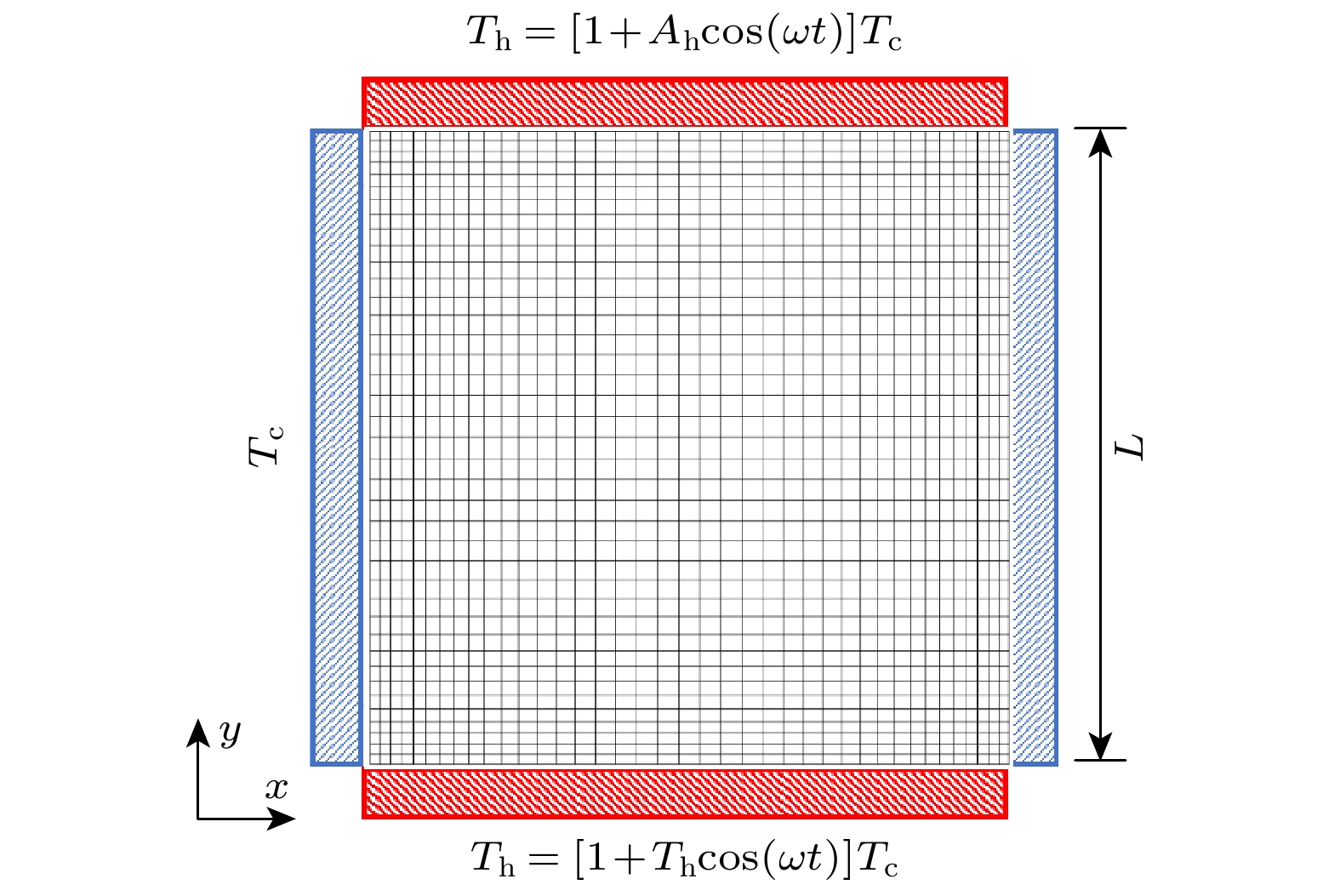

为考察壁面温度变化对受限空间内稀薄气体流动与传热特性的影响, 采用离散统一气体动理学格式(DUGKS)模拟研究了方腔内的热蠕流动. 腔体四周为静止漫反射恒温壁面, 上、下壁温度则随时间周期性变化. 模拟的参数范围如下: 变温频率0.5 ≤ St ≤ 5.0、变温振幅0.1 ≤ Ah ≤ 0.8和克努森数0.01 ≤ Kn ≤ 10. 数值结果表明: 方腔内气体流动与传热特性呈现周期性变化, 且不会出现反傅里叶热传递. 变温频率、振幅和克努森数的提高均可增强腔内热蠕流动强度, 且变温壁面附近速度滑移和温度跳跃增大. St和Kn的增大导致出现传热滞后现象, 壁面换热能力减弱. 特别地, 当St = 0.5较小时腔内观察到复杂涡流结构; St = 5.0时气体由变温壁面向腔体水平中心线均匀流动, 涡流消失的同时左、右壁面中点附近由吸热区转变为放热区. Ah增大时腔内温度场和速度场结构变化不大, 而壁面传热强度减小.In order to examine the influence of wall temperature change on the flow and heat transfer properties of rarefied gas in restricted space, the discrete unified gas kinetic scheme (DUGKS) is used to simulate the thermal creep flows in a square cavity. All the boundaries of the cavity are stationary diffuse reflection walls. The temperature of left wall and right wall are lower, and the temperature of the upper wall and the lower wall are both subjected to periodic variation. The simulation parameters considered in the present work are set as follows: the Knudsen number Kn is in a range 0.01–10, temperature change frequency St in a range of 0.5–5, and temperature change amplitude Ah in a range of 0.1–0.8. The results indicate that the velocity field and temperature field in the cavity exhibit periodic variations. No inverse Fourier heat transfer phenomenon is observed within the parameter ranges studied. The intensity of the thermal creep flow can be increased by increasing the frequency, temperature, and the Knudsen number. This can also raise the temperature jump and velocity slip close to the temperature change walls. Heat transfer lag and a reduction in the heat transfer capability of the wall are caused by increasing St and Kn. When St is small, say, St = 0.5, a complex vortex structure is seen in the cavity. As the value of St rises to 5, the vortex disappears, the gas travels from the variable temperature wall to the horizontal centerline of cavity, and the region close to the middle of the left wall and right wall changes from an endothermic zone to an exothermic zone. Furthermore, the temperature field and velocity field inside the cavity hardly change, but the degree of heat transfer on the wall decreases with the increase of Ah. The main results are shown in the figure attached below. This work provides helpful recommendations for designing the MEMS devices by using pulsed heating.

-

Keywords:

- thermal creep flows /

- discrete unified gas kinetic scheme /

- thermally induced oscillating flow /

- diffuse boundary

[1] 沈青 2006 力学进展 36 142

Google Scholar

Google Scholar

Shen Q 2006 Adv. Mech. 36 142

Google Scholar

Google Scholar

[2] Frangi A, Frezzotti A, Lorenzani S 2007 Comput. Struct. 85 810

Google Scholar

Google Scholar

[3] 梅涛, 陈占秀, 杨历, 朱洪漫, 苗瑞灿 2020 69 224701

Google Scholar

Google Scholar

Mei T, Chen Z X, Yang L, Zhu H M, Miao R C 2020 Acta Phys. Sin. 69 224701

Google Scholar

Google Scholar

[4] Ramadan K M, Qisieh O, Tlili I 2022 Proc. Inst. Mech. Eng. Part C 236 5033

Google Scholar

Google Scholar

[5] Mousivand M, Roohi E 2022 Phys. Fluids 34 052002

Google Scholar

Google Scholar

[6] Lan J, Xie J, Ye J, Peng W Z, Jiao X Y 2022 Int. J. Hydrogen Energy 47 19206

Google Scholar

Google Scholar

[7] 韩峰, 王晓伟, 张文青, 张世伟, 张志军 2023 真空科学与技术学报 43 238

Google Scholar

Google Scholar

Han F, Wang X W, Zhang W Q, Zhang S W, Zhang Z J 2023 J. Vac. Sci. Technol. 43 238

Google Scholar

Google Scholar

[8] 王晓伟, 张志军, 张文青, 苏天一, 张世伟 2020 真空与低温 26 73

Google Scholar

Google Scholar

Wang X W, Zhang Z J, Zhang W Q, Su T Y, Zhang S W 2020 Vac. Cryogen 26 73

Google Scholar

Google Scholar

[9] Wu L, Zhang Y H, Li Z H 2017 Sci. Sin. phys. Mech. As. 47 070004

Google Scholar

Google Scholar

[10] Tsimpoukis A, Vasileiadis N, Tatsios G, Valougeorgis D 2019 Phys. Fluids 31 067108

Google Scholar

Google Scholar

[11] Taassob A, Kamali R, Bordbar A 2018 Vacuum 151 197

Google Scholar

Google Scholar

[12] Nabapure D 2021 J. Comput. Sci. Neth. 49 101276.

Google Scholar

Google Scholar

[13] Wu L, Reese J M, Zhang Y 2014 J. Fluid Mech. 748 350

Google Scholar

Google Scholar

[14] Ogata Y, Kawaguchi T 2011 J. Fluid Sci. Technol. 6 215

Google Scholar

Google Scholar

[15] Palharini R C, Scanlon T J, White C 2018 Comput. Fluids 165 173

Google Scholar

Google Scholar

[16] Yang W Q, Tang S, Yang H 2019 Appl. Sci. 9 2733

Google Scholar

Google Scholar

[17] 单小东, 王沫然 2013 工程热 34 2159

Shan X D, Wang M R 2013 J. Eng. Thermophys. 34 2159

[18] 张帅, 方蜀州, 许阳 2021 推进技术 42 2002

Google Scholar

Google Scholar

Zhang S, Fang S Z, Xu Y 2021 J. Propul. Technol. 42 2002

Google Scholar

Google Scholar

[19] Zhang J, Yao S Q, Fei F, Ghalambaz M, Wen D S 2020 Phys. Fluids 32 102001

Google Scholar

Google Scholar

[20] Moghadam E Y, Roohi E, Esfahani J A 2014 Vacuum 109 333

Google Scholar

Google Scholar

[21] Yamaguchi H, Perrier P, Ho M T, Méolans J G, Niimi T, Graur I 2016 J. Fluid Mech. 795 690

Google Scholar

Google Scholar

[22] Barbera E, Brini F 2018 Europhys. Lett. 120 34001

Google Scholar

Google Scholar

[23] Akhlaghi H, Roohi E, Stefanov S 2018 Sci. Rep. 8 13533

Google Scholar

Google Scholar

[24] Han Y L 2010 Fluid Dyn. Res. 42 045505

Google Scholar

Google Scholar

[25] Zhu M B, Roohi E, Ebrahimi A 2023 Phys. Fluids 35 052012

Google Scholar

Google Scholar

[26] Roohi E, Shahabi V, Bagherzadeh A 2018 Int. J. Therm. Sci. 125 381

Google Scholar

Google Scholar

[27] Wang P, Zhu L H, Su W, Wu L, Zhang Y H 2018 Phys. Rev. E 97 043103

Google Scholar

Google Scholar

[28] Zhu L H, Guo Z L, Xu K 2016 Comput. Fluids 127 211

Google Scholar

Google Scholar

[29] Wang X W, Su T Y, Zhang W Q, Zhang Z J, Zhang S W 2020 Microsyst. Nanoeng. 6 26

Google Scholar

Google Scholar

[30] 张贝豪, 郑林 2020 69 164401

Google Scholar

Google Scholar

Zhang B H, Zheng L 2020 Acta Phys. Sin. 69 164401

Google Scholar

Google Scholar

[31] Ou Y, Qu F, Wang G Y, Nie M Y, Li Z G, Ou W, Xie C Q 2016 Appl. Phys. Lett. 109 023512

Google Scholar

Google Scholar

[32] 万启坤, 张月, 郭照立 2023 计算物理 40 653

Wan Q K, Zhang Y, Guo Z L 2023 Chinese J. Comput. Phys. 40 653

[33] Kalempa D, Sharipov F, Silva J C 2019 Vacuum 159 82

Google Scholar

Google Scholar

[34] Bargatin I, Kozinsky I, Roukes M L 2007 Appl. Phys. Lett. 90 093116

Google Scholar

Google Scholar

[35] Ilic B, Yang Y, Aubin K, Reichenbach R, Krylov S, Craighead H G 2005 Nano Lett. 5 925

Google Scholar

Google Scholar

[36] Juvé V, Crut A, Maioli P, Pellarin M, Broyer M, Del Fatti N, Vallée F 2010 Nano Lett. 10 1853

Google Scholar

Google Scholar

[37] Guo Z L, Wang R J, Xu K 2015 Phys. Rev. E 91 033313

Google Scholar

Google Scholar

[38] 孙喜明, 姚朝晖, 杨京龙 2002 51 1942

Google Scholar

Google Scholar

Sun X M, Yao Z H, Yang J L 2002 Acta Phys. Sin. 51 1942

Google Scholar

Google Scholar

[39] 孙佳坤, 林传栋, 苏咸利, 谭志城, 陈亚楼, 明平剑 2024 73 110504

Google Scholar

Google Scholar

Sun J K, Lin C D, Su X L, Tan Z C, Chen Y L, Ming P J 2024 Acta Phys. Sin. 73 110504

Google Scholar

Google Scholar

[40] Huang J C, Xu K, Yu P 2013 Commun. Comput. Phys. 14 1147

Google Scholar

Google Scholar

[41] Wang Y, Zhong C W, Liu S 2019 Phys. Rev. E 100 063310

Google Scholar

Google Scholar

[42] Zhu L H, Chen S Z, Guo Z L 2017 Comput. Phys. Commun. 213 155

Google Scholar

Google Scholar

[43] Vargas M, Tatsios G, Valougeorgis D, Stefanov S 2014 Phys. Fluids 26 057101

Google Scholar

Google Scholar

-

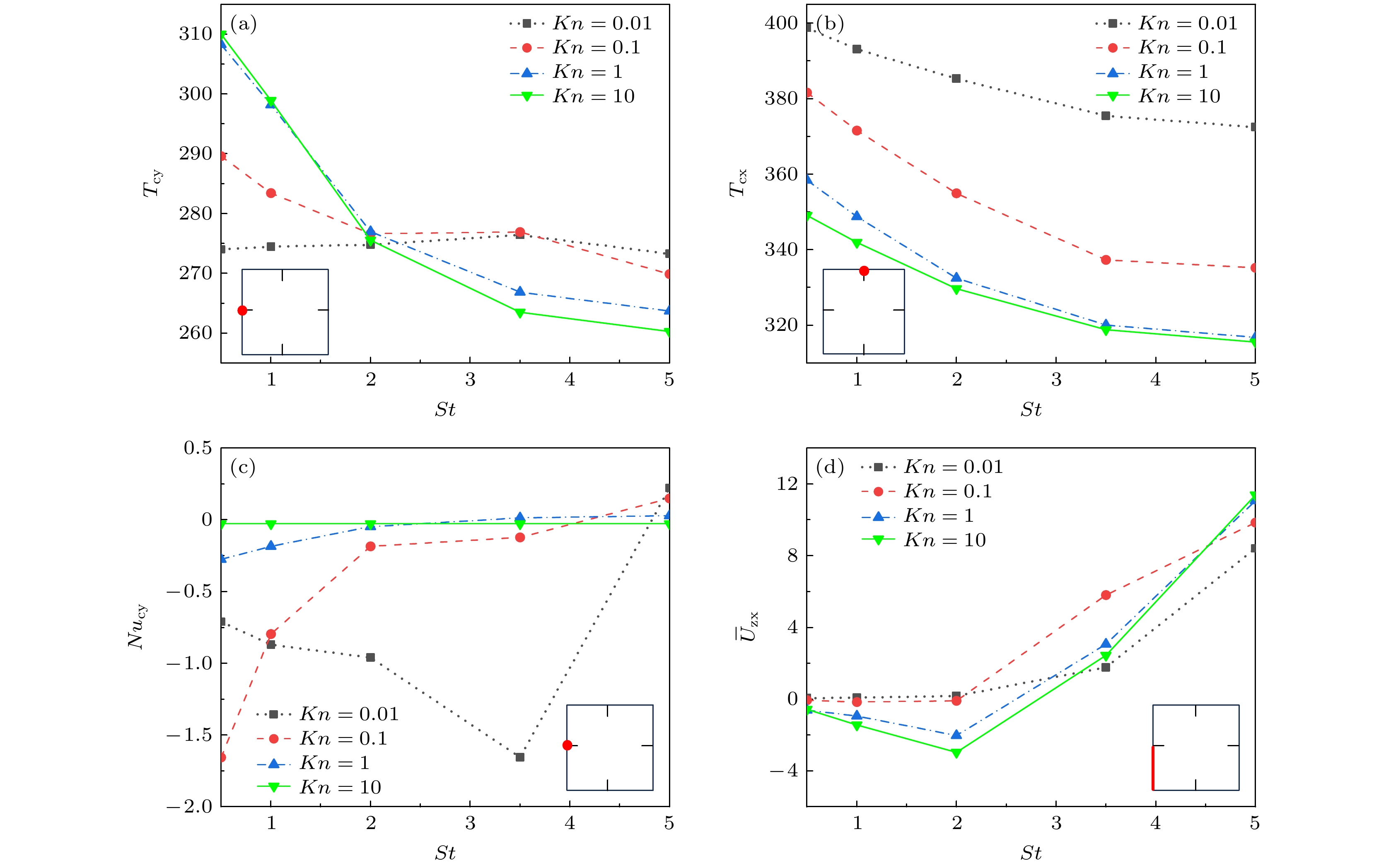

图 8 Ah = 0.5, t = 0时不同参数在不同St和Kn下的变化 (a)左壁面中点温度Tcy; (b)上壁面中点温度Tcx; (c)左壁面中点努塞尔数Nucy; (d)左壁面下半部分平均速度$ {\overline{U}}_{{\mathrm{z}}{\mathrm{x}}} $

Fig. 8. Variations of different parameters under different St and Kn when Ah = 0.5 and t = 0: (a) Temperature of the midpoint of the left wall Tcy; (b) temperature of the midpoint of the upper wall Tcx; (c) Nussel number of the midpoint of the left wall Nucy; (d) the average velocity of the lower half of the left wall $ {\overline{U}}_{{\mathrm{z}}{\mathrm{x}}} $.

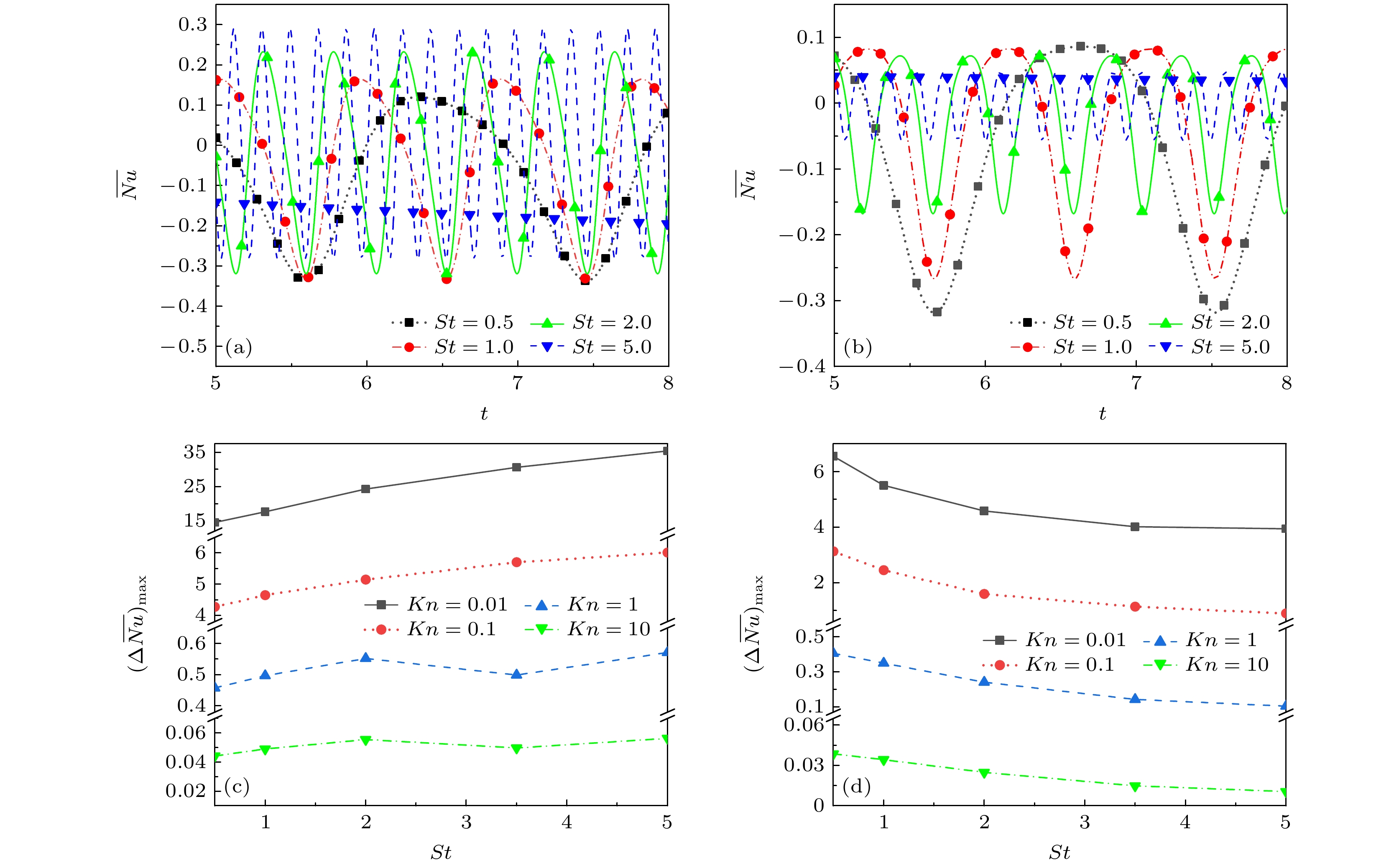

图 9 不同St和Kn下, 壁面平均努塞尔数$\overline{Nu} $的时间历程及$\overline{Nu} $的极差$ {\left(\Delta\overline{Nu}\right)}_{{\mathrm{m}}{\mathrm{a}}{\mathrm{x}}} $ (a), (c) Y = 0, 下壁面; (b), (d) X = 0, 左壁面

Fig. 9. The time history of the average Nussel number $\overline{Nu} $ and the range $ {\left(\Delta\overline{Nu}\right)}_{{\mathrm{m}}{\mathrm{a}}{\mathrm{x}}} $of $\overline{Nu} $ on the wall under different St and Kn: (a), (c) Lower wall surface, Y = 0; (b), (d) left wall, X = 0.

图 13 St = 1.0, t = 0时, 不同参数在不同Ah和Kn下的变化 (a)左壁面中点温度Tcy; (b)上壁面中点温度Tcx; (c)左壁面中点努塞尔数Nucy; (d)左下半壁面平均速度$ {\overline{U}}_{{\mathrm{z}}{\mathrm{x}}} $

Fig. 13. Variations of different parameters under different Ah and Kn when St = 1.0 and t = 0: (a) The midpoint temperature of the left wall Tcy; (b) temperature of the midpoint of the upper wall Tcx; (c) Nusselt number of the left wall midpoint Nucy; (d) the average velocity of the lower left half of the wall $ {\overline{U}}_{{\mathrm{z}}{\mathrm{x}}} $.

图 15 St = 1.0时不同Ah和Kn下, 壁面平均努塞尔数$\overline{Nu} $的时间历程及$\overline{Nu} $的极差$ {\left(\Delta\overline{Nu}\right)}_{{\mathrm{m}}{\mathrm{a}}{\mathrm{x}}} $ (a), (c) X = 0, 左壁面; (b), (d) Y= 0, 下壁面

Fig. 15. The time history of the average Nussel number $\overline{Nu} $ and the range $ {\left(\Delta\overline{Nu}\right)}_{{\mathrm{m}}{\mathrm{a}}{\mathrm{x}}} $ of $\overline{Nu} $ on the wall under different Ah and Kn when St = 1.0: (a), (c) Left wall, X = 0; (b), (d) lower wall surface, Y = 0.

-

[1] 沈青 2006 力学进展 36 142

Google Scholar

Google Scholar

Shen Q 2006 Adv. Mech. 36 142

Google Scholar

Google Scholar

[2] Frangi A, Frezzotti A, Lorenzani S 2007 Comput. Struct. 85 810

Google Scholar

Google Scholar

[3] 梅涛, 陈占秀, 杨历, 朱洪漫, 苗瑞灿 2020 69 224701

Google Scholar

Google Scholar

Mei T, Chen Z X, Yang L, Zhu H M, Miao R C 2020 Acta Phys. Sin. 69 224701

Google Scholar

Google Scholar

[4] Ramadan K M, Qisieh O, Tlili I 2022 Proc. Inst. Mech. Eng. Part C 236 5033

Google Scholar

Google Scholar

[5] Mousivand M, Roohi E 2022 Phys. Fluids 34 052002

Google Scholar

Google Scholar

[6] Lan J, Xie J, Ye J, Peng W Z, Jiao X Y 2022 Int. J. Hydrogen Energy 47 19206

Google Scholar

Google Scholar

[7] 韩峰, 王晓伟, 张文青, 张世伟, 张志军 2023 真空科学与技术学报 43 238

Google Scholar

Google Scholar

Han F, Wang X W, Zhang W Q, Zhang S W, Zhang Z J 2023 J. Vac. Sci. Technol. 43 238

Google Scholar

Google Scholar

[8] 王晓伟, 张志军, 张文青, 苏天一, 张世伟 2020 真空与低温 26 73

Google Scholar

Google Scholar

Wang X W, Zhang Z J, Zhang W Q, Su T Y, Zhang S W 2020 Vac. Cryogen 26 73

Google Scholar

Google Scholar

[9] Wu L, Zhang Y H, Li Z H 2017 Sci. Sin. phys. Mech. As. 47 070004

Google Scholar

Google Scholar

[10] Tsimpoukis A, Vasileiadis N, Tatsios G, Valougeorgis D 2019 Phys. Fluids 31 067108

Google Scholar

Google Scholar

[11] Taassob A, Kamali R, Bordbar A 2018 Vacuum 151 197

Google Scholar

Google Scholar

[12] Nabapure D 2021 J. Comput. Sci. Neth. 49 101276.

Google Scholar

Google Scholar

[13] Wu L, Reese J M, Zhang Y 2014 J. Fluid Mech. 748 350

Google Scholar

Google Scholar

[14] Ogata Y, Kawaguchi T 2011 J. Fluid Sci. Technol. 6 215

Google Scholar

Google Scholar

[15] Palharini R C, Scanlon T J, White C 2018 Comput. Fluids 165 173

Google Scholar

Google Scholar

[16] Yang W Q, Tang S, Yang H 2019 Appl. Sci. 9 2733

Google Scholar

Google Scholar

[17] 单小东, 王沫然 2013 工程热 34 2159

Shan X D, Wang M R 2013 J. Eng. Thermophys. 34 2159

[18] 张帅, 方蜀州, 许阳 2021 推进技术 42 2002

Google Scholar

Google Scholar

Zhang S, Fang S Z, Xu Y 2021 J. Propul. Technol. 42 2002

Google Scholar

Google Scholar

[19] Zhang J, Yao S Q, Fei F, Ghalambaz M, Wen D S 2020 Phys. Fluids 32 102001

Google Scholar

Google Scholar

[20] Moghadam E Y, Roohi E, Esfahani J A 2014 Vacuum 109 333

Google Scholar

Google Scholar

[21] Yamaguchi H, Perrier P, Ho M T, Méolans J G, Niimi T, Graur I 2016 J. Fluid Mech. 795 690

Google Scholar

Google Scholar

[22] Barbera E, Brini F 2018 Europhys. Lett. 120 34001

Google Scholar

Google Scholar

[23] Akhlaghi H, Roohi E, Stefanov S 2018 Sci. Rep. 8 13533

Google Scholar

Google Scholar

[24] Han Y L 2010 Fluid Dyn. Res. 42 045505

Google Scholar

Google Scholar

[25] Zhu M B, Roohi E, Ebrahimi A 2023 Phys. Fluids 35 052012

Google Scholar

Google Scholar

[26] Roohi E, Shahabi V, Bagherzadeh A 2018 Int. J. Therm. Sci. 125 381

Google Scholar

Google Scholar

[27] Wang P, Zhu L H, Su W, Wu L, Zhang Y H 2018 Phys. Rev. E 97 043103

Google Scholar

Google Scholar

[28] Zhu L H, Guo Z L, Xu K 2016 Comput. Fluids 127 211

Google Scholar

Google Scholar

[29] Wang X W, Su T Y, Zhang W Q, Zhang Z J, Zhang S W 2020 Microsyst. Nanoeng. 6 26

Google Scholar

Google Scholar

[30] 张贝豪, 郑林 2020 69 164401

Google Scholar

Google Scholar

Zhang B H, Zheng L 2020 Acta Phys. Sin. 69 164401

Google Scholar

Google Scholar

[31] Ou Y, Qu F, Wang G Y, Nie M Y, Li Z G, Ou W, Xie C Q 2016 Appl. Phys. Lett. 109 023512

Google Scholar

Google Scholar

[32] 万启坤, 张月, 郭照立 2023 计算物理 40 653

Wan Q K, Zhang Y, Guo Z L 2023 Chinese J. Comput. Phys. 40 653

[33] Kalempa D, Sharipov F, Silva J C 2019 Vacuum 159 82

Google Scholar

Google Scholar

[34] Bargatin I, Kozinsky I, Roukes M L 2007 Appl. Phys. Lett. 90 093116

Google Scholar

Google Scholar

[35] Ilic B, Yang Y, Aubin K, Reichenbach R, Krylov S, Craighead H G 2005 Nano Lett. 5 925

Google Scholar

Google Scholar

[36] Juvé V, Crut A, Maioli P, Pellarin M, Broyer M, Del Fatti N, Vallée F 2010 Nano Lett. 10 1853

Google Scholar

Google Scholar

[37] Guo Z L, Wang R J, Xu K 2015 Phys. Rev. E 91 033313

Google Scholar

Google Scholar

[38] 孙喜明, 姚朝晖, 杨京龙 2002 51 1942

Google Scholar

Google Scholar

Sun X M, Yao Z H, Yang J L 2002 Acta Phys. Sin. 51 1942

Google Scholar

Google Scholar

[39] 孙佳坤, 林传栋, 苏咸利, 谭志城, 陈亚楼, 明平剑 2024 73 110504

Google Scholar

Google Scholar

Sun J K, Lin C D, Su X L, Tan Z C, Chen Y L, Ming P J 2024 Acta Phys. Sin. 73 110504

Google Scholar

Google Scholar

[40] Huang J C, Xu K, Yu P 2013 Commun. Comput. Phys. 14 1147

Google Scholar

Google Scholar

[41] Wang Y, Zhong C W, Liu S 2019 Phys. Rev. E 100 063310

Google Scholar

Google Scholar

[42] Zhu L H, Chen S Z, Guo Z L 2017 Comput. Phys. Commun. 213 155

Google Scholar

Google Scholar

[43] Vargas M, Tatsios G, Valougeorgis D, Stefanov S 2014 Phys. Fluids 26 057101

Google Scholar

Google Scholar

计量

- 文章访问数: 3028

- PDF下载量: 66

- 被引次数: 0

下载:

下载: