-

随着我国油气管道铺设数量的增加, 对管道的维护工作也需予以更多的重视. 目前, 在油气输送站场内, 主要采用人工巡检、对射式和云台式检测设备来检测天然气泄漏. 但是这些方法存在响应度差、检测区域受限、泄漏点定位较慢等问题. 为了满足对油气管道泄漏实时监测和快速定位的需求, 本文设计了一种快速、精确控制的双楔形扫描镜系统, 结合可调谐半导体激光吸收光谱技术, 使得气体测量由原来的点测量转换为面测量. 通过反解迭代优化算法, 控制楔形镜的转角获得高效均匀的光束扫描轨迹, 并将激光束的偏转方向及检测位置与对应的甲烷浓度信息相融合, 构建了包含有位置信息的甲烷浓度数据, 实现甲烷气体的光谱成像. 实验中为了定量验证测量准确度及空间分辨率, 通过标准气袋模拟甲烷泄漏分布, 结果表明系统的成像浓度检测限小于500 ppm·m (1 ppm =10–6), 位置分辨率小于6 cm. 同时该方法可以依据油气站场的测量距离调节扫描步进节点, 从而实现成像分辨率的可调节, 该成像方法为精确定位甲烷气体泄漏提供了新的思路.With the increase in the number of oil and gas pipelines laid in China, more attention needs to be paid to pipeline maintenance work. At present, the main methods of detecting natural gas leaks in oil and gas transmission stations include manual inspections, opposing natural gas detection equipment, and cloud desktop natural gas detection equipment. Hand held natural gas detection equipment is used for manual inspection, which requires regular manual inspection. However, the response speed is poor and gas leaks cannot be detected in a timely manner. The opposed laser gas detection method can only detect the presence of gas on the beam path. If a larger area of leakage detection is desired, more equipment needs to be installed, resulting in a greatly increase in hardware costs. The existing cloud desktop laser gas detection method controls the deflection of the laser beam through the cloud platform to achieve leak detection at various points in the area to be tested. However, the rotation speed of the cloud platform is slow, and a complete detection cycle takes dozens of minutes, and only the presence of gas can be detected. For accurate leak location, manual on-site survey is also required to further determine the leak location. In order to meet the needs of the real-time monitoring and rapid positioning of oil and gas pipeline leaks, in this work, a fast and accurately controlled dual wedge scanning mirror system is designed, which combines tunable semiconductor laser absorption spectroscopy technology to convert the gas measurement laser beam from point measurement to surface measurement, thereby obtaining the two-dimensional distribution of gas, which is conducive to subsequent analysis and positioning of gas leakage sources. By using the inverse solution iterative optimization algorithm, the angle of the wedge mirror is controlled to obtain an efficient and uniform beam scanning trajectory. The deflection direction and detection position of the laser beam are fused with the corresponding methane concentration information, and a methane concentration data containing position information is constructed. In order to quantitatively verify the measurement accuracy and spatial resolution in the experiment, a standard air bag is used to simulate the methane leakage distribution. The results show that the minimum detection limit of the system can be lower than 5×10–4 m, and the spatial resolution can be less than 6 cm. At the same time, this method can adjust the scanning step node based on the measurement distance of the oil from gas station, thereby achieving adjustable imaging resolution. This imaging method provides a new idea for accurately positioning and detecting the methane leakage location and amount.

-

Keywords:

- tunable diode laser absorption spectroscopy /

- methane gas detection /

- double wedge scanning mirror /

- gas imaging

[1] 王小强, 王保群, 王博, 林燕红, 郭彩霞 2018 石油规划设计 29 1

Google Scholar

Google Scholar

Wang X Q, Wang B Q, Wang B, Lin Y H, Guo C X 2018 Petroleum Planning Eng. 29 1

Google Scholar

Google Scholar

[2] 张志荣, 孙鹏帅, 庞涛, 李哲, 夏滑, 崔小娟, 吴边, 徐启铭, 董凤忠 2018 光学精密工程 26 1925

Google Scholar

Google Scholar

Zhang Z R, Sun P S, Pang T, Li Z, Xia H, Cui X J, Wu B, Xu Q M, Dong F Z 2018 Opt. Precis. Eng. 26 1925

Google Scholar

Google Scholar

[3] 董高华, 赵廉斌, 曹永乐, 梁怿, 葛淩志, 马铁量, 孟书进 2023 化工自动化仪表 3 283

Google Scholar

Google Scholar

Dong G H, Zhao L B, Cao Y L, Liang Y, Ge L Z, Ma T L, Meng S J 2023 Contr. Instrum. Chem. Indust. 3 283

Google Scholar

Google Scholar

[4] 祁丽荣, 邢琳琳, 刘瑶, 王一君 2022 城市燃气 4 9

Google Scholar

Google Scholar

Qi L R, Xing L L, Liu Y, Wang Y J 2022 Urban Gas 4 9

Google Scholar

Google Scholar

[5] 朱云伟 2023 管道技术与设备 2 19

Google Scholar

Google Scholar

Zhu Y W 2023 Pipeline Technique and Equipment 2 19

Google Scholar

Google Scholar

[6] 庞涛, 王煜, 夏滑, 张志荣, 汤玉泉, 董凤忠 2016 光子学报 9 104

Google Scholar

Google Scholar

Pang T, Wang L, Xia H, Zhang Z R, Tang Y Q, Dong F Z 2016 Acta Photon. Sin. 9 104

Google Scholar

Google Scholar

[7] 徐俊, 李云飞, 程跃, 檀剑飞, 刘东, 周振 2023 激光与光电子学进展 6 376

Google Scholar

Google Scholar

Xu J, Li J, Li Y F, Cheng Y, Tan J F, Liu D, Zhou Z 2023 Laser Optoelectron. Prog. 6 376

Google Scholar

Google Scholar

[8] 孙鹏帅, 张志荣, 李俊, 夏滑, 韩荦, 李哲, 谭东杰, 马云宾, 董凤忠 2016 光学与光电技术 5 62

Sun P S, Zhang Z R, Li J, Xia H, Han H, Li Z, Tan D J, Ma Y B, Dong F Z 2016 Opt. Optoelectron. Tech. 5 62

[9] Fox T A , Barchyn T E, Risk D, Ravikumar A P, Hugenholtz C H 2019 Environ. Res. Lett. 14 053002

Google Scholar

Google Scholar

[10] van Well B, Murray S, Hodgkinson J, Pride R, Strzoda R, Gibson G, Padgett M 2005 J. Opt. 7 s420

Google Scholar

Google Scholar

[11] Wainner R T, Green B D, Allen M G, White M A, Stafford-Evans J, Naper R 2002 Appl. Phys. B-Lasers O 75 249

Google Scholar

Google Scholar

[12] Lagueux P, Tremblay P, Morton V, Chamberland M, Farley V, Kastek M, Firmanty K 2017 Meas. Autom. Monit. 63 65

[13] Hu Y Y, Xu L, Shen X C, Jin L, Xu H Y, Deng Y S, Liu J G, Liu W Q 2021 Appl. Opt. 60 9396

Google Scholar

Google Scholar

[14] Zhao Q, Nie X, Luo D, Wang J, Li Q, Chen W 2022 Photonics 9 992

Google Scholar

Google Scholar

[15] Gibson G M, Sun B Q, Edgar M P, Phillips D B, Hempler N, Maker G T, Malcolm G P A, Padgett M J 2017 Opt. Express 25 2998

Google Scholar

Google Scholar

[16] McRae T G, Kulp T J 1993 Appl. Opt. 32 4037

Google Scholar

Google Scholar

[17] 范大鹏, 周远, 鲁亚飞, 黑墨, 熊飞湍, 李凯 2013 中国光学 2 136

Google Scholar

Google Scholar

Fan D P, Zhou Y, Lu Y F, Hei M, Xiong F C, Li K 2013 Chin. Opt. 2 136

Google Scholar

Google Scholar

[18] 孙琳洋 2016 硕士学位论文 (成都: 电子科技大学)

Sun L Y 2016 M. S. Thesis (Chengdu: University of Electronic Science and Technology of China

[19] Marshall G F 1999 Conference on Optical Scanning - Design and Application Denver, Colorado JUL 21–22, 1999 p74

[20] Garcia-Torales G 2022 Conference on Advances in 3OM - Opto-Mechatronics, Opto-Mechanics, and Optical Metrology Opto-Mechanics, and Optical Metrology Timisoara, ROMANIA Timisoara, December 13–14, 2021 p121700H

[21] 秦聪明 2021 硕士学位论文 (成都: 中国科学院大学, 中国科学院光电技术研究所)

Qin C M 2021 M. S. Thesis (Chengdu: University of Chinese Academy of Sciences, Institute of Optics and Electronics, Chinese Academy of Sciences

[22] Sun J F, Liu L R, Yun M J, Wan L Y, Zhang M L 2006 Opt. Eng. 45 043004

Google Scholar

Google Scholar

[23] Roy G, Cao X Y, Bernier R, Roy S 2015 Appl. Opt. 54 10213

Google Scholar

Google Scholar

[24] 曾昊旻, 李松, 张智宇, 伍煜 2019 光学精密工程 27 1444

Zeng H W, Li S, Zhang Z Y, Wu Y 2019 Opt. Precis. Eng. 27 1444

[25] Sandoval J D, Delgado K, Fariña D, de la Puente F, Esper-Chaín R, Martín M 2022 Appl. Sci. Basel 12 21

[26] Titchener J, Millington-Smith D, Goldsack C, Harrison G, Dunning A, Ai X, Reed M 2022 Appl. Energy 306 118086

Google Scholar

Google Scholar

[27] Gibson G, van Well B, Hodgkinson J, Pride R, Strzoda R, Murray S, Bishton S, Padgett M 2006 New J. Phys. 8 26

Google Scholar

Google Scholar

-

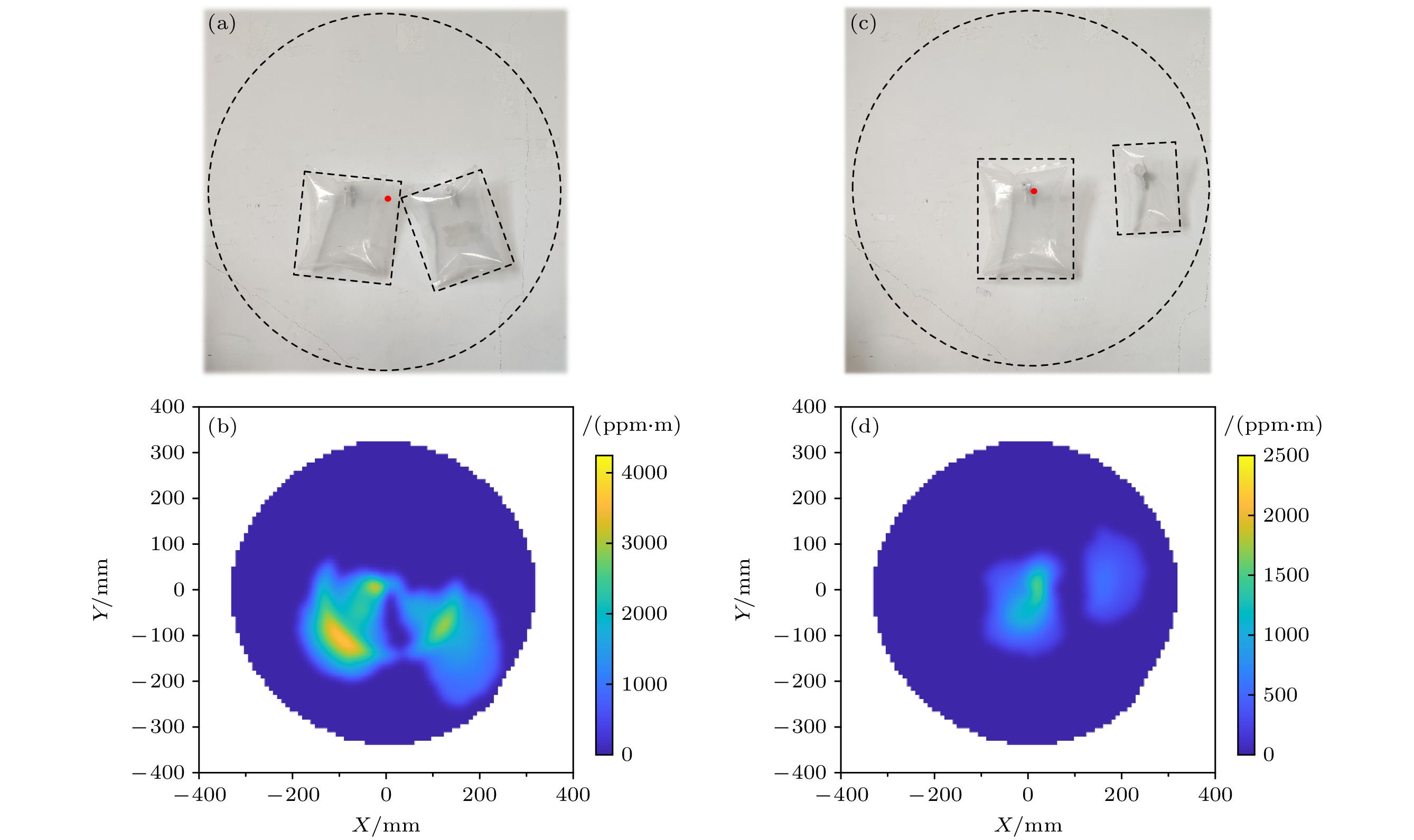

图 9 甲烷气袋的成像对比实验 (a) 相同气袋充不同浓度的甲烷气体; (b) 相同气袋充不同浓度的甲烷气体成像图; (c) 不同气袋充相同浓度的甲烷气体; (d) 不同气袋充相同浓度的甲烷气体成像图

Fig. 9. Imaging comparative experiment of methane gas bags: (a) Filling the same gas bag with different concentrations of methane gas; (b) imaging images of methane gas with the same gas bag filled with different concentrations; (c) filling different gas bags with methane gas of the same concentration; (d) imaging images of methane gas with different gas bags filled with the same concentration.

-

[1] 王小强, 王保群, 王博, 林燕红, 郭彩霞 2018 石油规划设计 29 1

Google Scholar

Google Scholar

Wang X Q, Wang B Q, Wang B, Lin Y H, Guo C X 2018 Petroleum Planning Eng. 29 1

Google Scholar

Google Scholar

[2] 张志荣, 孙鹏帅, 庞涛, 李哲, 夏滑, 崔小娟, 吴边, 徐启铭, 董凤忠 2018 光学精密工程 26 1925

Google Scholar

Google Scholar

Zhang Z R, Sun P S, Pang T, Li Z, Xia H, Cui X J, Wu B, Xu Q M, Dong F Z 2018 Opt. Precis. Eng. 26 1925

Google Scholar

Google Scholar

[3] 董高华, 赵廉斌, 曹永乐, 梁怿, 葛淩志, 马铁量, 孟书进 2023 化工自动化仪表 3 283

Google Scholar

Google Scholar

Dong G H, Zhao L B, Cao Y L, Liang Y, Ge L Z, Ma T L, Meng S J 2023 Contr. Instrum. Chem. Indust. 3 283

Google Scholar

Google Scholar

[4] 祁丽荣, 邢琳琳, 刘瑶, 王一君 2022 城市燃气 4 9

Google Scholar

Google Scholar

Qi L R, Xing L L, Liu Y, Wang Y J 2022 Urban Gas 4 9

Google Scholar

Google Scholar

[5] 朱云伟 2023 管道技术与设备 2 19

Google Scholar

Google Scholar

Zhu Y W 2023 Pipeline Technique and Equipment 2 19

Google Scholar

Google Scholar

[6] 庞涛, 王煜, 夏滑, 张志荣, 汤玉泉, 董凤忠 2016 光子学报 9 104

Google Scholar

Google Scholar

Pang T, Wang L, Xia H, Zhang Z R, Tang Y Q, Dong F Z 2016 Acta Photon. Sin. 9 104

Google Scholar

Google Scholar

[7] 徐俊, 李云飞, 程跃, 檀剑飞, 刘东, 周振 2023 激光与光电子学进展 6 376

Google Scholar

Google Scholar

Xu J, Li J, Li Y F, Cheng Y, Tan J F, Liu D, Zhou Z 2023 Laser Optoelectron. Prog. 6 376

Google Scholar

Google Scholar

[8] 孙鹏帅, 张志荣, 李俊, 夏滑, 韩荦, 李哲, 谭东杰, 马云宾, 董凤忠 2016 光学与光电技术 5 62

Sun P S, Zhang Z R, Li J, Xia H, Han H, Li Z, Tan D J, Ma Y B, Dong F Z 2016 Opt. Optoelectron. Tech. 5 62

[9] Fox T A , Barchyn T E, Risk D, Ravikumar A P, Hugenholtz C H 2019 Environ. Res. Lett. 14 053002

Google Scholar

Google Scholar

[10] van Well B, Murray S, Hodgkinson J, Pride R, Strzoda R, Gibson G, Padgett M 2005 J. Opt. 7 s420

Google Scholar

Google Scholar

[11] Wainner R T, Green B D, Allen M G, White M A, Stafford-Evans J, Naper R 2002 Appl. Phys. B-Lasers O 75 249

Google Scholar

Google Scholar

[12] Lagueux P, Tremblay P, Morton V, Chamberland M, Farley V, Kastek M, Firmanty K 2017 Meas. Autom. Monit. 63 65

[13] Hu Y Y, Xu L, Shen X C, Jin L, Xu H Y, Deng Y S, Liu J G, Liu W Q 2021 Appl. Opt. 60 9396

Google Scholar

Google Scholar

[14] Zhao Q, Nie X, Luo D, Wang J, Li Q, Chen W 2022 Photonics 9 992

Google Scholar

Google Scholar

[15] Gibson G M, Sun B Q, Edgar M P, Phillips D B, Hempler N, Maker G T, Malcolm G P A, Padgett M J 2017 Opt. Express 25 2998

Google Scholar

Google Scholar

[16] McRae T G, Kulp T J 1993 Appl. Opt. 32 4037

Google Scholar

Google Scholar

[17] 范大鹏, 周远, 鲁亚飞, 黑墨, 熊飞湍, 李凯 2013 中国光学 2 136

Google Scholar

Google Scholar

Fan D P, Zhou Y, Lu Y F, Hei M, Xiong F C, Li K 2013 Chin. Opt. 2 136

Google Scholar

Google Scholar

[18] 孙琳洋 2016 硕士学位论文 (成都: 电子科技大学)

Sun L Y 2016 M. S. Thesis (Chengdu: University of Electronic Science and Technology of China

[19] Marshall G F 1999 Conference on Optical Scanning - Design and Application Denver, Colorado JUL 21–22, 1999 p74

[20] Garcia-Torales G 2022 Conference on Advances in 3OM - Opto-Mechatronics, Opto-Mechanics, and Optical Metrology Opto-Mechanics, and Optical Metrology Timisoara, ROMANIA Timisoara, December 13–14, 2021 p121700H

[21] 秦聪明 2021 硕士学位论文 (成都: 中国科学院大学, 中国科学院光电技术研究所)

Qin C M 2021 M. S. Thesis (Chengdu: University of Chinese Academy of Sciences, Institute of Optics and Electronics, Chinese Academy of Sciences

[22] Sun J F, Liu L R, Yun M J, Wan L Y, Zhang M L 2006 Opt. Eng. 45 043004

Google Scholar

Google Scholar

[23] Roy G, Cao X Y, Bernier R, Roy S 2015 Appl. Opt. 54 10213

Google Scholar

Google Scholar

[24] 曾昊旻, 李松, 张智宇, 伍煜 2019 光学精密工程 27 1444

Zeng H W, Li S, Zhang Z Y, Wu Y 2019 Opt. Precis. Eng. 27 1444

[25] Sandoval J D, Delgado K, Fariña D, de la Puente F, Esper-Chaín R, Martín M 2022 Appl. Sci. Basel 12 21

[26] Titchener J, Millington-Smith D, Goldsack C, Harrison G, Dunning A, Ai X, Reed M 2022 Appl. Energy 306 118086

Google Scholar

Google Scholar

[27] Gibson G, van Well B, Hodgkinson J, Pride R, Strzoda R, Murray S, Bishton S, Padgett M 2006 New J. Phys. 8 26

Google Scholar

Google Scholar

计量

- 文章访问数: 4854

- PDF下载量: 79

- 被引次数: 0

下载:

下载: