-

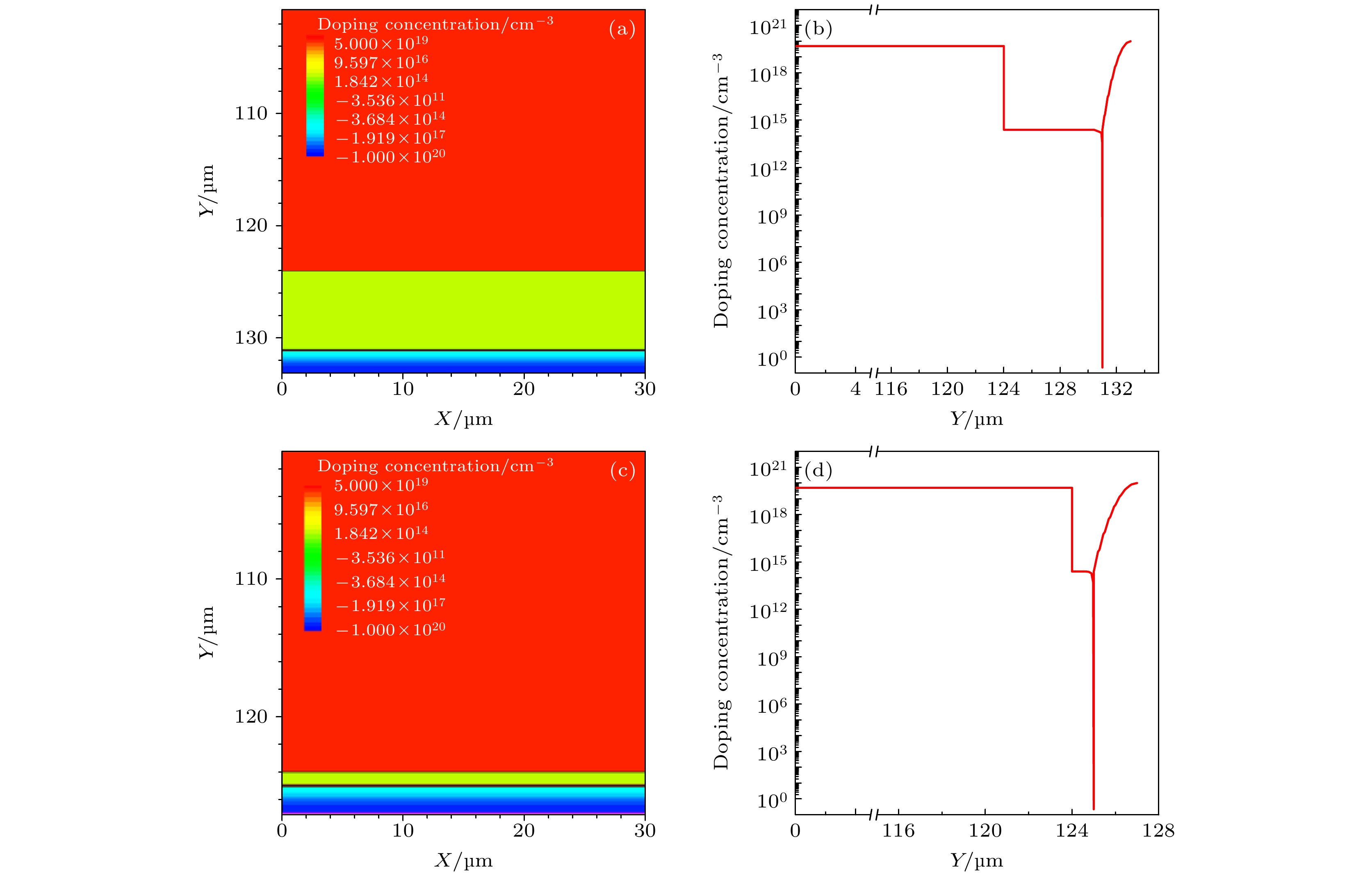

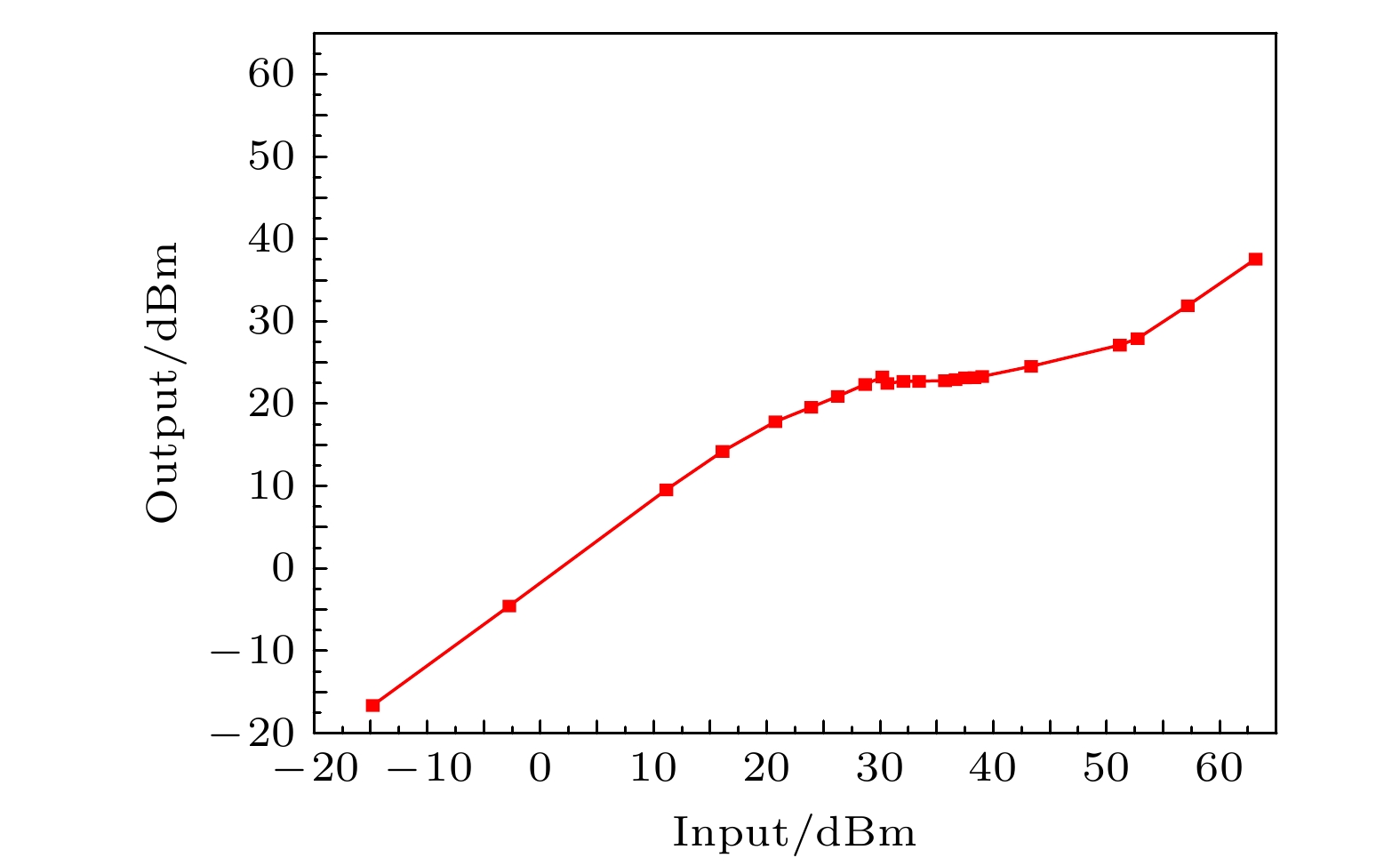

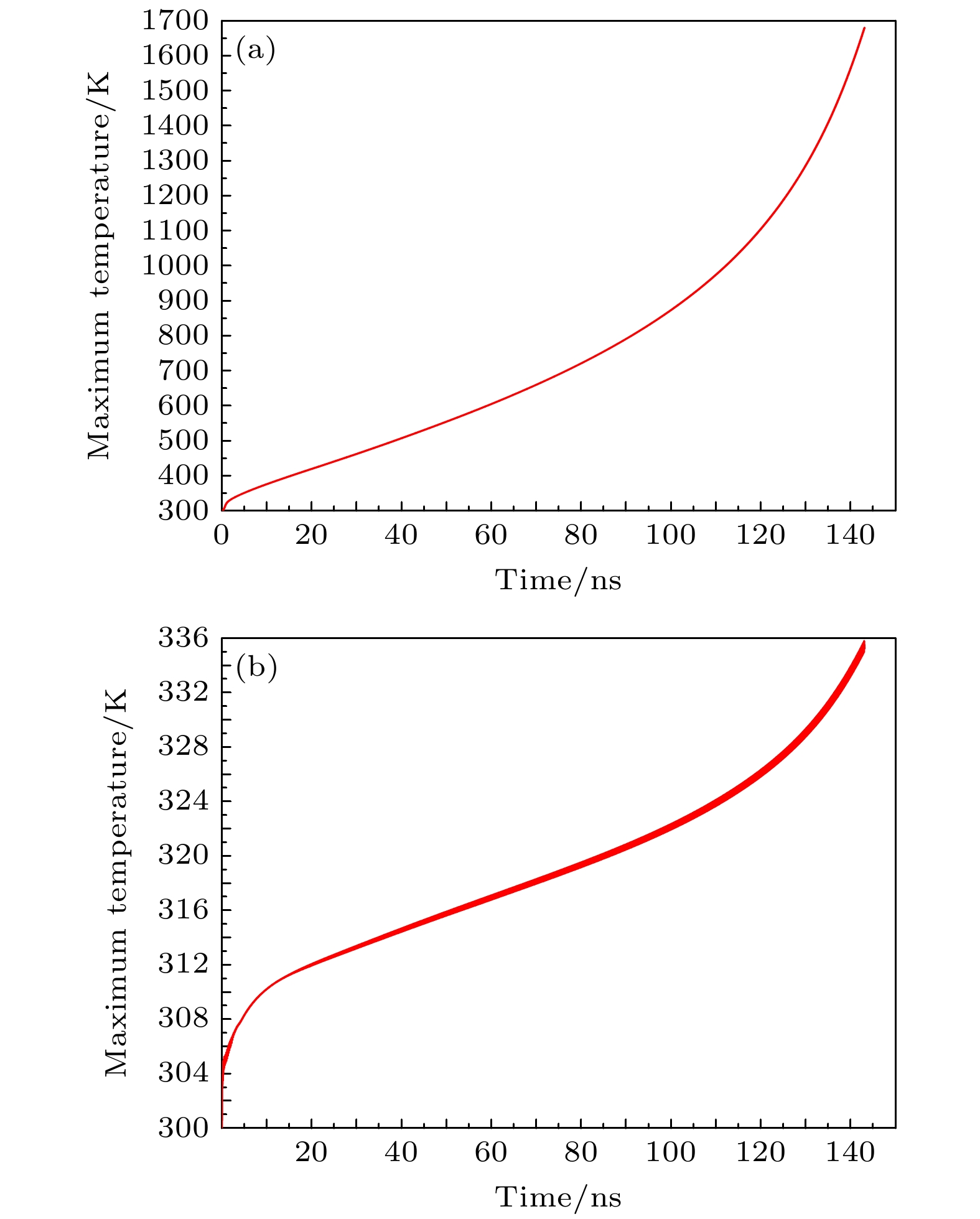

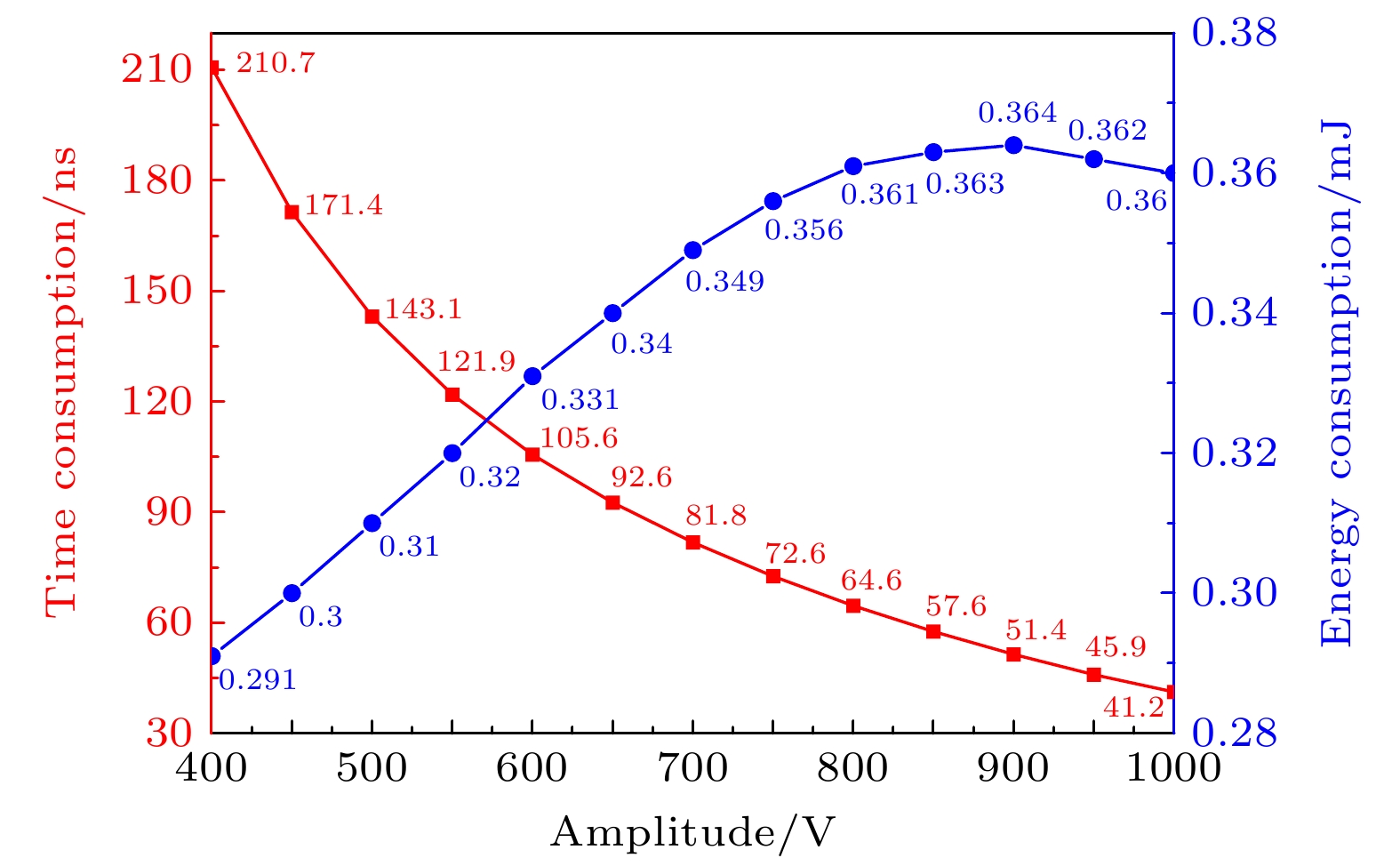

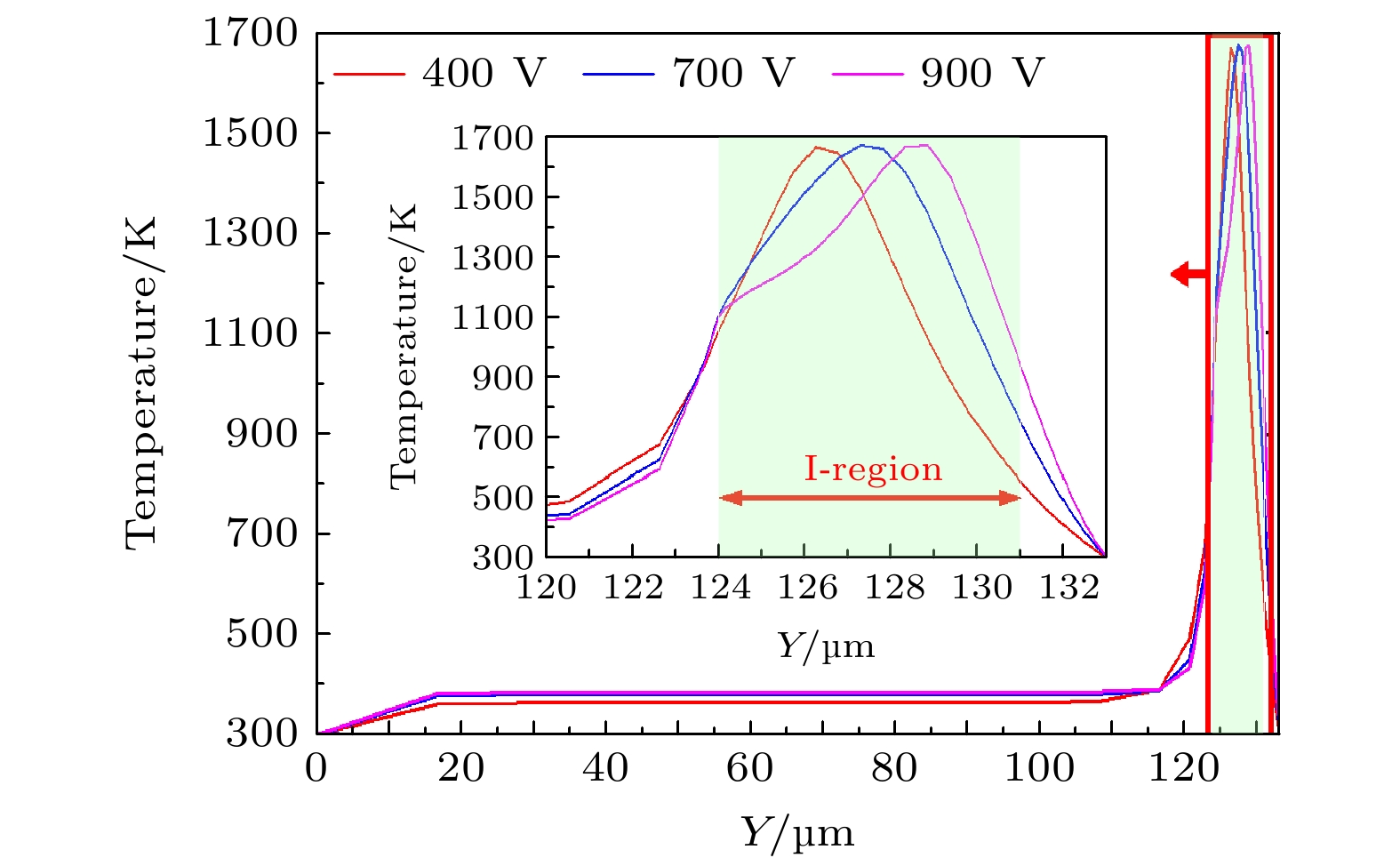

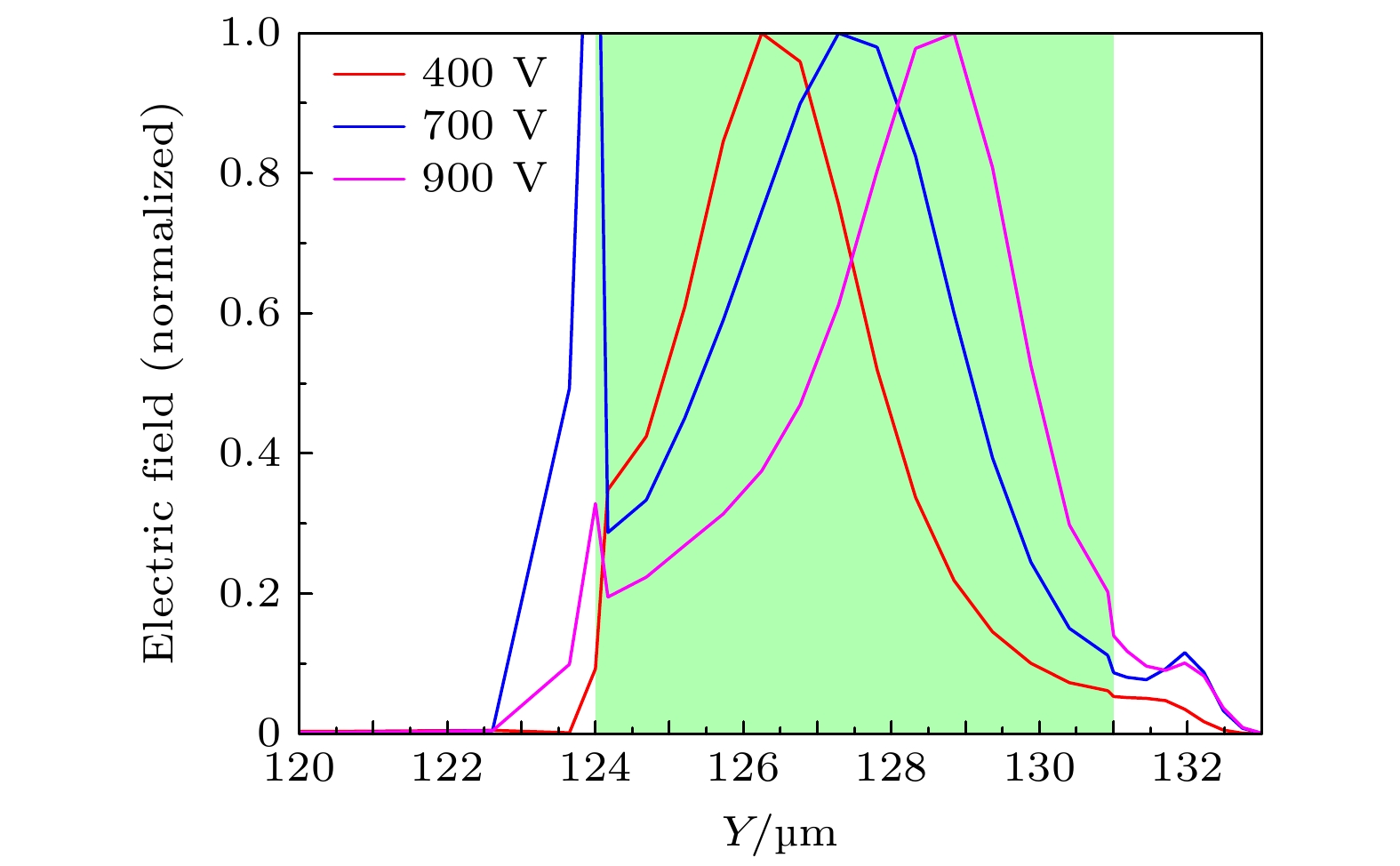

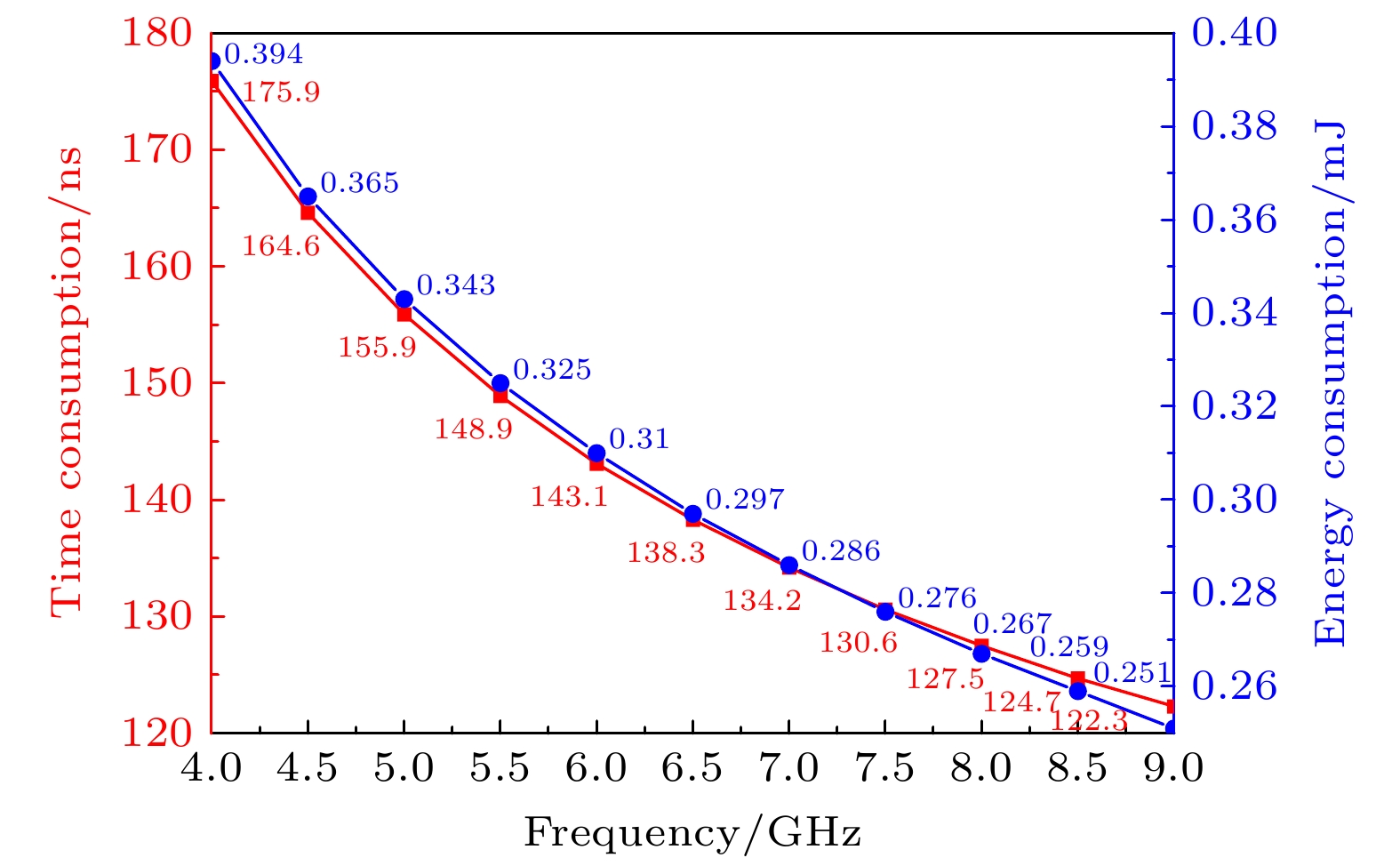

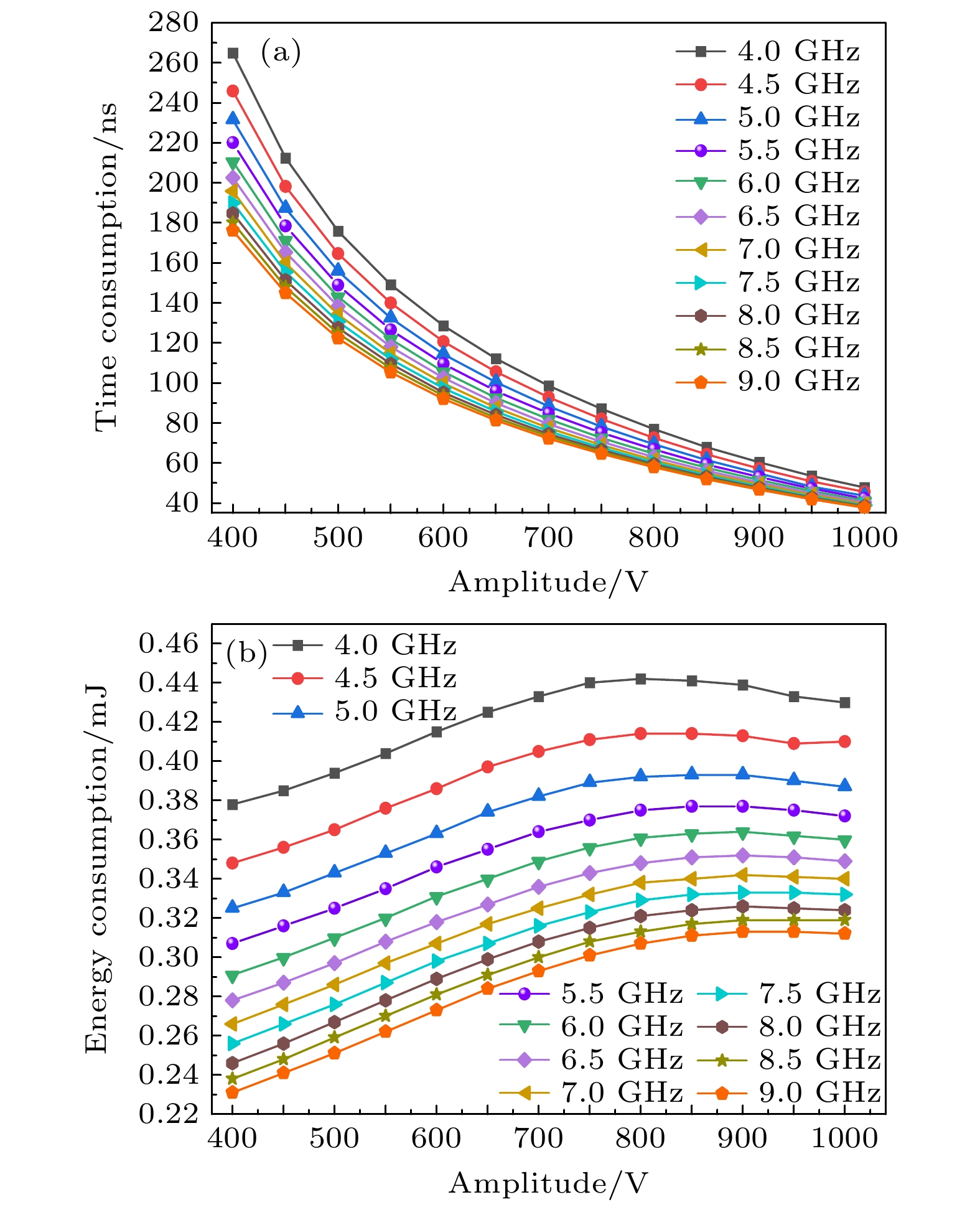

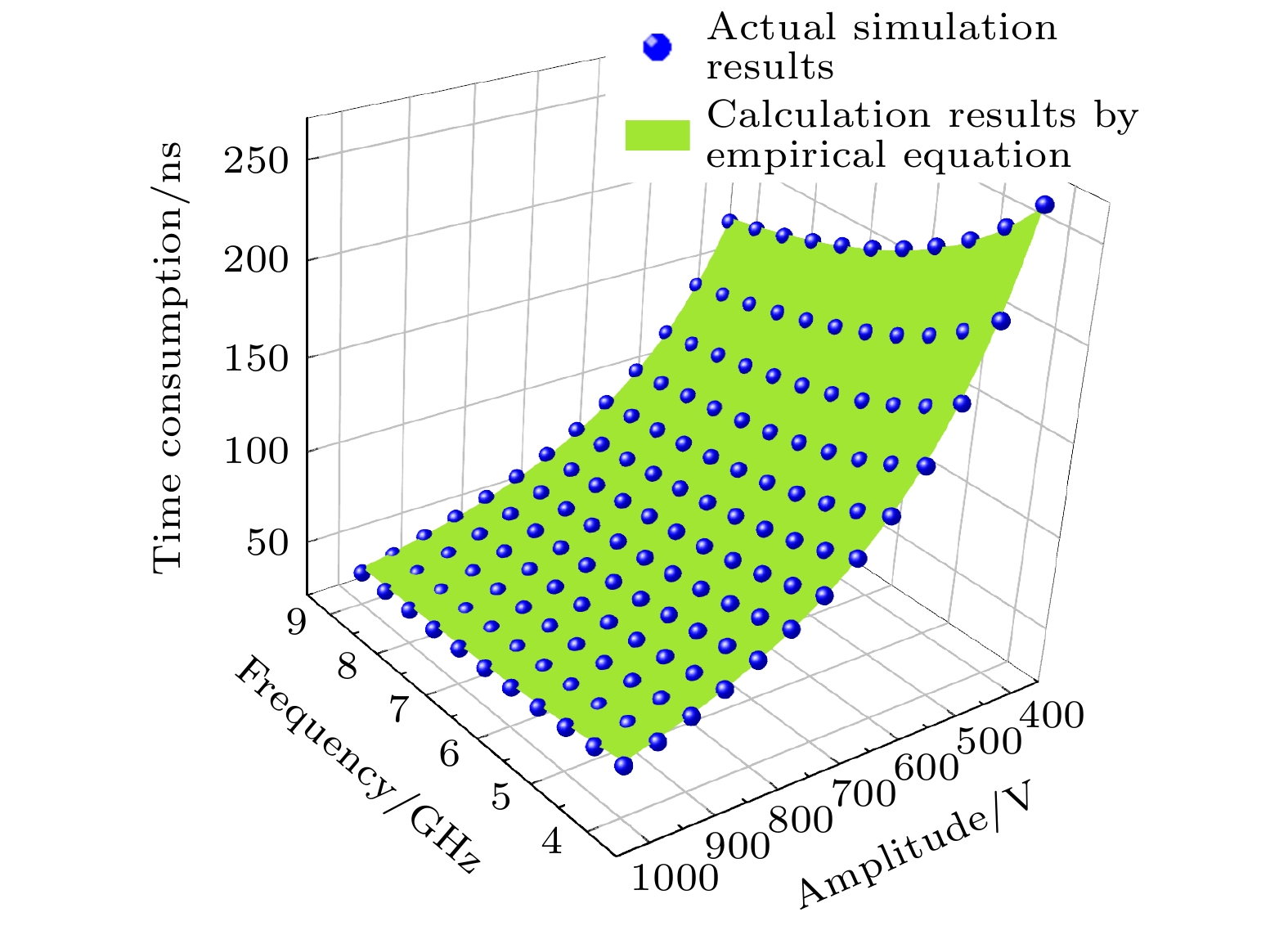

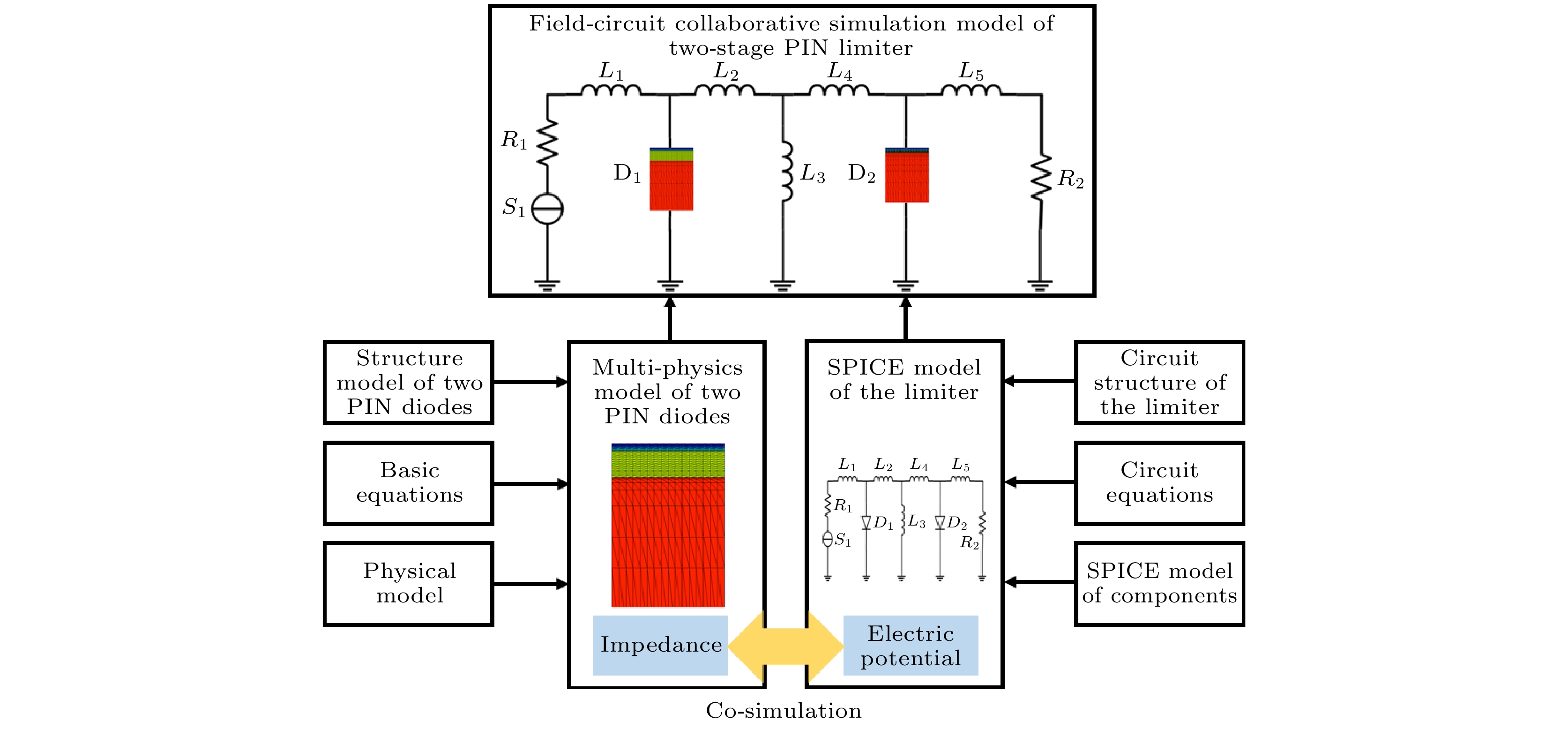

基于双级限幅器中两个PIN二极管的多物理场仿真模型与限幅器中其他电路元器件的SPICE模型, 搭建了Si基双级PIN限幅器的场路协同仿真模型, 利用这一模型对微波脉冲作用下限幅器中两级PIN二极管的温度响应特性进行了仿真. 在此基础上对限幅器在不同频率、幅值微波脉冲信号作用下内部发生熔化现象所需的时间与能量进行了仿真, 并对这一过程进行了机理分析与响应特性规律总结. 仿真结果表明, 当限幅器中第一级PIN二极管内部最高温度已达到材料熔点时, 第二级PIN二极管的温度变化幅度较小. 限幅器内部发生熔化现象所消耗的时间与能量随信号幅值、频率的变化呈现出规律性关系, 发生熔化现象所需的时间随信号幅值或频率的提升而减小; 发生熔化现象所需的能量随频率的提升而降低, 随幅值的变化存在极大值点; 限幅器的响应特性对信号参数表现出了不同的敏感性.

This paper aims to analyze the failure mechanism of the two-stage PIN limiter after having been injected by a microwave pulse. A two-stage PIN limiter model with high computational efficiency and accuracy is built by using the method of field-circuit collaborative simulation. Using this model, the temperature change of the PIN diodes during the injection of microwave pulse is simulated. The melting temperature of the PIN diode is selected as the failure criterion of the PIN limiter. The time and energy required for the failure of the PIN limiter under injection of microwave pulses with different frequencies and amplitudes are simulated. Furthermore, the mechanisms that trigger off these effects are analyzed. The relationship between the microwave pulse parameters and the PIN limiter failure time is summarized by using an empirical formula. According to the simulation results, the temperature change of the second-stage PIN diode is relatively small compared with that of the first-stage. During the injection of the microwave pulse, the failure time and energy consumption of limiter show a certain regularity with the variation of microwave pulse amplitude and frequency, and this work discusses this regularity from the following three aspects. Firstly, the failure time and energy consumption decrease in a similar trend with frequency increasing. And with the increase in signal amplitude, the failure time and energy consumption tend to stabilize. Secondly, the increase in the signal amplitude leads failure time to decrease, which is similar to the relationship between failure time and the signal frequency mentioned before. But as the signal’s amplitude increases, the energy consumption first increases and then decreases slightly when the amplitude reaches about 900 V. Based on the theoretical analysis and the physical image of the two-stage PIN limiter, the reasons for these effects can be explained as the changes in the I-region's impedance and heat distribution change caused by electric field changes. Thirdly, the failure time and energy consumption show different sensitivities to different parameters of the microwave pulse. The signal frequency change has greater influence on the energy consumption than the signal amplitude change, while the amplitude change can exert a greater influence on the failure time than the frequency change. -

Keywords:

- two-stage PIN limiter /

- microwave pulse /

- field-circuit collaborative simulation /

- heat effect

[1] Yu X H, Chai C C, Liu Y, Yang Y T, Fan Q Y 2015 Microelectron. Reliab. 55 1174

Google Scholar

Google Scholar

[2] Zhang C B, Zhang J D, Wang H G, Du G X 2015 Microelectron. Reliab. 55 508

Google Scholar

Google Scholar

[3] Li H, Chai C C, Liu Y Q, Wu H, Yang Y T 2018 Chin. Phys. B 27 088502

Google Scholar

Google Scholar

[4] Zhang C B, Zhang J D, Wang H G, Du G X 2016 Microelectron. Reliab. 60 41

Google Scholar

Google Scholar

[5] Zhou L, Chen X, Peng H L, Yin W Y, Mao J F 2018 IEEE Trans. Electromagn. Cmpat. 60 1427

Google Scholar

Google Scholar

[6] Zhou L, Zhang S, Yin W Y, Mao J F 2016 IEEE Trans. Electromagn. Compat. 58 487

Google Scholar

Google Scholar

[7] 赵振国, 马弘舸, 王艳 2012 微波学报 28 297

Google Scholar

Google Scholar

Zhao Z G, Ma H G, Wang Y 2012 J. Microwaves 28 297

Google Scholar

Google Scholar

[8] Zhang C B, Wang H G, Zhang J D, Du G X, Yang J 2014 IEEE Trans. Electromagn. Compat. 56 1545

Google Scholar

Google Scholar

[9] Hampel G, Kolodner P, Gammel P L, Polakos P A, Obaldia E D, Mankiewich P M, Anderson A, Slattery R, Zhang D, Liang G C, Shih C F 1996 Appl. Phys. Lett. 69 571

Google Scholar

Google Scholar

[10] Liu Y, Chai C C, Fan Q Y, Shi C L, Xi X W, Yu X H, Yang Y T 2016 Microelectron. Reliab. 66 32

Google Scholar

Google Scholar

[11] 马振洋, 柴常春, 任兴荣, 杨银堂, 陈斌 2012 61 078501

Google Scholar

Google Scholar

Ma Z Y, Chai C C, Ren X R, Yang Y T, Chen B 2012 Acta Phys. Sin. 61 078501

Google Scholar

Google Scholar

[12] 马振洋, 柴常春, 任兴荣, 杨银堂, 乔丽萍, 史春蕾 2013 62 128501

Google Scholar

Google Scholar

Ma Z Y, Chai C C, Ren X R, Yang Y T, Qiao L P, Shi C L 2013 Acta Phys. Sin. 62 128501

Google Scholar

Google Scholar

[13] 任兴荣, 柴常春, 马振洋, 杨银堂, 乔丽萍 2013 62 068501

Google Scholar

Google Scholar

Ren X R, Chai C C, Ma Z Y, Yang Y T, Qiao L P 2013 Acta Phys. Sin. 62 068501

Google Scholar

Google Scholar

[14] 刘阳, 柴常春, 于新海, 樊庆扬, 杨银堂, 席晓文, 刘胜北 2016 65 038402

Google Scholar

Google Scholar

Liu Y, Chai C C, Yu X H, Fan Q Y, Yang Y T, Xi X W, Liu S B 2016 Acta Phys. Sin. 65 038402

Google Scholar

Google Scholar

[15] 张永战, 孟凡宝, 赵刚 2017 强激光与粒子束 29 093002

Google Scholar

Google Scholar

Zhang Y Z, Meng F B, Zhao G 2017 High Power Laser Part. Beams 29 093002

Google Scholar

Google Scholar

[16] 周怀安, 杜正伟, 龚克 2005 强激光与粒子束 17 783

Zhou H A, Du Z W, Gong K 2005 High Power Laser Part. Beams 17 783

[17] 戚玉佳, 李永东, 郝勇, 王洪广, 李平, 刘纯亮 2014 微波学报 30 220

Google Scholar

Google Scholar

Qi Y J, Li Y D, Hao Y, Wang H G, Li P, Liu C L 2014 J. Microwaves 30 220

Google Scholar

Google Scholar

[18] 李勇, 宣春, 谢海燕, 夏洪富, 王建国 2013 强激光与粒子束 25 2061

Google Scholar

Google Scholar

Li Y, Yi C, Xie H Y, Xia H F, Wang J G 2013 High Power Laser Part. Beams 25 2061

Google Scholar

Google Scholar

[19] 胡凯, 李天明, 汪海洋, 周翼鸿 2014 强激光与粒子束 26 063015

Google Scholar

Google Scholar

Hu K, Li T M, Wang H Y, Zhou Y H 2014 High Power Laser Part. Beams 26 063015

Google Scholar

Google Scholar

[20] 易世鹏, 杜正伟, 赵景涛, 赵刚 2019 电波科学学报 34 479

Google Scholar

Google Scholar

Yi S P, Du Z W, Zhao J T, Zhao G 2019 Chin. J. Radio Sci. 34 479

Google Scholar

Google Scholar

[21] 王明, 马弘舸 2018 强激光与粒子束 30 063002

Google Scholar

Google Scholar

Wang M, Ma H G 2018 High Power Laser Part. Beams 30 063002

Google Scholar

Google Scholar

[22] 赵振国, 马弘舸, 赵刚, 王艳, 钟龙权 2013 强激光与粒子束 25 1741

Google Scholar

Google Scholar

Zhao Z G, Ma H G, Zhao G, Wang Y, Zhong L Q 2013 High Power Laser Part. Beams 25 1741

Google Scholar

Google Scholar

[23] Susanna R, Marina V, Luigi C, Massimo R, Giorgio B, Andreas D S, Fridolin I, Norbert F, Wolfgang F, Lucia Z 2002 IEEE. Trans. Electron. Devices 49 490

Google Scholar

Google Scholar

[24] Canali C, Majni G, Minder R, Ottaviani G 1975 IEEE. Trans. Electron. Devices 22 1045

Google Scholar

Google Scholar

[25] Leenov D 1964 IEEE. Trans. Electron. Devices 11 53

Google Scholar

Google Scholar

-

表 A1 UniBo模型相关参数

Table A1. Parameters related to UniBo model

参数 电子(P) 空穴(B) ${\mu _{\max }}$/(${\text{c}}{{\text{m}}^{2}} {\cdot} {{\text{V}}^{{{ - 1}}}} {\cdot} {{\text{s}}^{{{ - 1}}}}$) 1441 470.5 $c$ –0.11 0 $\gamma $ 2.45 2.16 ${\mu _{0 d}}$/(${\text{c}}{{\text{m}}^{2}} {\cdot} {{\text{V}}^{{{ - 1}}}} {\cdot} {{\text{s}}^{{{ - 1}}}}$) 62.2${T_n}^{{{ - }}{\gamma _{{0}d}}}$ 90.0$ {T_n}^{{{ - }}{\gamma _{{0}d}}} $ ${\gamma _{0 d}}$ 0.7 1.3 ${\mu _{1 d}}$/(${\text{c}}{{\text{m}}^{2}} {\cdot} {{\text{V}}^{{{ - 1}}}} {\cdot} {{\text{s}}^{{{ - 1}}}}$) 48.6${T_n}^{{{ - }}{\gamma _{{1}d}}}$ 28.2${T_n}^{{{ - }}{\gamma _{{1}d}}}$ ${\gamma _{1 d}}$ 0.7 2.0 ${\mu _{1 a}}$/(${\text{c}}{{\text{m}}^{2}} {\cdot} {{\text{V}}^{{{ - 1}}}} {\cdot} {{\text{s}}^{{{ - 1}}}}$) 73.5${T_n}^{{{ - }}{\gamma _{{1}a}}}$ 28.2${T_n}^{{{ - }}{\gamma _{{1}a}}}$ ${\gamma _{1 a}}$ 1.25 0.8 ${C_{r1}}$/cm–3 $8.5 \times {10^{16}} {T_n}^{{\gamma _{r1}}}$ $1.3 \times {10^{18}} {T_n}^{{\gamma _{r{1}}}}$ ${\gamma _{r1}}$ 3.65 2.2 ${C_{r2}}$/cm–3 $1.22 \times {10^{17}} {T_n}^{{\gamma _{r2}}}$ $2.45 \times {10^{17}} {T_n}^{{\gamma _{r{2}}}}$ ${\gamma _{r2}}$ 2.65 3.1 ${C_{s1}}$/cm–3 $4.0 \times {10^{20}} {T_n}^{{\gamma _{s{1}}}}$ $1.1 \times {10^{18}} {T_n}^{{\gamma _{s{1}}}}$ ${\gamma _{s1}}$ 0 6.2 ${C_{s2}}$/(1020 cm–3) $7.0$ $6.1$ $\alpha $ 0.68 0.77 $\beta $ 0.72 0.719 ${\mu _{0 a}}$/(${\text{c}}{{\text{m}}^{2}} {\cdot} {{\text{V}}^{{{ - 1}}}} {\cdot} {{\text{s}}^{{{ - 1}}}}$) 132.0${T_n}^{{{ - }}{\gamma _{{0}a}}}$ 44.0${T_n}^{{{ - }}{\gamma _{{0}a}}}$ ${\gamma _{0 a}}$ 1.3 0.7 表 A2 Conwell-Weisskopf模型相关参数

Table A2. Parameters related to Conwell-Weisskopf model

参数 值 $D$/(cm–1·V–1·s–1) $1.04 \times {10^{21}}$ $F$/cm–2 $7.452 \times {10^{13}}$ 表 A3 ${v_{{\text{sat}}}}$相关计算参数

Table A3. Parameters related to the calculation of ${v_{{\text{sat}}}}$

参数 电子 空穴 ${v_{{\text{sat, 0}}}}$/(107 cm·s–1) $1.07$ $0.837$ $ {v_{{\text{sat}}, \exp }} $ 0.87 0.52 表 A4 Canali模型相关参数

Table A4. Parameters related to Canali model

参数 电子 空穴 ${\beta _0}$ 1.109 1.213 ${\beta _{\exp }}$ 0.66 0.17 表 A5 SRH复合模型相关参数

Table A5. Parameters related to SRH Recombination model

参数 电子 空穴 ${\tau _{\min }}$/s 0 0 ${\tau _{\max }}$/μs $10$ $3$ ${\tau _0}$/μs $10$ $3$ ${N_{{\text{ref}}}}$/(1016 cm–3) $1$ $1$ $\gamma $ 1 1 ${T_{\text{α }}}$ –1.5 –1.5 ${E_{{\text{trap}}}}$/eV 0 0 表 A6 俄歇复合模型相关参数

Table A6. Parameters related to Auger recombination model

参数 电子 空穴 ${A_{\text{A}}}$/(10–32 cm6·s–1) $6.7$ $7.2$ ${B_{\text{A}}}$/(10–33 cm6·s–1) $245$ $4.5$ ${C_{\text{A}}}$/(10–33 cm6·s–1) $ - 2.2$ $2.63$ $H$ 3.46667 8.25688 ${N_0}$/(1018 cm–3) $1$ $1$ 表 A7 雪崩模型相关参数

Table A7. Parameters related to avalanche model

参数 电子 空穴 ${a_0}$/V 4.65403 2.26018 ${a_1}$/mV $ - 8.76031$ 13.4001 ${a_2}$/μV $13.4037$ $ - 5.87724$ ${a_3}$/nV $ - 2.75108$ $ - 1.14021$ ${b_0}$/V –0.128302 0.058547 ${b_1}$/(10–4 V) $44.5552$ $ - 1.95755$ ${b_2}$/(10–7 V) $ - 108.66$ $2.44357$ ${b_3}$/(10–10 V) $92.3119$ $ - 1.33202$ ${b_4}$/(10–14 V) $ - 182.482$ $2.68082$ ${b_5}$/V $ - 4.82689 \times {10^{ - 15}}$ 0 ${b_6}$/V $1.09402 \times {10^{ - 17}}$ 0 ${b_7}$/V $ - 1.24961 \times {10^{ - 20}}$ 0 ${b_8}$/V $7.55584 \times {10^{ - 24}}$ 0 ${b_9}$/V $ - 2.28615 \times {10^{ - 27}}$ 0 ${b_{10}}$/V $2.73344 \times {10^{ - 31}}$ 0 ${c_0}$/(103 V·cm–1) $7.76221$ $19.5399$ ${c_1}$/(V·cm–1) 25.18888 –104.441 ${c_2}$/(V·cm–1) $ - 1.37417 \times {10^{ - 3}}$ 0.498768 ${c_3}$/(V·cm–1) $1.59525 \times {10^{ - 4}}$ 0 ${d_0}$/(105 V·cm–1) $7.10481$ $20.7712$ ${d_1}$/(103 V·cm–1) $3.98594$ 0.993153 ${d_2}$/(V·cm–1) –7.19956 7.77769 ${d_3}$/(V·cm–1) $6.96431 \times {10^{ - 3}}$ 0 -

[1] Yu X H, Chai C C, Liu Y, Yang Y T, Fan Q Y 2015 Microelectron. Reliab. 55 1174

Google Scholar

Google Scholar

[2] Zhang C B, Zhang J D, Wang H G, Du G X 2015 Microelectron. Reliab. 55 508

Google Scholar

Google Scholar

[3] Li H, Chai C C, Liu Y Q, Wu H, Yang Y T 2018 Chin. Phys. B 27 088502

Google Scholar

Google Scholar

[4] Zhang C B, Zhang J D, Wang H G, Du G X 2016 Microelectron. Reliab. 60 41

Google Scholar

Google Scholar

[5] Zhou L, Chen X, Peng H L, Yin W Y, Mao J F 2018 IEEE Trans. Electromagn. Cmpat. 60 1427

Google Scholar

Google Scholar

[6] Zhou L, Zhang S, Yin W Y, Mao J F 2016 IEEE Trans. Electromagn. Compat. 58 487

Google Scholar

Google Scholar

[7] 赵振国, 马弘舸, 王艳 2012 微波学报 28 297

Google Scholar

Google Scholar

Zhao Z G, Ma H G, Wang Y 2012 J. Microwaves 28 297

Google Scholar

Google Scholar

[8] Zhang C B, Wang H G, Zhang J D, Du G X, Yang J 2014 IEEE Trans. Electromagn. Compat. 56 1545

Google Scholar

Google Scholar

[9] Hampel G, Kolodner P, Gammel P L, Polakos P A, Obaldia E D, Mankiewich P M, Anderson A, Slattery R, Zhang D, Liang G C, Shih C F 1996 Appl. Phys. Lett. 69 571

Google Scholar

Google Scholar

[10] Liu Y, Chai C C, Fan Q Y, Shi C L, Xi X W, Yu X H, Yang Y T 2016 Microelectron. Reliab. 66 32

Google Scholar

Google Scholar

[11] 马振洋, 柴常春, 任兴荣, 杨银堂, 陈斌 2012 61 078501

Google Scholar

Google Scholar

Ma Z Y, Chai C C, Ren X R, Yang Y T, Chen B 2012 Acta Phys. Sin. 61 078501

Google Scholar

Google Scholar

[12] 马振洋, 柴常春, 任兴荣, 杨银堂, 乔丽萍, 史春蕾 2013 62 128501

Google Scholar

Google Scholar

Ma Z Y, Chai C C, Ren X R, Yang Y T, Qiao L P, Shi C L 2013 Acta Phys. Sin. 62 128501

Google Scholar

Google Scholar

[13] 任兴荣, 柴常春, 马振洋, 杨银堂, 乔丽萍 2013 62 068501

Google Scholar

Google Scholar

Ren X R, Chai C C, Ma Z Y, Yang Y T, Qiao L P 2013 Acta Phys. Sin. 62 068501

Google Scholar

Google Scholar

[14] 刘阳, 柴常春, 于新海, 樊庆扬, 杨银堂, 席晓文, 刘胜北 2016 65 038402

Google Scholar

Google Scholar

Liu Y, Chai C C, Yu X H, Fan Q Y, Yang Y T, Xi X W, Liu S B 2016 Acta Phys. Sin. 65 038402

Google Scholar

Google Scholar

[15] 张永战, 孟凡宝, 赵刚 2017 强激光与粒子束 29 093002

Google Scholar

Google Scholar

Zhang Y Z, Meng F B, Zhao G 2017 High Power Laser Part. Beams 29 093002

Google Scholar

Google Scholar

[16] 周怀安, 杜正伟, 龚克 2005 强激光与粒子束 17 783

Zhou H A, Du Z W, Gong K 2005 High Power Laser Part. Beams 17 783

[17] 戚玉佳, 李永东, 郝勇, 王洪广, 李平, 刘纯亮 2014 微波学报 30 220

Google Scholar

Google Scholar

Qi Y J, Li Y D, Hao Y, Wang H G, Li P, Liu C L 2014 J. Microwaves 30 220

Google Scholar

Google Scholar

[18] 李勇, 宣春, 谢海燕, 夏洪富, 王建国 2013 强激光与粒子束 25 2061

Google Scholar

Google Scholar

Li Y, Yi C, Xie H Y, Xia H F, Wang J G 2013 High Power Laser Part. Beams 25 2061

Google Scholar

Google Scholar

[19] 胡凯, 李天明, 汪海洋, 周翼鸿 2014 强激光与粒子束 26 063015

Google Scholar

Google Scholar

Hu K, Li T M, Wang H Y, Zhou Y H 2014 High Power Laser Part. Beams 26 063015

Google Scholar

Google Scholar

[20] 易世鹏, 杜正伟, 赵景涛, 赵刚 2019 电波科学学报 34 479

Google Scholar

Google Scholar

Yi S P, Du Z W, Zhao J T, Zhao G 2019 Chin. J. Radio Sci. 34 479

Google Scholar

Google Scholar

[21] 王明, 马弘舸 2018 强激光与粒子束 30 063002

Google Scholar

Google Scholar

Wang M, Ma H G 2018 High Power Laser Part. Beams 30 063002

Google Scholar

Google Scholar

[22] 赵振国, 马弘舸, 赵刚, 王艳, 钟龙权 2013 强激光与粒子束 25 1741

Google Scholar

Google Scholar

Zhao Z G, Ma H G, Zhao G, Wang Y, Zhong L Q 2013 High Power Laser Part. Beams 25 1741

Google Scholar

Google Scholar

[23] Susanna R, Marina V, Luigi C, Massimo R, Giorgio B, Andreas D S, Fridolin I, Norbert F, Wolfgang F, Lucia Z 2002 IEEE. Trans. Electron. Devices 49 490

Google Scholar

Google Scholar

[24] Canali C, Majni G, Minder R, Ottaviani G 1975 IEEE. Trans. Electron. Devices 22 1045

Google Scholar

Google Scholar

[25] Leenov D 1964 IEEE. Trans. Electron. Devices 11 53

Google Scholar

Google Scholar

计量

- 文章访问数: 3135

- PDF下载量: 61

- 被引次数: 0

下载:

下载: