-

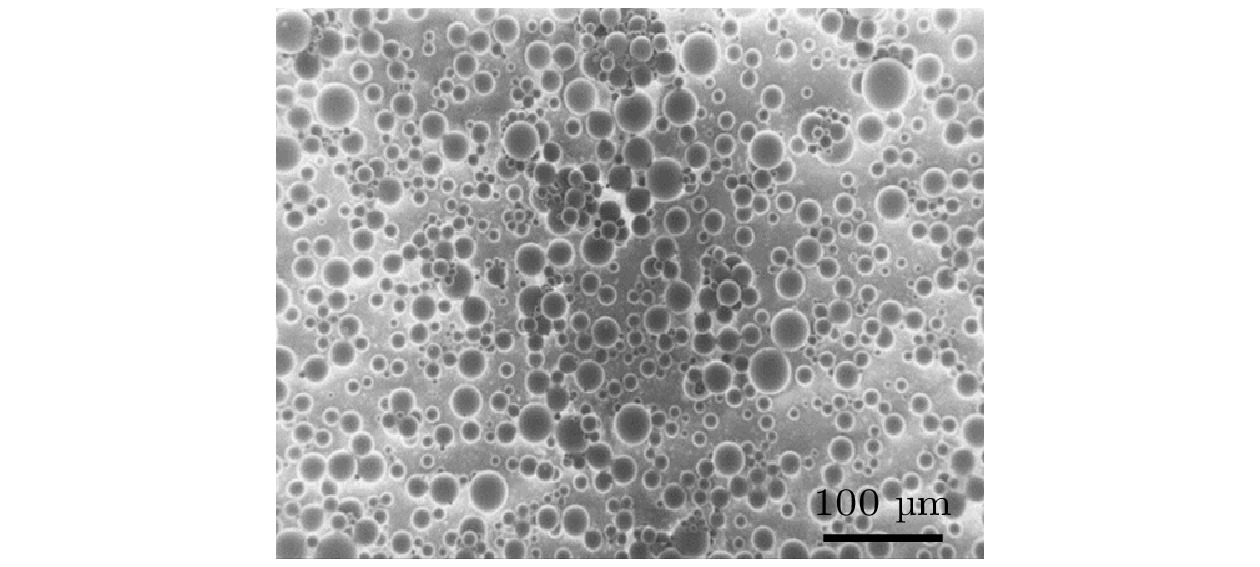

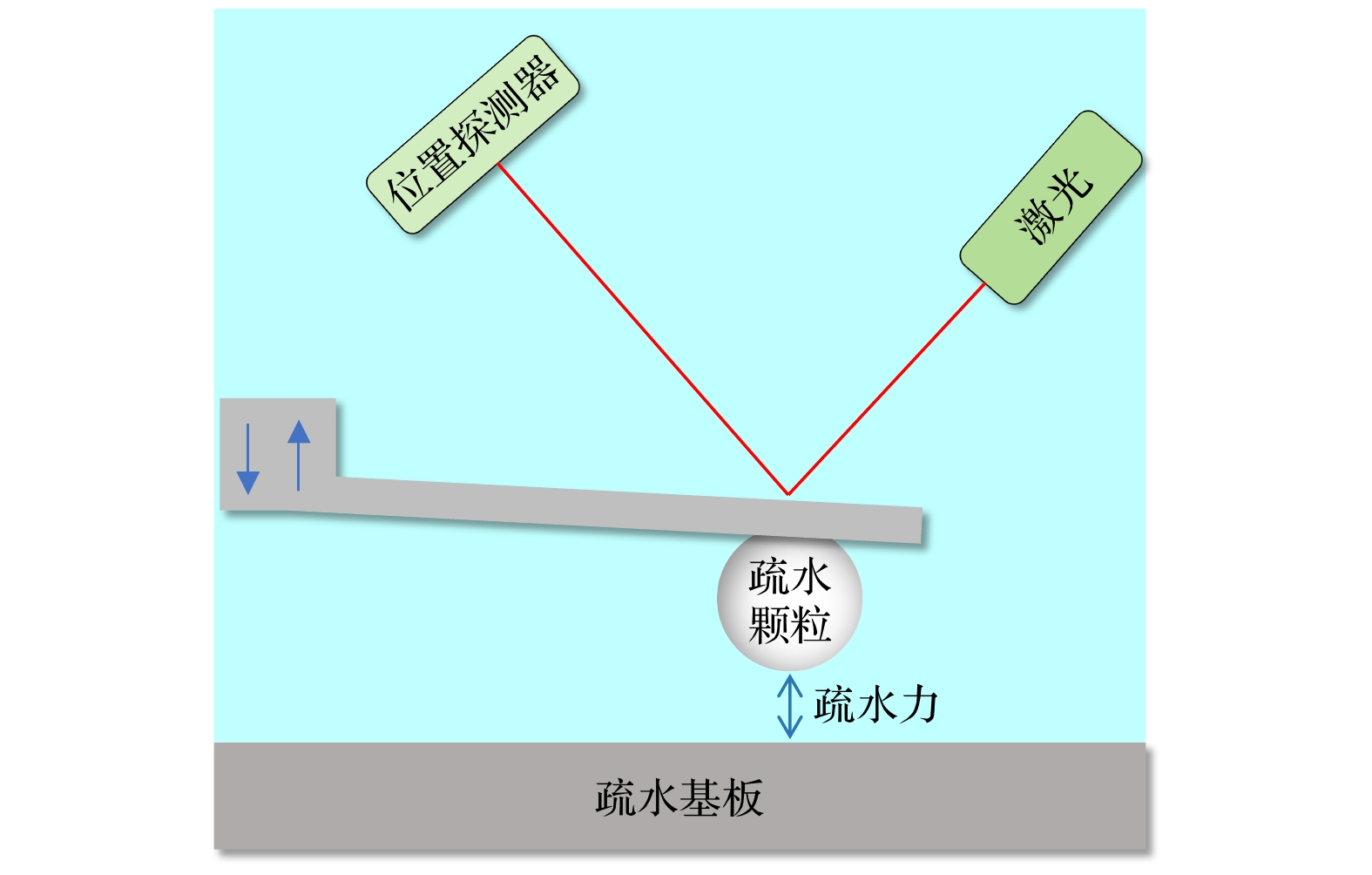

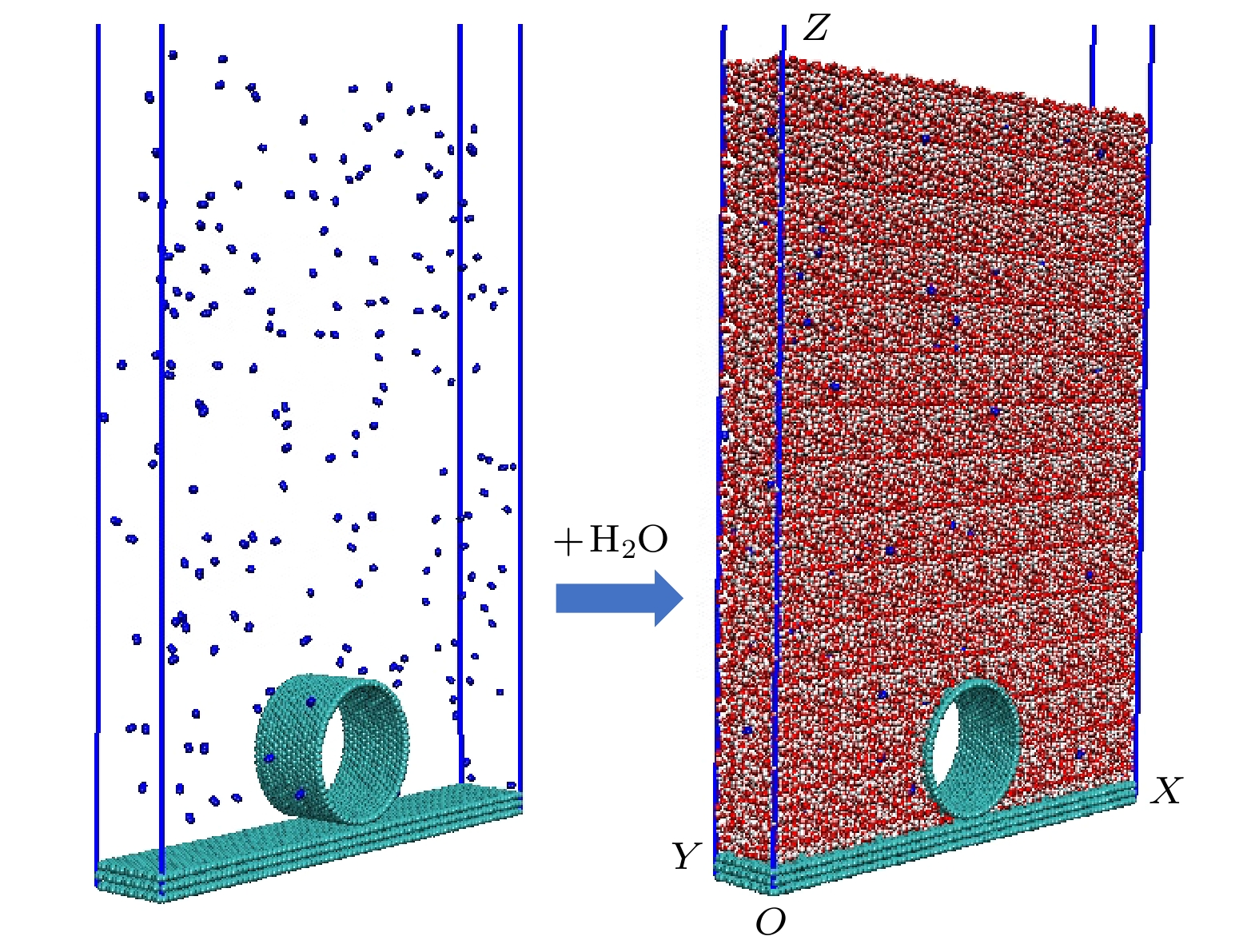

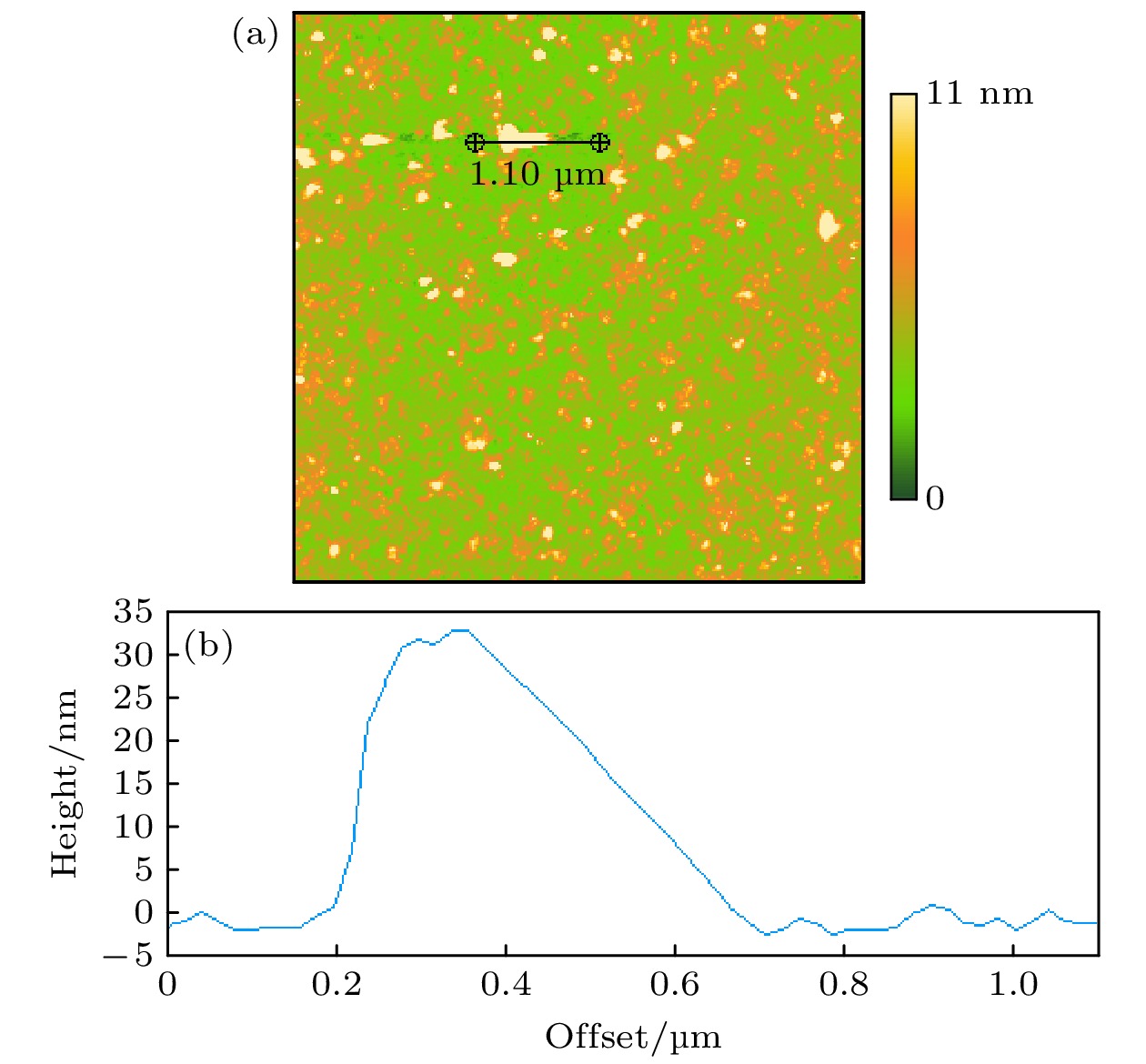

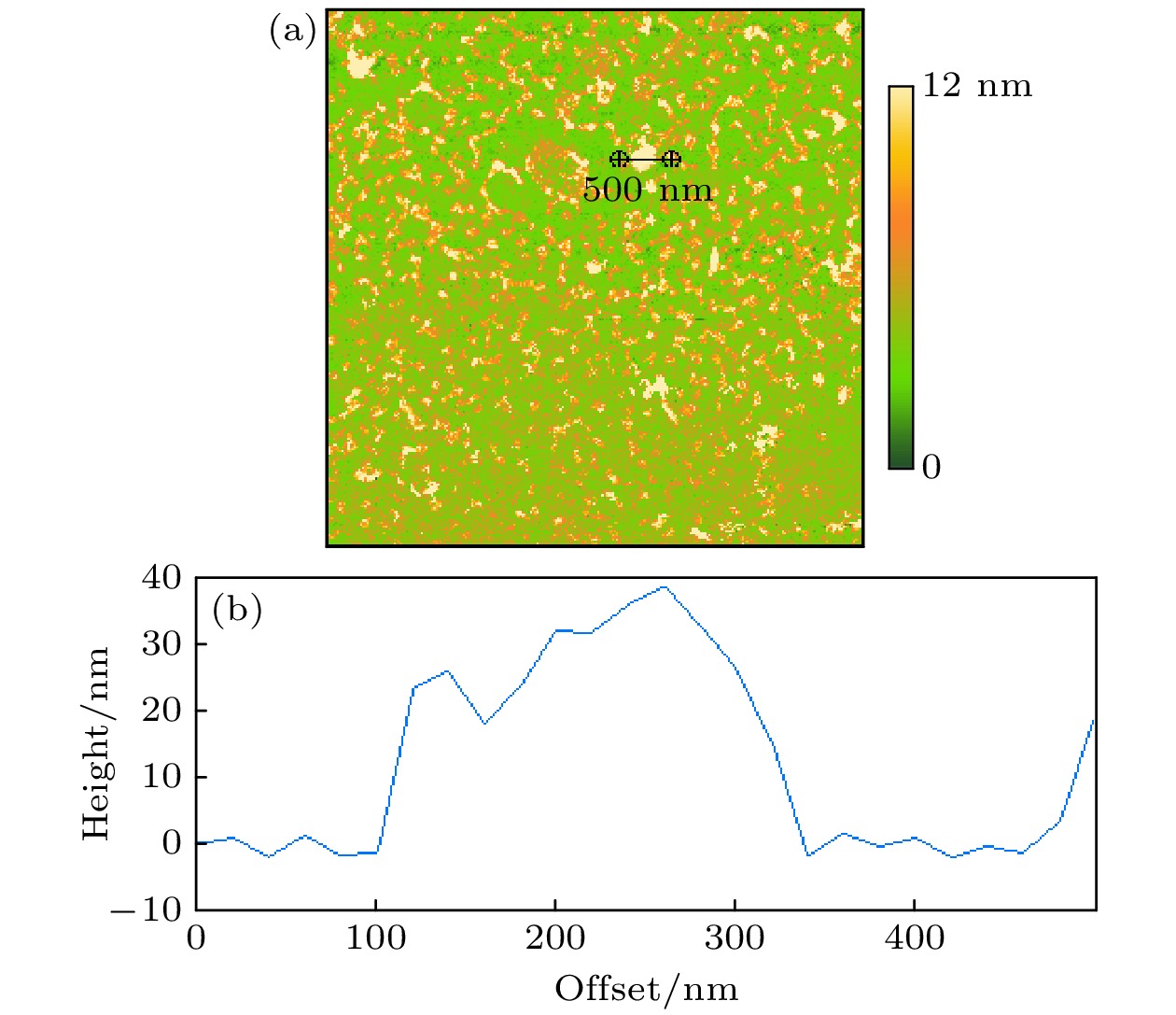

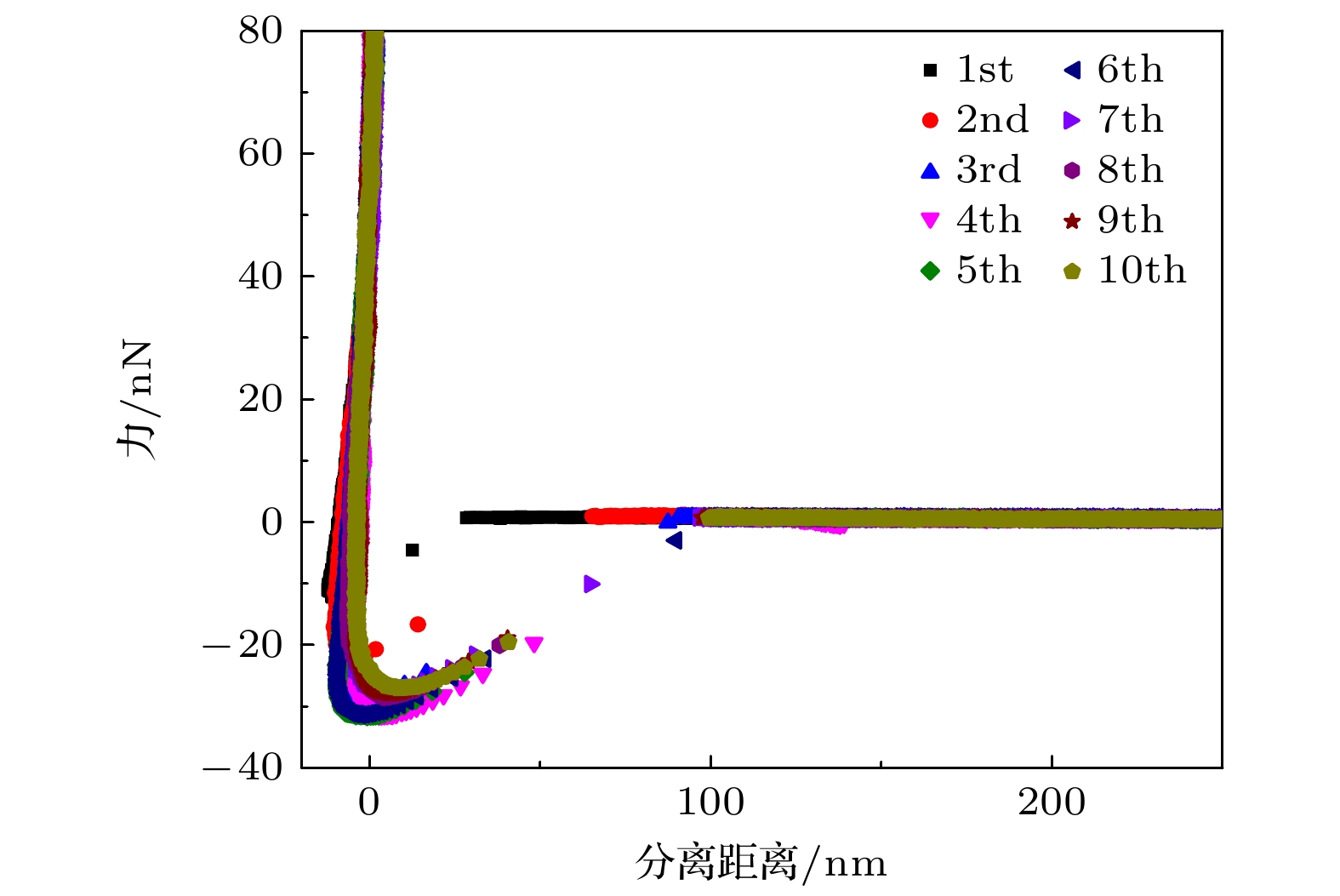

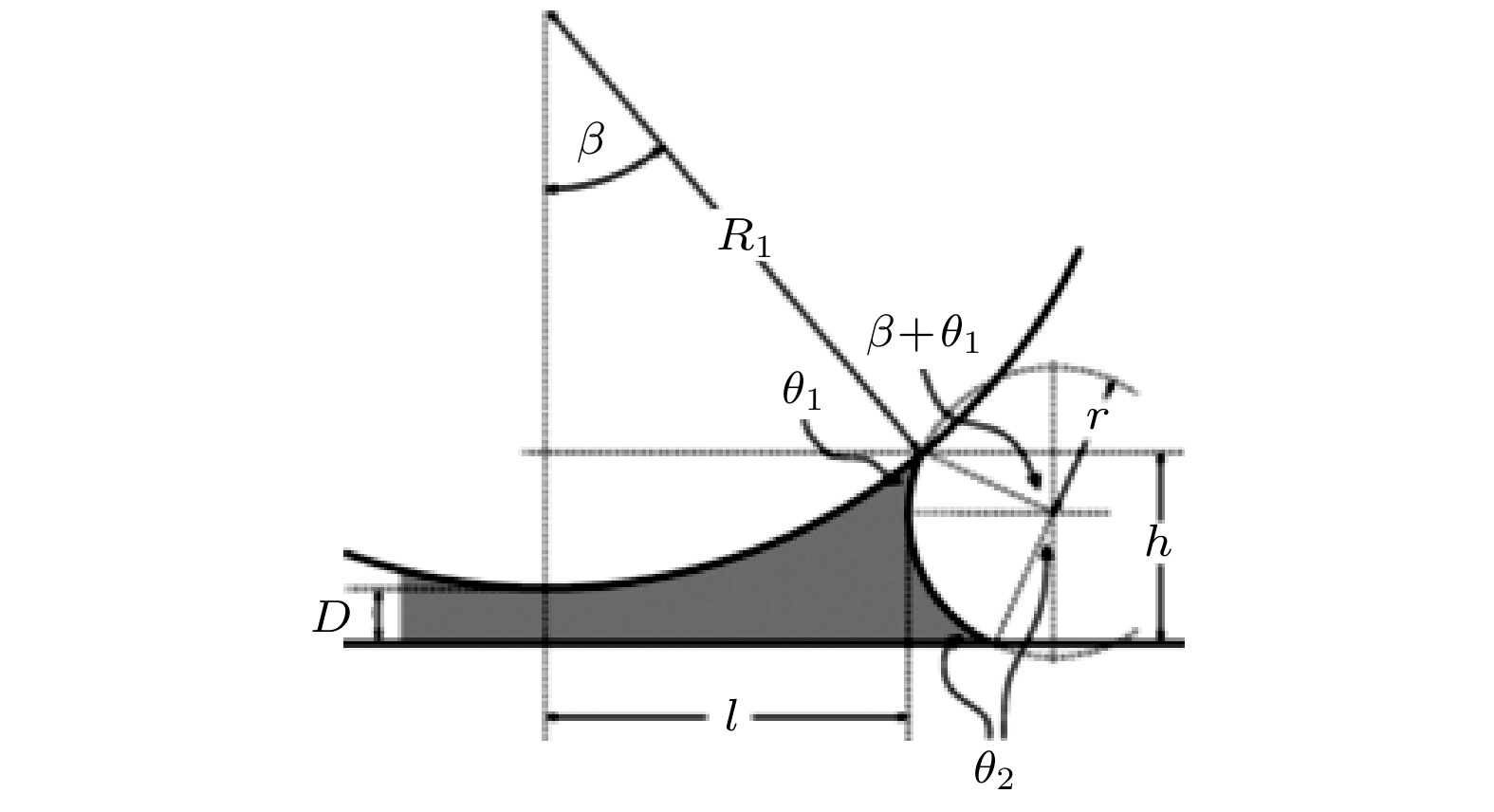

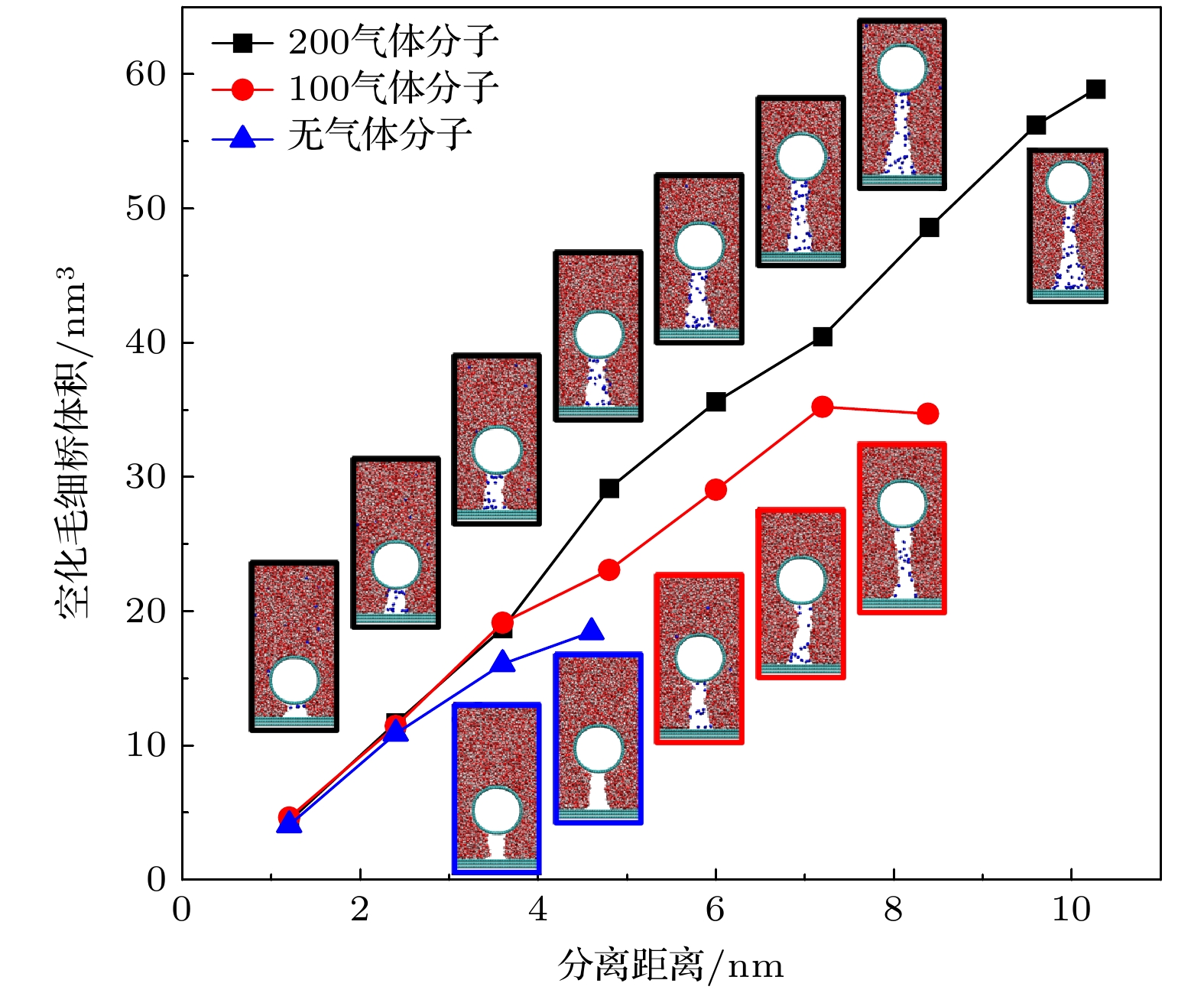

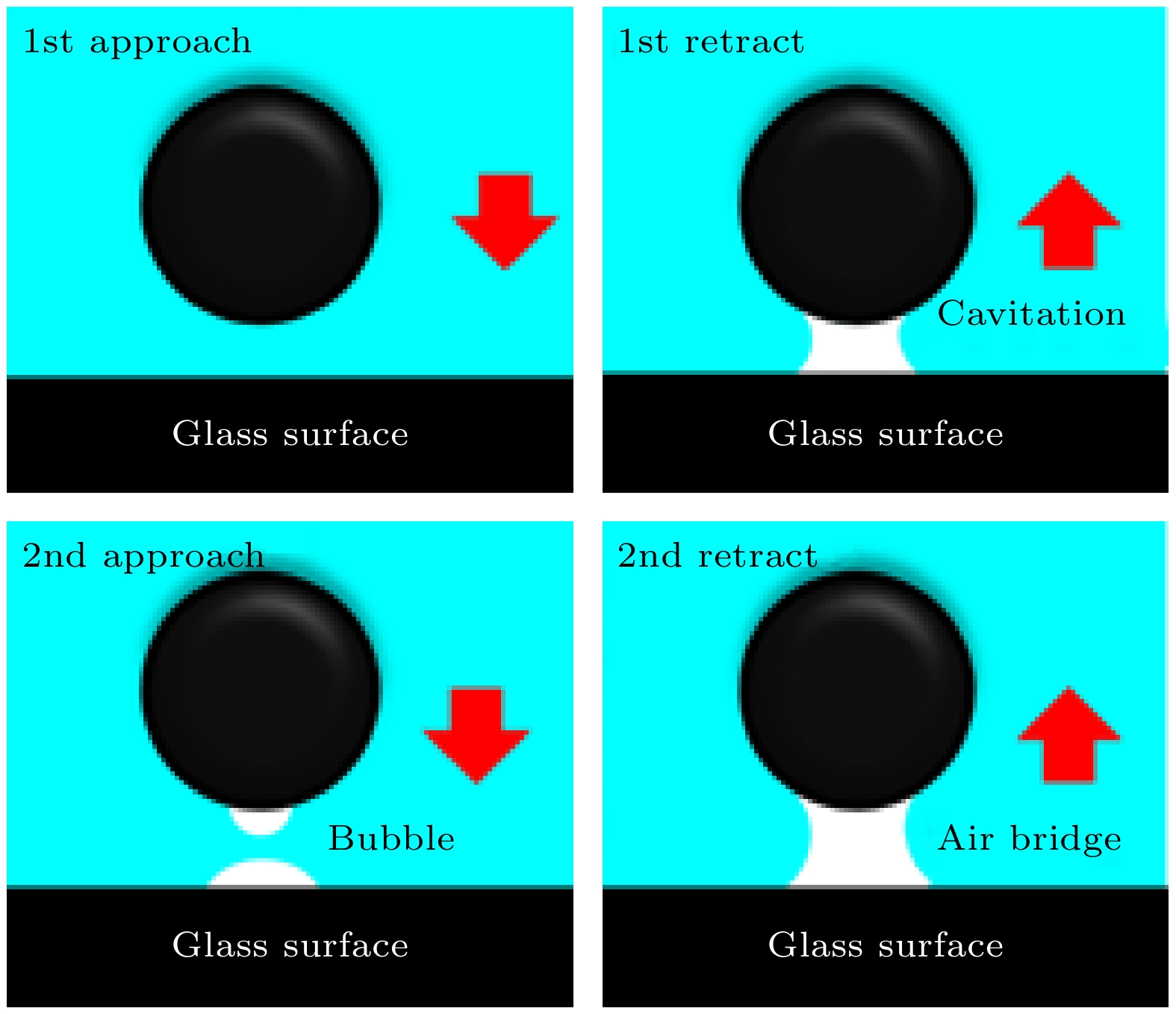

疏水力作为胶体物理化学及生物大分子体系中重要作用力, 具有典型的多尺度作用程特征, 其中亚稳态液膜空化气泡桥接诱发长程疏水力和固液界面水分子重排熵效应诱导短程疏水力假说占据着当前学术主流, 但仍缺少系统理论研究. 为进一步阐明基于亚稳态液膜空化的长程疏水力作用机制, 借助原子力显微镜(AFM)及分子动力学模拟对全氟辛基三氯硅烷疏水化颗粒与表面间长程疏水力进行了系统研究. AFM力测试结果表明: 长程疏水力作用程随接近次数增加而逐渐增大并逐渐趋于稳定, 第十次接触时进针曲线跳入黏附距离达到502.01 nm, 退针曲线中观察到了预示空化气泡毛细桥断裂的台阶. 此外, 发现经典毛细力数学模型可以较好地拟合进针曲线, 通过计算得到毛细桥体积约为0.30 μm3, 从理论角度直接验证了亚稳态液膜空化气泡毛细桥的存在. 进一步借助GROMACS (GROningen MAchine for Chemical Simulations)大尺度牵引分子动力学模拟从分子尺度探索疏水颗粒分离过程中空化气泡毛细桥产生、演化过程与力学行为的内在关联机制, 结果表明: 疏水颗粒从基板表面跳出分离瞬间, 产生的局部压降吸引氮气分子向液膜内部扩散从而形成空化气泡毛细桥, 同时, 在毛细桥断裂时刻在计算弹簧势力曲线中观察到了力跳跃行为. 最后研究了溶液气体含量对长程疏水力的影响规律, 发现气体分子含量和空化气泡毛细桥体积增长速率与毛细桥拉伸断裂长度呈现正相关关系, 进一步表明了长程疏水力的气体浓度依赖效应. 基于亚稳态液膜空化的长程疏水力作用机制的揭示有助于进一步完善胶体物理化学及生物大分子间相互作用理论体系, 同时对调控实际矿物浮选过程具有重要指导意义.Hydrophobic force, a key driving force in colloid physicochemical system and biological macromolecular system, exhibits a distinct multi-scale effect. The prevailing scholarly consensus attributes long-range hydrophobic force to bubble bridging, facilitated by unstable liquid film cavitation, while short-range force is thought to arise from the reorganization of water molecules at the solid-liquid interface. However, a comprehensive theoretical study remains elusive. To further elucidate the mechanism of the long-range hydrophobic force based on unstable liquid film cavitation, we carry out systematic research on the long-range hydrophobic force between perfluorooctyl trichlorosilane hydrophobic particles and the surface, by utilizing atomic force microscopy (AFM) and molecular dynamics simulations. According to AFM force tests, the long-range hydrophobic force escalates incrementally with subsequent close contacts before reaching a plateau. On the tenth contact, the penetration curve exhibits a sudden jump to an adhesion distance of 502.01 nm. A distinct step in the retraction curve suggests the rupture of the cavitation bubble capillary bridge. Importantly, the classical capillary force mathematical model provides an effective fit for the penetration curve. Our calculations estimate the volume of the capillary bridge at 0.30 μm³, offering direct theoretical evidence of the unstable liquid film cavitation bubble capillary bridge. Further insights are gained from large-scale tensile molecular dynamics simulations by using GROningen MAchine for Chemical Simulations (GROMACS). The inherent correlation mechanism of the formation, evolution, and mechanical behavior of the cavitation bubble capillary bridge in the separation process of hydrophobic particles are further explored from a molecular perspective. The results demonstrate that the local pressure drop occurring at the moment of “jump-out” separation of the hydrophobic particles attracts nitrogen molecules to diffuse into the liquid film, thereby forming a cavitation bubble capillary bridge. Simultaneously, a jumping behavior is observed in the calculated spring potential curve at the moment of capillary bridge rupture. Finally, the influence of solution gas content on long-range hydrophobic force is investigated. There is a positive correlation between gas molecule content and both the growth rate of cavitation bubble capillary bridge volume and the length of capillary bridge stretch-rupture, further demonstrating the gas concentration dependence of long-range hydrophobic forces. In a word, revealing the long-range hydrophobic force mechanism based on the cavitation of unstable liquid film can enhance our understanding of the interaction between colloid physical chemistry and biological macromolecules. Meanwhile, hydrophobic force is the fundamental driving force of particle-bubble adhesion in mineral flotation system, and the revelation of its action mechanism has important guiding significance for regulating the actual mineral flotation process.

-

Keywords:

- long-range hydrophobic force /

- atomic force microscope /

- cavitation /

- capillary force /

- molecular dynamics simulation

[1] 马红孺 2016 65 184701

Google Scholar

Google Scholar

Ma H R 2016 Acta Phys. Sin. 65 184701

Google Scholar

Google Scholar

[2] Nikolov A, Lee J, Wasan D 2023 Adv. Colloid Interface Sci. 313 102847

Google Scholar

Google Scholar

[3] 彭家略, 郭浩, 尤天涯, 纪献兵, 徐进良 2021 70 044701

Google Scholar

Google Scholar

Peng J L, Guo H, You T Y, Ji X B, Xu J L 2021 Acta Phys. Sin. 70 044701

Google Scholar

Google Scholar

[4] 赵昶, 纪献兵, 杨聿昊, 孟宇航, 徐进良, 彭家略 2022 71 214701

Google Scholar

Google Scholar

Zhao C, Ji X B, Yang Y H, Meng Y H, Xu J L, Peng J L 2022 Acta Phys. Sin. 71 214701

Google Scholar

Google Scholar

[5] Li Q, Liao C, Hou J, Wang W, Zhang J 2022 Fuel 316 123271

Google Scholar

Google Scholar

[6] 顾帼华, 锁军, 柳建设, 钟素姣 2006 中国有色金属学报 16 1462

Google Scholar

Google Scholar

Gu G H, Suo J, Liu J S, Zhong S J 2006 Chin. J. of Nonferrous Met. 16 1462

Google Scholar

Google Scholar

[7] 张天辉, 曹镜声, 梁颖, 刘向阳 2016 65 176401

Google Scholar

Google Scholar

Zhang T H, Cao J S, Liang Y, Liu X Y 2016 Acta Phys. Sin. 65 176401

Google Scholar

Google Scholar

[8] 邢耀文, 桂夏辉, 曹亦俊, 刘炯天 2019 煤炭学报 44 3185

Google Scholar

Google Scholar

Xing Y W, Gui X H, Cao Y J, Liu J T 2019 J. China Coal Soc. 44 3185

Google Scholar

Google Scholar

[9] 蒋昊, 罗汇丰, 谢佳辉, 韩文平 2022 中国有色金属学报 32 545

Google Scholar

Google Scholar

Jiang H, Liu H F, Xie J H, Han W P 2022 Chin. J. of Nonferrous Met. 32 545

Google Scholar

Google Scholar

[10] Christenson H K, Claesson P M 2001 Adv. Colloid Interface Sci. 91 391

Google Scholar

Google Scholar

[11] Meyer E E, Rosenberg K J, Israelachvili J 2006 Proc. Natl. Acad. Sci. U. S. A. 103 15739

Google Scholar

Google Scholar

[12] Kékicheff P 2019 Adv. Colloid Interface Sci. 270 191

Google Scholar

Google Scholar

[13] 王市委, 陈松降, 陶秀祥, 石开仪, 陈鹏, 陈文辉 2019 煤炭学报 44 2236

Google Scholar

Google Scholar

Wang S W, Chen S J, Tao X X, Shi K Y, Chen P, Chen W H 2019 J. China Coal Soc. 44 2236

Google Scholar

Google Scholar

[14] Christensen H, Claesson P 1988 Science 239 390

Google Scholar

Google Scholar

[15] Yakubov G E, Butt H J, Vinogradova O I 2000 J. Phys. Chem. B 104 3407

Google Scholar

Google Scholar

[16] Azadi M, Nguyen A V, Yakubov G E 2015 Langmuir 31 1941

Google Scholar

Google Scholar

[17] Faghihnejad A, Zeng H 2012 Soft Matter 8 2746

Google Scholar

Google Scholar

[18] Abraham M J, Murtola T, Schulz R, Páll S, Smith J C, Hess B, Lindahl E 2015 SoftwareX 1 19

Google Scholar

Google Scholar

[19] Humphrey W, Dalke A, Schulten K 1996 J. Mol. Graph. 14 33

Google Scholar

Google Scholar

[20] Yang H, Zhang F, Xing Y, Gui X, Cao Y 2022 Front. Mater. 8 644

Google Scholar

Google Scholar

[21] Pandit S, Maroli N, Naskar S, Khatri B, Maiti P K, De M 2022 Nanoscale 14 7881

Google Scholar

Google Scholar

[22] Wang X, Ramírez-Hinestrosa S, Dobnikar J, Frenkel D 2020 Phys. Chem. Chem. Phys. 22 10624

Google Scholar

Google Scholar

[23] Vassetti D, Pagliai M, Procacci P 2019 J. Chem. Theory Comput. 15 1983

Google Scholar

Google Scholar

[24] Potoff J J, Ilja Siepmann J 2001 AIChE J. 47 1676

Google Scholar

Google Scholar

[25] Sedighi M, Talaie M R, Sabzyan H, Aghamiri S, Chen P 2022 Fuel 308 121965

Google Scholar

Google Scholar

[26] Xia Y C, Zhang R, Cao Y J, Xing Y W, Gui X H 2020 Fuel 262 116535

Google Scholar

Google Scholar

[27] Zimmermann K 1991 J. Comput. Chem. 12 310

Google Scholar

Google Scholar

[28] Bussi G, Donadio D, Parrinello M 2007 J. Chem. Phys. 126 14101

Google Scholar

Google Scholar

[29] Essmann U, Perera L, Berkowitz M L, Darden T, Lee H, Pedersen L G 1995 J. Chem. Phys. 103 8577

Google Scholar

Google Scholar

[30] Hammer M U, Anderson T H, Chaimovich A, Shell M S, Israelachvili J 2010 Faraday Discuss. 146 299

Google Scholar

Google Scholar

[31] Mezger M, Reichert H, Schöder S, Okasinski J, Schröder H, Dosch H, Palms D, Ralston J, Honkimäki V 2006 Proc. Natl. Acad. Sci. U. S. A. 103 18401

Google Scholar

Google Scholar

[32] Butt H J, Kappl M 2009 Adv. Colloid Interface Sci. 146 48

Google Scholar

Google Scholar

[33] Brown D, Neyertz S 1995 Molecular Physics 84 577

Google Scholar

Google Scholar

-

-

[1] 马红孺 2016 65 184701

Google Scholar

Google Scholar

Ma H R 2016 Acta Phys. Sin. 65 184701

Google Scholar

Google Scholar

[2] Nikolov A, Lee J, Wasan D 2023 Adv. Colloid Interface Sci. 313 102847

Google Scholar

Google Scholar

[3] 彭家略, 郭浩, 尤天涯, 纪献兵, 徐进良 2021 70 044701

Google Scholar

Google Scholar

Peng J L, Guo H, You T Y, Ji X B, Xu J L 2021 Acta Phys. Sin. 70 044701

Google Scholar

Google Scholar

[4] 赵昶, 纪献兵, 杨聿昊, 孟宇航, 徐进良, 彭家略 2022 71 214701

Google Scholar

Google Scholar

Zhao C, Ji X B, Yang Y H, Meng Y H, Xu J L, Peng J L 2022 Acta Phys. Sin. 71 214701

Google Scholar

Google Scholar

[5] Li Q, Liao C, Hou J, Wang W, Zhang J 2022 Fuel 316 123271

Google Scholar

Google Scholar

[6] 顾帼华, 锁军, 柳建设, 钟素姣 2006 中国有色金属学报 16 1462

Google Scholar

Google Scholar

Gu G H, Suo J, Liu J S, Zhong S J 2006 Chin. J. of Nonferrous Met. 16 1462

Google Scholar

Google Scholar

[7] 张天辉, 曹镜声, 梁颖, 刘向阳 2016 65 176401

Google Scholar

Google Scholar

Zhang T H, Cao J S, Liang Y, Liu X Y 2016 Acta Phys. Sin. 65 176401

Google Scholar

Google Scholar

[8] 邢耀文, 桂夏辉, 曹亦俊, 刘炯天 2019 煤炭学报 44 3185

Google Scholar

Google Scholar

Xing Y W, Gui X H, Cao Y J, Liu J T 2019 J. China Coal Soc. 44 3185

Google Scholar

Google Scholar

[9] 蒋昊, 罗汇丰, 谢佳辉, 韩文平 2022 中国有色金属学报 32 545

Google Scholar

Google Scholar

Jiang H, Liu H F, Xie J H, Han W P 2022 Chin. J. of Nonferrous Met. 32 545

Google Scholar

Google Scholar

[10] Christenson H K, Claesson P M 2001 Adv. Colloid Interface Sci. 91 391

Google Scholar

Google Scholar

[11] Meyer E E, Rosenberg K J, Israelachvili J 2006 Proc. Natl. Acad. Sci. U. S. A. 103 15739

Google Scholar

Google Scholar

[12] Kékicheff P 2019 Adv. Colloid Interface Sci. 270 191

Google Scholar

Google Scholar

[13] 王市委, 陈松降, 陶秀祥, 石开仪, 陈鹏, 陈文辉 2019 煤炭学报 44 2236

Google Scholar

Google Scholar

Wang S W, Chen S J, Tao X X, Shi K Y, Chen P, Chen W H 2019 J. China Coal Soc. 44 2236

Google Scholar

Google Scholar

[14] Christensen H, Claesson P 1988 Science 239 390

Google Scholar

Google Scholar

[15] Yakubov G E, Butt H J, Vinogradova O I 2000 J. Phys. Chem. B 104 3407

Google Scholar

Google Scholar

[16] Azadi M, Nguyen A V, Yakubov G E 2015 Langmuir 31 1941

Google Scholar

Google Scholar

[17] Faghihnejad A, Zeng H 2012 Soft Matter 8 2746

Google Scholar

Google Scholar

[18] Abraham M J, Murtola T, Schulz R, Páll S, Smith J C, Hess B, Lindahl E 2015 SoftwareX 1 19

Google Scholar

Google Scholar

[19] Humphrey W, Dalke A, Schulten K 1996 J. Mol. Graph. 14 33

Google Scholar

Google Scholar

[20] Yang H, Zhang F, Xing Y, Gui X, Cao Y 2022 Front. Mater. 8 644

Google Scholar

Google Scholar

[21] Pandit S, Maroli N, Naskar S, Khatri B, Maiti P K, De M 2022 Nanoscale 14 7881

Google Scholar

Google Scholar

[22] Wang X, Ramírez-Hinestrosa S, Dobnikar J, Frenkel D 2020 Phys. Chem. Chem. Phys. 22 10624

Google Scholar

Google Scholar

[23] Vassetti D, Pagliai M, Procacci P 2019 J. Chem. Theory Comput. 15 1983

Google Scholar

Google Scholar

[24] Potoff J J, Ilja Siepmann J 2001 AIChE J. 47 1676

Google Scholar

Google Scholar

[25] Sedighi M, Talaie M R, Sabzyan H, Aghamiri S, Chen P 2022 Fuel 308 121965

Google Scholar

Google Scholar

[26] Xia Y C, Zhang R, Cao Y J, Xing Y W, Gui X H 2020 Fuel 262 116535

Google Scholar

Google Scholar

[27] Zimmermann K 1991 J. Comput. Chem. 12 310

Google Scholar

Google Scholar

[28] Bussi G, Donadio D, Parrinello M 2007 J. Chem. Phys. 126 14101

Google Scholar

Google Scholar

[29] Essmann U, Perera L, Berkowitz M L, Darden T, Lee H, Pedersen L G 1995 J. Chem. Phys. 103 8577

Google Scholar

Google Scholar

[30] Hammer M U, Anderson T H, Chaimovich A, Shell M S, Israelachvili J 2010 Faraday Discuss. 146 299

Google Scholar

Google Scholar

[31] Mezger M, Reichert H, Schöder S, Okasinski J, Schröder H, Dosch H, Palms D, Ralston J, Honkimäki V 2006 Proc. Natl. Acad. Sci. U. S. A. 103 18401

Google Scholar

Google Scholar

[32] Butt H J, Kappl M 2009 Adv. Colloid Interface Sci. 146 48

Google Scholar

Google Scholar

[33] Brown D, Neyertz S 1995 Molecular Physics 84 577

Google Scholar

Google Scholar

计量

- 文章访问数: 3944

- PDF下载量: 263

- 被引次数: 0

下载:

下载: