-

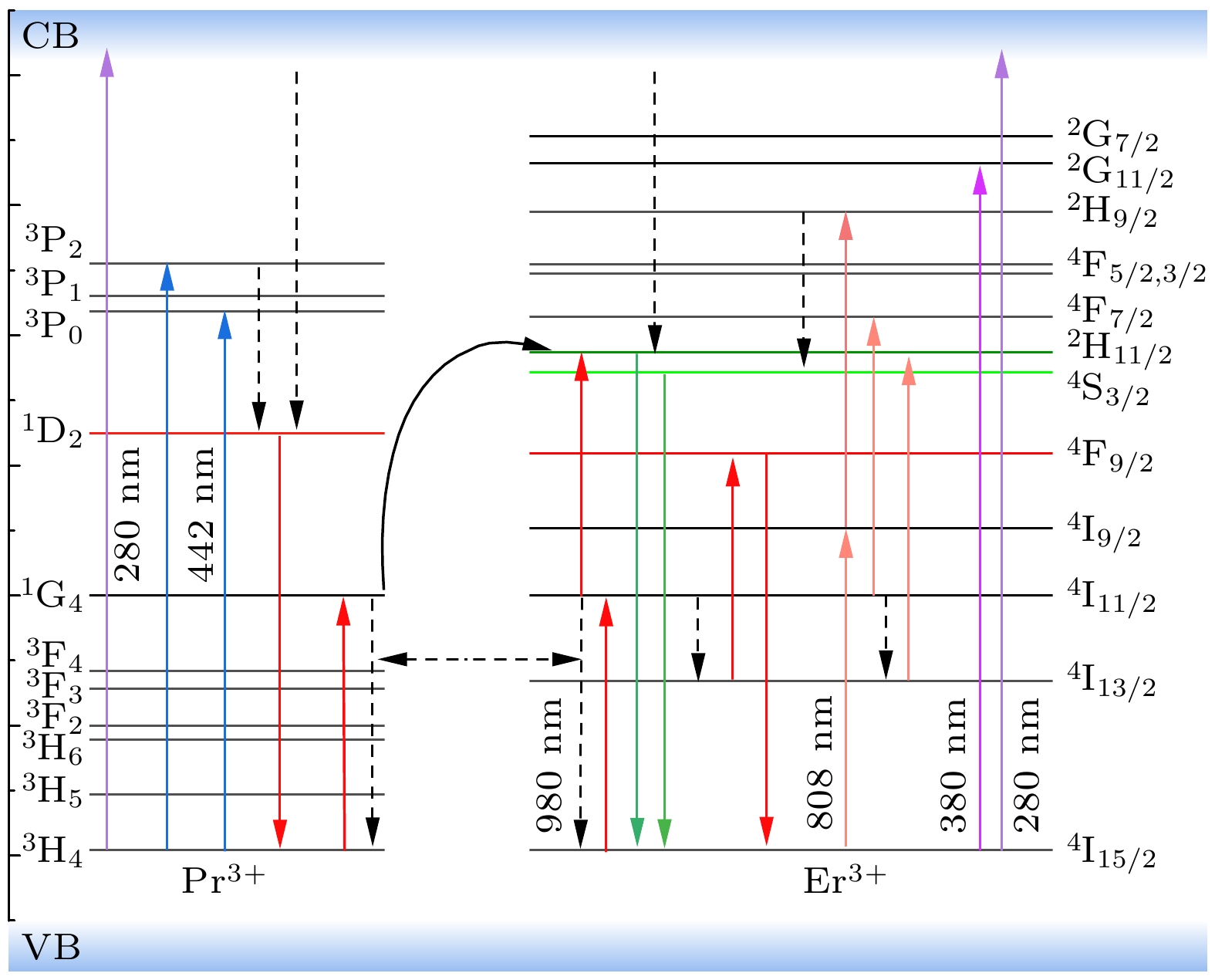

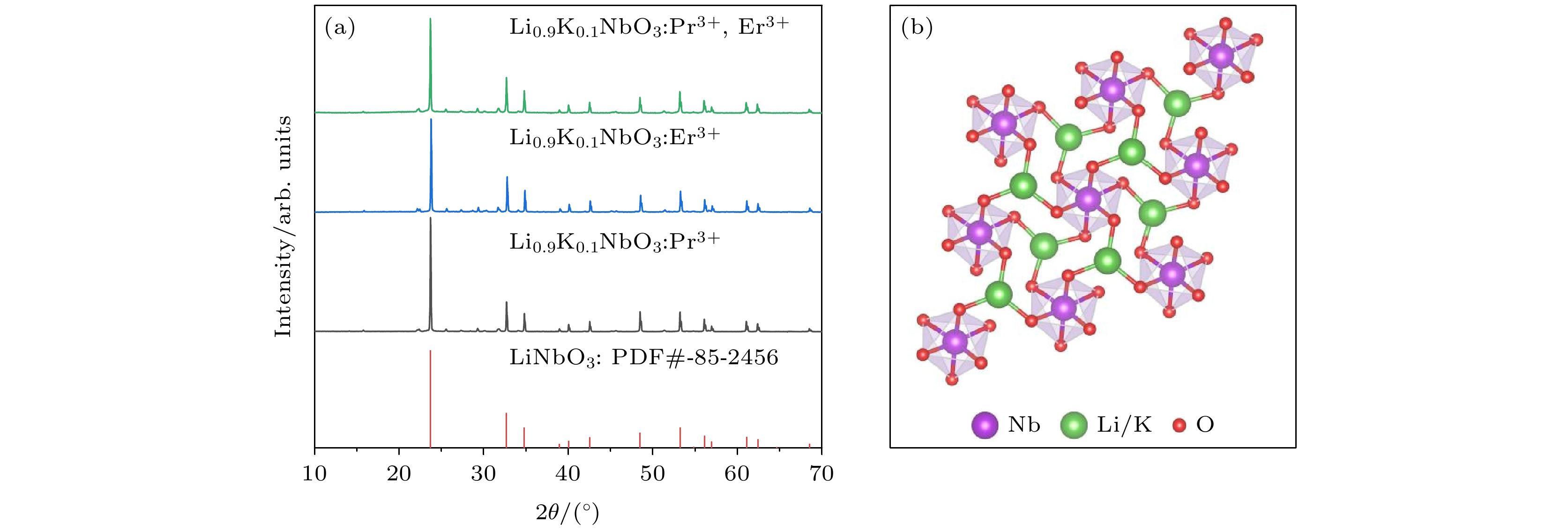

光热传感对于智能穿戴设备的开发至关重要. 然而, 设计合成具有合适多波长发射的发光材料, 并在单一材料体系中利用多组探针构建宽温度范围的高灵敏温度传感器是一个巨大挑战. 本研究采用高温固相法成功制备了Li0.9K0.1NbO3:Pr3+/Er3+单掺及双掺荧光粉. 通过X射线衍射仪、扫描电子显微镜、荧光光谱仪以及自制的加热装置对其结构、形貌及激发波长和温度依赖的荧光特性进行了表征. 详细研究了Er3+单掺与Pr3+, Er3+共掺样品的上/下转换荧光及Er3+的双模荧光温度传感特性. 结果表明: Pr3+掺杂优化了Li0.9K0.1NbO3:Er3+荧光粉中源自于Er3+离子热耦合能级的双模光学测温性能. 本研究为温度探测提供了材料基础和光学测温技术.Photothermal sensing is crucial in developing smart wearable devices. However, designing and synthesizing luminescent materials with suitable multi-wavelength emission and constructing multiple sets of probes in a single material system is a huge challenge for constructing sensitive temperature sensors with a wide temperature range. In this paper, Pr3+, Er3+ single-doped and double-doped Li0.9K0.1NbO3 phosphors are successfully prepared by high temperature solid phase method, and their structures, morphologies, excitation wavelengths and temperature-dependent fluorescence properties are characterized by XRD, SEM, fluorescence spectrometer and self-made heating device. Firstly, the photoluminescences of the synthesized series of samples are investigated. The results show that comparing with the single-doped Li0.9K0.1NbO3: Er3+ sample, the up/down-conversion spectra of Pr3+, Er3+ co-doped phosphors under 808 nm/380 nm excitation show that the green fluorescence emission of Er3+ is enhanced. In addition, under 980 nm excitation, Pr3+ can effectively regulate the fluorescence energy level population pathway, so that the electrons are more effectively arranged in the 2H11/2 and 4S3/2 energy levels in the excitation process. The red emission is weakened and the green emission is enhanced, which improves the signal resolution of the fluorescent material and has a significant influence on the optical temperature measurement. Secondly, the up-conversion fluorescence property of Er3+ under 808 nm/980 nm laser excitation in Li0.9K0.1NbO3:Er3+ and Li0.9K0.1NbO3:Pr3+,Er3+ phosphors are investigated. The results show that the red and green fluorescence emissions of Er3+ are two-photon processes. Finally, the up/down-conversion dual-mode temperature sensing properties of Er3+ in Li0.9K0.1NbO3:Er3+ and Li0.9K0.1NbO3:Pr3+, Er3+ phosphors are investigated. It is found that both materials have good optical temperature measurement performances. The Pr3+ doping optimizes the dual-mode optical temperature measurement performances of Li0.9K0.1NbO3:Er3+ phosphors derived from the thermal coupling energy level of Er3+ ions. In addition, the up/down-conversion fluorescence mechanism of Li0.9K0.1NbO3:Er3+ and Li0.9K0.1NbO3:Er3+, Pr3+ phosphors are proposed, and the enhanced green fluorescence by Pr3+ co-doping is attributed to the energy transfer from Pr3+ ions to Er3+ ions, leading to the increase of green fluorescence level population and the decrease of red fluorescence level population of the Er3+ ions. This new dual-mode optical temperature measurement material provides a material basis and optical temperature measurement technology for exploring other temperature measurement materials.

-

Keywords:

- niobate /

- up/down-conversion /

- multi-wavelength /

- temperature detection

[1] Abbas M T, Khan N Z, Mao J, Qiu L, Wei X, Chen Y, Khan S A 2022 Mater. Today Chem. 24 100903

Google Scholar

Google Scholar

[2] Hua Y B, Yu J S 2021 ACS Sustainable Chem. Eng. 9 5105

Google Scholar

Google Scholar

[3] Wang X F, Liu Q, Bu Y Y, Liu C S, Liu T, Yan X H 2015 RSC Adv. 5 86219

Google Scholar

Google Scholar

[4] Chen Y H, Chen J, Tong Y, Zhang W N, Peng X S, Guo H, Huang D X 2021 J. Rare Earths 39 1512

Google Scholar

Google Scholar

[5] Tian Y, Tian B N, Cui C, Huang P, Wang L, Chen B J 2015 RSC Adv. 5 14123

Google Scholar

Google Scholar

[6] Zhang J, Chen J J, Jin C 2020 J. Alloys Compd. 846 156397

Google Scholar

Google Scholar

[7] León-Luis S F, Rodríguez-Mendoza U R, Martín I R, Lalla E, Lavín V 2013 Sens. Actuators, B 176 1167

Google Scholar

Google Scholar

[8] Alencar M A, Maciel G S, de Araújo C B, Patra A 2004 Appl. Phys. Lett. 84 4753

Google Scholar

Google Scholar

[9] Suo H, Guo C F, Li T 2016 J. Phys. Chem. C 120 2914

Google Scholar

Google Scholar

[10] Zheng W, Sun B Y, Li Y M, Lei T, Wang R, Wu J Z 2020 ACS Sustainable Chem. Eng. 8 9578

Google Scholar

Google Scholar

[11] Yu D C, Li H Y, Zhang D W, Zhang Q Y, Meijerink A, Suta M 2021 Light-Sci. Appl. 10 236

Google Scholar

Google Scholar

[12] Singh A K, Singh S K, Gupta B K, Prakash R, Rai S B 2013 Dalton Trans. 42 1065

Google Scholar

Google Scholar

[13] Zhao C L, Gao Y, Zhou D C, Zhu F M, Chen J Y, Qiu J B 2023 J. Alloys Compd. 944 169134

Google Scholar

Google Scholar

[14] Wang Z Y, Zhang F H, Datsenko O I, Golovynskyi S, Sun Z H, Li B K, Wu H L 2023 J. Alloys Compd. 946 169350

Google Scholar

Google Scholar

[15] 阿热帕提·夏克尔, 王林香, 李晴, 柏云凤, 穆妮热·买买提 2023 72 060701

Google Scholar

Google Scholar

Arepati X, Wang L X, Li Q, Bai Y F, Munire M 2023 Acta Phys. Sin. 72 060701

Google Scholar

Google Scholar

[16] Chen J, Guo J J, Chen Y H, Peng X S, Ashraf G A, Guo H 2021 J. Lumin. 238 118294

Google Scholar

Google Scholar

[17] Gao D L, Zhao D, Pan Y, Chai R P, Pang Q, Zhang X Y, Chen W 2021 Ceram. Int. 47 32000

Google Scholar

Google Scholar

[18] Li T, Guo C F, Zhou S H, Duan C K, Yin M 2015 J. Am. Ceram. Soc. 98 2812

Google Scholar

Google Scholar

[19] Wu Y F, Suo H, He D, Guo C F 2018 Mater. Res. Bull. 106 14

Google Scholar

Google Scholar

[20] Li X F, Guan L L, Li Y, Sun H Q, Zhang Q W, Hao X H 2020 J. Mater. Chem. C 8 15685

Google Scholar

Google Scholar

[21] Gao D L, Gao F, Wu J L, Kuang Q Q, Xing C, Chen W 2022 Appl. Surf. Sci. 587 152820

Google Scholar

Google Scholar

[22] Jilili S, Aierken P, Wang Q L, Tuerxun A, Wang L, Sidike A 2022 Ceram. Int. 48 15755

Google Scholar

Google Scholar

[23] Maurya A, Bahadur A, Dwivedi A, Choudhary A K, Yadav T P, Vishwakarma P K, Rai S B 2018 J. Phys. Chem. Solids 119 228

Google Scholar

Google Scholar

[24] Gao D L, Gao J, Zhao D, Pang Q, Xiao G Q, Wang L L, Ma K W 2020 J. Mater. Chem. C 8 17318

Google Scholar

Google Scholar

[25] Tan S Y, Wang X S, Zhao Y, Li Y X, Yao X 2023 J. Lumin. 257 119747

Google Scholar

Google Scholar

[26] Lu H Y, Lu Y, Zhu J, Li J X, Wang J Y, Zou H 2023 Phys. Status Solidi RRL 17 2200379

Google Scholar

Google Scholar

[27] Kolesnikov I E, Mamonova D V, Kurochkin M A, Medvedev V A, Bai G X, Ivanova T Y, Kolesnikov E Y 2022 Phys. Chem. Chem. Phys. 24 15349

Google Scholar

Google Scholar

[28] Liu Y, Bai G X, Pan E, Hua Y J, Chen L, Xu S Q 2020 J. Alloys Compd. 822 153449

Google Scholar

Google Scholar

[29] Rakov N, Maciel G S 2014 Dalton Trans. 43 16025

Google Scholar

Google Scholar

[30] Cortés-Adasme E, Vega M, Martin I R, Llanos J 2017 RSC Adv. 7 46796

Google Scholar

Google Scholar

[31] Girisha H R, Lavanya D R, Daruka P B, Sharma S C, Nagabhushana H 2022 Opt. Mater. 134 113053

Google Scholar

Google Scholar

[32] Raju G S R, Pavitra E, Rao G M, Jeon T J, Jeon S W, Huh Y S, Han Y K 2018 J. Alloys Compd. 756 82

Google Scholar

Google Scholar

[33] Sahu M K, Jayasimhadri M, Haranath D 2022 Solid State Sci. 131 106956

Google Scholar

Google Scholar

[34] Fu J, Zhou L Y, Chen Y L, Lin J H, Ye R G, Lei L, Shen Y, Deng D G, Xu S 2023 J. Am. Ceram. Soc. 106 1333

Google Scholar

Google Scholar

[35] Zhu Y, Li X F, Guo Z Z, Sun H Q, Zhang Q W, Hao X H 2020 J. Am. Ceram. Soc. 103 3205

Google Scholar

Google Scholar

[36] Banwal A, Bokolia R 2022 Ceram. Int. 48 2230

Google Scholar

Google Scholar

[37] Fan Y, Xiao Q, Yin X M, Lv L, Wu X Y, Dong X Y, Xing M M, Tian Y, Luo X X 2022 Solid State Sci. 132 106966

Google Scholar

Google Scholar

[38] Liu Q, Pan E, Deng H, Liu F C 2023 Ceram. Int. 49 14981

Google Scholar

Google Scholar

[39] Chen Y L, Lin J H, Fu J, Ye R G, Lei L, Shen Y, Deng D G, Xu S Q 2022 J. Lumin. 252 119404

Google Scholar

Google Scholar

[40] Yin X M, Xiao Q, Lü L, Wu X Y, Dong X Y, Fan Y, Zhou N, Luo X X 2023 Spectrochim. Acta, Part A 291 122324

Google Scholar

Google Scholar

[41] Zhou W, Yang J, Jin X L, Peng Y, Luo J 2022 J. Lumin. 252 119275

Google Scholar

Google Scholar

[42] Liu Y W, Meng L S, Wang H, Jiao J X, Xing M M, Peng Y, Luo X X, Tian Y 2021 Dalton Trans. 50 960

Google Scholar

Google Scholar

-

图 2 Li0.9K0.1NbO3:Ln3+样品的SEM图片及EDX元素谱 (a) Li0.9K0.1NbO3:Er3+的SEM图片; (b) Li0.9K0.1NbO3:Pr3+, Er3+的SEM图片; (c) Li0.9K0.1NbO3:Er3+荧光粉的EDX元素分布图谱

Fig. 2. SEM images and element mappings of Li0.9K0.1NbO3:Ln3+ phosphors: (a) SEM image of Li0.9K0.1NbO3:Er3+; (b) SEM image of Li0.9K0.1NbO3:Pr3+, Er3+; (c) EDX elemental distribution spectra of Li0.9K0.1NbO3:Er3+ phosphors.

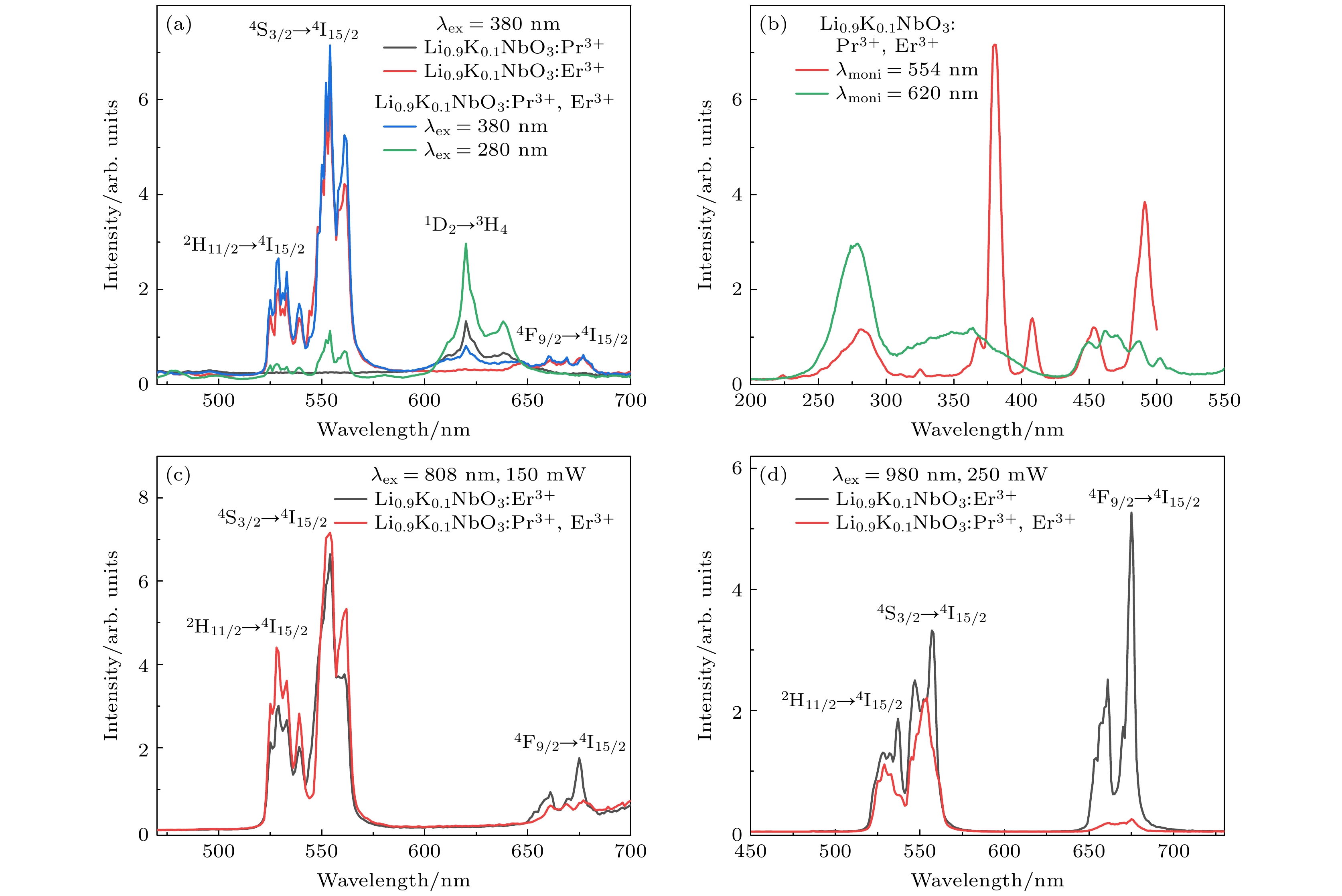

图 3 不同波长激发下, Li0.9K0.1NbO3:Ln3+的上/下转换发射谱比较 (a) Pr3+和Er3+单掺样品及Pr3+, Er3+共掺样品的发射谱 (λex = 280 nm/380 nm); (b) Pr3+, Er3+共掺样品的激发谱(λmoni = 554 nm/620 nm); Er3+单掺及Pr3+, Er3+共掺样品在(c) λex= 808 nm, (d) 980 nm激光激发下的上转换发射谱

Fig. 3. Comparison of up-conversion and down-conversion emission spectra of rare earth doped Li0.9K0.1NbO3:Ln3+ under different excitation wavelengths: (a) Emission spectra of Pr3+ and Er3+ single-doped samples and Pr3+, Er3+ co-doped samples (λex = 280 nm/380 nm); (b) excitation spectra of Pr3+, Er3+ co-doped samples (λmoni = 554 nm/620 nm); (c), (d) up-conversion emission spectra of Er3+ single doped and Pr3+, Er3+ co-doped samples under 808 and 980 nm excitations.

图 4 激发功率依赖的Li0.9K0.1NbO3:Er3+和Li0.9K0.1NbO3:Pr3+, Er3+荧光粉的发射谱, 其中内插图为对应发光强度与入射激光的功率关系 (a), (b) Li0.9K0.1NbO3:Er3+荧光粉的发射谱(λex = 808 nm和λex = 980 nm); (c), (d) Li0.9K0.1NbO3:Pr3+, Er3+荧光粉的发射谱(λex = 808 nm和λex = 980 nm)

Fig. 4. Excitation power-dependent emission spectra of Li0.9K0.1NbO3:Er3+ and Li0.9K0.1NbO3:Pr3+, Er3+ phosphors, where the insets are the relationships between luminescence intensity and incident laser power: (a), (b) Emission spectra of Li0.9K0.1NbO3:Er3+ phosphors (λex = 808 nm and λex = 980 nm); (c), (d) emission spectra of Li0.9K0.1NbO3:Pr3+, Er3+ phosphors (λex = 808 nm and λex = 980 nm).

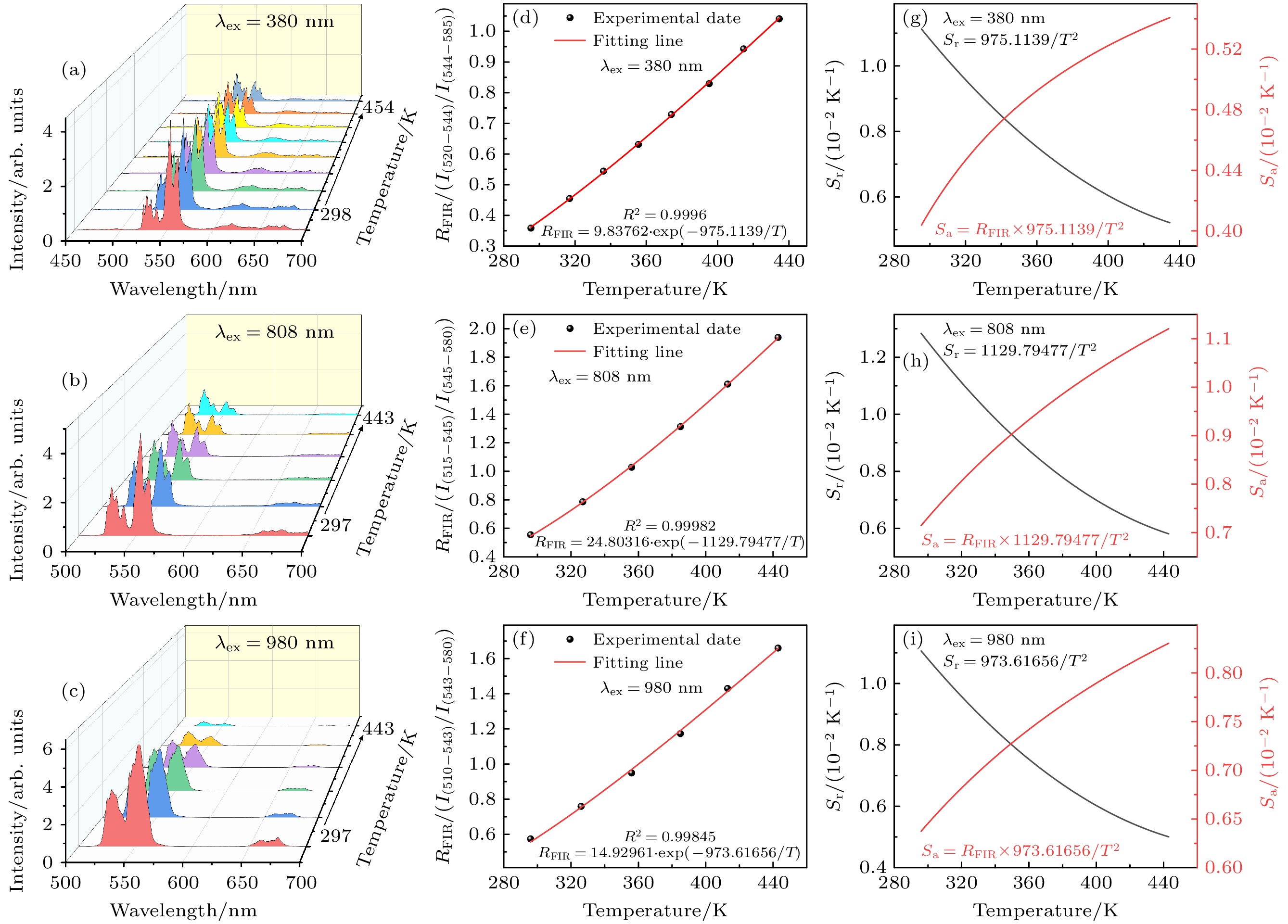

图 5 Li0.9K0.1NbO3:Er3+荧光粉的上、下转换测温性能 (a)—(c) 分别在380, 808, 980 nm激发下的发射谱; (d)—(f) 相应于图(a)—(c)中的上/下转换发射谱的双峰绿色FIR与温度的关系; (g)—(i) 相应于图(d)—(f)中双峰荧光强度比率测温的灵敏度曲线

Fig. 5. Up/down-conversion temperature measurement performance of Li0.9K0.1NbO3:Er3+ phosphor: (a)–(c) The emission spectra excited at 380, 808 and 980 nm, respectively; (d)–(f) the relationship between the bimodal green FIR and temperature corresponding to the up/down-conversion emission spectra in panel (a)–(c); (g)–(i) the sensitivity curves of temperature measurement of bimodal FIR corresponding to panel (d)–(f).

图 6 Li0.9K0.1NbO3:Pr3+, Er3+荧光粉的上/下转换双模式光学测温性能 (a)—(c) 分别在380, 808, 980 nm激发下的发射谱; (d)—(f) 相应于图(a)—(c)中的上/下转换发射谱的双峰绿色FIR与温度的关系; (g)—(i) 相应于图(d)—(f)中双峰FIR测温的灵敏度曲线

Fig. 6. Up/down-conversion temperature measurement performance of Li0.9K0.1NbO3:Pr3+, Er3+ phosphor: (a)–(c) The emission spectra excited at 380, 808, and 980 nm, respectively; (d)–(f) the relationship between the bimodal green FIR and temperature corresponding to the up/down-conversion emission spectra in panel (a)–(c); (g)–(i) the sensitivity curves of temperature measurement of bimodal FIR corresponding to panel (d)–(f).

表 1 基于FIR技术下不同基质中掺杂Er3+的温度传感材料光学参数

Table 1. Optical parameters of temperature sensing materials doped with Er3+ in different substrates based on FIR technology

Materials Wavelength/nm Sr-Max/(10–2 K–1) Sa-Max/(10–2 K–1) References SrSnO3:Er 975 nm 0.997(294 K) 0.791(368 K) [30] BaBiNb2O9:Er 980 nm 0.959(300 K) 0.996(483 K) [36] La2CaZnO5:Er 378 nm 1.454(300 K) — [31] Sr2Gd8(SiO4)6O2:Er 379 nm — 0.34(463 K) [32] Ca3Bi(PO4)3:Er 376 nm 1.21(300 K) 0.312(473 K) [33] La2Mo2O9:Er 980 nm 1.16(293 K) 0.527(493 K) [37] (K, Na)NbO3:Er 980 nm

375 nm0.96(303 K)

16.17(80 K)0.28(433 K)

0.37(280 K)[38] Cs3Bi2Cl9:Er 808 nm

980 nm1.4(303 K)

1.38(303 K)0.62(573 K)

0.61(573 K)[13] Li0.9K0.1NbO3:Er 380 nm

808 nm

980 nm0.97(303 K)

1.286(297 K)

1.221(297 K)0.44(463 K)

0.89(443 K)

0.81(443 K)This

work表 2 基于FIR技术下不同基质中掺杂Er3+-Ln3+的温度传感材料光学参数

Table 2. Optical parameters of temperature sensing materials doped with Er3+-Ln3+ in different substrates based on FIR technology.

Materials Wavelength/nm Sr-Max/(10–2 K–1) Sa-Max/(10–2 K–1) References La2MgGeO6:Bi, Er 980 nm 1.23(293 K) 0.94(473 K) [39] K3Gd(PO4)2:Yb, Er, Tm 980 nm 1.35(300 K) 0.456(608 K) [40] NaLuF4:Er, Tm 1532 nm 1.265(293 K) 0.4(519 K) [41] BiVO4:Er, Tm 980 nm 1.1(293 K) 0.7(473 K) [42] 1550 nm 1.1(293 K) 0.56(453 K) Y2SiO5:Er, Tm 808 nm 0.395(298 K) — [29] KYb(MoO4)2:Er, Gd 980 nm 1.1(303 K) 0.97(513 K) [25] KYb(MoO4)2:Er, La 1.1(303 K) 0.95(513 K) KYb(MoO4)2:Er, Y 1.11(303 K) 0.91(513 K) Li0.9K0.1NbO3:Pr, Er 380 nm 1.12(296 K) 0.54(434 K) This

work808 nm 1.284(296 K) 1.12(443 K) 980 nm 1.106(296 K) 0.83(443 K) -

[1] Abbas M T, Khan N Z, Mao J, Qiu L, Wei X, Chen Y, Khan S A 2022 Mater. Today Chem. 24 100903

Google Scholar

Google Scholar

[2] Hua Y B, Yu J S 2021 ACS Sustainable Chem. Eng. 9 5105

Google Scholar

Google Scholar

[3] Wang X F, Liu Q, Bu Y Y, Liu C S, Liu T, Yan X H 2015 RSC Adv. 5 86219

Google Scholar

Google Scholar

[4] Chen Y H, Chen J, Tong Y, Zhang W N, Peng X S, Guo H, Huang D X 2021 J. Rare Earths 39 1512

Google Scholar

Google Scholar

[5] Tian Y, Tian B N, Cui C, Huang P, Wang L, Chen B J 2015 RSC Adv. 5 14123

Google Scholar

Google Scholar

[6] Zhang J, Chen J J, Jin C 2020 J. Alloys Compd. 846 156397

Google Scholar

Google Scholar

[7] León-Luis S F, Rodríguez-Mendoza U R, Martín I R, Lalla E, Lavín V 2013 Sens. Actuators, B 176 1167

Google Scholar

Google Scholar

[8] Alencar M A, Maciel G S, de Araújo C B, Patra A 2004 Appl. Phys. Lett. 84 4753

Google Scholar

Google Scholar

[9] Suo H, Guo C F, Li T 2016 J. Phys. Chem. C 120 2914

Google Scholar

Google Scholar

[10] Zheng W, Sun B Y, Li Y M, Lei T, Wang R, Wu J Z 2020 ACS Sustainable Chem. Eng. 8 9578

Google Scholar

Google Scholar

[11] Yu D C, Li H Y, Zhang D W, Zhang Q Y, Meijerink A, Suta M 2021 Light-Sci. Appl. 10 236

Google Scholar

Google Scholar

[12] Singh A K, Singh S K, Gupta B K, Prakash R, Rai S B 2013 Dalton Trans. 42 1065

Google Scholar

Google Scholar

[13] Zhao C L, Gao Y, Zhou D C, Zhu F M, Chen J Y, Qiu J B 2023 J. Alloys Compd. 944 169134

Google Scholar

Google Scholar

[14] Wang Z Y, Zhang F H, Datsenko O I, Golovynskyi S, Sun Z H, Li B K, Wu H L 2023 J. Alloys Compd. 946 169350

Google Scholar

Google Scholar

[15] 阿热帕提·夏克尔, 王林香, 李晴, 柏云凤, 穆妮热·买买提 2023 72 060701

Google Scholar

Google Scholar

Arepati X, Wang L X, Li Q, Bai Y F, Munire M 2023 Acta Phys. Sin. 72 060701

Google Scholar

Google Scholar

[16] Chen J, Guo J J, Chen Y H, Peng X S, Ashraf G A, Guo H 2021 J. Lumin. 238 118294

Google Scholar

Google Scholar

[17] Gao D L, Zhao D, Pan Y, Chai R P, Pang Q, Zhang X Y, Chen W 2021 Ceram. Int. 47 32000

Google Scholar

Google Scholar

[18] Li T, Guo C F, Zhou S H, Duan C K, Yin M 2015 J. Am. Ceram. Soc. 98 2812

Google Scholar

Google Scholar

[19] Wu Y F, Suo H, He D, Guo C F 2018 Mater. Res. Bull. 106 14

Google Scholar

Google Scholar

[20] Li X F, Guan L L, Li Y, Sun H Q, Zhang Q W, Hao X H 2020 J. Mater. Chem. C 8 15685

Google Scholar

Google Scholar

[21] Gao D L, Gao F, Wu J L, Kuang Q Q, Xing C, Chen W 2022 Appl. Surf. Sci. 587 152820

Google Scholar

Google Scholar

[22] Jilili S, Aierken P, Wang Q L, Tuerxun A, Wang L, Sidike A 2022 Ceram. Int. 48 15755

Google Scholar

Google Scholar

[23] Maurya A, Bahadur A, Dwivedi A, Choudhary A K, Yadav T P, Vishwakarma P K, Rai S B 2018 J. Phys. Chem. Solids 119 228

Google Scholar

Google Scholar

[24] Gao D L, Gao J, Zhao D, Pang Q, Xiao G Q, Wang L L, Ma K W 2020 J. Mater. Chem. C 8 17318

Google Scholar

Google Scholar

[25] Tan S Y, Wang X S, Zhao Y, Li Y X, Yao X 2023 J. Lumin. 257 119747

Google Scholar

Google Scholar

[26] Lu H Y, Lu Y, Zhu J, Li J X, Wang J Y, Zou H 2023 Phys. Status Solidi RRL 17 2200379

Google Scholar

Google Scholar

[27] Kolesnikov I E, Mamonova D V, Kurochkin M A, Medvedev V A, Bai G X, Ivanova T Y, Kolesnikov E Y 2022 Phys. Chem. Chem. Phys. 24 15349

Google Scholar

Google Scholar

[28] Liu Y, Bai G X, Pan E, Hua Y J, Chen L, Xu S Q 2020 J. Alloys Compd. 822 153449

Google Scholar

Google Scholar

[29] Rakov N, Maciel G S 2014 Dalton Trans. 43 16025

Google Scholar

Google Scholar

[30] Cortés-Adasme E, Vega M, Martin I R, Llanos J 2017 RSC Adv. 7 46796

Google Scholar

Google Scholar

[31] Girisha H R, Lavanya D R, Daruka P B, Sharma S C, Nagabhushana H 2022 Opt. Mater. 134 113053

Google Scholar

Google Scholar

[32] Raju G S R, Pavitra E, Rao G M, Jeon T J, Jeon S W, Huh Y S, Han Y K 2018 J. Alloys Compd. 756 82

Google Scholar

Google Scholar

[33] Sahu M K, Jayasimhadri M, Haranath D 2022 Solid State Sci. 131 106956

Google Scholar

Google Scholar

[34] Fu J, Zhou L Y, Chen Y L, Lin J H, Ye R G, Lei L, Shen Y, Deng D G, Xu S 2023 J. Am. Ceram. Soc. 106 1333

Google Scholar

Google Scholar

[35] Zhu Y, Li X F, Guo Z Z, Sun H Q, Zhang Q W, Hao X H 2020 J. Am. Ceram. Soc. 103 3205

Google Scholar

Google Scholar

[36] Banwal A, Bokolia R 2022 Ceram. Int. 48 2230

Google Scholar

Google Scholar

[37] Fan Y, Xiao Q, Yin X M, Lv L, Wu X Y, Dong X Y, Xing M M, Tian Y, Luo X X 2022 Solid State Sci. 132 106966

Google Scholar

Google Scholar

[38] Liu Q, Pan E, Deng H, Liu F C 2023 Ceram. Int. 49 14981

Google Scholar

Google Scholar

[39] Chen Y L, Lin J H, Fu J, Ye R G, Lei L, Shen Y, Deng D G, Xu S Q 2022 J. Lumin. 252 119404

Google Scholar

Google Scholar

[40] Yin X M, Xiao Q, Lü L, Wu X Y, Dong X Y, Fan Y, Zhou N, Luo X X 2023 Spectrochim. Acta, Part A 291 122324

Google Scholar

Google Scholar

[41] Zhou W, Yang J, Jin X L, Peng Y, Luo J 2022 J. Lumin. 252 119275

Google Scholar

Google Scholar

[42] Liu Y W, Meng L S, Wang H, Jiao J X, Xing M M, Peng Y, Luo X X, Tian Y 2021 Dalton Trans. 50 960

Google Scholar

Google Scholar

计量

- 文章访问数: 3940

- PDF下载量: 89

- 被引次数: 0

下载:

下载: