-

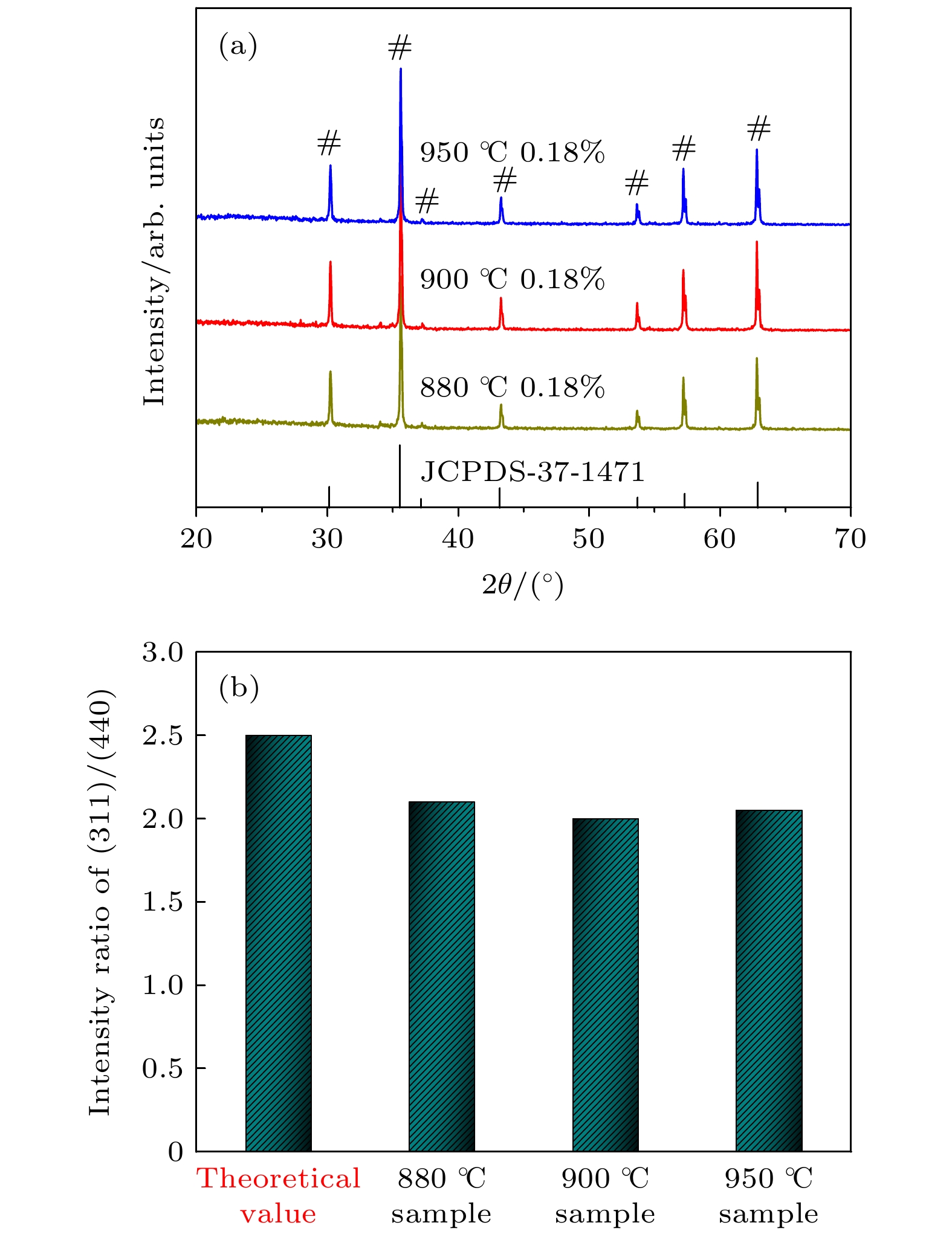

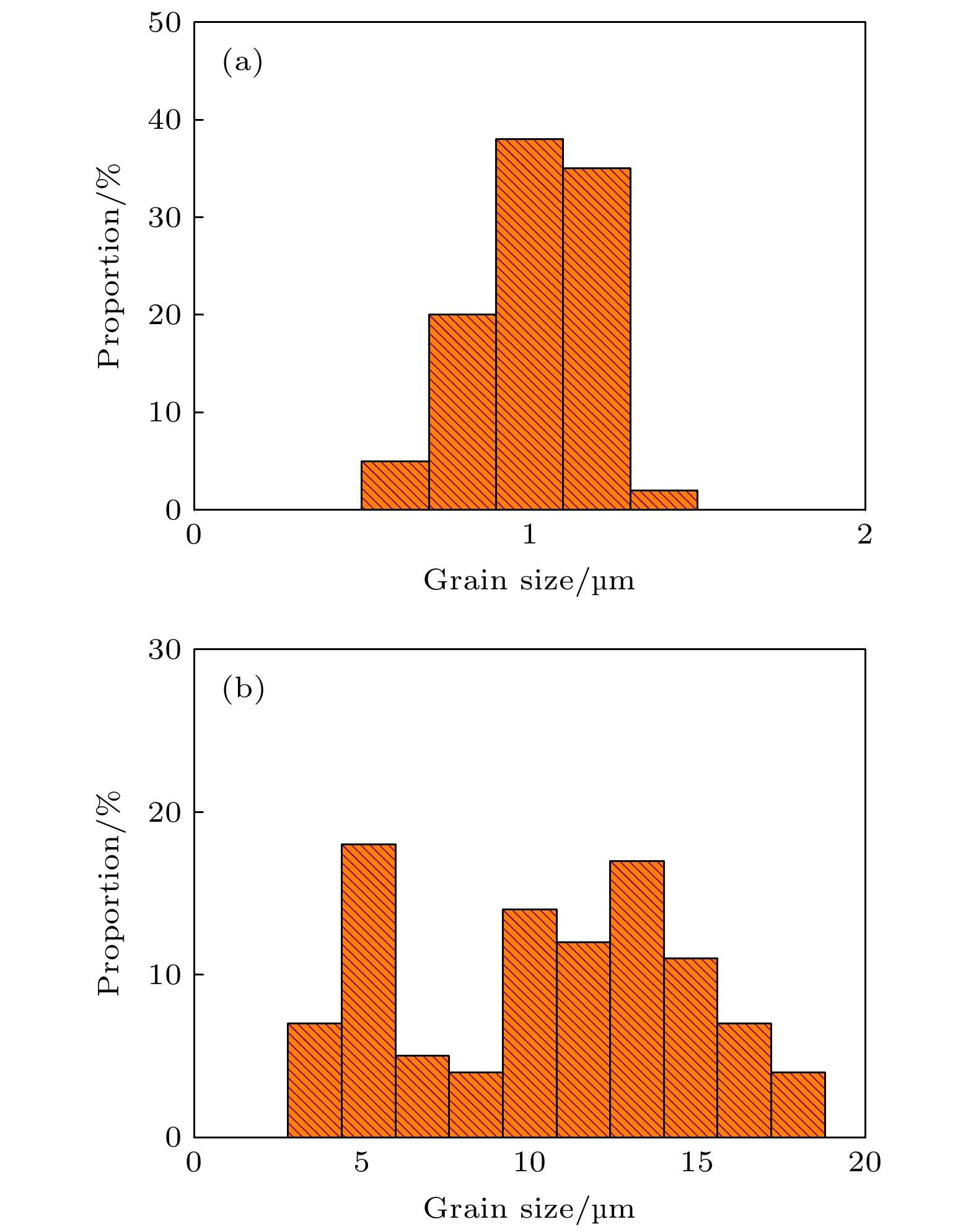

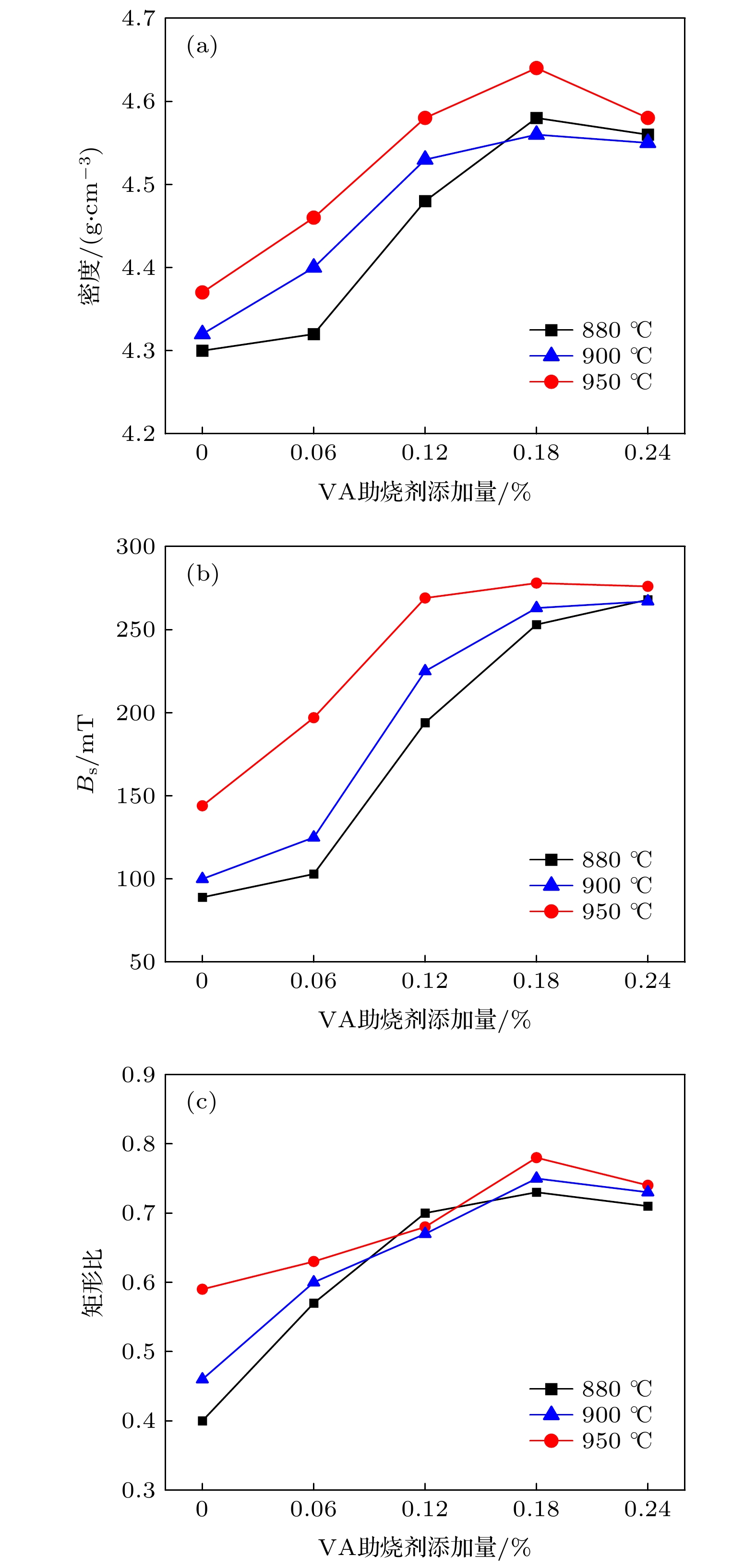

随着现代无线通信技术的进步, 微波通信器件向小型化、一体化方向发展, 其中低温共烧陶瓷/铁氧体技术是关键所在. 针对适用于雷达移相器中的Li-Zn微波铁氧体, 本文通过加入V2O5-Al2O3(VA)助烧剂实现低温烧结(低于950 ℃), 并研究助烧剂添加量及烧结温度对于材料晶体结构、微观形貌以及磁性能(饱和磁感应强度、矫顽力、铁磁共振线宽等)的影响. VA助烧剂的参与可以在降低烧结温度的同时维持Li-Zn微波铁氧体的尖晶石晶体结构, 并能促进晶粒的生长, Li-Zn铁氧体的平均晶粒尺寸由最初的0.92 μm增至9.74 μm. 在Li-Zn铁氧体烧结过程中, VA助烧剂中的V2O5由于具有较低的熔点会先融化形成液相, 促进晶粒的生长; 同时具有较高熔点的Al2O3可以抑制晶粒的过大增长, 使晶粒均匀化. 未添加助烧剂与添加VA助烧剂(质量分数为0.18%)制备的铁氧体相比, 样品的饱和磁感应强度(Bs)由144 mT增至281 mT; 矩形比(Mr/Ms)由0.57升至0.78; 矫顽力(Hc)由705 A/m降低至208 A/m; 铁磁共振线宽(ΔH)由648 Oe减至247 Oe (1 Oe = 103/(4π) A/m). 总体来说, VA助烧剂可以有效提升Li-Zn微波铁氧体的多项性能, 对低温共烧陶瓷/铁氧体技术的发展具有积极意义.

-

关键词:

- 低温共烧陶瓷 /

- 移相器 /

- Li-Zn微波铁氧体 /

- V2O5-Al2O3助烧剂

With the progress of modern wireless communication technology, microwave communication devices are developing toward miniaturization and integration, and low-temperature co-firing ceramic/ferrite technology is the key to meet the above demands. In this paper, V2O5-Al2O3 (VA) sintering aid is used to realize low-temperature sintering (below melting point of silver that is 950 ℃) of Li-Zn microwave ferrite, which is suitable for radar phase shifter. In this work, firstly, Li-Zn ferrite pre-firing material is prepared by mechanochemical ball-milling method, and then VA composite is selected as sintering aid to prepare Li0.42Zn0.27Ti0.11Mn0.1Fe2.1O4 ferrite at low temperatures. The effects of adding amount of VA sintering aid and sintering temperature on crystal structure, microstructure and magnetic properties (saturation induction, coercivity, linewidth of ferromagnetic resonance, etc.) of the materials are also studied. The VA sintering aid can reduce the sintering temperature and maintain the spinel crystal structure of Li-Zn microwave ferrite, the diffraction peaks of V2O5 and Al2O3 involved in the sintering process are observed from none of the samples sintered at different temperatures, because the additive amount of VA sintering aid is very low compared with that of Li-Zn ferrite, so no corresponding impurity peaks are detected. The introduction of VA sintering aid can promote the grain growth, with the average grain size increasing from 0.92 μm to 9.74 μm. In the sintering process of Li-Zn ferrite, V2O5 in VA sintering aid will melt first to form liquid phase due to its low melting point, which promotes the growth of grains. At the same time, Al2O3 with higher melting point can inhibit the grain growth and make the grain uniform. It is worth noting that when excessive VA sintering aid is added, the grain size of ferrite will decrease instead, because too much VA sintering aid will form a large number of liquid phases around the grains, thus splitting the grains and hindering the further growth of the Li-Zn grains. Under the condition of optimal VA sintering aid addition (0.18%, weight percentage), the saturation induction of the sample increases from 144 mT to 281 mT; the rectangular ratio increases from 0.57 to 0.78; the coercivity decreases from 705 A/m to 208 A/m; the linewidth of ferromagnetic resonance decreases from 648 Oe to 247 Oe. In summary, VA sintering aid can effectively improve the properties of Li-Zn microwave ferrite, which has a positive significance in developing low- temperature co-firing ceramic/ferrite technology.-

Keywords:

- low temperature co-firing ceramic /

- phase shifter /

- Li-Zn microwave ferrite /

- V2O5-Al2O3 sintering aid

[1] Liao Y L, Xu F, Zhang D N, Zhou T C, Wang Q, Wang X Y, Jia L J, Li J, Su H, Zhong Z Y, Zhang H W 2015 J. Am. Ceram. Soc. 98 2556

Google Scholar

Google Scholar

[2] 叶康平, 裴文瑾, 郗翔, 蒲殷, 伍瑞新 2020 69 017801

Google Scholar

Google Scholar

Ye K P, Pei W J, Xi X, Pu Y, Wu R X 2020 Acta Phys. Sin. 69 017801

Google Scholar

Google Scholar

[3] 冯涛, 党锐, 袁红兰, 罗建成 2020 磁性材料及器件 51 40

Google Scholar

Google Scholar

Feng T, Dang R, Yuan H L, Luo J C 2020 J. Magn. Mater. Device 51 40

Google Scholar

Google Scholar

[4] Li J, Lu B, Zhang Y, Wu J, Yang Y, Han X N, Wen D D, Liang Z, Zhang H W 2022 Chin. Phys. B 31 047502

Google Scholar

Google Scholar

[5] Guo R D, Yu Z, Sun K, Wang W, Wu G H, Liu Y, Liu H, Jiang X N, Lan Z W 2020 J. Alloys Compd. 815 152504

Google Scholar

Google Scholar

[6] Liao Y L, Wang Y Y, Chen Z W, Wang X Y, Li J, Guo R D, Liu C, Gan G W, Wang G, Li Y X, Zhang H W 2020 Ceram. Int. 46 487

Google Scholar

Google Scholar

[7] Zhou T C, Zhang H W, Liu C, Jin L C, Xu F, Liao Y L, Jia N, Wang Y, Gan G W, Su H, Jia L J 2016 Ceram. Int. 42 16198

Google Scholar

Google Scholar

[8] Wang X Y, Zhong Z Y, Chen Z W, Zhang H W, Li Y X, Liu C, Li J, Liao Y L 2020 Ceram. Int. 46 5719

Google Scholar

Google Scholar

[9] 赵强, 杨青慧, 张怀武 2014 磁性材料及器件 45 50

Zhao Q, Yang Q H, Zhang H W 2014 J. Magn. Mater. Device 45 50

[10] Guo R D, Yu Z, Yang Y, Jiang X N, Sun K, Wu C J, Xu Z Y, Lan Z W 2014 J. Alloys Compd. 589 1

Google Scholar

Google Scholar

[11] Wang X Y, Li Y X, Chen Z W, Zhang H W, Su H, Wang G, Liao Y L, Zhong Z Y 2019 J. Alloys Compd. 797 566

Google Scholar

Google Scholar

[12] Samir Ullah M, Firoz Uddin M, Momin A A, Hakim M A 2021 Mater. Res. Express 8 016102

Google Scholar

Google Scholar

[13] 邱华, 贾利军, 张素娜, 沈琦杭, 解飞, 张怀武 2019 磁性材料及器件 50 10

Google Scholar

Google Scholar

Qiu H, Jia L J, Zhang S N, Shen Q H, Xie F, Zhang H W 2019 J. Magn. Mater. Device 50 10

Google Scholar

Google Scholar

[14] Xu F, Shi X L, Liao Y L, Li J, Hu J 2020 Ceram. Int. 46 14669

Google Scholar

Google Scholar

[15] Xie F, Liu H, Zhou S, Chen Y, Xu F, Bai M Y, Liu W G 2021 J. Alloys Compd. 862 158650

Google Scholar

Google Scholar

[16] Xie F, Liu H, Zhao J J, Wen S, Bai M Y, Chen Y, Zhu Y C, Li Y, Liu W G 2021 J. Alloys Compd. 851 156806

Google Scholar

Google Scholar

[17] Zhang D N, Wang X Y, Xu F, Li J, Zhou T C, Jia L J, Zhang H W, Liao Y L 2016 J. Alloys Compd. 654 140

Google Scholar

Google Scholar

[18] Zhou T C, Zhang H W, Jia L J, Liao Y L, Zhong Z Y, Bai F M, Su H, Li J, Jin L C, Liu C 2015 J. Alloys Compd. 620 421

Google Scholar

Google Scholar

[19] 张志东 2015 64 067503

Google Scholar

Google Scholar

Zhang Z D 2015 Acta Phys. Sin. 64 067503

Google Scholar

Google Scholar

-

-

[1] Liao Y L, Xu F, Zhang D N, Zhou T C, Wang Q, Wang X Y, Jia L J, Li J, Su H, Zhong Z Y, Zhang H W 2015 J. Am. Ceram. Soc. 98 2556

Google Scholar

Google Scholar

[2] 叶康平, 裴文瑾, 郗翔, 蒲殷, 伍瑞新 2020 69 017801

Google Scholar

Google Scholar

Ye K P, Pei W J, Xi X, Pu Y, Wu R X 2020 Acta Phys. Sin. 69 017801

Google Scholar

Google Scholar

[3] 冯涛, 党锐, 袁红兰, 罗建成 2020 磁性材料及器件 51 40

Google Scholar

Google Scholar

Feng T, Dang R, Yuan H L, Luo J C 2020 J. Magn. Mater. Device 51 40

Google Scholar

Google Scholar

[4] Li J, Lu B, Zhang Y, Wu J, Yang Y, Han X N, Wen D D, Liang Z, Zhang H W 2022 Chin. Phys. B 31 047502

Google Scholar

Google Scholar

[5] Guo R D, Yu Z, Sun K, Wang W, Wu G H, Liu Y, Liu H, Jiang X N, Lan Z W 2020 J. Alloys Compd. 815 152504

Google Scholar

Google Scholar

[6] Liao Y L, Wang Y Y, Chen Z W, Wang X Y, Li J, Guo R D, Liu C, Gan G W, Wang G, Li Y X, Zhang H W 2020 Ceram. Int. 46 487

Google Scholar

Google Scholar

[7] Zhou T C, Zhang H W, Liu C, Jin L C, Xu F, Liao Y L, Jia N, Wang Y, Gan G W, Su H, Jia L J 2016 Ceram. Int. 42 16198

Google Scholar

Google Scholar

[8] Wang X Y, Zhong Z Y, Chen Z W, Zhang H W, Li Y X, Liu C, Li J, Liao Y L 2020 Ceram. Int. 46 5719

Google Scholar

Google Scholar

[9] 赵强, 杨青慧, 张怀武 2014 磁性材料及器件 45 50

Zhao Q, Yang Q H, Zhang H W 2014 J. Magn. Mater. Device 45 50

[10] Guo R D, Yu Z, Yang Y, Jiang X N, Sun K, Wu C J, Xu Z Y, Lan Z W 2014 J. Alloys Compd. 589 1

Google Scholar

Google Scholar

[11] Wang X Y, Li Y X, Chen Z W, Zhang H W, Su H, Wang G, Liao Y L, Zhong Z Y 2019 J. Alloys Compd. 797 566

Google Scholar

Google Scholar

[12] Samir Ullah M, Firoz Uddin M, Momin A A, Hakim M A 2021 Mater. Res. Express 8 016102

Google Scholar

Google Scholar

[13] 邱华, 贾利军, 张素娜, 沈琦杭, 解飞, 张怀武 2019 磁性材料及器件 50 10

Google Scholar

Google Scholar

Qiu H, Jia L J, Zhang S N, Shen Q H, Xie F, Zhang H W 2019 J. Magn. Mater. Device 50 10

Google Scholar

Google Scholar

[14] Xu F, Shi X L, Liao Y L, Li J, Hu J 2020 Ceram. Int. 46 14669

Google Scholar

Google Scholar

[15] Xie F, Liu H, Zhou S, Chen Y, Xu F, Bai M Y, Liu W G 2021 J. Alloys Compd. 862 158650

Google Scholar

Google Scholar

[16] Xie F, Liu H, Zhao J J, Wen S, Bai M Y, Chen Y, Zhu Y C, Li Y, Liu W G 2021 J. Alloys Compd. 851 156806

Google Scholar

Google Scholar

[17] Zhang D N, Wang X Y, Xu F, Li J, Zhou T C, Jia L J, Zhang H W, Liao Y L 2016 J. Alloys Compd. 654 140

Google Scholar

Google Scholar

[18] Zhou T C, Zhang H W, Jia L J, Liao Y L, Zhong Z Y, Bai F M, Su H, Li J, Jin L C, Liu C 2015 J. Alloys Compd. 620 421

Google Scholar

Google Scholar

[19] 张志东 2015 64 067503

Google Scholar

Google Scholar

Zhang Z D 2015 Acta Phys. Sin. 64 067503

Google Scholar

Google Scholar

计量

- 文章访问数: 6316

- PDF下载量: 69

- 被引次数: 0

下载:

下载: