-

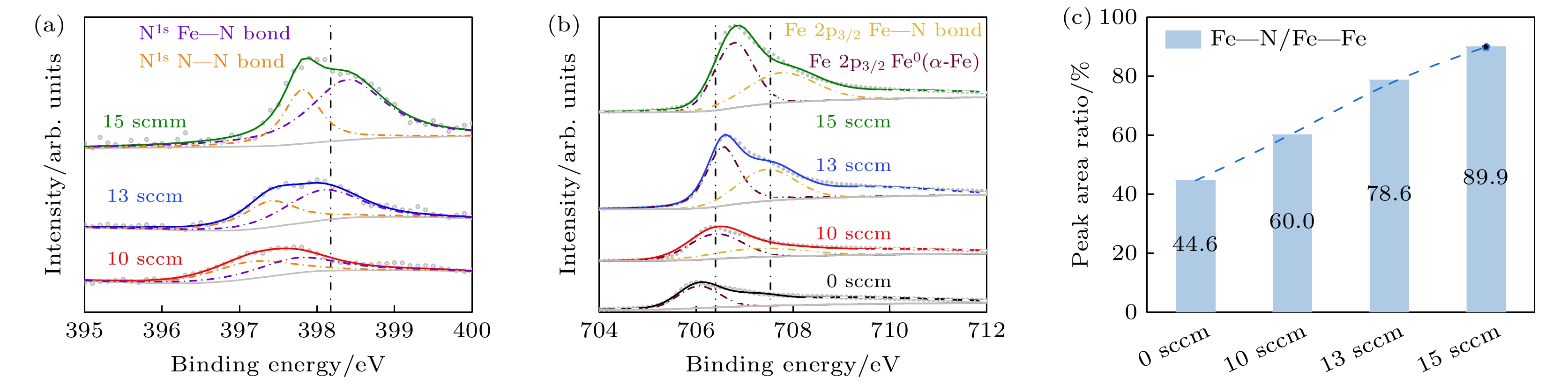

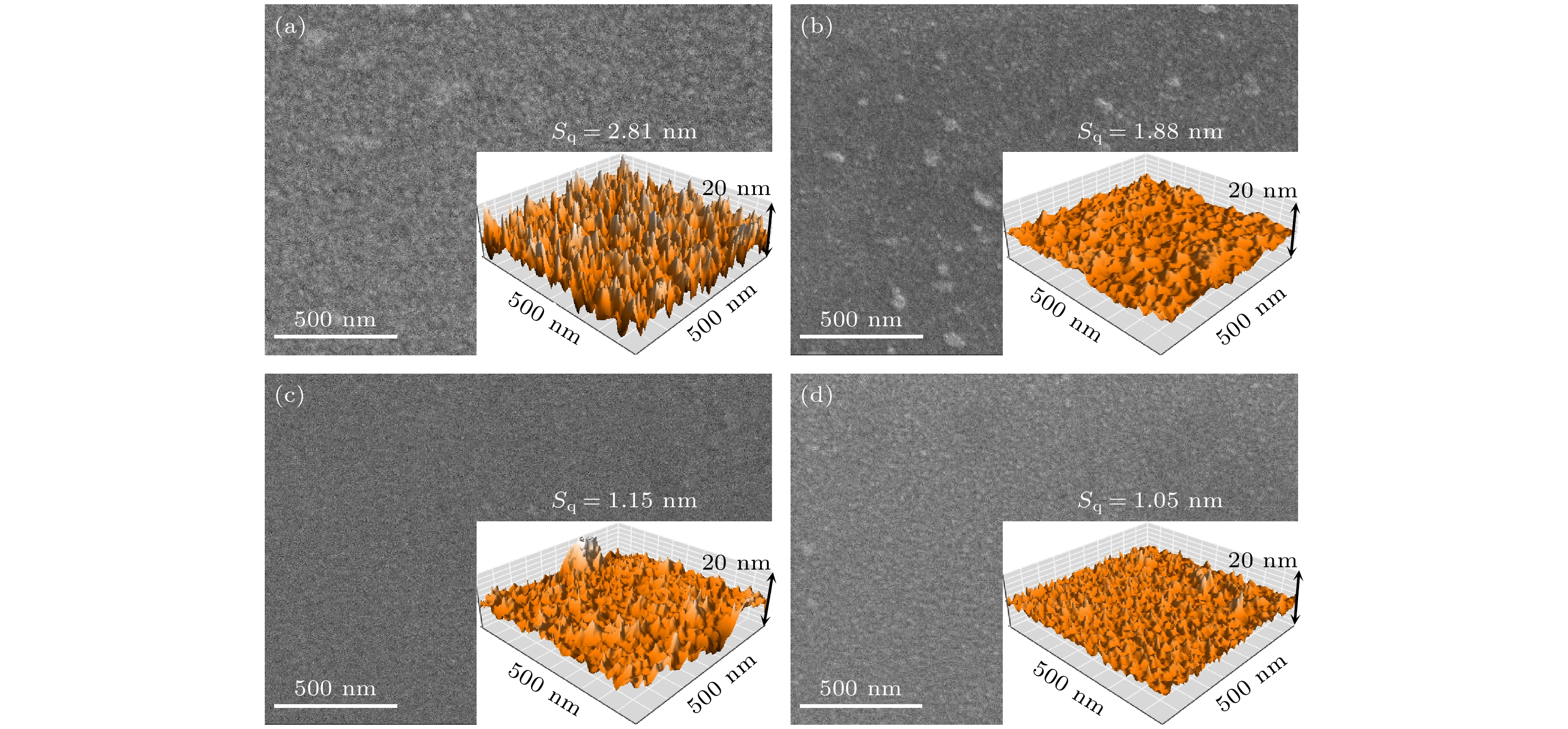

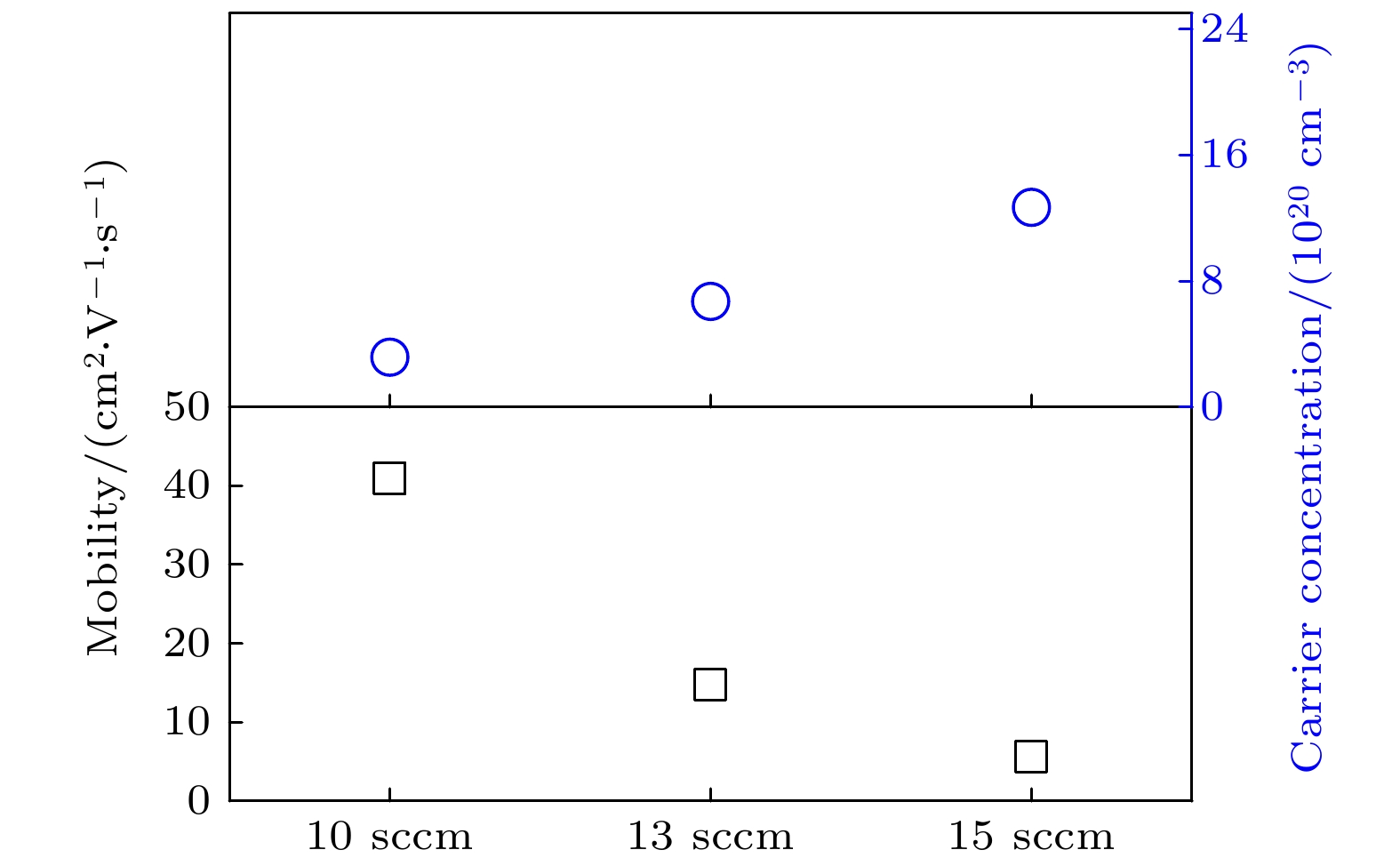

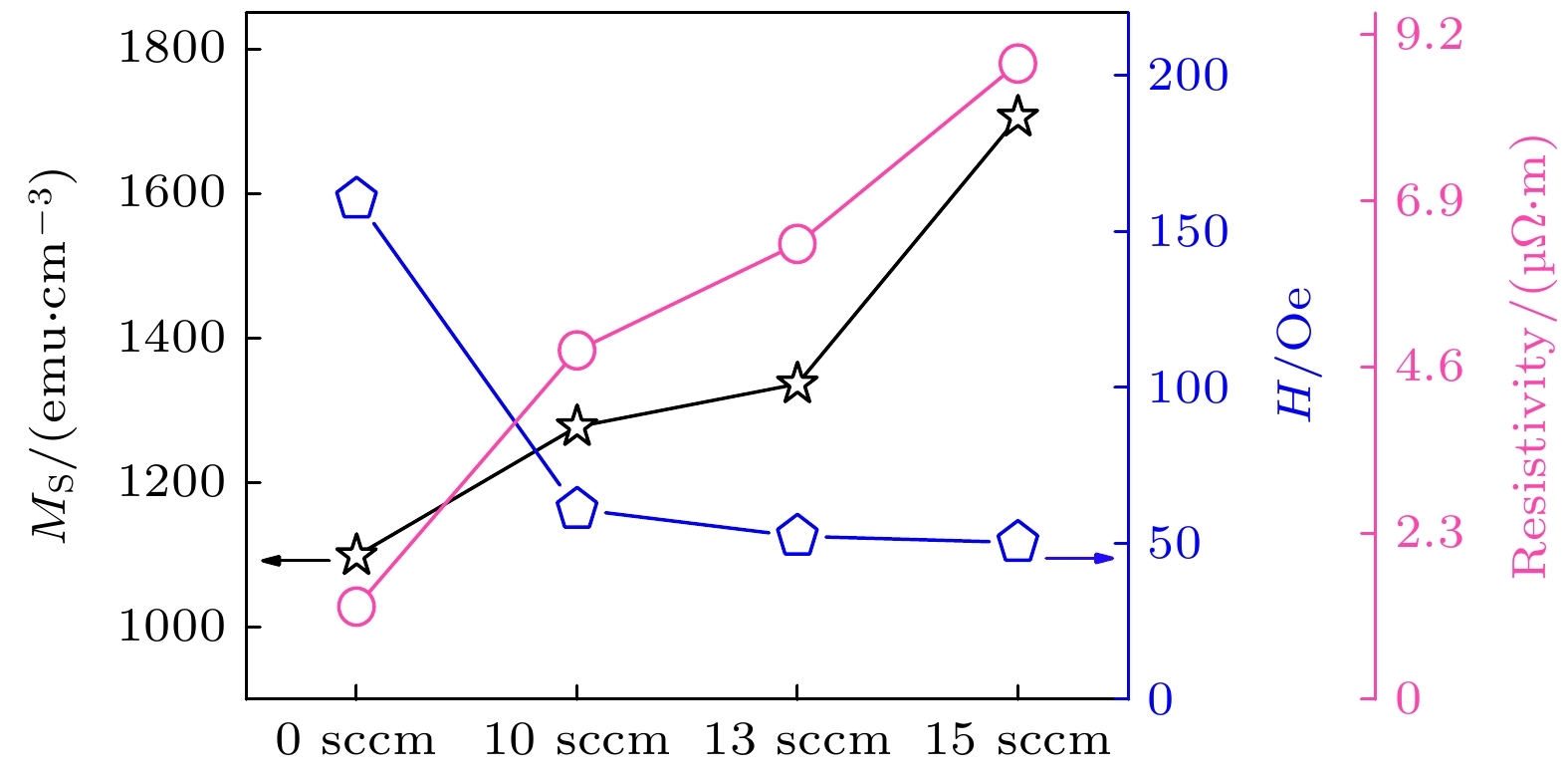

微电子器件具有广泛的应用前景, 为了使微电子器件具有优良的高频特性, 同时具有高饱和磁化强度、低矫顽力以及高电阻率软磁薄膜的研发成为其中的关键. 本文采用射频原子源辅助真空热蒸发方法制备了不同N原子含量的Fe-Fe3N软磁薄膜. 高饱和磁化强度Fe3N相含量和(102)取向度的增大, 使薄膜的饱和磁化强度增大, 相比于Fe薄膜, 饱和磁化强度提高了55.2%, 达到1705.6 emu/cm3 (1 emu/cm3 = 103 A/m). 此外, Fe3N(102)取向度的增大会产生较大的晶格错配, 阻碍Fe和Fe3N晶粒的生长, 使薄膜晶粒尺寸降低, 矫顽力(50.3 Oe (1 Oe = 103/(4π) A/m))比Fe薄膜降低了68.6%. 同时, 较大的晶格错配也会促进载流子散射, 提高了Fe-Fe3N薄膜电阻率, 使得其电阻率(8.80 μΩ·m)比Fe薄膜增大了7倍. 因此, 本文为高饱和磁化强度、低矫顽力以及高电阻率软磁薄膜的研发提供了新方法.Microelectronic devices have a wide range of application prospects. In order to make microelectronic devices that have excellent high-frequency characteristics, developing of soft magnetic films with high saturation magnetization, low coercivity and high resistivity becomes the key to the research. In this work, Fe-Fe3N soft magnetic films with different numbers of N atoms are prepared by radio-frequency atomic source assisted vacuum thermal evaporation. Among them, the RF atom source provides N atoms with higher chemical activity than N molecules, which reduces the formation energy between Fe atoms and N atoms. The vacuum thermal evaporation is beneficial to accurately controlling the growth rate, impurity concentration and composition ratio of multiple compounds of the film at the atomic level. The combination of the two Fe aom and N atom is easier to form nitrides with Fe atoms. Thus in this way the Fe-N films with stable structure are obtained. In the prepared Fe-Fe3N soft magnetic film, the introduction of N atoms makes the surface of the film more uniform, resulting in the increase of density. Compared with Fe, surface roughness is reduced by two times, and the crystallinity is obviously enhanced. Owing to the high saturation magnetization, the content of Fe3N phase is increased by 29% and the (102) orientation of Fe3N increases to 0.64. Therefore the directionality of the magnetic moment arrangement is improved. Comparing with Fe film, the saturation magnetization of the film is increased by 55.2%, reaching 1705.6 emu/cm3. In addition, with the increase of the (102) orientation of Fe3N, a large number of lattice mismatches are produced, which impedes the growth of Fe and Fe3N grains and reduces the grain size and anisotropy of the film. Thus the coercivity of the film decreases. The coercivity (50.3 Oe) is 68.6% lower than that of the Fe film. At the same time, the larger lattice mismatch results in the increase of heterointerface, which promotes the carrier scattering and increases the resistivity of Fe-Fe3N thin film. The resistivity (8.80 μΩ·m) of Fe-Fe3N thin film is 7 times higher than that of Fe thin film. Therefore, this research provides a new method for studying and developing soft magnetic films with high saturation magnetization, low coercivity and high resistivity.

-

Keywords:

- magnetic film /

- Fe-Fe3N /

- vacuum thermal evaporation /

- radio frequency atomic source

[1] Fan J P, Sun J, Yang Y, Liang R Y, Jiang Y N, Zhang J, Xu X H 2016 J. Alloy. Compd. 662 541

Google Scholar

Google Scholar

[2] Huang M Q, Wu C, Jiang Y Z, Yan M 2015 J. Alloy. Compd. 644 124

Google Scholar

Google Scholar

[3] Shokrollahi H, Janghorban K J 2012 Mater. Process. Tech. 189 1

Google Scholar

Google Scholar

[4] Patelli N, Cugini F, Wang D, Sanna S, Solzi M, Hahn H, Pasquini L 2021 J. Alloy. Compd. 890 161863

Google Scholar

Google Scholar

[5] Kim D, Kim J, Lee J, Kang M K, Kim S, Park S H, Kim J, Choa Y H, Lim J H 2019 J. Electrochem. Soc. 166 131

Google Scholar

Google Scholar

[6] Swain M, Kong H, Lee J, Park S, Jeen H 2018 Mater. Res. Express 5 116104

Google Scholar

Google Scholar

[7] Zhang Y, Turghun M, Huang C J, Wang T, Wang F F, Shi W Z 2018 Acta Metall. Sin. Engl. 31 623

Google Scholar

Google Scholar

[8] Brajpuriya R, Rajan S, Jani S, Vyas A 2018 Surf. Interface Anal. 51 371

Google Scholar

Google Scholar

[9] Liu S Y, Ma Y H, Chang L, Li G J, Wang J H, Wang Q 2018 Thin Solid Films 651 1

Google Scholar

Google Scholar

[10] Li G J, Li M M, Wang J H, Du J J, Wang K, Wang Q 2017 J. Magn. Magn. Mater. 423 353

Google Scholar

Google Scholar

[11] Meng B Y, Yang B, Zhang X X, Zhou B H, Li X P, Yu R H 2020 Mater. Chem. Phys. 242 122478

Google Scholar

Google Scholar

[12] Adi W A, Yunasfi 2020 Mat. Sci. Eng. B 262 114760

Google Scholar

Google Scholar

[13] Akdogan N G, Akdogan O 2019 AIP Adv. 9 125139

Google Scholar

Google Scholar

[14] Naito M, Uehara K, Takeda R, Taniyasu Y, Yamamoto H 2015 J. Cryst. Growth. 415 36

Google Scholar

Google Scholar

[15] Hattori T, Miyamachi T, Yokoyama T, Komori F 2019 J. Phys. Condens. Matter 31 255001

Google Scholar

Google Scholar

[16] Fang H A, Zhang R, Liu B, Tao Z K, Wang X F, Xie Z L, Xiu X Q, Zheng Y D 2012 J. Phys. D 45 315002

Google Scholar

Google Scholar

[17] Zhang Y, Mi W B, Wang X C, Zhang X X 2015 Phys. Chem. Chem. Phys. 17 15435

Google Scholar

Google Scholar

[18] Dirba I, Komissinskiy P, Gutfleisch O, Alff L 2015 J. Appl. Phys. 117 173911

Google Scholar

Google Scholar

[19] Higashikozono S, Ito K, Takata F, Gushi, Toko K, Suemasu T 2017 J. Cryst. Growth 468 691

Google Scholar

Google Scholar

[20] Houari A, Matar S F, Belkhir M A, Nakhl M 2007 Phys. Rev. B 75 064420

Google Scholar

Google Scholar

[21] Telling N D, Jones G A, Grundy P J, Blythe H J 2001 J. Magn. Magn. Mater. 226–230 1659

Google Scholar

Google Scholar

[22] Mosca D H, Dionisio P H, Schreiner W H, Baumvol T J R, Achete C 1990 J. Appl. Phys. 67 7514

Google Scholar

Google Scholar

[23] Ji N, Wu Y M, Wang J P 2011 J. Appl. Phys. 109 07B767

Google Scholar

Google Scholar

[24] Ji N, Osofsky M S, Lauter V, Allard L F, Li X, Jensen K L, Ambaye H, Lara-Curzio E, Wang J P 2011 Phys. Rev. B 84 245310

Google Scholar

Google Scholar

[25] Ji N A, Allard L F, Lara-Curzio E, Wang J P 2011 Appl. Phys. Lett. 98 092506

Google Scholar

Google Scholar

[26] Coehoorn R, Daalderop G H O, Jansen H J F 1993 Phys. Rev. B 48 3830

Google Scholar

Google Scholar

[27] Li Z W, Morrish A H, Ortiz C 2001 J. Mater. Sci. 36 5835

Google Scholar

Google Scholar

[28] Lu Q H, Xie M L, Han G L, Zheng B, Song Y Z, Qiang J, Wang X Q, Wu Z G, Yan P X, Liu W M 2019 J. Magn. Magn. Mater. 474 76

Google Scholar

Google Scholar

[29] Fang H, Peng X, Li Y, Tao Z K 2019 Mater. Res. Express 6 106443

Google Scholar

Google Scholar

[30] Zhang L L, Gao S P, Hu Q W, Qi L, Feng L H, Lei L 2017 Mater. Chem. Phys. 197 94

Google Scholar

Google Scholar

[31] Nadzri N, Ibrahim D, Sompon S 2019 IOP Conference Series Materials Science and Engineering Beijing, China, May 11-13, 2019 p012047

[32] Hung W, Wang X L 2008 Nanoscale Res. Lett. 3 260

Google Scholar

Google Scholar

[33] Zhang P, Wang X B, Wang W, Lei X, Yin W X, Yang H 2015 RSC Adv. 5 68758

Google Scholar

Google Scholar

[34] Sundararajan J A, Kaur M, Jiang W L, McCloy J S, Qiang Y 2014 J. Appl. Phys. 115 17B507

Google Scholar

Google Scholar

[35] Yamaguchi K, Yui T, Ichikawa Y, Yamaki K, Kakeya I, Kadowaki K, Suemasu T 2006 Jpn. J. Appl. Phys. 45 705

Google Scholar

Google Scholar

[36] Ahmad Z, Cross G B, Vernon M, Gebregiorgis D, Deocampo D, Kozhanov A 2019 Appl. Phys. Lett. 115 223101

Google Scholar

Google Scholar

[37] Kikuchi T, Somintac A S, Ariyada O, Wada M, Ohachi T 2006 J. Cryst. Growth 292 221

Google Scholar

Google Scholar

[38] Kuwano K, Nezu A, Matsuura H, Akatsuka H 2016 Jpn. J. Appl. Phys. 55 086101

Google Scholar

Google Scholar

[39] Agarwal S, Hoex B, Van De Sanden M C M, Maroudas D, Aydil E S 2003 Appl. Phys. Lett. 83 4918

Google Scholar

Google Scholar

[40] Du J J, Li G J, Wang Q, Ma Y H, Cao Y Z, He J C 2015 Vacuum 121 88

Google Scholar

Google Scholar

[41] Sato H, Yamashita D, Ban S 2008 J. Ceram. Soc. Jpn. 116 28

Google Scholar

Google Scholar

[42] Yin W X, Zhang D G, Zhang P, Wang X B, Wang X B, Wang W, Lei X. Shi Z, Yang H 2016 J. Alloy. Compd. 688 828

Google Scholar

Google Scholar

[43] Cheng Y H, Zheng R K, Liu H, Tian Y, Li Z Q 2009 Phys. Rev. B 80 174412

Google Scholar

Google Scholar

[44] Lv Z Q, Fu W T, Sun S H, Wang Z H, Fan W, Qv M G 2010 Solid State Sci. 12 404

Google Scholar

Google Scholar

[45] Wriedt H, Gokcen G, Nafziger R H 1987 Mater. Sci. 8 355

Google Scholar

Google Scholar

[46] Fan X A, Wu Z Y, Li G Q, Wang J, Xiang Z D, Gan Z H 2016 Mater. Design 89 1251

Google Scholar

Google Scholar

[47] Yang B, Li X P, Guo R Y, Yu R H 2017 Mater. Design 121 272

Google Scholar

Google Scholar

[48] Khan W, Wang Q, Jin X, Feng T F 2017 Materials 10 217

Google Scholar

Google Scholar

[49] 杜娇娇, 李国建, 王强, 马永会, 王慧敏, 李萌萌 2015 金属学报 51 799

Google Scholar

Google Scholar

Du J J, Li G J, Wang Q, Ma Y H, Wang H M, Li M M 2015 Acta Metall. Sin. 51 799

Google Scholar

Google Scholar

[50] Aravindh S A, Jaya S M, Valsakumar M C, Sundar C S 2012 Superlattice. Microst. 51 92

Google Scholar

Google Scholar

[51] Yartseva N S, Yartsev S V, Parlebas J C 2008 Surf. Sci. 602 3388

Google Scholar

Google Scholar

[52] Sun Y, Gao R W, Han B P, Liu M, Han G B, Feng W C 2007 Prog. Nat. Sci-Mater. 17 131

Google Scholar

Google Scholar

[53] Ding J, Li Y, Chen L F, Deng C R, Shi Y, Chow Y S, Gang T B 2001 J. Alloys Compd. 314 262

Google Scholar

Google Scholar

[54] Herzer G 1990 IEEE. Trans. Mag. 26 1397

Google Scholar

Google Scholar

[55] Kronmvler H, Fischer R, Seeger M, Zern A 1996 J. Phys. D Appl. Phys. 29 2274

Google Scholar

Google Scholar

[56] Zhao N, Wang W, Lei X, Ye Z T, Chen X D, Ding H, Yang H 2017 J. Mater. Sci. 28 15701

Google Scholar

Google Scholar

[57] Gupta R, Tayal A, Amir S M, Gupta M, Gupta A, Horisberger M, Stahn J 2011 J. Appl. Phys. 111 103520

Google Scholar

Google Scholar

[58] Naganuma H, Nakatani R, Endo Y, Kawamura Y, Yamamoto M 2016 Sci. Technol. Adv. Mat. 5 101

Google Scholar

Google Scholar

[59] Mayadas A F, Shatzkes M 1970 Phys. Rev. B 1 1382

Google Scholar

Google Scholar

[60] Zhang Z Z, Wu S X, Niu Y, Jiang J, Wang C 2019 J. Mater. Sci. 30 5177

Google Scholar

Google Scholar

-

-

[1] Fan J P, Sun J, Yang Y, Liang R Y, Jiang Y N, Zhang J, Xu X H 2016 J. Alloy. Compd. 662 541

Google Scholar

Google Scholar

[2] Huang M Q, Wu C, Jiang Y Z, Yan M 2015 J. Alloy. Compd. 644 124

Google Scholar

Google Scholar

[3] Shokrollahi H, Janghorban K J 2012 Mater. Process. Tech. 189 1

Google Scholar

Google Scholar

[4] Patelli N, Cugini F, Wang D, Sanna S, Solzi M, Hahn H, Pasquini L 2021 J. Alloy. Compd. 890 161863

Google Scholar

Google Scholar

[5] Kim D, Kim J, Lee J, Kang M K, Kim S, Park S H, Kim J, Choa Y H, Lim J H 2019 J. Electrochem. Soc. 166 131

Google Scholar

Google Scholar

[6] Swain M, Kong H, Lee J, Park S, Jeen H 2018 Mater. Res. Express 5 116104

Google Scholar

Google Scholar

[7] Zhang Y, Turghun M, Huang C J, Wang T, Wang F F, Shi W Z 2018 Acta Metall. Sin. Engl. 31 623

Google Scholar

Google Scholar

[8] Brajpuriya R, Rajan S, Jani S, Vyas A 2018 Surf. Interface Anal. 51 371

Google Scholar

Google Scholar

[9] Liu S Y, Ma Y H, Chang L, Li G J, Wang J H, Wang Q 2018 Thin Solid Films 651 1

Google Scholar

Google Scholar

[10] Li G J, Li M M, Wang J H, Du J J, Wang K, Wang Q 2017 J. Magn. Magn. Mater. 423 353

Google Scholar

Google Scholar

[11] Meng B Y, Yang B, Zhang X X, Zhou B H, Li X P, Yu R H 2020 Mater. Chem. Phys. 242 122478

Google Scholar

Google Scholar

[12] Adi W A, Yunasfi 2020 Mat. Sci. Eng. B 262 114760

Google Scholar

Google Scholar

[13] Akdogan N G, Akdogan O 2019 AIP Adv. 9 125139

Google Scholar

Google Scholar

[14] Naito M, Uehara K, Takeda R, Taniyasu Y, Yamamoto H 2015 J. Cryst. Growth. 415 36

Google Scholar

Google Scholar

[15] Hattori T, Miyamachi T, Yokoyama T, Komori F 2019 J. Phys. Condens. Matter 31 255001

Google Scholar

Google Scholar

[16] Fang H A, Zhang R, Liu B, Tao Z K, Wang X F, Xie Z L, Xiu X Q, Zheng Y D 2012 J. Phys. D 45 315002

Google Scholar

Google Scholar

[17] Zhang Y, Mi W B, Wang X C, Zhang X X 2015 Phys. Chem. Chem. Phys. 17 15435

Google Scholar

Google Scholar

[18] Dirba I, Komissinskiy P, Gutfleisch O, Alff L 2015 J. Appl. Phys. 117 173911

Google Scholar

Google Scholar

[19] Higashikozono S, Ito K, Takata F, Gushi, Toko K, Suemasu T 2017 J. Cryst. Growth 468 691

Google Scholar

Google Scholar

[20] Houari A, Matar S F, Belkhir M A, Nakhl M 2007 Phys. Rev. B 75 064420

Google Scholar

Google Scholar

[21] Telling N D, Jones G A, Grundy P J, Blythe H J 2001 J. Magn. Magn. Mater. 226–230 1659

Google Scholar

Google Scholar

[22] Mosca D H, Dionisio P H, Schreiner W H, Baumvol T J R, Achete C 1990 J. Appl. Phys. 67 7514

Google Scholar

Google Scholar

[23] Ji N, Wu Y M, Wang J P 2011 J. Appl. Phys. 109 07B767

Google Scholar

Google Scholar

[24] Ji N, Osofsky M S, Lauter V, Allard L F, Li X, Jensen K L, Ambaye H, Lara-Curzio E, Wang J P 2011 Phys. Rev. B 84 245310

Google Scholar

Google Scholar

[25] Ji N A, Allard L F, Lara-Curzio E, Wang J P 2011 Appl. Phys. Lett. 98 092506

Google Scholar

Google Scholar

[26] Coehoorn R, Daalderop G H O, Jansen H J F 1993 Phys. Rev. B 48 3830

Google Scholar

Google Scholar

[27] Li Z W, Morrish A H, Ortiz C 2001 J. Mater. Sci. 36 5835

Google Scholar

Google Scholar

[28] Lu Q H, Xie M L, Han G L, Zheng B, Song Y Z, Qiang J, Wang X Q, Wu Z G, Yan P X, Liu W M 2019 J. Magn. Magn. Mater. 474 76

Google Scholar

Google Scholar

[29] Fang H, Peng X, Li Y, Tao Z K 2019 Mater. Res. Express 6 106443

Google Scholar

Google Scholar

[30] Zhang L L, Gao S P, Hu Q W, Qi L, Feng L H, Lei L 2017 Mater. Chem. Phys. 197 94

Google Scholar

Google Scholar

[31] Nadzri N, Ibrahim D, Sompon S 2019 IOP Conference Series Materials Science and Engineering Beijing, China, May 11-13, 2019 p012047

[32] Hung W, Wang X L 2008 Nanoscale Res. Lett. 3 260

Google Scholar

Google Scholar

[33] Zhang P, Wang X B, Wang W, Lei X, Yin W X, Yang H 2015 RSC Adv. 5 68758

Google Scholar

Google Scholar

[34] Sundararajan J A, Kaur M, Jiang W L, McCloy J S, Qiang Y 2014 J. Appl. Phys. 115 17B507

Google Scholar

Google Scholar

[35] Yamaguchi K, Yui T, Ichikawa Y, Yamaki K, Kakeya I, Kadowaki K, Suemasu T 2006 Jpn. J. Appl. Phys. 45 705

Google Scholar

Google Scholar

[36] Ahmad Z, Cross G B, Vernon M, Gebregiorgis D, Deocampo D, Kozhanov A 2019 Appl. Phys. Lett. 115 223101

Google Scholar

Google Scholar

[37] Kikuchi T, Somintac A S, Ariyada O, Wada M, Ohachi T 2006 J. Cryst. Growth 292 221

Google Scholar

Google Scholar

[38] Kuwano K, Nezu A, Matsuura H, Akatsuka H 2016 Jpn. J. Appl. Phys. 55 086101

Google Scholar

Google Scholar

[39] Agarwal S, Hoex B, Van De Sanden M C M, Maroudas D, Aydil E S 2003 Appl. Phys. Lett. 83 4918

Google Scholar

Google Scholar

[40] Du J J, Li G J, Wang Q, Ma Y H, Cao Y Z, He J C 2015 Vacuum 121 88

Google Scholar

Google Scholar

[41] Sato H, Yamashita D, Ban S 2008 J. Ceram. Soc. Jpn. 116 28

Google Scholar

Google Scholar

[42] Yin W X, Zhang D G, Zhang P, Wang X B, Wang X B, Wang W, Lei X. Shi Z, Yang H 2016 J. Alloy. Compd. 688 828

Google Scholar

Google Scholar

[43] Cheng Y H, Zheng R K, Liu H, Tian Y, Li Z Q 2009 Phys. Rev. B 80 174412

Google Scholar

Google Scholar

[44] Lv Z Q, Fu W T, Sun S H, Wang Z H, Fan W, Qv M G 2010 Solid State Sci. 12 404

Google Scholar

Google Scholar

[45] Wriedt H, Gokcen G, Nafziger R H 1987 Mater. Sci. 8 355

Google Scholar

Google Scholar

[46] Fan X A, Wu Z Y, Li G Q, Wang J, Xiang Z D, Gan Z H 2016 Mater. Design 89 1251

Google Scholar

Google Scholar

[47] Yang B, Li X P, Guo R Y, Yu R H 2017 Mater. Design 121 272

Google Scholar

Google Scholar

[48] Khan W, Wang Q, Jin X, Feng T F 2017 Materials 10 217

Google Scholar

Google Scholar

[49] 杜娇娇, 李国建, 王强, 马永会, 王慧敏, 李萌萌 2015 金属学报 51 799

Google Scholar

Google Scholar

Du J J, Li G J, Wang Q, Ma Y H, Wang H M, Li M M 2015 Acta Metall. Sin. 51 799

Google Scholar

Google Scholar

[50] Aravindh S A, Jaya S M, Valsakumar M C, Sundar C S 2012 Superlattice. Microst. 51 92

Google Scholar

Google Scholar

[51] Yartseva N S, Yartsev S V, Parlebas J C 2008 Surf. Sci. 602 3388

Google Scholar

Google Scholar

[52] Sun Y, Gao R W, Han B P, Liu M, Han G B, Feng W C 2007 Prog. Nat. Sci-Mater. 17 131

Google Scholar

Google Scholar

[53] Ding J, Li Y, Chen L F, Deng C R, Shi Y, Chow Y S, Gang T B 2001 J. Alloys Compd. 314 262

Google Scholar

Google Scholar

[54] Herzer G 1990 IEEE. Trans. Mag. 26 1397

Google Scholar

Google Scholar

[55] Kronmvler H, Fischer R, Seeger M, Zern A 1996 J. Phys. D Appl. Phys. 29 2274

Google Scholar

Google Scholar

[56] Zhao N, Wang W, Lei X, Ye Z T, Chen X D, Ding H, Yang H 2017 J. Mater. Sci. 28 15701

Google Scholar

Google Scholar

[57] Gupta R, Tayal A, Amir S M, Gupta M, Gupta A, Horisberger M, Stahn J 2011 J. Appl. Phys. 111 103520

Google Scholar

Google Scholar

[58] Naganuma H, Nakatani R, Endo Y, Kawamura Y, Yamamoto M 2016 Sci. Technol. Adv. Mat. 5 101

Google Scholar

Google Scholar

[59] Mayadas A F, Shatzkes M 1970 Phys. Rev. B 1 1382

Google Scholar

Google Scholar

[60] Zhang Z Z, Wu S X, Niu Y, Jiang J, Wang C 2019 J. Mater. Sci. 30 5177

Google Scholar

Google Scholar

计量

- 文章访问数: 5928

- PDF下载量: 107

- 被引次数: 0

下载:

下载: