-

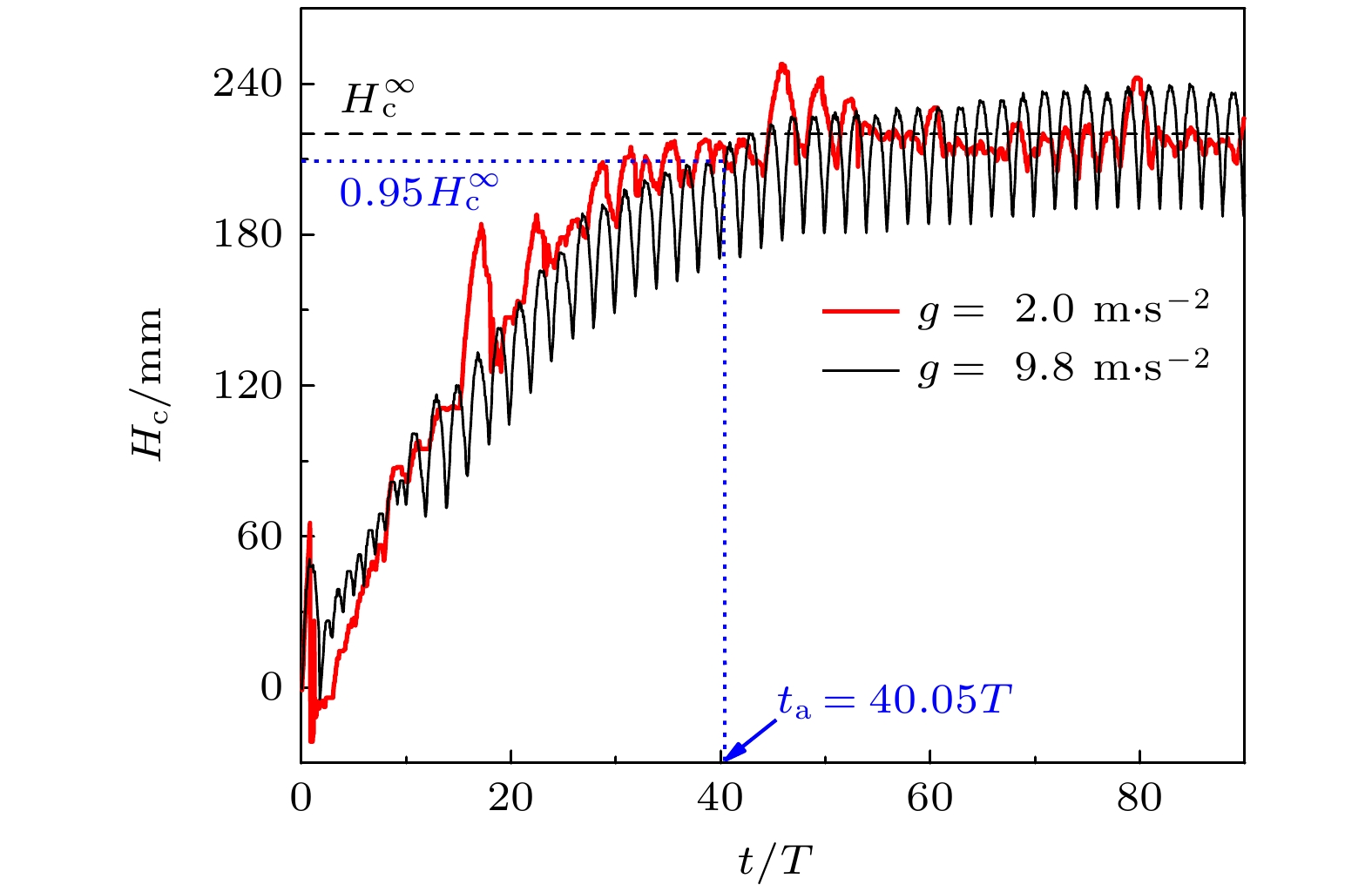

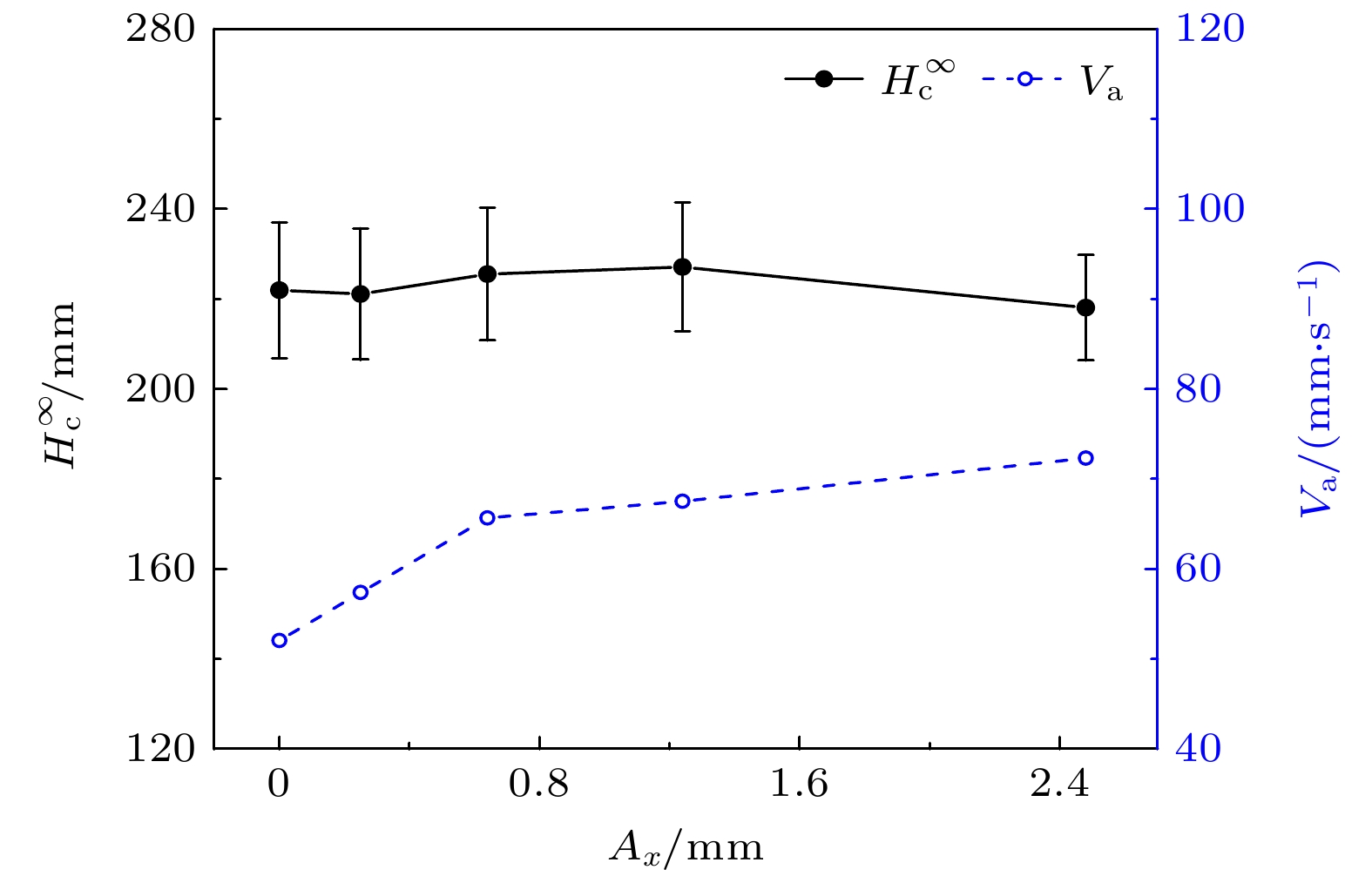

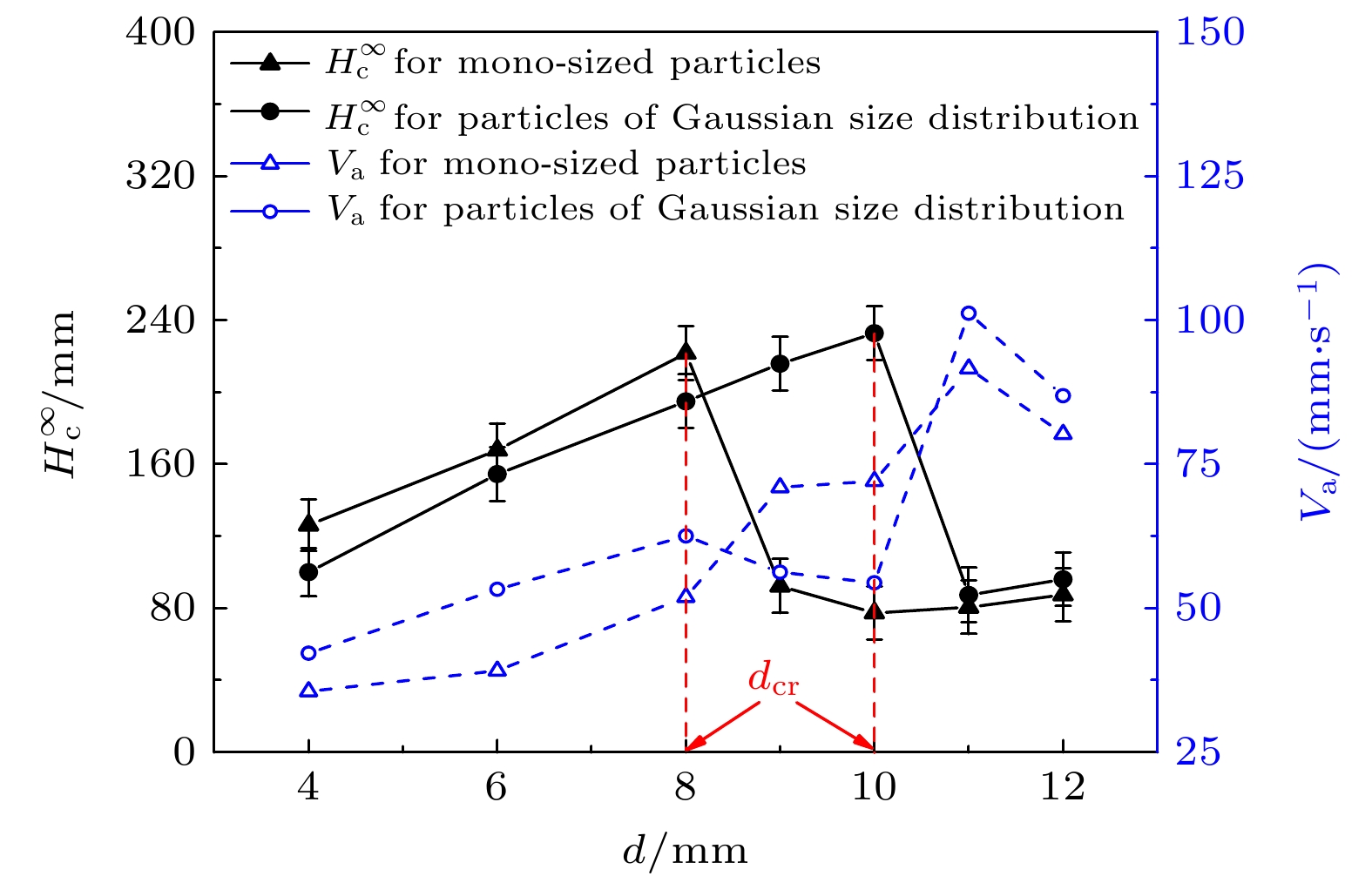

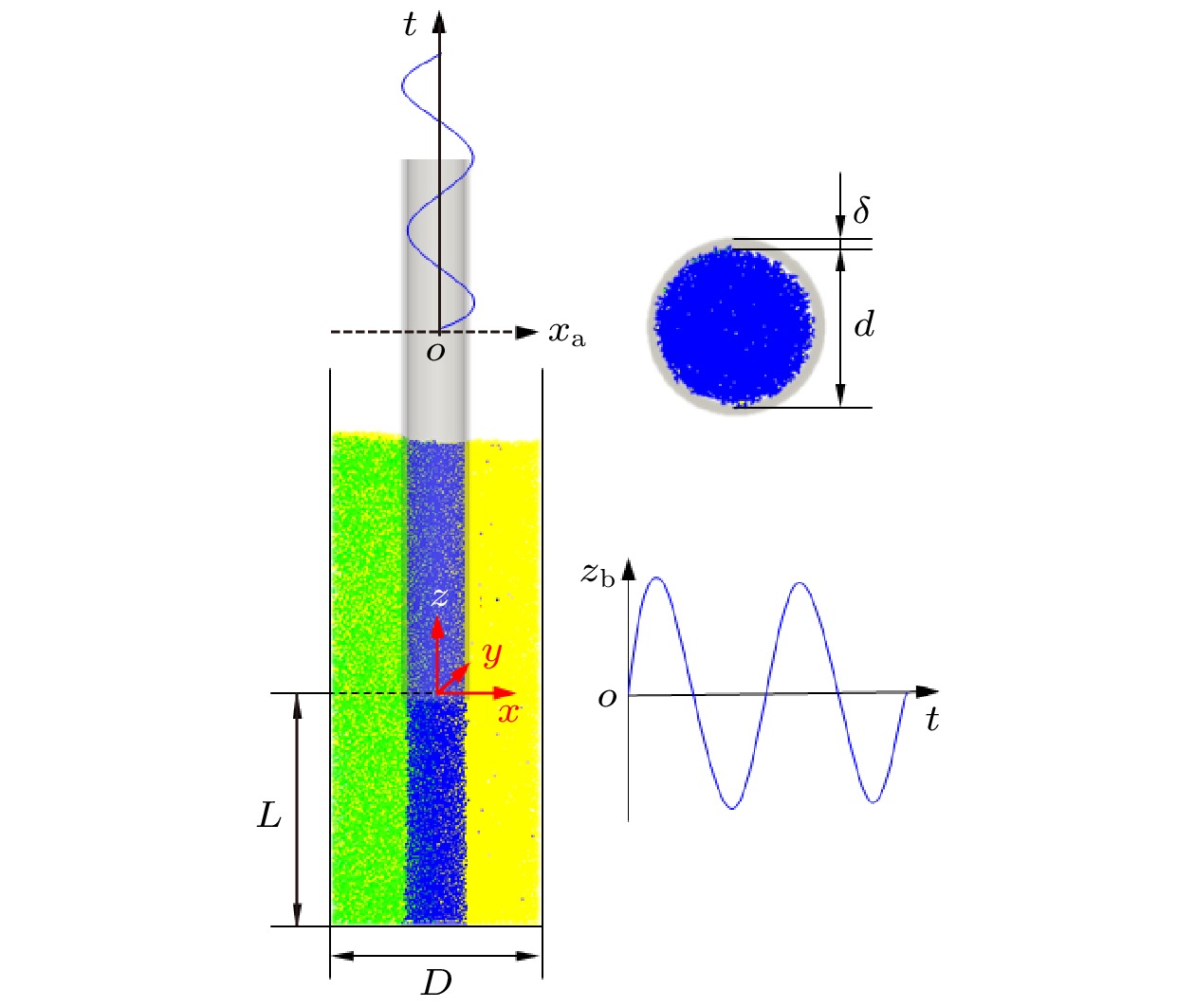

竖直振动激励下颗粒毛细上升现象为颗粒物料的提升、输运和采集提供了一种全新的技术路径. 然而, 已有颗粒毛细上升行为研究仍存在明显不足, 特别是缺乏对重力加速度、水平振动分量、颗粒粒径分布影响的深入探究. 针对这些问题, 采用离散元方法, 对不同操作条件下颗粒毛细上升现象开展数值模拟研究, 并对颗粒最终毛细上升高度和平均毛细上升速度进行计算分析. 结果表明, 在低重力条件下, 颗粒毛细效应仍能发生, 颗粒最终毛细上升高度和平均毛细上升速度随重力加速度均呈现先增加后减小的趋势; 颗粒最终毛细上升高度对水平振动分量的变化不敏感, 而平均毛细上升速度随水平振动分量的增大而增加; 在平均粒径相等的情况下, 粒径服从高斯分布的颗粒比单一粒径颗粒的最终毛细上升高度最大值对应的临界管径更大, 并且同处于堵塞效应影响的管径区域时平均毛细上升速度也更快.The phenomenon of granular capillary rising under vertical vibration provides a novel technical route for hoisting, transporting and collecting granular materials. However, there are still obvious deficiencies in the existing studies of the granular capillary rising behavior, especially the intensive investigation on the effects of gravitational acceleration, horizontal vibration component and particle size distribution are still lacking. To address these problems, the discrete element method is used to numerically simulate the granular capillary rising phenomenon under different operating conditions. The final capillary rising height and average capillary rising velocity of the granular matter are computed and analyzed based on the numerical simulations. The results show that the granular capillarity can also occur under low gravity conditions, and that the final capillary rising height and the average capillary rising velocity first increase and then decrease with the gravitational acceleration. It is also found that the final capillary rising height is insensitive to the variation of horizontal vibrational component, whereas the average capillary rising velocity increases with the augmentation of horizontal vibrational component. Compared with the mono-sized particles, the particles with the same mean size but having a Gaussian size distribution exhibit a maximal capillary rising height at a larger critical tube diameter. Meanwhile, the average capillary rising velocity of the particles having a Gaussian size distribution is faster in the tube diameter range where the granular capillary dynamics for both size distributions is dominated by the jamming effect.

-

Keywords:

- granular matter /

- capillary effect /

- vertical vibration /

- discrete element method

[1] Xing Y, Zheng J, Li J D, Cao Y X, Pan W, Zhang J, Wang Y J 2021 Phys. Rev. Lett. 126 048002

Google Scholar

Google Scholar

[2] Li Z F, Zeng Z K, Xing Y, Li J D, Zheng J, Mao Q H, Zhang J, Hou M Y, Wang Y J 2021 Sci. Adv. 7 eabe8737

Google Scholar

Google Scholar

[3] Then H Z, Sekiguchi T, Okumura K 2020 Soft Matter 16 8612

Google Scholar

Google Scholar

[4] Kogane A, Kuwagi K, Mawatari Y, Mawatari Y, Davoren L, Seville J P K, Parker D J 2020 J. Phys. Commun. 4 075012

Google Scholar

Google Scholar

[5] van Gerner H J, van der Weele K, van der Meer D, van der Hoef M A 2015 Phys. Rev. E Stat. Nonlinear Soft Matter Phys. 92 042203

Google Scholar

Google Scholar

[6] Sánchez I, Díaz A A, Guerrero B, Trosel Y, Rojas C 2015 Mech. Res. Commun. 67 1

Google Scholar

Google Scholar

[7] 郭宇, 凡凤仙, 白鹏博, 刘举 2019 上海理工大学学报 41 409

Google Scholar

Google Scholar

Guo Y, Fan F X, Bai P B, Lu J 2019 J. Univ. Shanghai for Sci. Technol. 41 409

Google Scholar

Google Scholar

[8] Sánchez I, Darias J R, Paredes R, Lobb C J, Gutiérrez G 2009 Traffic Granular Flow 545

[9] Liu C P, Wu P, Wang L 2013 Soft Matter 9 4762

Google Scholar

Google Scholar

[10] 张富翁, 王立, 刘传平, 吴平 2014 63 014501

Google Scholar

Google Scholar

Zhang F W, Wang L, Liu C P, Wu P 2014 Acta. Phys. Sin. 63 014501

Google Scholar

Google Scholar

[11] Fan F X, Parteli E J R, Pöschel T 2017 Phys. Rev. Lett. 118 218001

Google Scholar

Google Scholar

[12] 张华腾, 凡凤仙, 王志强 2020 力学学报 52 442

Google Scholar

Google Scholar

Zhang H T, Fan F X, Wang Z Q 2020 Chin. J. Theo. Appl. Mech. 52 442

Google Scholar

Google Scholar

[13] 凡凤仙, 王志强, 刘举, 张华腾 2019 力学学报 51 415

Google Scholar

Google Scholar

Fan F X, Wang Z Q, Liu J, Zhang H T 2019 Chin. J. Theo. Appl. Mech. 51 415

Google Scholar

Google Scholar

[14] Fan F X, Liu J, Parteli E J R, Pschel T 2017 EPJ Web of Conferences 140 16008

Google Scholar

Google Scholar

[15] 刘举, 白鹏博, 凡凤仙, 胡晓红 2016 化工进展 35 1956

Google Scholar

Google Scholar

Liu J, Bai P B, Fan F X, Hu X H 2016 Chem. Ind. Eng. Prog. 35 1956

Google Scholar

Google Scholar

[16] Zhang F W, Cronin K, Lin Y H, Miao S, Liu C P, Wang L 2019 Powder Technol. 343 383

Google Scholar

Google Scholar

[17] Zhang F W, Cronin K, Lin Y, Liu C, Wang L 2018 Powder Technol. 333 421

Google Scholar

Google Scholar

[18] Zhang F W, Wang L, Liu C P, Wu P 2017 Adv Powder Technol. 28 356

Google Scholar

Google Scholar

[19] Liu C P, Zhang F W, Wu P, Wang 2014 Powder Technol. 259 137

Google Scholar

Google Scholar

[20] Kawamoto H, Kubo K, Kikumiya R, Adachi M 2021 J. Aerosp. Eng. 34 04021097

Google Scholar

Google Scholar

[21] Liu Y, Zhao J H 2015 Chin. Phys. B 24 034502

Google Scholar

Google Scholar

[22] Xu Y P, Musser J, Li T, Padding J T, Rogers W A 2017 Powder Technol. 320 304

Google Scholar

Google Scholar

[23] Zhang N, Cheng B, Baoyin H 2019 Appl. Math. Mech. Engl. Ed. 40 127

Google Scholar

Google Scholar

[24] Brilliantov N V, Spahn F, Hertzsch J M, Pöschel T 1996 Phys. Rev. E 53 5382

Google Scholar

Google Scholar

[25] Cundall P A, Strack O D 1979 Géotechnique 29 47

Google Scholar

Google Scholar

[26] Ai J, Chen J F, Rotter J M, Ooi J Y 2011 Powder Technol. 206 269

Google Scholar

Google Scholar

[27] Kloss C, Goniva C, Hager A, Amberger S, Pirker S 2012 Prog. Comput. Fluid Dyn. 12 140

Google Scholar

Google Scholar

[28] Shäfer J, Dippel S, Wolf D E 1996 J. Phys. I 6 5

Google Scholar

Google Scholar

[29] 赵永志, 程易, 郑津洋 2009 计算力学学报 26 239

Zhao Y Z, Cheng Y, Zheng J Y 2009 Chin. J. Comput. Mech. 26 239

[30] Ng T T, Zhou W, Ma G, Chang X L 2014 J. Eng. Mech. 141 04014167

Google Scholar

Google Scholar

-

表 1 数值模拟参数

Table 1. Parameters used in numerical simulations

参数 符号 数值 容器内径/mm D 28.2 管内径/mm d 8 颗粒数目 Np 200000 管壁厚度/mm δ 0.6 管底面距容器底面的距离/mm L 30 颗粒密度/(kg⋅m–3) ρp 2500 杨氏模量/MPa Y 10 泊松比 υ 0.25 恢复系数 ε 0.5 颗粒间滑动摩擦系数 μpp,s 0.8 颗粒间滚动摩擦系数 μpp,r 0.1 颗粒-壁面间滑动摩擦系数 μpw,s 0.58 颗粒-壁面间滚动摩擦系数 μpw,r 0.05 振幅/mm Az 12.42 频率/Hz f 10 -

[1] Xing Y, Zheng J, Li J D, Cao Y X, Pan W, Zhang J, Wang Y J 2021 Phys. Rev. Lett. 126 048002

Google Scholar

Google Scholar

[2] Li Z F, Zeng Z K, Xing Y, Li J D, Zheng J, Mao Q H, Zhang J, Hou M Y, Wang Y J 2021 Sci. Adv. 7 eabe8737

Google Scholar

Google Scholar

[3] Then H Z, Sekiguchi T, Okumura K 2020 Soft Matter 16 8612

Google Scholar

Google Scholar

[4] Kogane A, Kuwagi K, Mawatari Y, Mawatari Y, Davoren L, Seville J P K, Parker D J 2020 J. Phys. Commun. 4 075012

Google Scholar

Google Scholar

[5] van Gerner H J, van der Weele K, van der Meer D, van der Hoef M A 2015 Phys. Rev. E Stat. Nonlinear Soft Matter Phys. 92 042203

Google Scholar

Google Scholar

[6] Sánchez I, Díaz A A, Guerrero B, Trosel Y, Rojas C 2015 Mech. Res. Commun. 67 1

Google Scholar

Google Scholar

[7] 郭宇, 凡凤仙, 白鹏博, 刘举 2019 上海理工大学学报 41 409

Google Scholar

Google Scholar

Guo Y, Fan F X, Bai P B, Lu J 2019 J. Univ. Shanghai for Sci. Technol. 41 409

Google Scholar

Google Scholar

[8] Sánchez I, Darias J R, Paredes R, Lobb C J, Gutiérrez G 2009 Traffic Granular Flow 545

[9] Liu C P, Wu P, Wang L 2013 Soft Matter 9 4762

Google Scholar

Google Scholar

[10] 张富翁, 王立, 刘传平, 吴平 2014 63 014501

Google Scholar

Google Scholar

Zhang F W, Wang L, Liu C P, Wu P 2014 Acta. Phys. Sin. 63 014501

Google Scholar

Google Scholar

[11] Fan F X, Parteli E J R, Pöschel T 2017 Phys. Rev. Lett. 118 218001

Google Scholar

Google Scholar

[12] 张华腾, 凡凤仙, 王志强 2020 力学学报 52 442

Google Scholar

Google Scholar

Zhang H T, Fan F X, Wang Z Q 2020 Chin. J. Theo. Appl. Mech. 52 442

Google Scholar

Google Scholar

[13] 凡凤仙, 王志强, 刘举, 张华腾 2019 力学学报 51 415

Google Scholar

Google Scholar

Fan F X, Wang Z Q, Liu J, Zhang H T 2019 Chin. J. Theo. Appl. Mech. 51 415

Google Scholar

Google Scholar

[14] Fan F X, Liu J, Parteli E J R, Pschel T 2017 EPJ Web of Conferences 140 16008

Google Scholar

Google Scholar

[15] 刘举, 白鹏博, 凡凤仙, 胡晓红 2016 化工进展 35 1956

Google Scholar

Google Scholar

Liu J, Bai P B, Fan F X, Hu X H 2016 Chem. Ind. Eng. Prog. 35 1956

Google Scholar

Google Scholar

[16] Zhang F W, Cronin K, Lin Y H, Miao S, Liu C P, Wang L 2019 Powder Technol. 343 383

Google Scholar

Google Scholar

[17] Zhang F W, Cronin K, Lin Y, Liu C, Wang L 2018 Powder Technol. 333 421

Google Scholar

Google Scholar

[18] Zhang F W, Wang L, Liu C P, Wu P 2017 Adv Powder Technol. 28 356

Google Scholar

Google Scholar

[19] Liu C P, Zhang F W, Wu P, Wang 2014 Powder Technol. 259 137

Google Scholar

Google Scholar

[20] Kawamoto H, Kubo K, Kikumiya R, Adachi M 2021 J. Aerosp. Eng. 34 04021097

Google Scholar

Google Scholar

[21] Liu Y, Zhao J H 2015 Chin. Phys. B 24 034502

Google Scholar

Google Scholar

[22] Xu Y P, Musser J, Li T, Padding J T, Rogers W A 2017 Powder Technol. 320 304

Google Scholar

Google Scholar

[23] Zhang N, Cheng B, Baoyin H 2019 Appl. Math. Mech. Engl. Ed. 40 127

Google Scholar

Google Scholar

[24] Brilliantov N V, Spahn F, Hertzsch J M, Pöschel T 1996 Phys. Rev. E 53 5382

Google Scholar

Google Scholar

[25] Cundall P A, Strack O D 1979 Géotechnique 29 47

Google Scholar

Google Scholar

[26] Ai J, Chen J F, Rotter J M, Ooi J Y 2011 Powder Technol. 206 269

Google Scholar

Google Scholar

[27] Kloss C, Goniva C, Hager A, Amberger S, Pirker S 2012 Prog. Comput. Fluid Dyn. 12 140

Google Scholar

Google Scholar

[28] Shäfer J, Dippel S, Wolf D E 1996 J. Phys. I 6 5

Google Scholar

Google Scholar

[29] 赵永志, 程易, 郑津洋 2009 计算力学学报 26 239

Zhao Y Z, Cheng Y, Zheng J Y 2009 Chin. J. Comput. Mech. 26 239

[30] Ng T T, Zhou W, Ma G, Chang X L 2014 J. Eng. Mech. 141 04014167

Google Scholar

Google Scholar

计量

- 文章访问数: 6682

- PDF下载量: 97

- 被引次数: 0

下载:

下载: