-

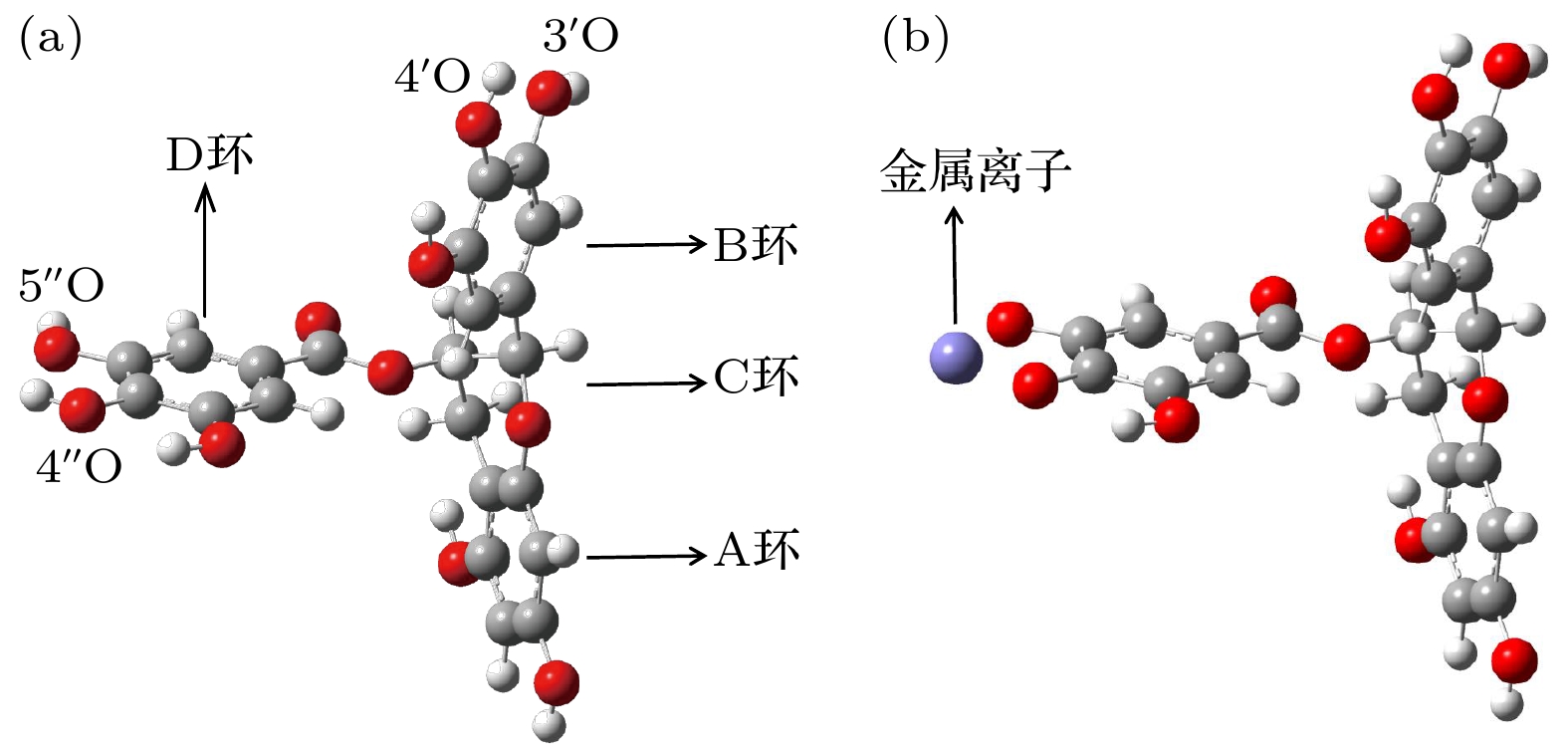

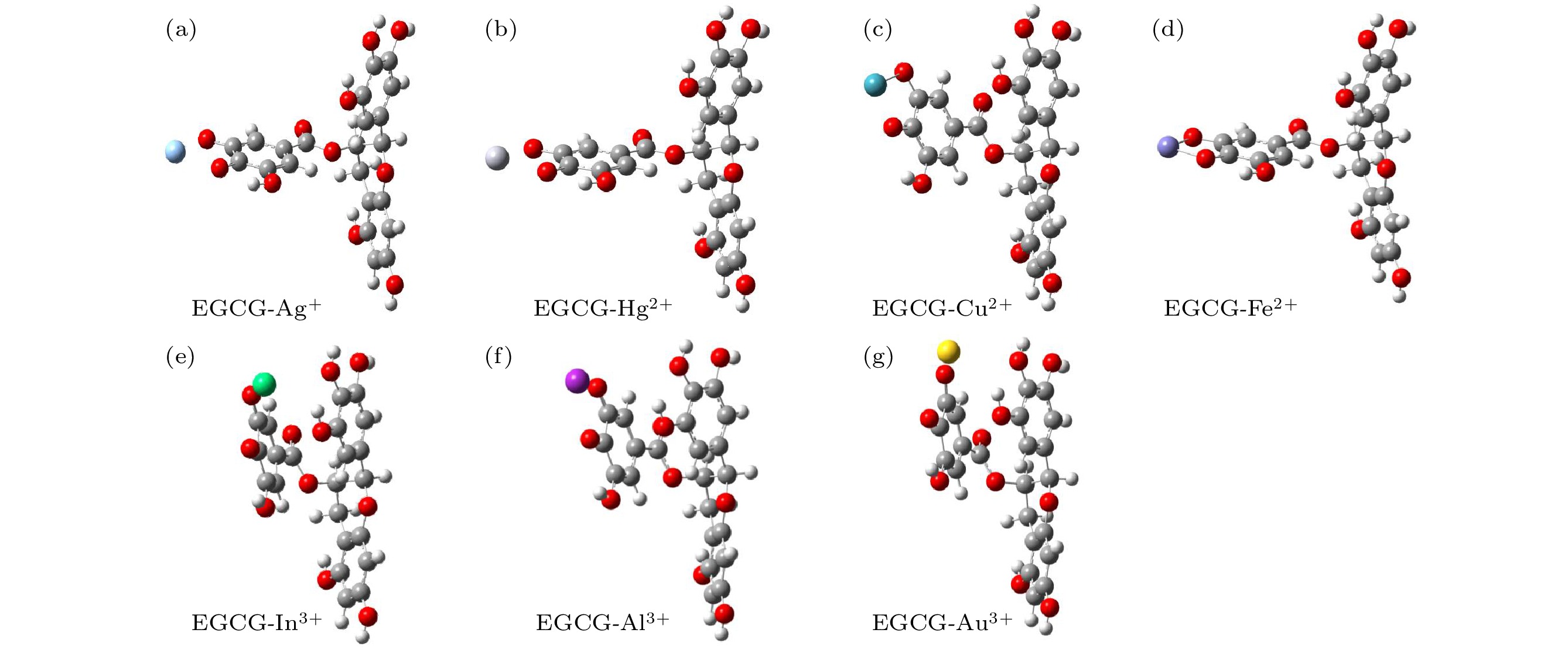

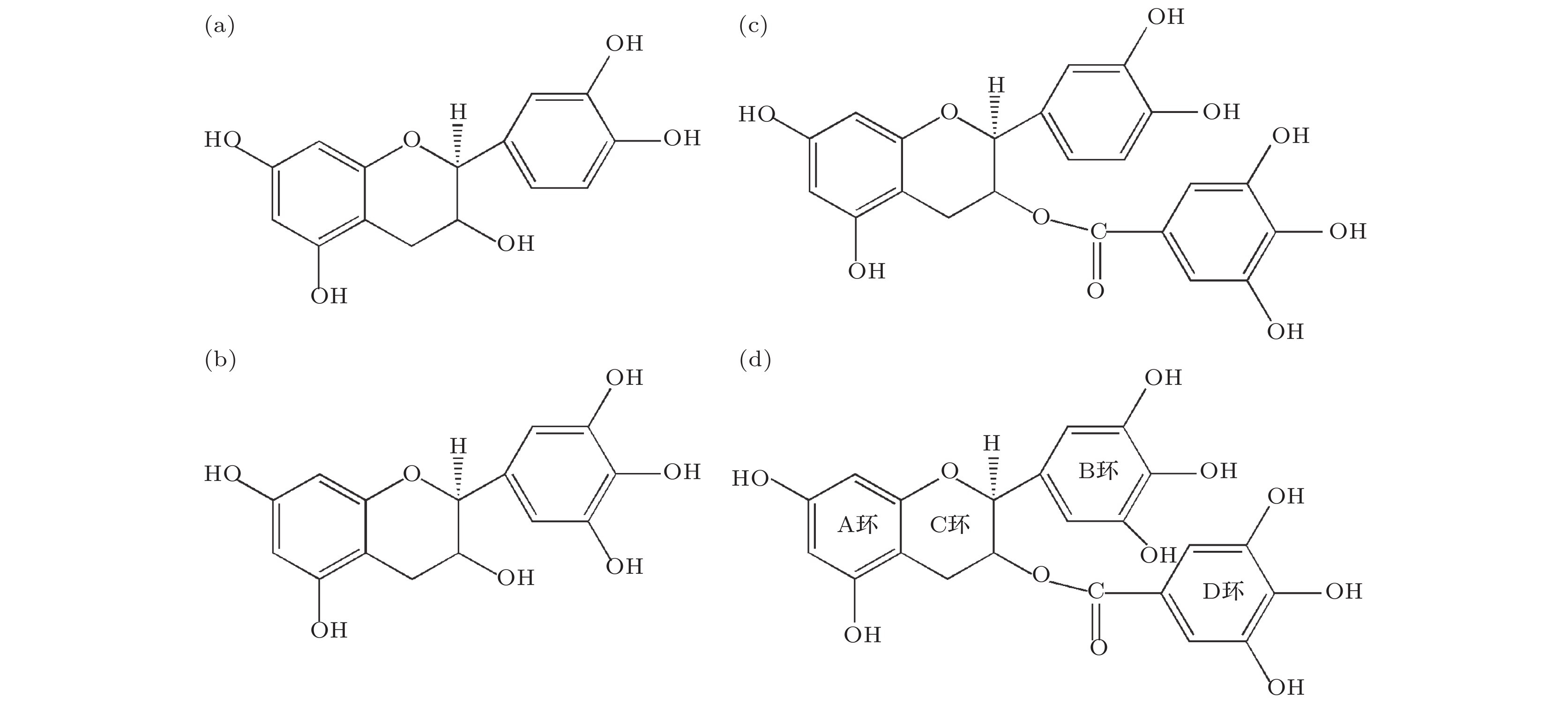

柿单宁具有优良的吸附重金属离子的效能, 表没食子儿茶素没食子酸酯(EGCG)是柿单宁发挥其活性作用的关键结构单体. 为分析柿单宁与金属离子相互作用的本质, 本文利用密度泛函理论(density functional thoery, DFT)的B3LYP方法, 从EGCG-金属复合物的构型、Mayer键级、自然布居分析、结合能、以及弱相互作用方面, 计算分析了EGCG与金属离子(Ag+, Hg2+, Cu2+, Fe2+, In3+, Al3+, Au3+)的相互作用关系. 研究结果表明, EGCG-Fe2+复合物主要以螯合键的形式吸附在一起; 而EGCG主要是通过静电吸引作用吸附Ag+和Hg2+离子; In3+, Al3+和Au3+离子与EGCG形成了独特的“腔状结构”金属复合物; Cu2+离子与EGCG的复合则同时存在着螯合作用、静电吸引作用和芳环堆积作用. 结合能计算显示, 金属离子所带电荷量越多, 越容易进行电荷转移, EGCG对其的静电吸引作用就越强. 这些计算分析可为探究柿单宁吸附金属离子的机理提供帮助.Persimmon tannin has excellent adsorption efficiency of heavy metal ions, and epigallocatechin gallate (EGCG) is the key structural monomer of persimmon tannin to play its active role. In order to analyze the nature of the interaction between persimmon tannin and metal ions, in this paper the density functional theory (DFT) is used to calculate and analyze the interactions between EGCG and metal ions (Ag+, Hg2+, Cu2+, Fe2+, In3+, Al3+, Au3+), from the respects of EGCG-metal complex configuration, Mayer bond order, natural population analysis, binding energy, and weak interaction. In this paper, the B3LYP combined with DFT-D3 dispersion correction method is mainly used. For metal atoms, the Lanl2dz basis set is adopted. For H, C and O atoms, the 6-311G (d, p) basis set is adopted for optimizing the structure, and the more accurate 6-311+G (d, p) basis set is selected for calculating the single point energy. At the same time, the study adds the SMD solvation model with water as the solvent. All calculations are done by using the Gaussian 09 package. The method of reduced density gradient function is used to study the weak interactions between EGCG and metal ions. The results of research show that EGCG-Fe2+ complex is adsorbed mainly by chelating bond. However, the EGCG adsorbs mainly Ag+, Hg2+ ions through electrostatic attraction. The configurations of the complexes show that In3+, Al3+ and Au3+ ions with EGCG form unique “luminal structure” metal complexes, so there is not only electrostatic attraction, but also aromatic ring stacking between these three metal ions and D ring 4"O, 5"O. The calculated Mayer bond order indicates that the bond order of the composite bond is formed by Fe2+ ion and the EGCG is the largest in the seven metal complexes, and the bond order is formed by In3+ ion, and EGCG is smallest. The compound of Cu2+ ion and EGCG have chelation, electrostatic attraction and aromatic ring stacking. By observing the binding energy, it can be found that the more charges the metal ions have, the easier the charge transfer will be and the stronger the electrostatic attraction of EGCG may be. These results will provide enlightenment for further studying the mechanism of persimmon tannin's adsorption of metal ions.

-

Keywords:

- persimmon tannin /

- metal ion /

- absorb /

- density functional theory

[1] Matheus J R V, Andrade C J D, Miyahira R F, Fai A E C 2020 Food Rev. Int.

Google Scholar

Google Scholar

[2] Elhabiri M, Carrer C, Marmolle F, Traboulsi H 2007 Inorg. Chim. Acta 360 353

Google Scholar

Google Scholar

[3] Chen Y M, Wang M K, Huang P M 2006 J. Agric. Food Chem. 54 212

Google Scholar

Google Scholar

[4] Li X J, Wang Z M, Liang H J, Ning J L, Li G Y, Zhou Z D 2017 Environ. Technol. 40 112

Google Scholar

Google Scholar

[5] Wang Z M, Gao M M, Li X J, Ning J L, Zhou Z D, Li G Y 2020 Mater. Sci. Eng., C 108 110196

Google Scholar

Google Scholar

[6] Nakajima A, Sakaguchi T 1993 J. Chem. Technol. Biotechnol. 57 321

Google Scholar

Google Scholar

[7] Gurung M, Adhikari B B, Kawakita H, Ohto K, Inoue K, Alam S 2012 Ind. Eng. Chem. Res. 51 11901

Google Scholar

Google Scholar

[8] Zhou Z D, Liu F L, Huang Y, Wang Z M, Li G Y 2015 Int. J. Biol. Macromol. 77 336

Google Scholar

Google Scholar

[9] Gurung M, Adhikari B B, Morisada S, Kawakita H, Ohto K, Inoue K, Alam S 2013 Bioresource Technol. 129 108

Google Scholar

Google Scholar

[10] Yi Q, Fan R, Xie F, Zhang Q, Luo Z 2016 J. Taiwan Inst. Chem. Eng. 61 299

Google Scholar

Google Scholar

[11] Li C M, Leverence R, Trombley J D, Xu S, Yang J, Tian Y, Reed J D 2010 J. Agric. Food Chem. 58 9033

Google Scholar

Google Scholar

[12] 江腾, 马万福, 谢楠, 周平 2011 物理化学学报 27 2291

Google Scholar

Google Scholar

Jiang T, Ma W F, Xie N, Zhou P 2011 Acta Phys-Chim. Sin. 27 2291

Google Scholar

Google Scholar

[13] 王晓巍, 蒋刚, 杜际广 2011 物理化学学报 27 309

Google Scholar

Google Scholar

Wang X W, Jiang G, Du J G 2011 Acta Phys.-Chim. Sin. 27 309

Google Scholar

Google Scholar

[14] Kohn W, Sham L J 1965 Phys. Rev. 140 A1133

Google Scholar

Google Scholar

[15] Becke A D 1993 J. Chem. Phys. 98 5648

Google Scholar

Google Scholar

[16] Malgorzata B, Pawel P, Giovanni S, Julien B, Vincenzo B 2010 J. Chem. Theory Comput. 6 2115

Google Scholar

Google Scholar

[17] Jonathon W, Matthew G, Jeffrey B N, Martin H 2015 J. Chem. Theory Comput. 11 1481

Google Scholar

Google Scholar

[18] Becke A D 1988 Phys. Rev. A 38 3098

Google Scholar

Google Scholar

[19] Lee C, Yang W, Parr R G 1988 Phys. Rev. B 37 785

Google Scholar

Google Scholar

[20] Bougherara H, Kadri R, Kadri M, Yekhlef M, Boumaza A 2021 J. Mol. Struct. 1223 128855

Google Scholar

Google Scholar

[21] Viji A, Revathi B, Balachandran V, Babiyana S, Narayana B, Salian V V 2020 Chem.l Data Collections 30 100585

Google Scholar

Google Scholar

[22] Goerigk L, Grimme S 2011 Phys. Chem. Chem. Phys. 13 6670

Google Scholar

Google Scholar

[23] Frisch M J, Trucks G W, Schlegel H B, et al. 2009 Gaussian 09 (Rev. A.02). (Gaussian: Inc., Wallingford CT)

[24] Johnson E R, Kernan S, Mori-Sanchez P, Contreras-Garcia J, Cohen A J, Yang W T 2010 J. Am. Chem. Soc. 132 6498

Google Scholar

Google Scholar

[25] 施斌, 袁荔, 唐天宇, 陆利敏, 赵先豪, 魏晓楠, 唐延林 2021 70 053102

Google Scholar

Google Scholar

Shi B, Yuan L, Tang T Y, Lu L M, Zhao X H, W X N, Tang Y L 2021 Acta Phys. Sin. 70 053102

Google Scholar

Google Scholar

[26] Navarro R E, Santacruz H, Inoue M 2005 J. Inorg. Biochem. 99 584

Google Scholar

Google Scholar

[27] Inoue M B, Inoue M, Fernando Q, Valcic S, Timmermann B N 2002 J. Inorg. Biochem. 88 7

Google Scholar

Google Scholar

[28] Esparza I, Salinas I, Santamaria C, Garcia-Mina J M, Fernandez J M 2005 Anal. Chim. Acta 543 267

Google Scholar

Google Scholar

[29] Lu T, Chen F W 2013 J. Phys. Chem. A. 117 3100

Google Scholar

Google Scholar

[30] 卢天, 陈飞武 2012 物理化学学报 28 1

Google Scholar

Google Scholar

Lu T, Chen F W 2012 Acta Phys.-Chim. Sin. 28 1

Google Scholar

Google Scholar

[31] Lu T, Chen F W 2012 J. Comput. Chem. 33 580

Google Scholar

Google Scholar

[32] Humphrey W, Dalke A, Schulten K 1996 J. Mol. Graphics. 14 33

Google Scholar

Google Scholar

-

表 1 EGCG-金属复合物的复合键键长

Table 1. Composite bond lengths of the EGCG-metal complexes.

EGCG-金属复合物 复合键 键长/Å ECGC-Ag+ 4"O—Ag 2.363 5"O—Ag 2.302 EGCG-Hg2+ 4"O—Hg 2.366 5"O—Hg 2.333 EGCG-Cu2+ 4"O—Cu 1.941 5"O—Cu 1.916 EGCG-Fe2+ 4"O—Fe 1.926 5"O—Fe 1.893 EGCG-In3+ 4"O—In 2.929 5"O—In 2.683 EGCG-Al3+ 4"O—Al 2.418 5"O—Al 2.008 EGCG-Au3+ 4"O—Au 2.979 5"O—Au 2.194 表 2 EGCG-金属复合物中复合键的Mayer键级

Table 2. The Mayer bond orders of composite bond in the EGCG-metal complexes.

EGCG-金属复合物 复合键 Mayer键级 ECGC-Ag+ 4"O—Ag 0.3462 5"O—Ag 0.4304 EGCG-Hg2+ 4"O—Hg 0.3870 5"O—Hg 0.4697 EGCG-Cu2+ 4"O—Cu 0.5089 5"O—Cu 0.5458 EGCG-Fe2+ 4"O—Fe 0.5940 5"O—Fe 0.7480 EGCG-In3+ 4"O—In 0.0742 5"O—In 0.1183 EGCG-Al3+ 4"O—Al 0.1635 5"O—Al 0.3022 EGCG-Au3+ 4"O—Au 0.1058 5"O—Au 0.4331 表 3 EGCG-金属复合物中复合原子的自然布居分析

Table 3. Natural population analysis of composite atoms in the EGCG-metal complexes.

EGCG-金属复合物 复合原子 自然电荷分布 ECGC-Ag+ Ag 0.7803 4"O –0.8837 5"O –0.9144 EGCG-Hg2+ Hg 1.7086 4"O –0.8860 5"O –0.9045 EGCG-Cu2+ Cu 1.4836 4"O –0.8479 5"O –0.8421 EGCG-Fe2+ Fe 1.4342 4"O –0.8121 5"O –0.8417 EGCG-In3+ In 1.0761 4"O –0.5587 5"O –0.6041 EGCG-Al3+ Al 0.8686 4"O –0.5978 5"O –0.7942 EGCG-Au3+ Au 0.8679 4"O –0.5229 5"O –0.6244 -

[1] Matheus J R V, Andrade C J D, Miyahira R F, Fai A E C 2020 Food Rev. Int.

Google Scholar

Google Scholar

[2] Elhabiri M, Carrer C, Marmolle F, Traboulsi H 2007 Inorg. Chim. Acta 360 353

Google Scholar

Google Scholar

[3] Chen Y M, Wang M K, Huang P M 2006 J. Agric. Food Chem. 54 212

Google Scholar

Google Scholar

[4] Li X J, Wang Z M, Liang H J, Ning J L, Li G Y, Zhou Z D 2017 Environ. Technol. 40 112

Google Scholar

Google Scholar

[5] Wang Z M, Gao M M, Li X J, Ning J L, Zhou Z D, Li G Y 2020 Mater. Sci. Eng., C 108 110196

Google Scholar

Google Scholar

[6] Nakajima A, Sakaguchi T 1993 J. Chem. Technol. Biotechnol. 57 321

Google Scholar

Google Scholar

[7] Gurung M, Adhikari B B, Kawakita H, Ohto K, Inoue K, Alam S 2012 Ind. Eng. Chem. Res. 51 11901

Google Scholar

Google Scholar

[8] Zhou Z D, Liu F L, Huang Y, Wang Z M, Li G Y 2015 Int. J. Biol. Macromol. 77 336

Google Scholar

Google Scholar

[9] Gurung M, Adhikari B B, Morisada S, Kawakita H, Ohto K, Inoue K, Alam S 2013 Bioresource Technol. 129 108

Google Scholar

Google Scholar

[10] Yi Q, Fan R, Xie F, Zhang Q, Luo Z 2016 J. Taiwan Inst. Chem. Eng. 61 299

Google Scholar

Google Scholar

[11] Li C M, Leverence R, Trombley J D, Xu S, Yang J, Tian Y, Reed J D 2010 J. Agric. Food Chem. 58 9033

Google Scholar

Google Scholar

[12] 江腾, 马万福, 谢楠, 周平 2011 物理化学学报 27 2291

Google Scholar

Google Scholar

Jiang T, Ma W F, Xie N, Zhou P 2011 Acta Phys-Chim. Sin. 27 2291

Google Scholar

Google Scholar

[13] 王晓巍, 蒋刚, 杜际广 2011 物理化学学报 27 309

Google Scholar

Google Scholar

Wang X W, Jiang G, Du J G 2011 Acta Phys.-Chim. Sin. 27 309

Google Scholar

Google Scholar

[14] Kohn W, Sham L J 1965 Phys. Rev. 140 A1133

Google Scholar

Google Scholar

[15] Becke A D 1993 J. Chem. Phys. 98 5648

Google Scholar

Google Scholar

[16] Malgorzata B, Pawel P, Giovanni S, Julien B, Vincenzo B 2010 J. Chem. Theory Comput. 6 2115

Google Scholar

Google Scholar

[17] Jonathon W, Matthew G, Jeffrey B N, Martin H 2015 J. Chem. Theory Comput. 11 1481

Google Scholar

Google Scholar

[18] Becke A D 1988 Phys. Rev. A 38 3098

Google Scholar

Google Scholar

[19] Lee C, Yang W, Parr R G 1988 Phys. Rev. B 37 785

Google Scholar

Google Scholar

[20] Bougherara H, Kadri R, Kadri M, Yekhlef M, Boumaza A 2021 J. Mol. Struct. 1223 128855

Google Scholar

Google Scholar

[21] Viji A, Revathi B, Balachandran V, Babiyana S, Narayana B, Salian V V 2020 Chem.l Data Collections 30 100585

Google Scholar

Google Scholar

[22] Goerigk L, Grimme S 2011 Phys. Chem. Chem. Phys. 13 6670

Google Scholar

Google Scholar

[23] Frisch M J, Trucks G W, Schlegel H B, et al. 2009 Gaussian 09 (Rev. A.02). (Gaussian: Inc., Wallingford CT)

[24] Johnson E R, Kernan S, Mori-Sanchez P, Contreras-Garcia J, Cohen A J, Yang W T 2010 J. Am. Chem. Soc. 132 6498

Google Scholar

Google Scholar

[25] 施斌, 袁荔, 唐天宇, 陆利敏, 赵先豪, 魏晓楠, 唐延林 2021 70 053102

Google Scholar

Google Scholar

Shi B, Yuan L, Tang T Y, Lu L M, Zhao X H, W X N, Tang Y L 2021 Acta Phys. Sin. 70 053102

Google Scholar

Google Scholar

[26] Navarro R E, Santacruz H, Inoue M 2005 J. Inorg. Biochem. 99 584

Google Scholar

Google Scholar

[27] Inoue M B, Inoue M, Fernando Q, Valcic S, Timmermann B N 2002 J. Inorg. Biochem. 88 7

Google Scholar

Google Scholar

[28] Esparza I, Salinas I, Santamaria C, Garcia-Mina J M, Fernandez J M 2005 Anal. Chim. Acta 543 267

Google Scholar

Google Scholar

[29] Lu T, Chen F W 2013 J. Phys. Chem. A. 117 3100

Google Scholar

Google Scholar

[30] 卢天, 陈飞武 2012 物理化学学报 28 1

Google Scholar

Google Scholar

Lu T, Chen F W 2012 Acta Phys.-Chim. Sin. 28 1

Google Scholar

Google Scholar

[31] Lu T, Chen F W 2012 J. Comput. Chem. 33 580

Google Scholar

Google Scholar

[32] Humphrey W, Dalke A, Schulten K 1996 J. Mol. Graphics. 14 33

Google Scholar

Google Scholar

计量

- 文章访问数: 9750

- PDF下载量: 140

- 被引次数: 0

下载:

下载: