-

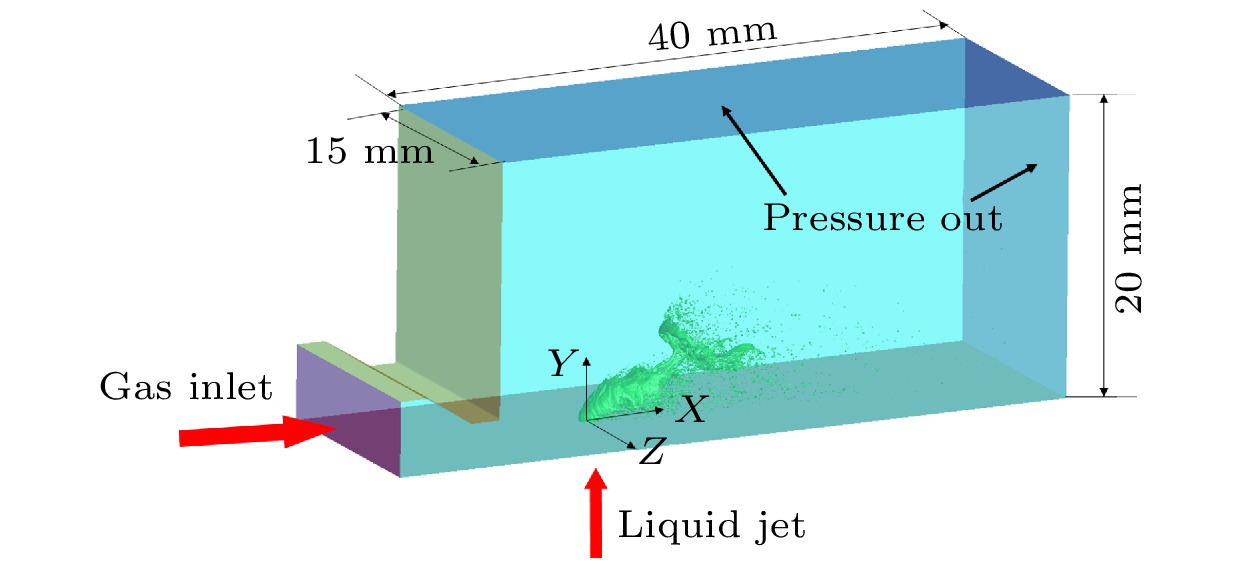

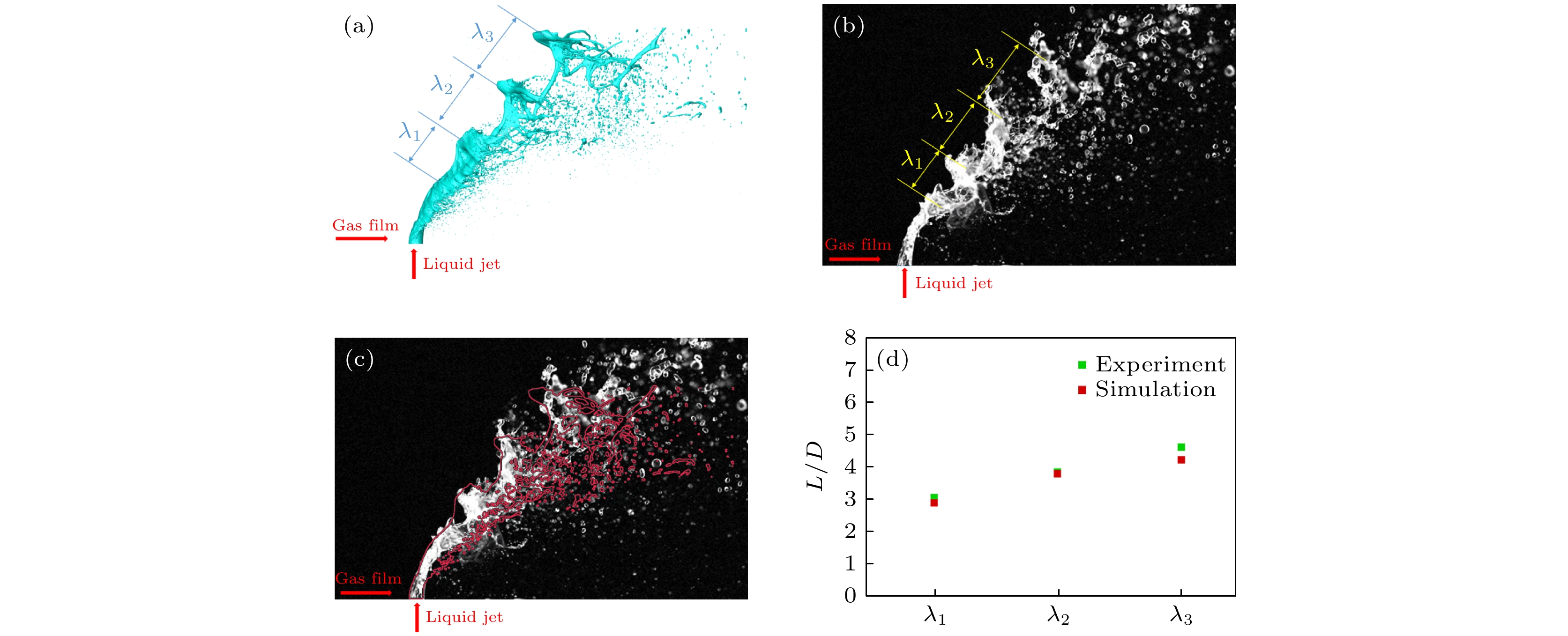

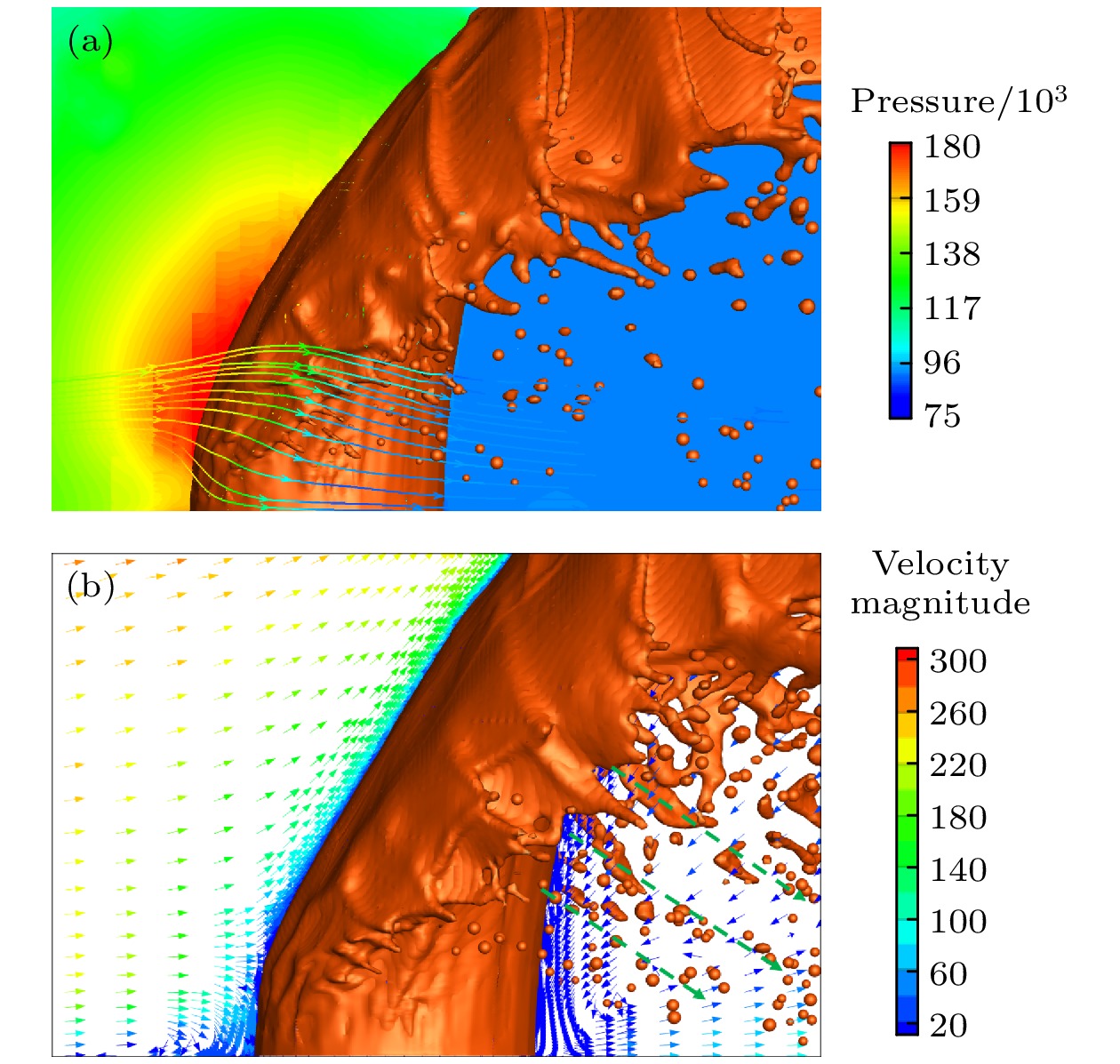

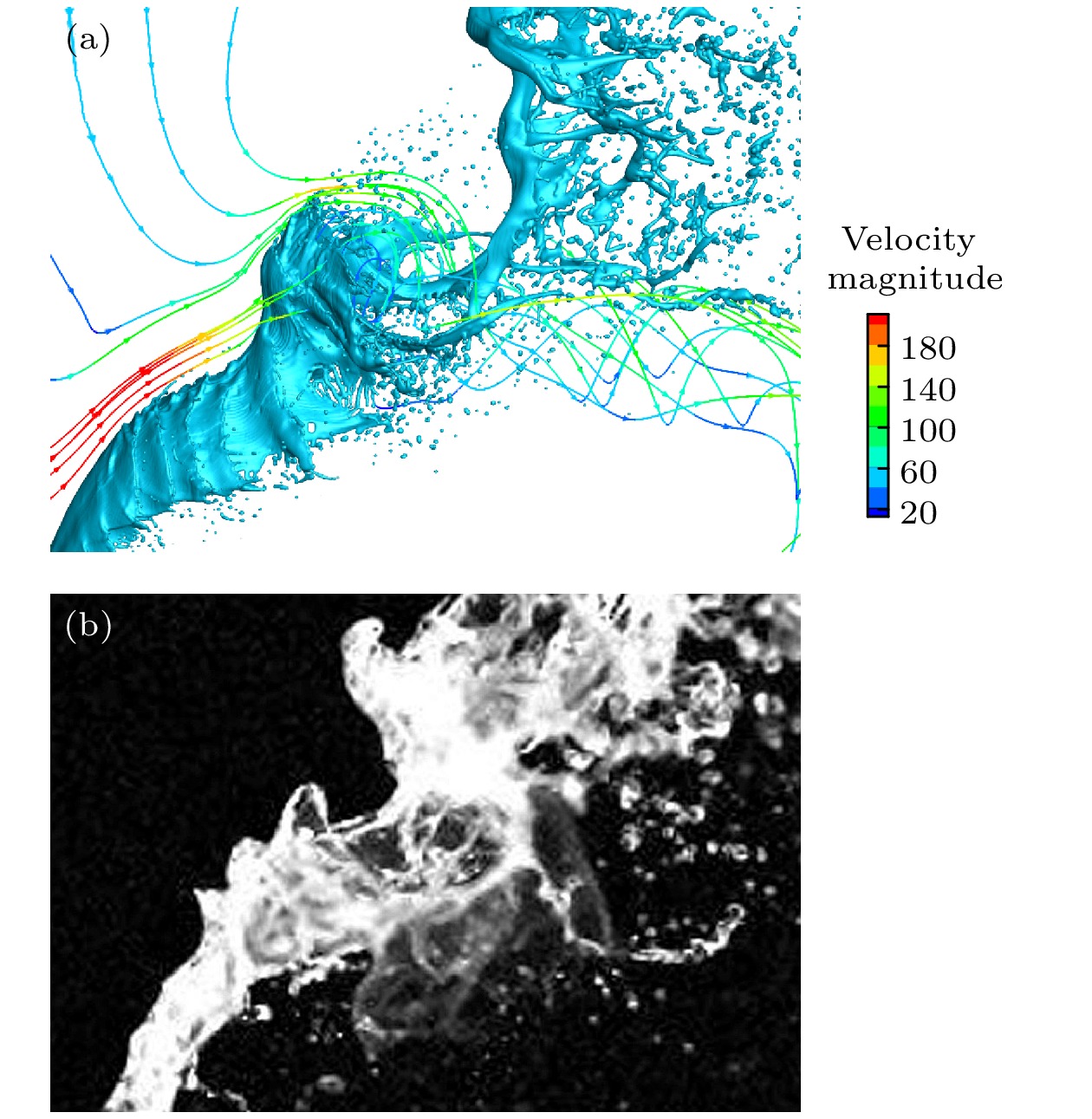

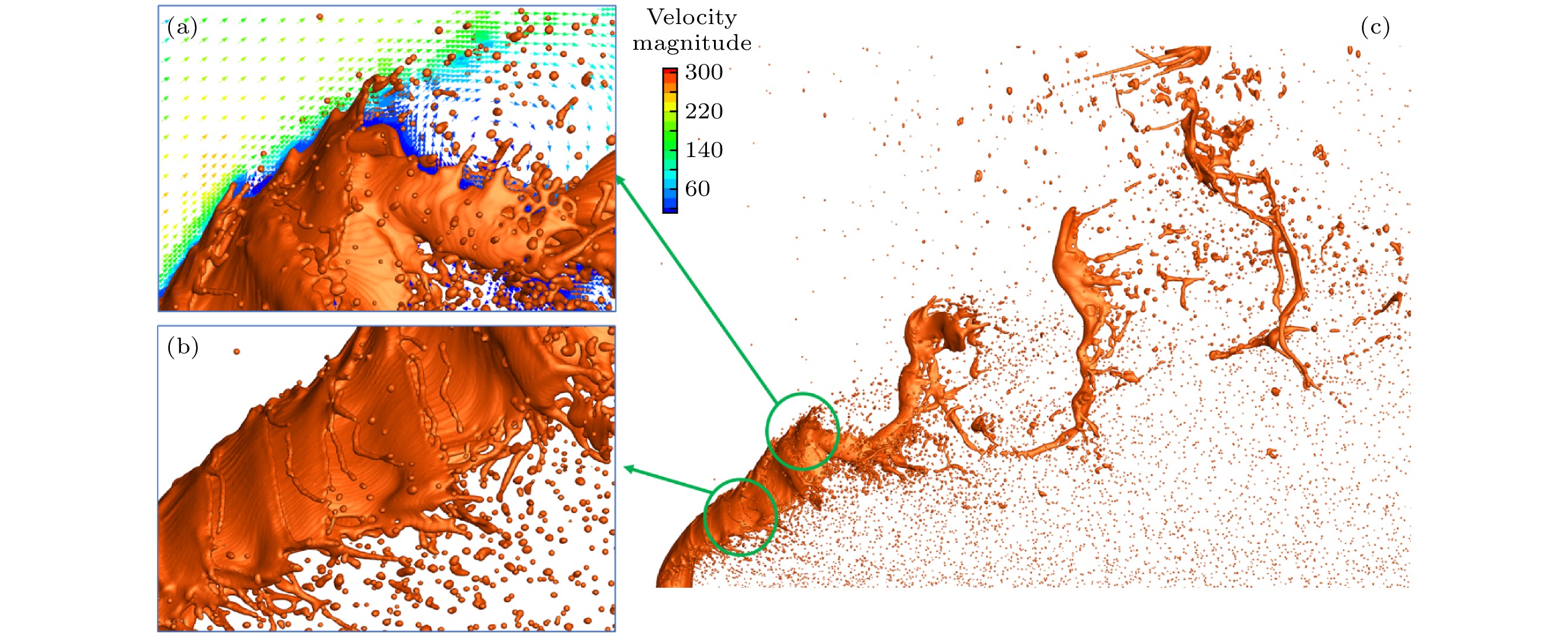

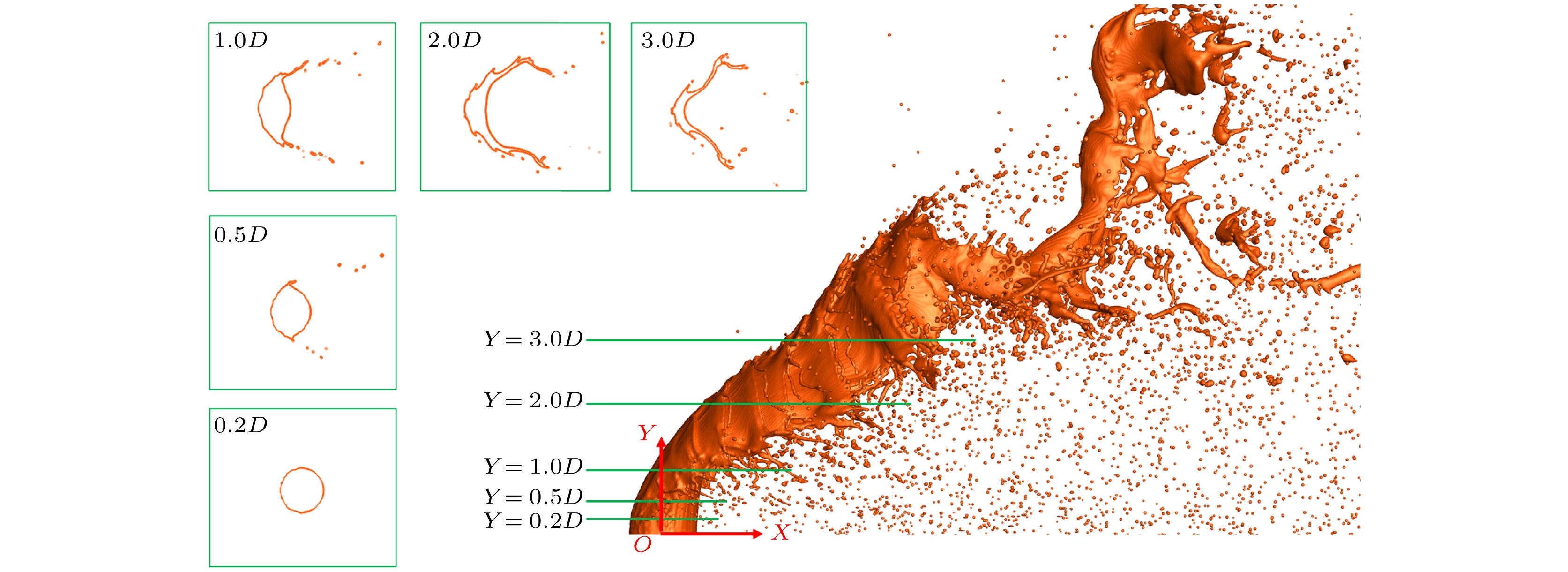

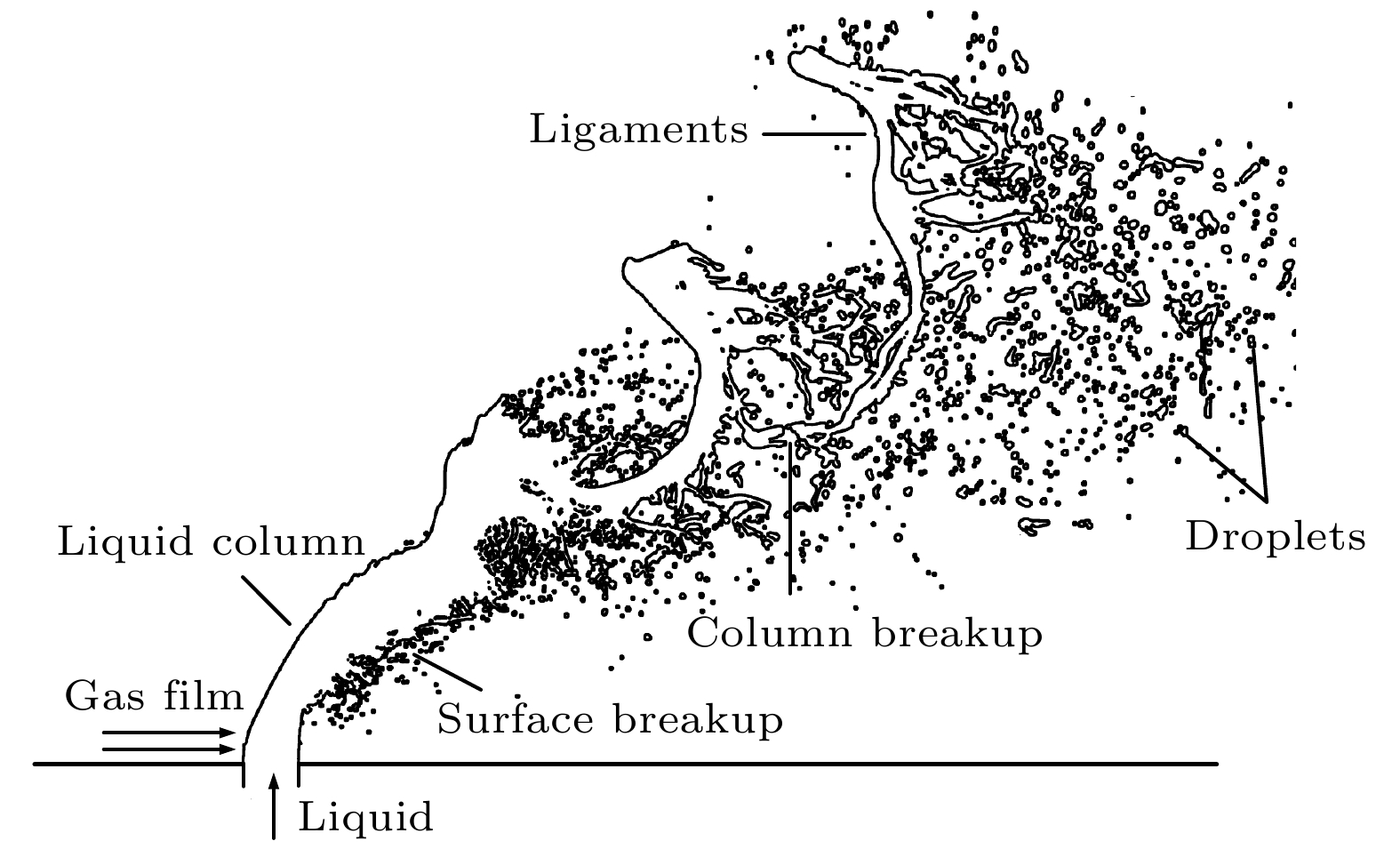

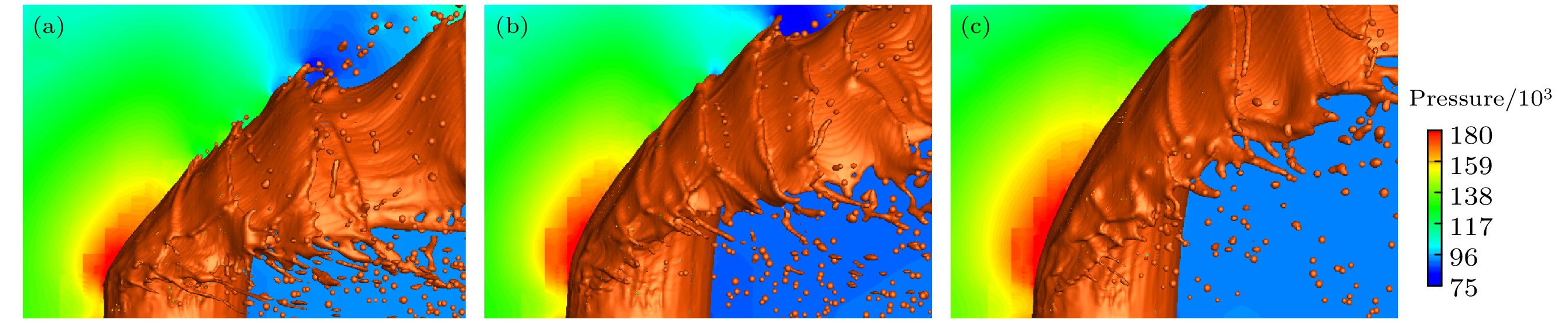

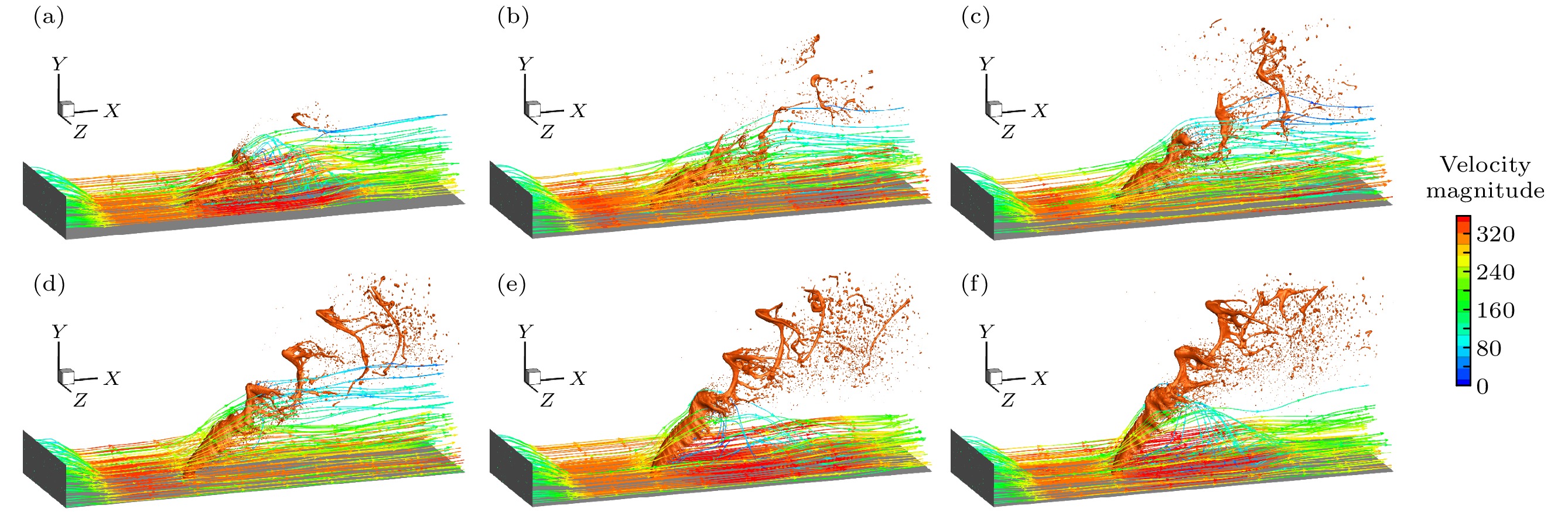

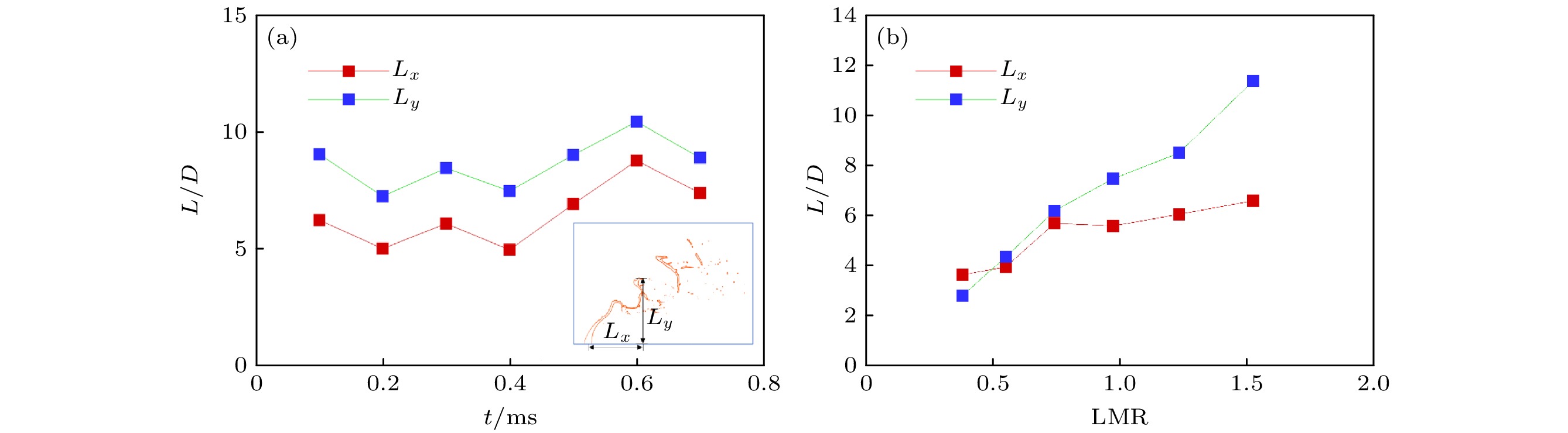

为了研究液体横向射流在气膜作用下的破碎过程, 采用背景光成像技术及VOF TO DPM方法进行了实验研究和仿真研究, 模拟介质为水和空气. 研究结果表明, 液体射流在气膜作用下主要存在两种破碎过程: 柱状破碎和表面破碎. Rayleigh-Taylor (R-T)不稳定性产生的表面波是液体射流发生柱状破碎的主要原因, 气流穿透表面波的波谷导致射流柱破碎, 破碎后的液丝沿流向逐渐发展呈带状分布. Kelvin-Helmholtz (K-H)不稳定性产生的表面波是液体射流发生表面破碎的主要原因, 液丝和液滴从射流表面剥离. 局部动量比对液体横向射流的破碎过程具有重要影响, 当局部动量比较低时, 液体射流的破碎由K-H不稳定性主导; 随着局部动量比的增大液体射流的破碎逐渐由R-T不稳定性主导. 液体射流的破碎长度及穿透深度均随局部动量比的增大而增大.In order to study the breakup process of liquid jet in gas film, the backlit photography technique and the VOF TO DPM method are used for experimental and simulation research respectively. Water and air are used as simulant media. Grid adaptive technology is used to refine the gas-liquid interface grid and improve the capture accuracy of the gas-liquid interface. The results show that there are two main breakup processes of liquid jet in gas film: column breakup and surface breakup. The local high-pressure zone in front of the liquid jet makes the jet have a large normal velocity gradient, which causes R-T instability. The surface wave that is generated by the R-T instability is mainly responsible for the liquid column breakup. When the thin liquid film reaches a column breakup point, the airflow penetrating the trough of the surface wave causes the jet column to break. The tangential velocity gradient is generated when the gas film bypasses the liquid jet surface, which causes K-H instability. The K-H surface waves cause ligaments and droplets to strip from the surface of the liquid jet. The local momentum ratio has an important influence on the breakup process of the liquid jet in gas film. When the local momentum ratio is low, the breakup of liquid jet is dominated by the K-H instability. As the local momentum ratio increases, the breakup of liquid jet is gradually dominated by R-T instability. The local momentum ratio plays an important role in the distribution range of the liquid jet in gas film. When the local momentum ratio is low, the ligaments and droplets caused by the liquid jet are mainly distributed within the range of gas film. As the local momentum ratio increases, part of the ligaments and droplets escape from the range of the gas film. The liquid jet penetrates the gas film when the local momentum ratio is greater than 0.74. The breakup length and the penetration depth are both affected by the local momentum ratio. The breakup length increases with the local momentum ratio increasing. The penetration depth also increases with the local momentum ratio, and the penetration depth increases significantly when the liquid jet penetrates the gas film.

-

Keywords:

- liquid jet /

- breakup process /

- surface wave /

- gas film

[1] 岳春国, 李进贤, 侯晓, 冯喜平, 杨姝君 2009 中国科学: 技术科学 39 464

Google Scholar

Google Scholar

Yue C G, Li J X, Hou X, Feng X P, Yang S J 2009 Sci. Sin.: Tech. 39 464

Google Scholar

Google Scholar

[2] 张雪松 2017 卫星与网络 6 40

Google Scholar

Google Scholar

Zhang X S 2017 Satell. Network 6 40

Google Scholar

Google Scholar

[3] Heister S D 2011 Handbook of Atomization and Sprays: Theory and Applications (New York: Springer Science Business Media) pp647−655

[4] Son M, Radhakrishnan K, Yoon Y, Koo J 2017 Acta Astronaut. 135 139

Google Scholar

Google Scholar

[5] Dressler G A, Bauer J M 2000 36th AIAA/ASME/SAE/ ASEE Joint Propulsion Conference and Exhibit Huntsville, Alabama, July 16–19, 2000 p2000

[6] Ninish S, Vaidyanathan A, Nandakumar K 2018 Exp. Therm. Fluid Sci. 97 324

Google Scholar

Google Scholar

[7] 方昕昕, 沈赤兵, 张新桥 2016 航空动力学报 31 3004

Google Scholar

Google Scholar

Fang X X, Shen C B, Zhang X Q 2016 J. Aerosp. Power 31 3004

Google Scholar

Google Scholar

[8] 方昕昕, 沈赤兵 2017 航空动力学报 32 2291

Google Scholar

Google Scholar

Fang X X, Shen C B 2017 J. Aerosp. Power 32 2291

Google Scholar

Google Scholar

[9] Son M, Yu K, Radhakrishnan K, Shin B, Koo J 2016 J. Therm. Sci. 25 90

Google Scholar

Google Scholar

[10] 刘昌波 2014 博士学位论文(西安: 西安航天动力研究所)

Liu C B 2014 Ph. D. Dissertation (Xi’an: Xi’an Aerospace Propulsion Institute) (in Chinese)

[11] Yates C L 1971 Proceedings of the 7 th Propulsion Joint Specialist Conference Salt Lake City, June 14–18, 1971 p724

[12] Kush E A, Schetz J A 1973 AIAA J. 11 1223

Google Scholar

Google Scholar

[13] Schetz J A, Kush E A, Joshi P B 1980 AIAA J. 18 774

Google Scholar

Google Scholar

[14] 陈亮, 乐嘉陵, 宋文艳, 杨顺华, 曹娜 2011 实验流体力学 25 29

Google Scholar

Google Scholar

Cheng L, Le J L, Song W Y, Yang S H, Cao N 2011 J. Exp. Fluid Mech. 25 29

Google Scholar

Google Scholar

[15] 曹娜, 徐青, 曹亮, 雷岚, 韩长材, 马继明, 杜继业 2013 现代应用物理 4 323

Google Scholar

Google Scholar

Cao N, Xu Q, Cao L, Lei L, Han C C, Ma J M, Du J Y 2013 Mod. Appl. Phys. 4 323

Google Scholar

Google Scholar

[16] Yang S H, Le J L 2006 Proceedings of the 12th Chinese National Symposium on Shock’Waves Luoyang, July 24, 2006 p70

[17] 徐胜利, Archer R D, Milton B E, 岳朋涛 2000 中国科学:技术科学 30 179

Google Scholar

Google Scholar

Xu S L, Archer R D, Milton B E, Yue P T 2000 Sci. Sin.: Tech. 30 179

Google Scholar

Google Scholar

[18] 刘楠 2019 博士学位论文 (长沙: 国防科技大学)

Liu N 2019 Ph. D. Dissertation (Changsha: National University of Defense Technology) (in Chinese)

[19] Xiao F, Wang Z G, Sun M B, Liang J H, Liu N 2016 Int. J. Multiph. Flow 87 229

Google Scholar

Google Scholar

[20] Xiao F, Sun M B 2019 Atom. Sprays 28 975

Google Scholar

Google Scholar

[21] 李春, 沈赤兵, 李清廉, 朱元昊 2019 国防科技大学学报 41 73

Google Scholar

Google Scholar

Li C, Shen C B, Li Q L, Zhu Y H 2019 J. Natl. Univ. Def. Technol. 41 73

Google Scholar

Google Scholar

[22] Cheng P, Li Q L, Chen H Y 2019 Acta Astronaut. 154 61

Google Scholar

Google Scholar

[23] Chen H Y, Li Q L, Cheng P 2019 Acta Astronaut. 162 424

Google Scholar

Google Scholar

[24] 吴里银, 王振国, 李清廉, 李春 2016 65 094701

Google Scholar

Google Scholar

Wu L Y, Wang Z G, Li Q L, Li C 2016 Acta Phys. Sin. 65 094701

Google Scholar

Google Scholar

[25] Wu L Y, Wang Z G, Li Q L, Li C 2016 J. Vis. 19 337

Google Scholar

Google Scholar

[26] Lin K C, Kirkendall K A, Kennedy P J, Jackson T A 1999 Proceedings of the 35th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit Los Angeles, California, June 20–24, 1999 p2374

[27] Sallam K A, Aalburg C, Faeth G M, Lin K C, Carter C D, Jackson T A 2004 Proceedings of the 42nd AIAA Aerospace Sciences Meeting and Exhibit Reno, Nevada, January 5–8, 2004 p970

[28] Sallam K A, Aalburg C, Faeth G M 2004 AIAA J. 42 2529

Google Scholar

Google Scholar

[29] Richards J R, Lenhoff A M, Beris A N 1994 Phys. Fluids 6 2640

Google Scholar

Google Scholar

[30] Srinivasan V, Salazar A J, Saito K 2011 Appl. Math. Model. 35 3710

Google Scholar

Google Scholar

[31] Herrmann M 2011 Proc. Combust. Inst. 33 2079

Google Scholar

Google Scholar

[32] Desjardins O, Pitsch H 2009 J. Comput. Phys. 228 1658

Google Scholar

Google Scholar

[33] 高亚军, 姜汉桥, 李俊键, 赵玉云, 胡锦川, 常元昊 2017 66 024702

Google Scholar

Google Scholar

Gao Y J, Jiang H Q, Li J J, Zhao Y Y, Hu J C, Chang Y H 2017 Acta Phys. Sin. 66 024702

Google Scholar

Google Scholar

[34] Xiao F, Wang Z G, Sun M B, Liu N, Yang X 2017 Proc. Combust. Inst. 36 2417

Google Scholar

Google Scholar

[35] 梁刚涛, 郭亚丽, 沈胜强 2013 62 024705

Google Scholar

Google Scholar

Liang G T, Guo Y L, Shen S Q 2013 Acta Phys. Sin. 62 024705

Google Scholar

Google Scholar

[36] Li X Y, Soteriou M C, Arienti M, Sussman M M 2011 Proceedings of the 49th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition Orlando, Florida, January 4–7, 2011 p99

[37] Fontes D H, Vilela V, Souza Meira L D, Souza F J 2019 Int. J. Multiph. Flow 114 98

Google Scholar

Google Scholar

[38] Chu W, Li X Q, Tong Y H, Reng Y J 2020 Acta Astronaut. 175 204

Google Scholar

Google Scholar

[39] Liu N, Wang Z G, Sun M B, Deiterding R, Wang H B 2019 Aerosp. Sci. Technol. 91 456

Google Scholar

Google Scholar

[40] Li P B, Wang Z G, Sun M B, Wang H B 2017 Acta Astronaut. 134 333

Google Scholar

Google Scholar

[41] 李佩波, 王振国, 孙明波, 汪洪波 2016 宇航学报 37 209

Google Scholar

Google Scholar

Li P B, Wang Z G, Sun M B, Wang H B 2016 J. Astronaut. 37 209

Google Scholar

Google Scholar

[42] 成鹏 2018 博士学位论文 (长沙: 国防科技大学)

Cheng P 2018 Ph. D. Dissertation (Changsha: National University of Defense Technology) (in Chinese)

[43] Wu P K, Kirkendall K A, Fuller R P, Nejad A S 1997 J. Propul. Power 13 64

Google Scholar

Google Scholar

-

表 1 气膜工况参数

Table 1. Parameters of gas film.

总压/

MPa静压/

MPa质量流量/

(kg·s–1)速度/

(m·s–1)温

度/K膜厚/

mm0.2 0.1 0.02 315.4 300 3 表 2 液体射流工况参数

Table 2. Parameters of liquid jets.

密度/

(kg·m3)速度/

(m·s–1)孔径/

mm局部动量

比LMR998.2 12.5, 15.0, 17.5,

20.0, 22.5, 25.01.3 0.38, 0.55, 0.74,

0.97, 1.23, 1.52 -

[1] 岳春国, 李进贤, 侯晓, 冯喜平, 杨姝君 2009 中国科学: 技术科学 39 464

Google Scholar

Google Scholar

Yue C G, Li J X, Hou X, Feng X P, Yang S J 2009 Sci. Sin.: Tech. 39 464

Google Scholar

Google Scholar

[2] 张雪松 2017 卫星与网络 6 40

Google Scholar

Google Scholar

Zhang X S 2017 Satell. Network 6 40

Google Scholar

Google Scholar

[3] Heister S D 2011 Handbook of Atomization and Sprays: Theory and Applications (New York: Springer Science Business Media) pp647−655

[4] Son M, Radhakrishnan K, Yoon Y, Koo J 2017 Acta Astronaut. 135 139

Google Scholar

Google Scholar

[5] Dressler G A, Bauer J M 2000 36th AIAA/ASME/SAE/ ASEE Joint Propulsion Conference and Exhibit Huntsville, Alabama, July 16–19, 2000 p2000

[6] Ninish S, Vaidyanathan A, Nandakumar K 2018 Exp. Therm. Fluid Sci. 97 324

Google Scholar

Google Scholar

[7] 方昕昕, 沈赤兵, 张新桥 2016 航空动力学报 31 3004

Google Scholar

Google Scholar

Fang X X, Shen C B, Zhang X Q 2016 J. Aerosp. Power 31 3004

Google Scholar

Google Scholar

[8] 方昕昕, 沈赤兵 2017 航空动力学报 32 2291

Google Scholar

Google Scholar

Fang X X, Shen C B 2017 J. Aerosp. Power 32 2291

Google Scholar

Google Scholar

[9] Son M, Yu K, Radhakrishnan K, Shin B, Koo J 2016 J. Therm. Sci. 25 90

Google Scholar

Google Scholar

[10] 刘昌波 2014 博士学位论文(西安: 西安航天动力研究所)

Liu C B 2014 Ph. D. Dissertation (Xi’an: Xi’an Aerospace Propulsion Institute) (in Chinese)

[11] Yates C L 1971 Proceedings of the 7 th Propulsion Joint Specialist Conference Salt Lake City, June 14–18, 1971 p724

[12] Kush E A, Schetz J A 1973 AIAA J. 11 1223

Google Scholar

Google Scholar

[13] Schetz J A, Kush E A, Joshi P B 1980 AIAA J. 18 774

Google Scholar

Google Scholar

[14] 陈亮, 乐嘉陵, 宋文艳, 杨顺华, 曹娜 2011 实验流体力学 25 29

Google Scholar

Google Scholar

Cheng L, Le J L, Song W Y, Yang S H, Cao N 2011 J. Exp. Fluid Mech. 25 29

Google Scholar

Google Scholar

[15] 曹娜, 徐青, 曹亮, 雷岚, 韩长材, 马继明, 杜继业 2013 现代应用物理 4 323

Google Scholar

Google Scholar

Cao N, Xu Q, Cao L, Lei L, Han C C, Ma J M, Du J Y 2013 Mod. Appl. Phys. 4 323

Google Scholar

Google Scholar

[16] Yang S H, Le J L 2006 Proceedings of the 12th Chinese National Symposium on Shock’Waves Luoyang, July 24, 2006 p70

[17] 徐胜利, Archer R D, Milton B E, 岳朋涛 2000 中国科学:技术科学 30 179

Google Scholar

Google Scholar

Xu S L, Archer R D, Milton B E, Yue P T 2000 Sci. Sin.: Tech. 30 179

Google Scholar

Google Scholar

[18] 刘楠 2019 博士学位论文 (长沙: 国防科技大学)

Liu N 2019 Ph. D. Dissertation (Changsha: National University of Defense Technology) (in Chinese)

[19] Xiao F, Wang Z G, Sun M B, Liang J H, Liu N 2016 Int. J. Multiph. Flow 87 229

Google Scholar

Google Scholar

[20] Xiao F, Sun M B 2019 Atom. Sprays 28 975

Google Scholar

Google Scholar

[21] 李春, 沈赤兵, 李清廉, 朱元昊 2019 国防科技大学学报 41 73

Google Scholar

Google Scholar

Li C, Shen C B, Li Q L, Zhu Y H 2019 J. Natl. Univ. Def. Technol. 41 73

Google Scholar

Google Scholar

[22] Cheng P, Li Q L, Chen H Y 2019 Acta Astronaut. 154 61

Google Scholar

Google Scholar

[23] Chen H Y, Li Q L, Cheng P 2019 Acta Astronaut. 162 424

Google Scholar

Google Scholar

[24] 吴里银, 王振国, 李清廉, 李春 2016 65 094701

Google Scholar

Google Scholar

Wu L Y, Wang Z G, Li Q L, Li C 2016 Acta Phys. Sin. 65 094701

Google Scholar

Google Scholar

[25] Wu L Y, Wang Z G, Li Q L, Li C 2016 J. Vis. 19 337

Google Scholar

Google Scholar

[26] Lin K C, Kirkendall K A, Kennedy P J, Jackson T A 1999 Proceedings of the 35th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit Los Angeles, California, June 20–24, 1999 p2374

[27] Sallam K A, Aalburg C, Faeth G M, Lin K C, Carter C D, Jackson T A 2004 Proceedings of the 42nd AIAA Aerospace Sciences Meeting and Exhibit Reno, Nevada, January 5–8, 2004 p970

[28] Sallam K A, Aalburg C, Faeth G M 2004 AIAA J. 42 2529

Google Scholar

Google Scholar

[29] Richards J R, Lenhoff A M, Beris A N 1994 Phys. Fluids 6 2640

Google Scholar

Google Scholar

[30] Srinivasan V, Salazar A J, Saito K 2011 Appl. Math. Model. 35 3710

Google Scholar

Google Scholar

[31] Herrmann M 2011 Proc. Combust. Inst. 33 2079

Google Scholar

Google Scholar

[32] Desjardins O, Pitsch H 2009 J. Comput. Phys. 228 1658

Google Scholar

Google Scholar

[33] 高亚军, 姜汉桥, 李俊键, 赵玉云, 胡锦川, 常元昊 2017 66 024702

Google Scholar

Google Scholar

Gao Y J, Jiang H Q, Li J J, Zhao Y Y, Hu J C, Chang Y H 2017 Acta Phys. Sin. 66 024702

Google Scholar

Google Scholar

[34] Xiao F, Wang Z G, Sun M B, Liu N, Yang X 2017 Proc. Combust. Inst. 36 2417

Google Scholar

Google Scholar

[35] 梁刚涛, 郭亚丽, 沈胜强 2013 62 024705

Google Scholar

Google Scholar

Liang G T, Guo Y L, Shen S Q 2013 Acta Phys. Sin. 62 024705

Google Scholar

Google Scholar

[36] Li X Y, Soteriou M C, Arienti M, Sussman M M 2011 Proceedings of the 49th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition Orlando, Florida, January 4–7, 2011 p99

[37] Fontes D H, Vilela V, Souza Meira L D, Souza F J 2019 Int. J. Multiph. Flow 114 98

Google Scholar

Google Scholar

[38] Chu W, Li X Q, Tong Y H, Reng Y J 2020 Acta Astronaut. 175 204

Google Scholar

Google Scholar

[39] Liu N, Wang Z G, Sun M B, Deiterding R, Wang H B 2019 Aerosp. Sci. Technol. 91 456

Google Scholar

Google Scholar

[40] Li P B, Wang Z G, Sun M B, Wang H B 2017 Acta Astronaut. 134 333

Google Scholar

Google Scholar

[41] 李佩波, 王振国, 孙明波, 汪洪波 2016 宇航学报 37 209

Google Scholar

Google Scholar

Li P B, Wang Z G, Sun M B, Wang H B 2016 J. Astronaut. 37 209

Google Scholar

Google Scholar

[42] 成鹏 2018 博士学位论文 (长沙: 国防科技大学)

Cheng P 2018 Ph. D. Dissertation (Changsha: National University of Defense Technology) (in Chinese)

[43] Wu P K, Kirkendall K A, Fuller R P, Nejad A S 1997 J. Propul. Power 13 64

Google Scholar

Google Scholar

计量

- 文章访问数: 13483

- PDF下载量: 421

- 被引次数: 0

下载:

下载: