-

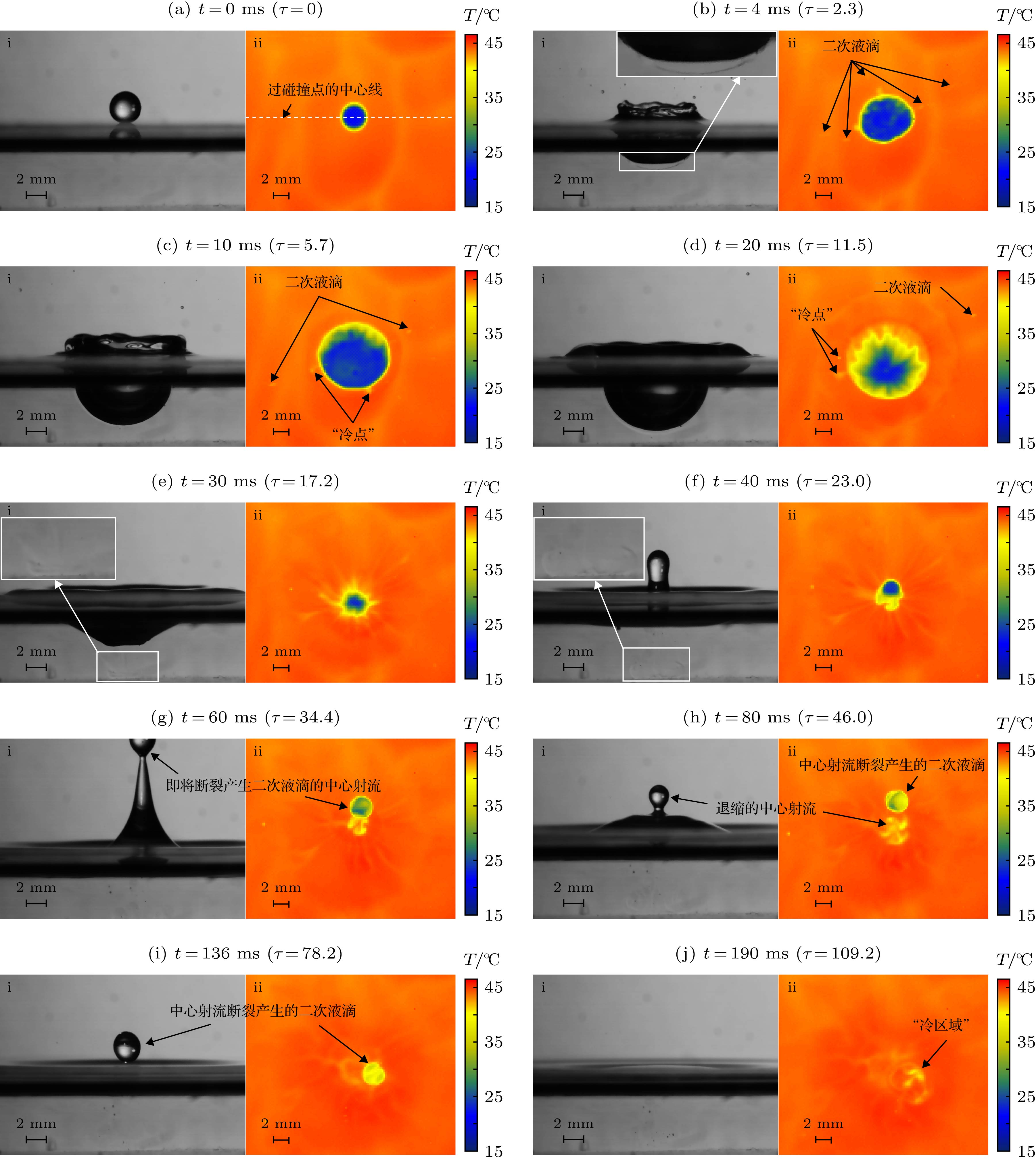

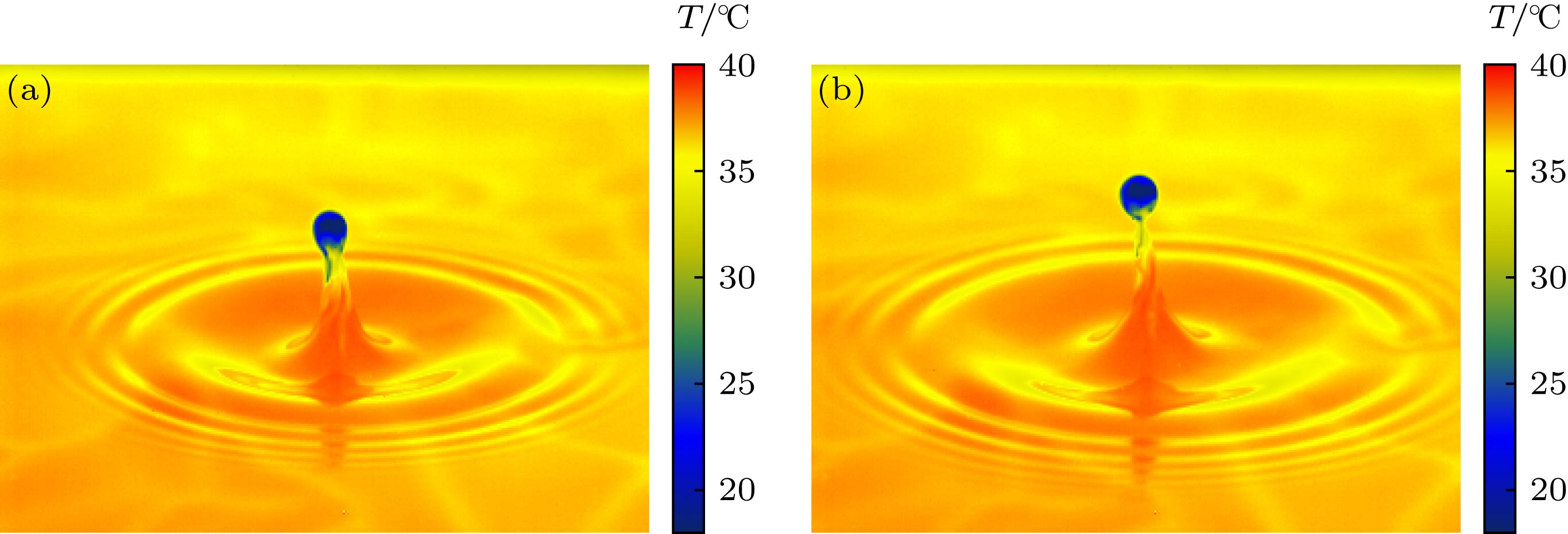

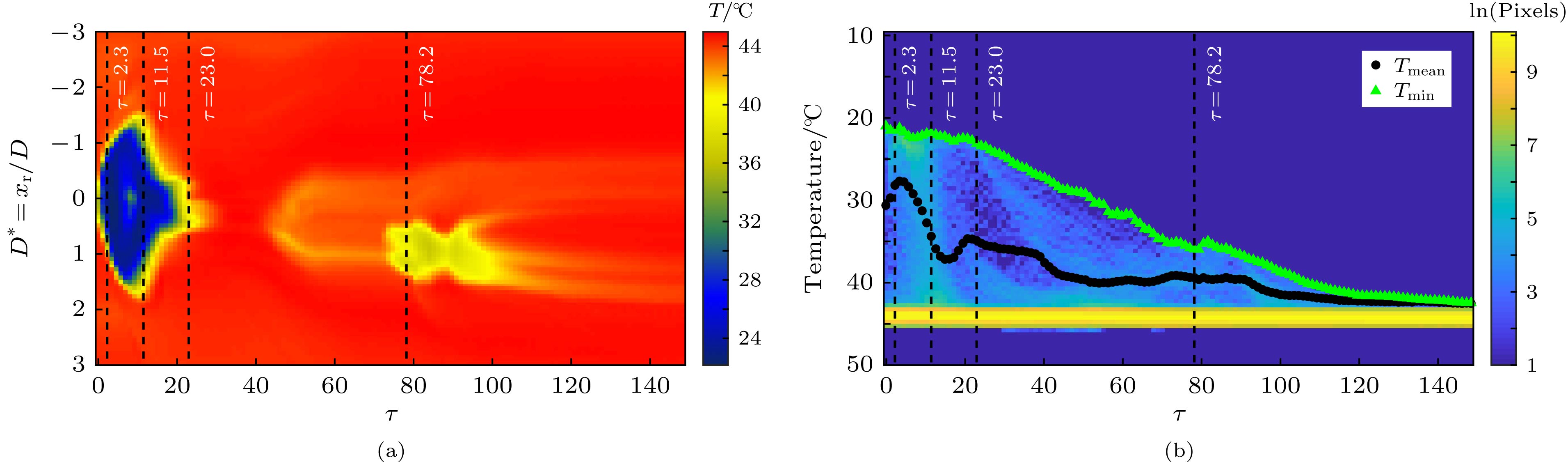

创建了“高速-红外”同步摄影装置, 并利用该装置开展了大量的冷液滴/热液池碰撞实验, 观测了冷液滴/热液池碰撞过程中混合换热区域的形态及温度变化, 分析了工况条件对碰撞过程中冷热液体混合换热的影响, 并建立了碰撞混合换热区域平均温度与工况条件间无量纲关系. 通过研究发现: 冷液滴/热液池碰撞区域温度迅速升高的主要原因为冷/热液体发生了混合; 在碰撞初始阶段, 冷液滴并没有与热液池迅速融为一体, 而是以新月状“变形液滴”的形式存在; 在中心射流向上移动的过程中, 正在混合的冷/热液体分成两部分, 一部分混合液体流向中心射流, 而另一部分流向液池底部; 混合区域的平均温度在碰撞初始阶段随着碰撞时间的增加先略有下降随后又迅速增加, 但其升高进程会被空腔坍缩打断, 并在空腔坍缩后达到极值点, 随后因中心射流的出现而产生波动现象; 混合区域平均温度极值点的温度值与碰撞韦伯数满足一定的无量纲关系, 而平均温度极值点出现时间与液滴弗劳德数满足一定的无量纲关系.A high speed camera-infrared camera synchronous shoot device is built to record the process of cold droplet impacting on hot pool and lots of experiments have been done in this paper. The mixing morphology and the temperature variation of the impact area are observed and analyzed based on simultaneous images taken by the infrared camera and the high speed camera. The influences of the impact conditions on mixing and heat transfer during droplet impacting on hot pool are also studied and then the dimensionless relationship between mean temperature of the impact area and impact condition is established. The experimental results show that the mixing of cold liquid from droplet and hot pool is one of the main reasons for the temperature increase in impact area. The cold droplet does not integrate with hot pool immediately at the beginning of impact and the droplet is deformed into a shape of " crescent moon” which is trapped near the crater. The interface between cold liquid from droplet and hot pool can be observed in a simultaneous image. When the crater begins to collapse, the mixing liquid is mainly divided into two parts: one part is left and curled at the bottom of the pool while the other part is rising with the central jet. Despite the stagnation at the beginning, the mean temperature increases with time going by in the early stage. However the growth trend is interrupted by the cavity collapse. The mean temperature arrives at a peak after the crater has reached its maximum depth. The peak of the dimensionless temperature

$T_{{\rm{peak}}}^{\rm{*}}$ increases with the Weber number increasing and$T_{{\rm{peak}}}^{\rm{*}}$ can be described as$T_{{\rm{peak}}}^{\rm{*}} = 0.34W{e^{0.15}}$ . The dimensionless time of the peak${\tau _{{\rm{peak}}}}$ increases with the Froude number increasing. In this paper, we also find that the dimensionless time of the peak${\tau _{{\rm{peak}}}}$ can be described as${\tau _{{\rm{peak}}}} = 0.85F{r^{5/8}}$ . After the mean temperature reaches the peak, the growth trend presents a trend of fluctuations. The shape of the trend line during this stage is related to Weber number. When the Weber number is small, the growth trend of mean temperature decreases in a short period of time and then restores and increases with time going by. When the Weber number is bigger, the growth rate becomes smoother during the long fluctuation period. The mean temperature will increase very slowly at the end of the impact. Only some cold spot are left on the surface during this period and the rising of the mean temperature becomes steady and slow.-

Keywords:

- simultaneous images /

- droplet impact /

- hot pool /

- heat transfer

[1] Worthington A M, Cole R S 1897 Phil. Trans. Roy. Soc. 189 A137

Google Scholar

Google Scholar

[2] Rein M 1993 Fluid Dyn. Res. 12 61

Google Scholar

Google Scholar

[3] Rein M 1996 J. Fluid Mech. 306 150

[4] Yarin A L, Weiss D A 1995 J. Fluid Mech. 283 141

Google Scholar

Google Scholar

[5] Cossali G E, Coghe A, Marengo M 1997 Exp. Fluids 22 465

[6] Roisman I V, Tropea C 2002 J. Fluid Mech. 472 373

Google Scholar

Google Scholar

[7] Roisman I V, van Hinsberg N P, Tropea C 2008 Phys. Rev. E 77 046305

Google Scholar

Google Scholar

[8] Bisighini A, Cossali G E, Tropea C 2010 Phys. Rev. E 82 036319

Google Scholar

Google Scholar

[9] Mitchell A J, Simmons K, Hann D 2015 Proceedings of the ASME International Mechanical Engineering Congress and Exposition Houston, USA, Novemeber 13−19, 2015 pV001T01A038

[10] Mitchell A J, Hann D, Simmons K 2017 Proceedings of the ASME Turbo Expo Charlotte, USA June 26−30, 2017 pV02DT48A006

[11] Hann D B, Cherdantsev A V, Mitchell A 2016 Exp. Fluids 27 46

[12] Moreira A L N, Moita A S, Panao M R 2010 Prog. Energ. Combust 36 554

Google Scholar

Google Scholar

[13] Bostanci H, Rini D P, Kizito J P 2012 Int. J. Heat Mass Transfer 55 3849

Google Scholar

Google Scholar

[14] Zhang Z, Li J, Jiang P 2013 Appl. Therm. Eng. 51 102

Google Scholar

Google Scholar

[15] Labergue A, Gradeck M, Lemoine F 2015 Int. J. Heat Mass Transfer 81 889

Google Scholar

Google Scholar

[16] Bernardin J, Stebbins C, Mudawar I 1997 Int. J. Heat Mass Transfer 40 247

Google Scholar

Google Scholar

[17] Pasandideh-Fard M, Aziz S, Chandra S, Mostaghimi J 2001 Int. J. Heat Fluid Flow 22 201

Google Scholar

Google Scholar

[18] Castanet G, Liénart T, Lemoine F 2009 Int. J. Heat Mass Transfer 52 670

Google Scholar

Google Scholar

[19] 叶学民, 李永康, 李春曦 2016 65 234701

Google Scholar

Google Scholar

Ye X M, Li Y K, Li C X 2016 Acta Phys. Sin. 65 234701

Google Scholar

Google Scholar

[20] Gao X, Kong L, Li R 2017 Int. J. Heat Mass Transfer 108 1068

Google Scholar

Google Scholar

[21] Liang G, Mu X, Guo Y 2016 Numer. Heat Tr. B: Fund 69 575

Google Scholar

Google Scholar

-

-

[1] Worthington A M, Cole R S 1897 Phil. Trans. Roy. Soc. 189 A137

Google Scholar

Google Scholar

[2] Rein M 1993 Fluid Dyn. Res. 12 61

Google Scholar

Google Scholar

[3] Rein M 1996 J. Fluid Mech. 306 150

[4] Yarin A L, Weiss D A 1995 J. Fluid Mech. 283 141

Google Scholar

Google Scholar

[5] Cossali G E, Coghe A, Marengo M 1997 Exp. Fluids 22 465

[6] Roisman I V, Tropea C 2002 J. Fluid Mech. 472 373

Google Scholar

Google Scholar

[7] Roisman I V, van Hinsberg N P, Tropea C 2008 Phys. Rev. E 77 046305

Google Scholar

Google Scholar

[8] Bisighini A, Cossali G E, Tropea C 2010 Phys. Rev. E 82 036319

Google Scholar

Google Scholar

[9] Mitchell A J, Simmons K, Hann D 2015 Proceedings of the ASME International Mechanical Engineering Congress and Exposition Houston, USA, Novemeber 13−19, 2015 pV001T01A038

[10] Mitchell A J, Hann D, Simmons K 2017 Proceedings of the ASME Turbo Expo Charlotte, USA June 26−30, 2017 pV02DT48A006

[11] Hann D B, Cherdantsev A V, Mitchell A 2016 Exp. Fluids 27 46

[12] Moreira A L N, Moita A S, Panao M R 2010 Prog. Energ. Combust 36 554

Google Scholar

Google Scholar

[13] Bostanci H, Rini D P, Kizito J P 2012 Int. J. Heat Mass Transfer 55 3849

Google Scholar

Google Scholar

[14] Zhang Z, Li J, Jiang P 2013 Appl. Therm. Eng. 51 102

Google Scholar

Google Scholar

[15] Labergue A, Gradeck M, Lemoine F 2015 Int. J. Heat Mass Transfer 81 889

Google Scholar

Google Scholar

[16] Bernardin J, Stebbins C, Mudawar I 1997 Int. J. Heat Mass Transfer 40 247

Google Scholar

Google Scholar

[17] Pasandideh-Fard M, Aziz S, Chandra S, Mostaghimi J 2001 Int. J. Heat Fluid Flow 22 201

Google Scholar

Google Scholar

[18] Castanet G, Liénart T, Lemoine F 2009 Int. J. Heat Mass Transfer 52 670

Google Scholar

Google Scholar

[19] 叶学民, 李永康, 李春曦 2016 65 234701

Google Scholar

Google Scholar

Ye X M, Li Y K, Li C X 2016 Acta Phys. Sin. 65 234701

Google Scholar

Google Scholar

[20] Gao X, Kong L, Li R 2017 Int. J. Heat Mass Transfer 108 1068

Google Scholar

Google Scholar

[21] Liang G, Mu X, Guo Y 2016 Numer. Heat Tr. B: Fund 69 575

Google Scholar

Google Scholar

计量

- 文章访问数: 10173

- PDF下载量: 83

- 被引次数: 0

下载:

下载: