-

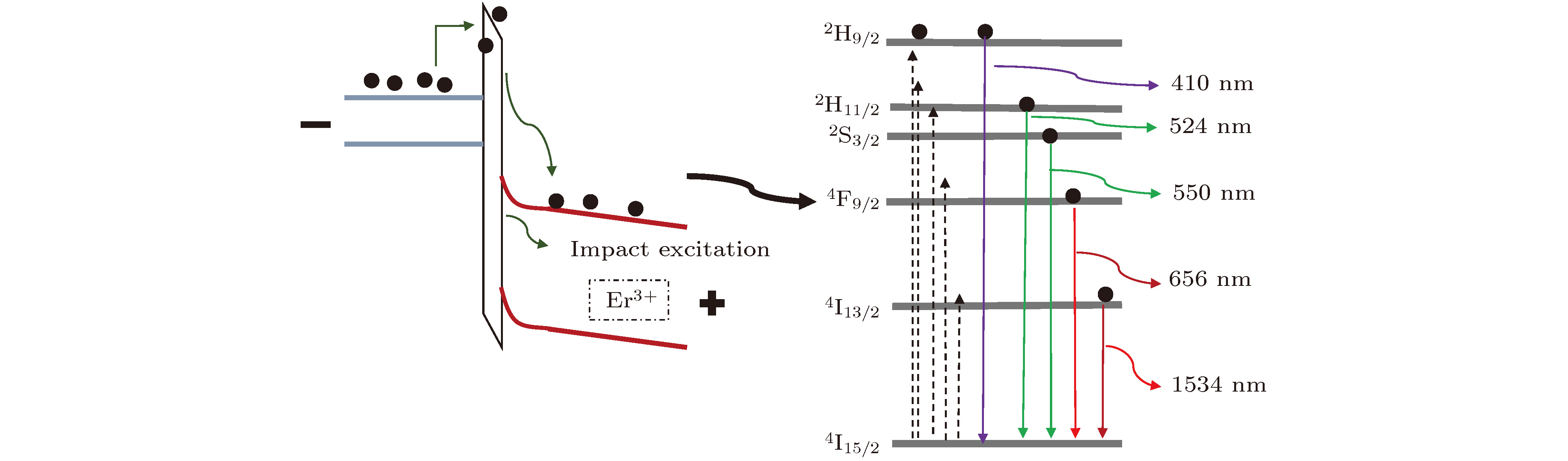

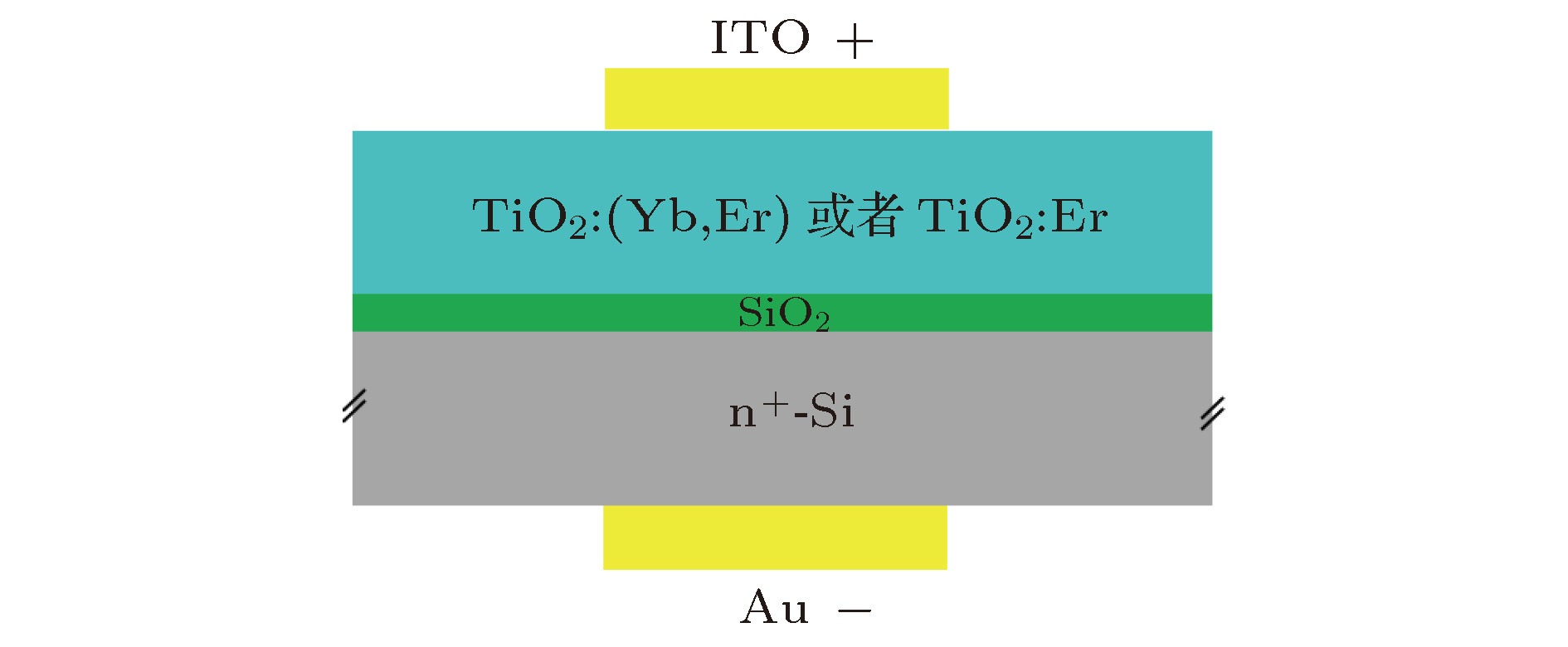

在我们以前的工作(Zhu C, Lü C Y, Gao Z F, Wang C X, Li D S, Ma X Y, Yang D R 2015 Appl. Phys. Lett. 107 131103)中, 利用掺铒(Er)二氧化钛薄膜(TiO2:Er)作为发光层, 实现了基于ITO/TiO2:Er/SiO2/n+-Si结构的发光器件的Er相关可见及近红外(约1540 nm)电致发光. 本文将镱(Yb)共掺入TiO2:Er薄膜中, 显著增强了Er相关可见及近红外电致发光. 研究表明, 一定量Yb的共掺会导致TiO2:Er薄膜由锐钛矿相转变为金红石相, 从而使得Er3+离子周围晶体场的对称性降低. 此外, Yb3+离子比Ti4+离子具有更大的半径, 这使TiO2基体中Er3+离子周围的晶体场进一步畸变. 晶体场的对称性降低及畸变使得Er3+离子4f能级间的跃迁概率增大. 由于上述原因, Yb在TiO2:Er薄膜的共掺显著增强了相关发光器件的电致发光.In the past years, light-emitting devices (LEDs) based on erbium (Er)-doped insulators or wide-bandgap semiconductors have received intensive attention because the intra-4f transition (4I13/2→4I15/2) of Er3+ ions at ~ 1540 nm has potential applications in the optical interconnection for silicon-based circuits. The LEDs with rare-earth (RE)-doped SiOx (x ≤ 2) or SiNx (x ≤ 4/3) films have been well investigated as the silicon-compatible emitters. However, they suffer difficulty in injecting current and easing fatigue. In this context, the LEDs with RE-doped oxide semiconductors have been extensively investigated out of research interest in recent years. Among the oxide semiconductors, TiO2 is a desirable host for RE-doping because it is transparent for visible and infrared light, and cost-effective, and has considerably high RE solubility. In our previous work (Zhu C, Lü C Y, Gao Z F, Wang C X, Li D S, Ma X Y, Yang D R 2015 Appl. Phys. Lett. 107 131103), we have realized erbium (Er)-related visible and near-infrared (~ 1540 nm) electroluminescence (EL) from the LED with a structure of ITO/TiO2:Er/SiO2/n+-Si, in which TiO2:Er refers to the Er-doped TiO2 film as the light-emitting layer. In this work, we co-dope ytterbium (Yb) into the TiO2:Er film in the aforementioned LED to significantly enhance the Er-related visible and near-infrared EL. It is revealed that a certain amount of Yb co-doping enables the TiO2:Er film to transform its crystal phase from anatase to rutile. Such a phase transformation reduces the symmetry of crystal field surrounding the Er3+ ions incorporated into the TiO2 host. Moreover, the substitution of over-sized Yb3+ ions for Ti4+ ions in the TiO2 host leads to the distortion of the crystal field around the Er3+ ions. The aforementioned symmetry-reduction and distortion of the crystal field increase the probabilities of the intra-4f transitions of Er3+ ions. Due to the aforementioned reason, the Yb co-doping into the TiO2:Er film remarkably enhances the EL from the corresponding LED. It is believed that the strategy of Yb-codoping can be adopted to enhance the EL from the LEDs with other RE-doped TiO2 films.

-

Keywords:

- silicon-based /

- electroluminescence /

- Er-doped TiO2 film /

- ytterbium-codoping

[1] Ennen H, Pomrenke G, Axmann A, Eisele K, Haydl W, Schneider J 1985 Appl. Phys. Lett. 46 381

Google Scholar

Google Scholar

[2] Zavada J M, Jin S X, Nepal N, Lin J Y, Jiang H X, Chow P, Hertog B 2004 Appl. Phys. Lett. 84 1061

Google Scholar

Google Scholar

[3] Ramírez J M, Cueff S, Berencén Y, Labbé C, Garrido B 2014 J. Appl. Phys. 116 083103

Google Scholar

Google Scholar

[4] Cueff S, Manel Ramírez J, Kurvits J A, Berencén Y, Zia R, Garrido B, Rizk R, Labbé C 2013 Appl. Phys. Lett. 103 191109

Google Scholar

Google Scholar

[5] Fujii M, Imakita K, Watanabe K, Hayashi S 2004 J. Appl. Phys. 95 272

Google Scholar

Google Scholar

[6] Castagna M E, Coffa S, Monaco M, Muscara A, Caristia L, Lorenti S, Messina A 2003 Mater. Sci. Eng. B 105 83

Google Scholar

Google Scholar

[7] Prucnal S, Sun J M, Rebohle L, Skorupa W 2008 Mater. Sci. Eng. B 146 241

Google Scholar

Google Scholar

[8] Bang H, Piao G, Sawahata J, Li Z, Nomura M 2002 Phys. Stat. Sol. 0 430

[9] Garter M, Scofield J, Birkhahn R, Steckl A J 1999 Appl. Phys. Lett. 74 182

Google Scholar

Google Scholar

[10] Steckl A J, Birkhahn R 1998 Appl. Phys. Lett. 73 1700

Google Scholar

Google Scholar

[11] Zhang Z, Qin J, Shi W, Zhang Y, Liu Y, Gao H, Mao Y 2018 Nanoscale. Res. Lett. 13 147

Google Scholar

Google Scholar

[12] Mokoena T P, Linganiso E C, Kumar V, Swart H C, Cho S H, Ntwaeaborwa O M 2017 J. Colloid. Interface. Sci. 496 87

Google Scholar

Google Scholar

[13] Wu Y, Lin S, Liu J, Ji Y, Xu J, Xu L, Chen K 2017 Opt. Express. 25 22648

Google Scholar

Google Scholar

[14] Dehdouh H, Bensaha R, Zergoug M J M R E 2017 Mater. Res. Express 4 086408

Google Scholar

Google Scholar

[15] Yang Y, Jin L, Ma X, Yang D 2012 Appl. Phys. Lett. 100 031103

Google Scholar

Google Scholar

[16] Zhu C, Lü C Y, Gao Z F, Wang C X, Li D S, Ma X Y, Yang D R 2015 Appl. Phys. Lett. 107 131103

Google Scholar

Google Scholar

[17] Judd B R 1962 Phys. Rev. 127 750

Google Scholar

Google Scholar

[18] Ting C C, Chen S Y, Lee H Y 2003 J. Appl. Phys. 94 2102

Google Scholar

Google Scholar

[19] Cao B S, He Y Y, Feng Z Q, Zhang H Z, Wei Z S, Dong B 2012 J. Sol-Gel. Sci. Techn. 62 419

Google Scholar

Google Scholar

[20] Shang Q K, Yu H, Kong X G, Wang H D, Wang X, Sun Y J, Zhang Y L, Zeng Q H 2008 J. Lumin. 128 1211

Google Scholar

Google Scholar

[21] Singh V, Rai V K, Singh N, Pathak M S, Rathaiah M, Venkatramu V, Patel R V, Singh P K, Dhoble S J 2017 Spectrochim. Acta, Part A 171 229

Google Scholar

Google Scholar

[22] Xu D, Yao L, Lin H, Yang S, Zhang Y 2018 J. Cryst. Growth. 490 41

Google Scholar

Google Scholar

[23] Yang Y, Lü C, Zhu C, Li S, Ma X, Yang D 2014 Appl. Phys. Lett. 104 201109

Google Scholar

Google Scholar

[24] Wang S F, Hsu Y F, Lee R L, Lee Y S 2004 Appl. Surf. Sci. 229 140

Google Scholar

Google Scholar

[25] Houng M P, Wang Y H, Chang W J 1999 J. Appl. Phys. 86 1488

Google Scholar

Google Scholar

[26] Berencén Y, Wutzler R, Rebohle L, Hiller D, Ramírez J M, Rodríguez J A, Skorupa W, Garrido B 2013 Appl. Phys. Lett. 103 111102

Google Scholar

Google Scholar

[27] Kadoshima M, Hiratani M, Shimamoto Y, Torii K, Miki H, Kimura S, Nabatame T 2003 Thin Solid Films 424 224

Google Scholar

Google Scholar

[28] Tang H, Prasad K, Sanjinès R, Schmid P E, Lévy F 1994 J. Appl. Phys. 75 2042

Google Scholar

Google Scholar

[29] Scanlon D O, Dunnill C W, Buckeridge J, Shevlin S A, Logsdail A J, Woodley S M, Catlow C R, Powell M J, Palgrave R G, Parkin I P, Watson G W, Keal T W, Sherwood P, Walsh A, Sokol A A 2013 Nat. Mater. 12 798

Google Scholar

Google Scholar

[30] Xiong G, Joly A G, Beck K M, Hess W P 2006 Phys. Stat. Sol. (c)

3 3598  Google Scholar

Google Scholar

[31] Le Boulbar E, Millon E, Ntsoenzok E, Hakim B, Seiler W, Boulmer-Leborgne C, Perrière J 2012 Opt. Mater. 34 1419

Google Scholar

Google Scholar

[32] Gao X, Liu X, Wen Q, Yang X, Xiao S 2014 J. Appl. Phys. 116 173105

Google Scholar

Google Scholar

-

图 3 在热氧化的硅衬底上生长并经过氧气氛下800 °C热处理1 h后的(a) TiO2:Er和(b) TiO2:(Yb, Er)薄膜的截面HRTEM照片; (c) TiO2:Er薄膜的HRTEM照片; (d) TiO2:(Yb, Er)薄膜的HRTEM照片

Fig. 3. Typical cross-sectional HRTEM images of (a) TiO2:Er and (b) TiO2:(Yb, Er) films annealed at 800 °C for 1 h on the SiO2/Si substrates; typical HRTEM images of (c) TiO2:Er and (d) TiO2:(Yb, Er) films.

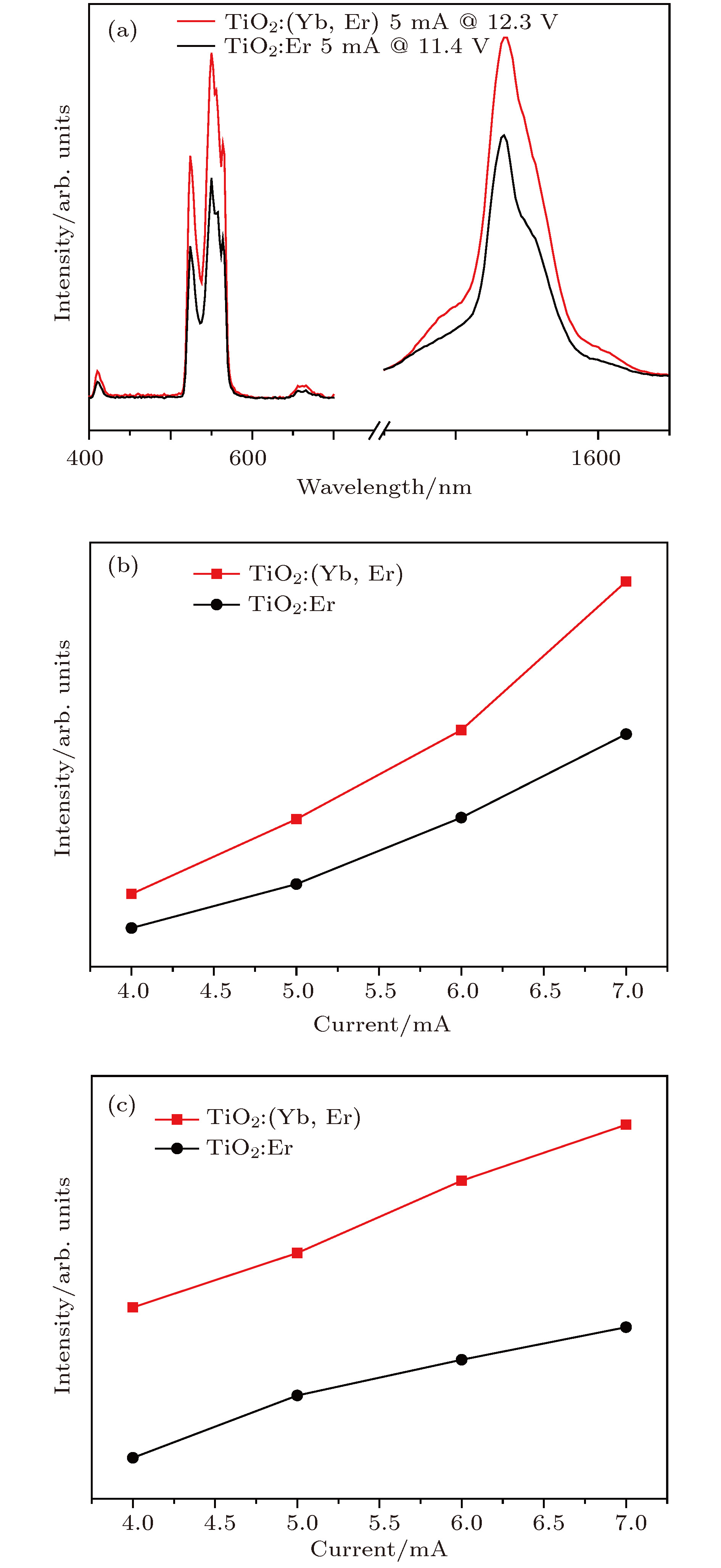

图 4 基于TiO2:Er和TiO2:(Yb, Er)薄膜的两种发光器件 (a) 在相同注入电流下获得的可见及近红外EL谱图; (b)约550和(c) 1534 nm处的发光峰在不同注入电流下的积分强度

Fig. 4. Two light-emitting devices with the TiO2:Er and TiO2:(Yb, Er) films: (a) Visible and near-infrared EL spectra under the same injection currents; integrated EL intensities of the bands peaking at (b) about 550 and (c) 1534 nm under different injection currents.

图 5 (a) 基于TiO2:Er和TiO2:(Yb, Er)薄膜的两种器件的I-V特性曲线; (b) 两种器件中的SiO2层在I-V特性曲线的快速上升部分所对应的lnJ和1/E的关系曲线

Fig. 5. (a) I-V characteristics for the two light-emitting devices with the TiO2:Er and TiO2:(Yb, Er) films; (b) plot of InJ versus 1/E corresponding to the fast rising part of I-V characteristics in SiO2 layer for the two LEDs with the TiO2:Er and TiO2:(Yb, Er) films, respectively.

-

[1] Ennen H, Pomrenke G, Axmann A, Eisele K, Haydl W, Schneider J 1985 Appl. Phys. Lett. 46 381

Google Scholar

Google Scholar

[2] Zavada J M, Jin S X, Nepal N, Lin J Y, Jiang H X, Chow P, Hertog B 2004 Appl. Phys. Lett. 84 1061

Google Scholar

Google Scholar

[3] Ramírez J M, Cueff S, Berencén Y, Labbé C, Garrido B 2014 J. Appl. Phys. 116 083103

Google Scholar

Google Scholar

[4] Cueff S, Manel Ramírez J, Kurvits J A, Berencén Y, Zia R, Garrido B, Rizk R, Labbé C 2013 Appl. Phys. Lett. 103 191109

Google Scholar

Google Scholar

[5] Fujii M, Imakita K, Watanabe K, Hayashi S 2004 J. Appl. Phys. 95 272

Google Scholar

Google Scholar

[6] Castagna M E, Coffa S, Monaco M, Muscara A, Caristia L, Lorenti S, Messina A 2003 Mater. Sci. Eng. B 105 83

Google Scholar

Google Scholar

[7] Prucnal S, Sun J M, Rebohle L, Skorupa W 2008 Mater. Sci. Eng. B 146 241

Google Scholar

Google Scholar

[8] Bang H, Piao G, Sawahata J, Li Z, Nomura M 2002 Phys. Stat. Sol. 0 430

[9] Garter M, Scofield J, Birkhahn R, Steckl A J 1999 Appl. Phys. Lett. 74 182

Google Scholar

Google Scholar

[10] Steckl A J, Birkhahn R 1998 Appl. Phys. Lett. 73 1700

Google Scholar

Google Scholar

[11] Zhang Z, Qin J, Shi W, Zhang Y, Liu Y, Gao H, Mao Y 2018 Nanoscale. Res. Lett. 13 147

Google Scholar

Google Scholar

[12] Mokoena T P, Linganiso E C, Kumar V, Swart H C, Cho S H, Ntwaeaborwa O M 2017 J. Colloid. Interface. Sci. 496 87

Google Scholar

Google Scholar

[13] Wu Y, Lin S, Liu J, Ji Y, Xu J, Xu L, Chen K 2017 Opt. Express. 25 22648

Google Scholar

Google Scholar

[14] Dehdouh H, Bensaha R, Zergoug M J M R E 2017 Mater. Res. Express 4 086408

Google Scholar

Google Scholar

[15] Yang Y, Jin L, Ma X, Yang D 2012 Appl. Phys. Lett. 100 031103

Google Scholar

Google Scholar

[16] Zhu C, Lü C Y, Gao Z F, Wang C X, Li D S, Ma X Y, Yang D R 2015 Appl. Phys. Lett. 107 131103

Google Scholar

Google Scholar

[17] Judd B R 1962 Phys. Rev. 127 750

Google Scholar

Google Scholar

[18] Ting C C, Chen S Y, Lee H Y 2003 J. Appl. Phys. 94 2102

Google Scholar

Google Scholar

[19] Cao B S, He Y Y, Feng Z Q, Zhang H Z, Wei Z S, Dong B 2012 J. Sol-Gel. Sci. Techn. 62 419

Google Scholar

Google Scholar

[20] Shang Q K, Yu H, Kong X G, Wang H D, Wang X, Sun Y J, Zhang Y L, Zeng Q H 2008 J. Lumin. 128 1211

Google Scholar

Google Scholar

[21] Singh V, Rai V K, Singh N, Pathak M S, Rathaiah M, Venkatramu V, Patel R V, Singh P K, Dhoble S J 2017 Spectrochim. Acta, Part A 171 229

Google Scholar

Google Scholar

[22] Xu D, Yao L, Lin H, Yang S, Zhang Y 2018 J. Cryst. Growth. 490 41

Google Scholar

Google Scholar

[23] Yang Y, Lü C, Zhu C, Li S, Ma X, Yang D 2014 Appl. Phys. Lett. 104 201109

Google Scholar

Google Scholar

[24] Wang S F, Hsu Y F, Lee R L, Lee Y S 2004 Appl. Surf. Sci. 229 140

Google Scholar

Google Scholar

[25] Houng M P, Wang Y H, Chang W J 1999 J. Appl. Phys. 86 1488

Google Scholar

Google Scholar

[26] Berencén Y, Wutzler R, Rebohle L, Hiller D, Ramírez J M, Rodríguez J A, Skorupa W, Garrido B 2013 Appl. Phys. Lett. 103 111102

Google Scholar

Google Scholar

[27] Kadoshima M, Hiratani M, Shimamoto Y, Torii K, Miki H, Kimura S, Nabatame T 2003 Thin Solid Films 424 224

Google Scholar

Google Scholar

[28] Tang H, Prasad K, Sanjinès R, Schmid P E, Lévy F 1994 J. Appl. Phys. 75 2042

Google Scholar

Google Scholar

[29] Scanlon D O, Dunnill C W, Buckeridge J, Shevlin S A, Logsdail A J, Woodley S M, Catlow C R, Powell M J, Palgrave R G, Parkin I P, Watson G W, Keal T W, Sherwood P, Walsh A, Sokol A A 2013 Nat. Mater. 12 798

Google Scholar

Google Scholar

[30] Xiong G, Joly A G, Beck K M, Hess W P 2006 Phys. Stat. Sol. (c)

3 3598  Google Scholar

Google Scholar

[31] Le Boulbar E, Millon E, Ntsoenzok E, Hakim B, Seiler W, Boulmer-Leborgne C, Perrière J 2012 Opt. Mater. 34 1419

Google Scholar

Google Scholar

[32] Gao X, Liu X, Wen Q, Yang X, Xiao S 2014 J. Appl. Phys. 116 173105

Google Scholar

Google Scholar

计量

- 文章访问数: 11109

- PDF下载量: 100

- 被引次数: 0

下载:

下载: