-

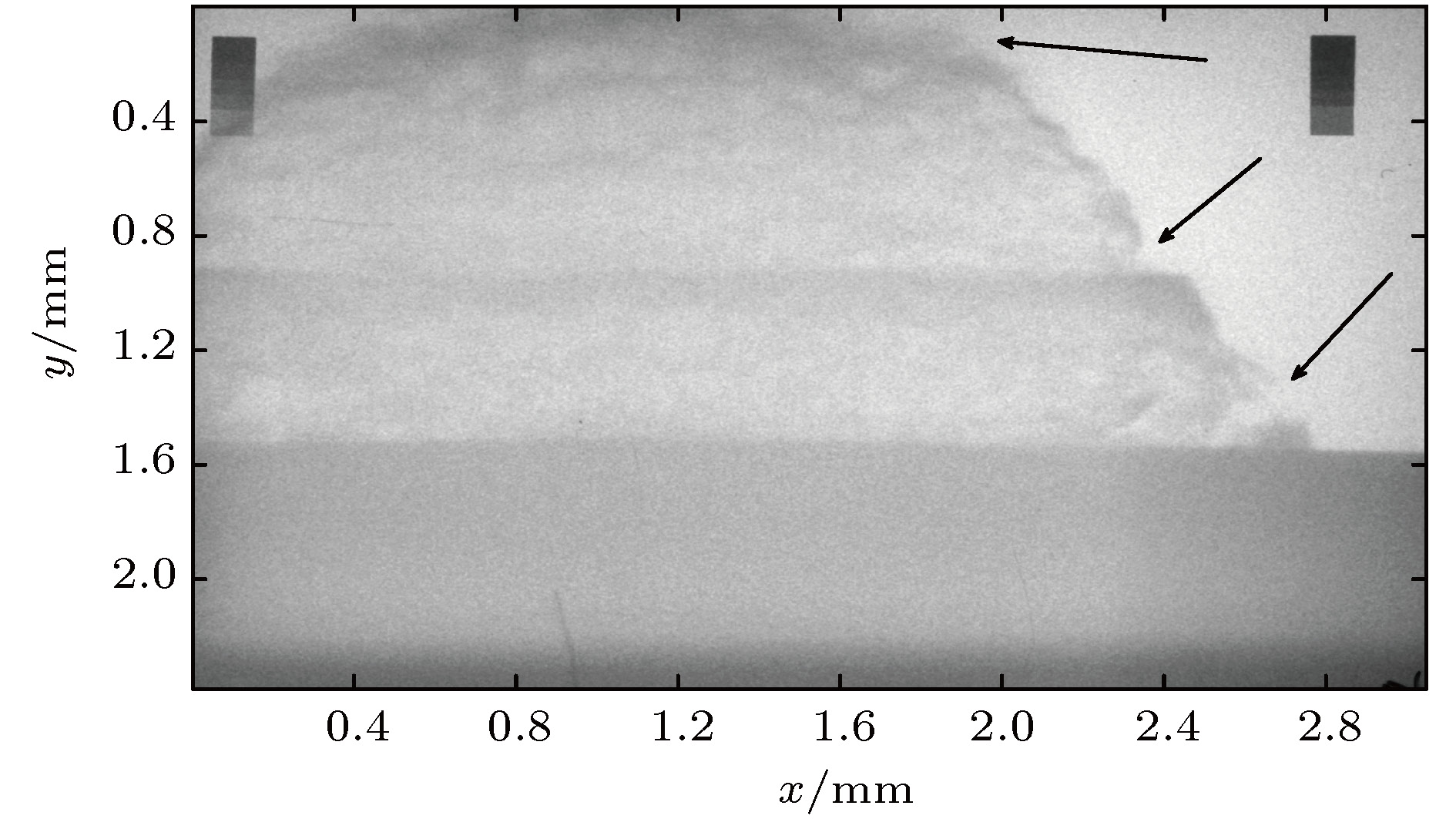

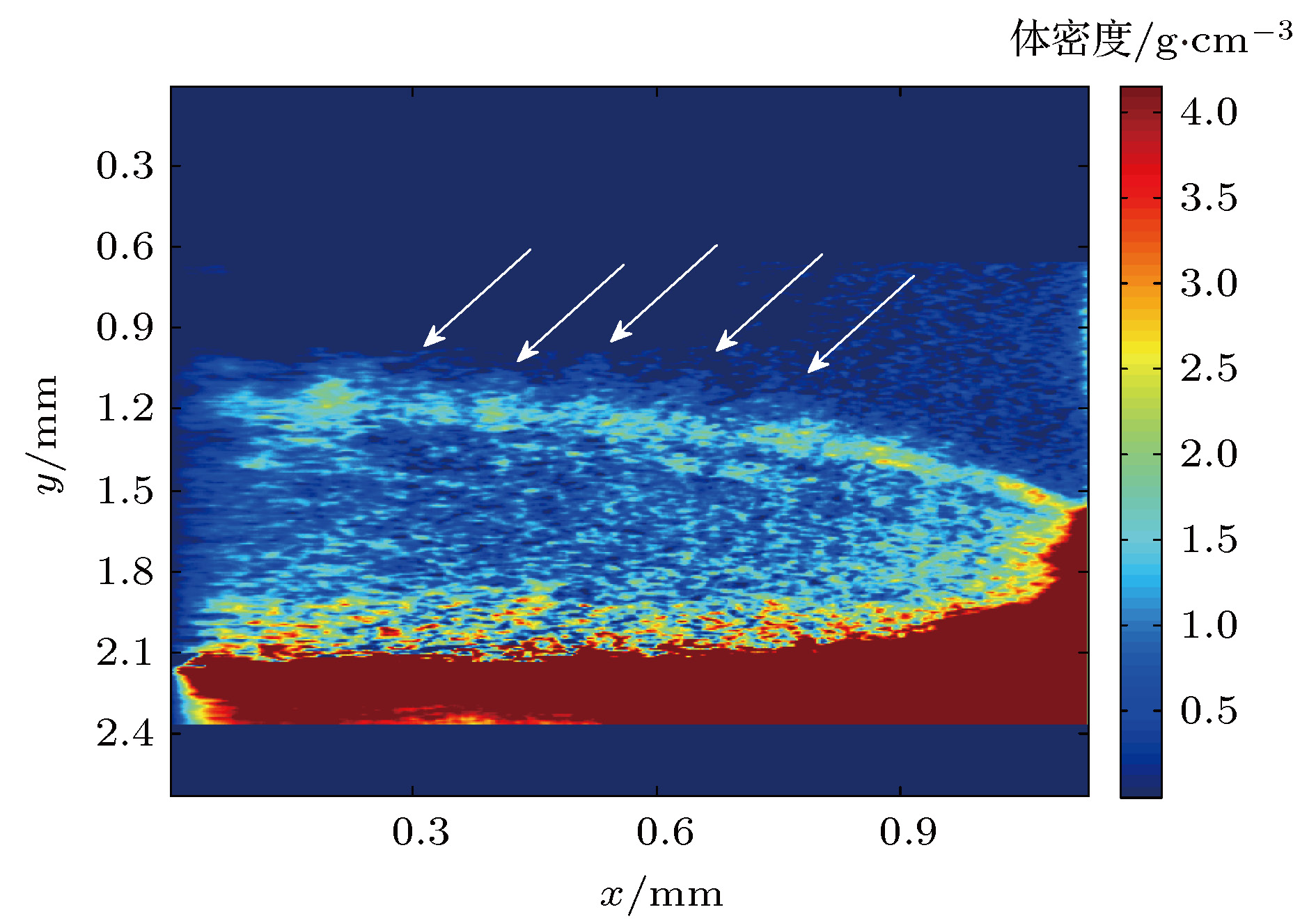

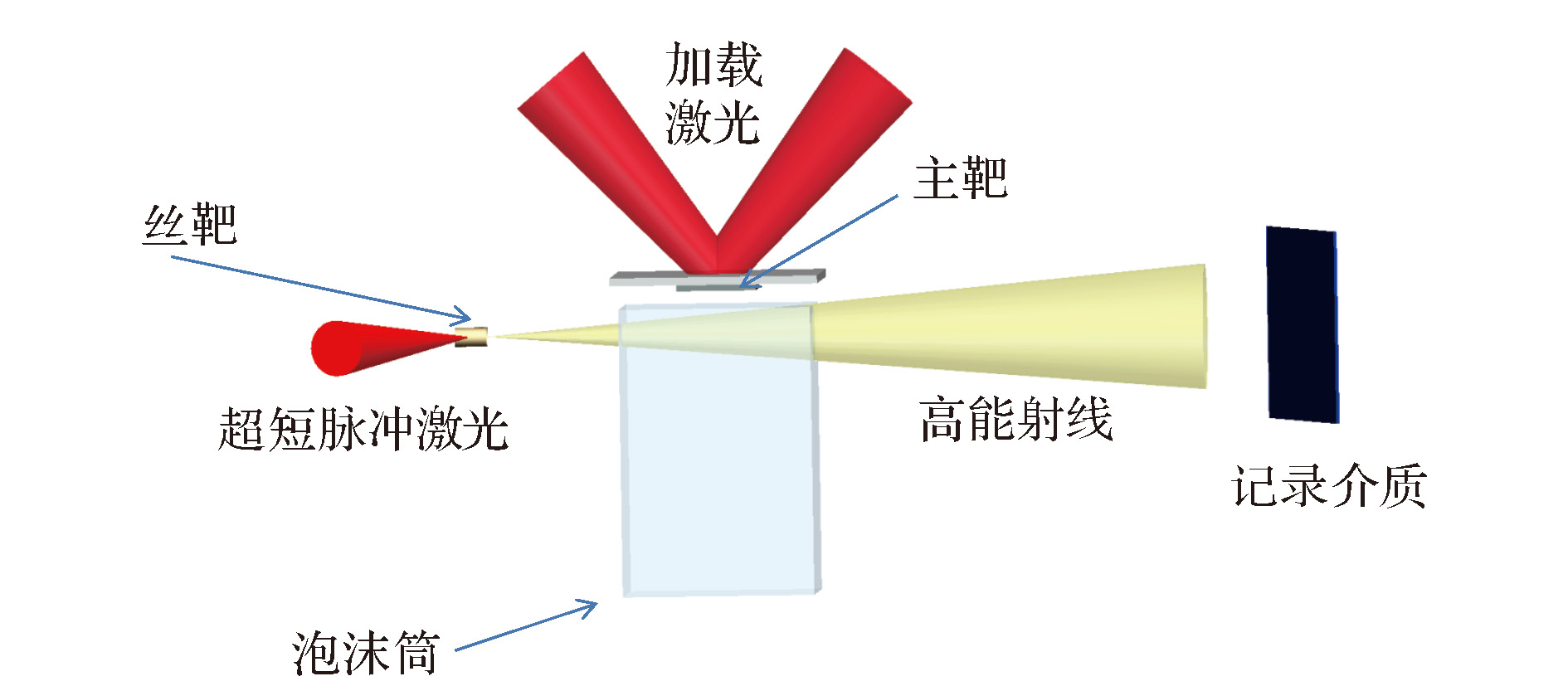

金属材料的微喷是冲击加载下金属表面发生的一种动态破碎现象, 微喷研究在很多领域都具有重要意义, 包括惯性约束聚变(ICF)和烟火制造等. 由于激光实验特有的优势, 近几年国内外开展了很多利用强激光驱动冲击加载研究材料微喷过程的实验. 利用泡沫材料对微喷颗粒进行静态软回收虽然可以获得颗粒的形态分布、颗粒尺寸及颗粒质量等定量结果, 但并不能反演微喷颗粒从进入泡沫到停滞过程中的动态混合过程. 为此, 在神光Ⅱ升级装置上利用皮秒脉冲激光照射金丝产生高能X射线, 实现了对锡微喷颗粒与低密度泡沫混合过程的高时间分辨和高空间分辨背光照相. 背光图像面密度结果证实微喷颗粒在泡沫中并没有发生二次破碎. 静态回收结果表明, 在锡材料与泡沫紧贴放置的情况下, 微喷颗粒在泡沫中的穿透深度随着加载压强升高呈现先增大后减小的规律, 与非紧贴放置的实验结果有明显的差别.Micron-scale fragment ejection of metal is a kind of surface dynamic fragmentation phenomenon upon shock loading. The study of ejecta is crucial in many fields, such as inertial confinement fusion and pyrotechnics. Due to the particular advantages of laser experiments, a lot of studies of ejecta by strong laser-induced shock loading have been conducted in recent years. The shapes, size and mass of particle can be obtained via static soft recovery technique with foam. However, the stagnation and succedent mixing of the ejecta in the foam could not be deduced by this technique. To study the mixing between the ejecta and foam, a radiography experiment is performed by using the X-ray generated through the irradiation of picosecond laser on the golden wire. This radiography technique has not only high spatial resolution but also high temporal resolution. Two kind of experiments are designed and performed. In the first one, the tin sample and the foam are close to each other while a vacuum gap is arranged between them in the other one. The mixing process is analyzed with the determined areal density and volume density, as well as the results of recovery. The areal density of the front mixing area is similar to the scenario in the case with a vacuum gap, suggesting that the ejecta have not underwent a secondary fragmentation due to the collision with foam. Furthermore, the static recovery results show a different characteristic of penetration depth for the ejecta in the foam. When the tin sample is not close to the foam, the penetration depth in the foam increases with the loading pressure increasing. However, the penetration depth begins to decrease at a critical pressure after a brief increase, which is attributed to the interaction between the shock and the foam before the ejecta coming, and also to the ejecta size and composition. The shock pressure is high enough to change the foam performance, thus enhancing the stagnation ability for ejecta penetration. Moreover, the size and composition vary with loading pressure, thereby leading to the momentum change of the ejecta related to the penetration depth. In the future work, we will improve the field of view of the X-ray radiography to achieve a direct comparison between the dynamic results and the recovery results. Moreover, we will arrange perturbations at the interface to study the mixing between the micro-jetting and the foam and the interface instability.

-

Keywords:

- micron-scale fragment ejecta /

- inertial confinement fusion /

- recovery /

- mixing

[1] 王裴, 何安民, 邵建立, 孙海权, 陈大伟, 刘文斌, 刘军 2018 中国科学: 物理学 力学 天文学 48 094608

Wang P, He A M, Shao J L, Sun H Q, Chen D W, Liu W B, Liu J 2018 Sci. China: Physica, Mechanica & Astronomica 48 094608

[2] de Resseguier T, Signor L, Dragon A, Boustie M, Roy G, Llorca F 2007 J. Appl. Phys. 101 013506

Google Scholar

Google Scholar

[3] de Resseguier T, Roland C, Prudhomme G, Lescoute E, Loison D, Mercier P 2016 J. Appl. Phys. 119 185108

Google Scholar

Google Scholar

[4] de Resseguier T, Roland C, Lescoute E, Sollier A, Loison D, Berthe L, Prudhomme G, Mercier P 2015 AIP Conf. Proc. 1793 100025

[5] de Resseguier T, Signor L, Dragon A, Severin P, Boustie M 2007 J. Appl. Phys. 102 073535

Google Scholar

Google Scholar

[6] de Resseguier T, Signor L, Dragon A, Boustie M, Berthe L 2008 Appl. Phys. Lett. 92 131910

Google Scholar

Google Scholar

[7] de Resseguier D, Signor L, Dragon A, Roy G 2010 Int. J. Fract. 163 109

Google Scholar

Google Scholar

[8] Zellner M B, McNeil W V, Hammerberg J E, Hixson R S, Obst A W, Olson R T, Payton J R, Rigg P A, Routley N, Stevens G D, Turley W D, Veeser L, Buttler W T 2008 J. Appl. Phys. 103 123502

Google Scholar

Google Scholar

[9] Franzkowiak J E, Prudhomme G, Mercier P, Lauriot S, Dubreuil E, Berthe L 2018 Rev. Sci. Instrum. 89 033901

Google Scholar

Google Scholar

[10] Asay J R 1978 J. Appl. Phys. 49 6173

Google Scholar

Google Scholar

[11] Morard G, de Resseguier T, Vinci T, Benuzzi-Mounaix A, Lescoute E, Brambrink E, Koenig M, Wei H, Diziere A, Occelli F, Fiquet G, Guyot F 2010 Phys. Rev. B 82 174102

Google Scholar

Google Scholar

[12] de Resseguier T, Lescoute E, Sollier A, Prudhomme G, Mercier P 2014 J. Appl. Phys. 115 043525

Google Scholar

Google Scholar

[13] Lescoute E, de Resseguier T, Chevalier J M, Boustie M, Cuq-Lelandais J P, Berthe L 2009 Appl. Phys. Lett. 95 211905

Google Scholar

Google Scholar

[14] 辛建婷, 谷渝秋, 李平, 罗炫, 蒋柏斌, 谭放, 韩丹, 巫殷忠, 赵宗清, 粟敬钦, 张保汉 2012 23 236201

Google Scholar

Google Scholar

Xin J T, Gu Y Q, Li P, Luo X, Jiang B B, Tan F, Han D, Wu Y Z, Zhao Z Q, Su J Q, Zhang B H 2012 Acta Phys. Sin. 23 236201

Google Scholar

Google Scholar

[15] He W H, Xin J T, Chu G B, Li J, Shao J L, Lu F, Shui M, Qian F, Cao L F, Wang P, Gu Y Q 2014 Optics Express 22 18924

Google Scholar

Google Scholar

[16] He W H, Xin J T, Zhao Y Q, Chu G B, Xi T, Shui M, Lu F, Gu Y Q 2017 AIP Advances 7 065306

Google Scholar

Google Scholar

[17] 辛建婷, 赵永强, 储根柏, 席涛, 税敏, 范伟, 何卫华, 谷渝秋 2017 18 186201

Google Scholar

Google Scholar

Xin J T, Zhao Y Q, Chu G B, Xi T, Shui M, Fan W, He W H, Gu Y Q 2017 Acta Phys. Sin. 18 186201

Google Scholar

Google Scholar

[18] 张林, 李英华, 程晋明, 李雪梅, 张祖根, 叶想平, 蔡灵仓 2016 强激光与粒子束 28 041003

Zhang L, Li Y H, Cheng J M, Li X M, Zhang Z G, Ye X P, Cai L C 2016 High Power Laser and Particle Beams 28 041003

[19] Chu G B, Xi T, Yu M H, Fan W, Zhao Y Q, Shui M, He W H, Zhang T K, Zhang B, Wu Y C, Zhou W M, Cao L F, Xin J T, Gu Y Q 2018 Rev. Sci. Instrum. 89 115106

Google Scholar

Google Scholar

[20] Marshall F J, McKenty P W, DelettrezJ A, Epstein R, Knauer J P, Smalyuk V A 2009 Phys. Rev. Lett. 102 185004

Google Scholar

Google Scholar

[21] Dimonte G, Gore R, and Schneider M 1998 Phys. Rev. Lett. 80 1212

Google Scholar

Google Scholar

[22] Buttler W T, Oro D M, Preston D L, Mikaelian K O, Cherne F J, Hixson R S, Mariam F G, Morris C, Stone J B, Terrones G, Tupa D 2012 J. Fluid Mech. 703 60

Google Scholar

Google Scholar

[23] Dimonte G, Terrones G, Cherne F J, Ramaprabhu P 2013 J Appl. Phys. 113 024905

Google Scholar

Google Scholar

[24] Dimonte G and Remington B 1993 Phys. Rev. Lett. 70 1806

Google Scholar

Google Scholar

[25] Kuranz C C, Park H S, Huntington C M, Miles A R, Remington B A, Plewa T, Trantham M R, Robey H F, Shvarts D, Shimony A, Raman K, MacLaren S, Wan W C, Doss F W, Kline J, Flippo K A, Malamud G, Handy T A, Prisbrey S, Krauland C M, Klein S R, Harding E C, Wallace R, Grosskopf M J, Marion D C, Kalantar D, Giraldez E, Drake R P 2018 Nature Communications 9 1564

Google Scholar

Google Scholar

-

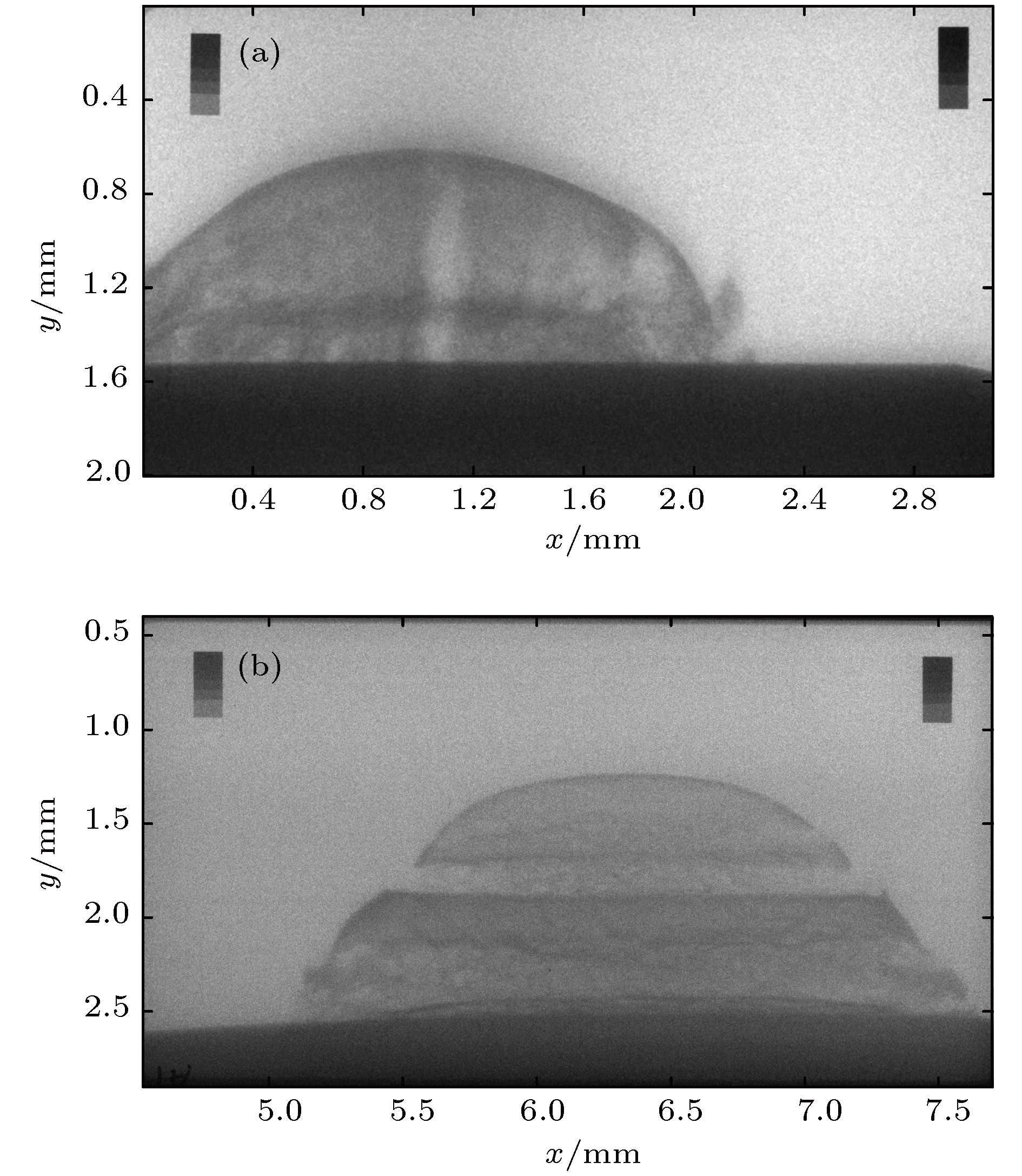

图 6 不同发次回收的微喷颗粒图像 (a) 72发, 2 GPa; (b) 73发, 20 GPa; (c) 72发, 24 GPa; (d) 76发, 25 GPa; (e) 75发, 28 GPa; (f) 77发, 31 GPa; (g) 78发, 32 GPa; (h) 80发, 39 GPa; (i) 79发, 41 GPa

Fig. 6. Recovery image of tin fragments stagnated in the foam by 2-D CT analysis: (a) 72 shot, 2 GPa; (b) 73 shot, 20 GPa; (c) 72 shot, 24 GPa; (d) 76 shot, 25 GPa; (e) 75 shot, 28 GPa; (f) 77 shot, 31 GPa; (g) 78 shot, 32 GPa; (h) 80 shot, 39 GPa; (i) 79 shot, 41 GPa.

表 1 神光II升级装置紧贴条件下(微)层裂实验数据参数统计

Table 1. Experimental parameter statistics of (micro-) spall without vacuum gap conducted at the SGII-U facility.

序号 发次号 ns激光能量/J ps激光能量/J 计算峰值压强/Ga 时间延迟/ns 备注 1 71 501.38 静态实验 2 72 106.7 486.28 2 2500 ns能量偏低 3 73 406 57.81 20 800 ps能量过低 4 74 547 529.6 24 800 5 76 588 556.7 25 1000 6 75 663 562.8 28 800 7 77 809 560.2 31 600 8 78 847 588 32 600 9 80 1231 621 39 900 10 79 352 592 41 600 表 2 神光II升级装置非紧贴条件下(微)层裂实验数据参数统计

Table 2. Experimental parameter statistics of (micro-) spall with vacuum gap conducted at the SGII-U facility.

序号 发次号 ns激光能量/J ps激光能量/J 计算峰值压强/GPa 时间延迟/ns 1 64 115.30 456.80 3 900 2 66 285.56 520.93 15 1500 3 55 644.07 556.10 27 900 4 56 763.46 576.95 30 600 5 62 1310.00 515.25 40 600 -

[1] 王裴, 何安民, 邵建立, 孙海权, 陈大伟, 刘文斌, 刘军 2018 中国科学: 物理学 力学 天文学 48 094608

Wang P, He A M, Shao J L, Sun H Q, Chen D W, Liu W B, Liu J 2018 Sci. China: Physica, Mechanica & Astronomica 48 094608

[2] de Resseguier T, Signor L, Dragon A, Boustie M, Roy G, Llorca F 2007 J. Appl. Phys. 101 013506

Google Scholar

Google Scholar

[3] de Resseguier T, Roland C, Prudhomme G, Lescoute E, Loison D, Mercier P 2016 J. Appl. Phys. 119 185108

Google Scholar

Google Scholar

[4] de Resseguier T, Roland C, Lescoute E, Sollier A, Loison D, Berthe L, Prudhomme G, Mercier P 2015 AIP Conf. Proc. 1793 100025

[5] de Resseguier T, Signor L, Dragon A, Severin P, Boustie M 2007 J. Appl. Phys. 102 073535

Google Scholar

Google Scholar

[6] de Resseguier T, Signor L, Dragon A, Boustie M, Berthe L 2008 Appl. Phys. Lett. 92 131910

Google Scholar

Google Scholar

[7] de Resseguier D, Signor L, Dragon A, Roy G 2010 Int. J. Fract. 163 109

Google Scholar

Google Scholar

[8] Zellner M B, McNeil W V, Hammerberg J E, Hixson R S, Obst A W, Olson R T, Payton J R, Rigg P A, Routley N, Stevens G D, Turley W D, Veeser L, Buttler W T 2008 J. Appl. Phys. 103 123502

Google Scholar

Google Scholar

[9] Franzkowiak J E, Prudhomme G, Mercier P, Lauriot S, Dubreuil E, Berthe L 2018 Rev. Sci. Instrum. 89 033901

Google Scholar

Google Scholar

[10] Asay J R 1978 J. Appl. Phys. 49 6173

Google Scholar

Google Scholar

[11] Morard G, de Resseguier T, Vinci T, Benuzzi-Mounaix A, Lescoute E, Brambrink E, Koenig M, Wei H, Diziere A, Occelli F, Fiquet G, Guyot F 2010 Phys. Rev. B 82 174102

Google Scholar

Google Scholar

[12] de Resseguier T, Lescoute E, Sollier A, Prudhomme G, Mercier P 2014 J. Appl. Phys. 115 043525

Google Scholar

Google Scholar

[13] Lescoute E, de Resseguier T, Chevalier J M, Boustie M, Cuq-Lelandais J P, Berthe L 2009 Appl. Phys. Lett. 95 211905

Google Scholar

Google Scholar

[14] 辛建婷, 谷渝秋, 李平, 罗炫, 蒋柏斌, 谭放, 韩丹, 巫殷忠, 赵宗清, 粟敬钦, 张保汉 2012 23 236201

Google Scholar

Google Scholar

Xin J T, Gu Y Q, Li P, Luo X, Jiang B B, Tan F, Han D, Wu Y Z, Zhao Z Q, Su J Q, Zhang B H 2012 Acta Phys. Sin. 23 236201

Google Scholar

Google Scholar

[15] He W H, Xin J T, Chu G B, Li J, Shao J L, Lu F, Shui M, Qian F, Cao L F, Wang P, Gu Y Q 2014 Optics Express 22 18924

Google Scholar

Google Scholar

[16] He W H, Xin J T, Zhao Y Q, Chu G B, Xi T, Shui M, Lu F, Gu Y Q 2017 AIP Advances 7 065306

Google Scholar

Google Scholar

[17] 辛建婷, 赵永强, 储根柏, 席涛, 税敏, 范伟, 何卫华, 谷渝秋 2017 18 186201

Google Scholar

Google Scholar

Xin J T, Zhao Y Q, Chu G B, Xi T, Shui M, Fan W, He W H, Gu Y Q 2017 Acta Phys. Sin. 18 186201

Google Scholar

Google Scholar

[18] 张林, 李英华, 程晋明, 李雪梅, 张祖根, 叶想平, 蔡灵仓 2016 强激光与粒子束 28 041003

Zhang L, Li Y H, Cheng J M, Li X M, Zhang Z G, Ye X P, Cai L C 2016 High Power Laser and Particle Beams 28 041003

[19] Chu G B, Xi T, Yu M H, Fan W, Zhao Y Q, Shui M, He W H, Zhang T K, Zhang B, Wu Y C, Zhou W M, Cao L F, Xin J T, Gu Y Q 2018 Rev. Sci. Instrum. 89 115106

Google Scholar

Google Scholar

[20] Marshall F J, McKenty P W, DelettrezJ A, Epstein R, Knauer J P, Smalyuk V A 2009 Phys. Rev. Lett. 102 185004

Google Scholar

Google Scholar

[21] Dimonte G, Gore R, and Schneider M 1998 Phys. Rev. Lett. 80 1212

Google Scholar

Google Scholar

[22] Buttler W T, Oro D M, Preston D L, Mikaelian K O, Cherne F J, Hixson R S, Mariam F G, Morris C, Stone J B, Terrones G, Tupa D 2012 J. Fluid Mech. 703 60

Google Scholar

Google Scholar

[23] Dimonte G, Terrones G, Cherne F J, Ramaprabhu P 2013 J Appl. Phys. 113 024905

Google Scholar

Google Scholar

[24] Dimonte G and Remington B 1993 Phys. Rev. Lett. 70 1806

Google Scholar

Google Scholar

[25] Kuranz C C, Park H S, Huntington C M, Miles A R, Remington B A, Plewa T, Trantham M R, Robey H F, Shvarts D, Shimony A, Raman K, MacLaren S, Wan W C, Doss F W, Kline J, Flippo K A, Malamud G, Handy T A, Prisbrey S, Krauland C M, Klein S R, Harding E C, Wallace R, Grosskopf M J, Marion D C, Kalantar D, Giraldez E, Drake R P 2018 Nature Communications 9 1564

Google Scholar

Google Scholar

计量

- 文章访问数: 11477

- PDF下载量: 77

- 被引次数: 0

下载:

下载: