-

The interactions between the energetic particles and atoms in materials would result in the atomic displacements and the associated radiation defects. The interstitial dislocation loop, as one of the primary radiation defects, is formed by the clustering of the supersaturated self-interstitial atoms from the displacement damages in body centered cubic (bcc) iron based materials. The radiation hardening, embrittlement, swelling, creep, etc. are generally related to these loops and their interactions with other defects. In addition, the irradiation would also result in the formation of the micro-cracks from the surface of the materials and also from the interface of grains, precipitates, and gas-bubbles inside the materials, which would result in the irradiation assisted stress corrosion crack (IASCC). Therefore, to understand the interaction between interstitial dislocation loop and micro-crack under the irradiation, is one of key steps to understand the underlying mechanism of IASCC. In this work, the interaction between interstitial dislocation loop and micro-crack is simulated by molecular dynamics method on an atomic scale. The distance, relative position between them and radius of dislocation loop, as the main factors affecting their interactions, are studied to explore the underlying reason for inducing the micro-crack to expand on the slip plane. The simulation results indicate that when the interaction between them dominates the whole process with the distance between them within the critical value, the dislocation network containing the

$ \langle 100 \rangle $ and 1/2$ \langle 111 \rangle $ segments, would interact with the crack tip to inhibit the crack from expanding through the pinning effect. When the size of loop is different, the pining effect would be available only when the interaction between loop core and crack tip dominates with the distance between them within the critical value. All these results provide new understanding for further exploring the IASCC under irradiation.-

Keywords:

- radiation damage /

- micro-crack /

- dislocation loop /

- molecular dynamics simulation

[1] Rana M A 2012 Radit. Meas. 47 50

Google Scholar

Google Scholar

[2] Ascheron C, Schindler A, Flagmeyer R, Otto G 1989 Nucl. Instrum. Methods B 36 163

Google Scholar

Google Scholar

[3] Ascheron C, Schindler A, Flagmeyer R, Otto G 1986 Phys. Status Solidi A 96 555

Google Scholar

Google Scholar

[4] Mikkelson R C, Miller J W, Holland R E, Gemmell D S 1973 J. Appl. Phys. 44 935

Google Scholar

Google Scholar

[5] Kohyama A, Hishinuma A, Gelles D S, Klueh R L, Dietz W, Ehrlich K 1996 J. Nucl. Mater. 233–237 138

[6] Jung P 2002 J. Nucl. Mater. 301 15

Google Scholar

Google Scholar

[7] Beyerlein I J, Caro A, Demkowicz M J, Mara N A, Misra A, Uberuaga B P 2013 Mater. Today 16 443

Google Scholar

Google Scholar

[8] Litwa P, Kurpaska L, Varin R A, Perkowski K, Jagielski J, Jozwiak S, Czujko T 2017 J. Alloys Compd. 711 111

Google Scholar

Google Scholar

[9] Wei Y P, Liu P P, Zhu Y M, Wang Z Q, Wan F R, Zhan Q 2016 J. Alloys Compd. 676 481

Google Scholar

Google Scholar

[10] Masters B C 1965 Philos. Mag. 11 881

Google Scholar

Google Scholar

[11] Scott P 1994 J. Nucl. Mater. 211 101

Google Scholar

Google Scholar

[12] Was G S, Busby J T 2005 Philos. Mag. 85 443

Google Scholar

Google Scholar

[13] Fukuya K, Nakano M, Fujii K, Torimaru T, Kitsunai Y 2004 J. Nucl. Sci. Technol. 41 1218

Google Scholar

Google Scholar

[14] 梁晋洁, 高宁, 李玉红 2020 69 036101

Google Scholar

Google Scholar

Liang J J, Gao N, Li Y H 2020 Acta Phys. Sin. 69 036101

Google Scholar

Google Scholar

[15] 黄依娜, 万发荣, 焦治杰 2011 60 036802

Google Scholar

Google Scholar

Huang Y N, Wan F R, Jiao Z J 2011 Acta Phys. Sin. 60 036802

Google Scholar

Google Scholar

[16] 杜玉峰, 崔丽娟, 万发荣 2019 工程科学学报 41 1016

Google Scholar

Google Scholar

Du Y F, Cui L J, Wan F R 2019 Chin. J. Eng. 41 1016

Google Scholar

Google Scholar

[17] 崔丽娟, 高进, 杜玉峰, 张高伟, 张磊, 龙毅, 杨善武, 詹倩, 万发荣 2016 65 066102

Google Scholar

Google Scholar

Cui L J, Gao J, Du Y F, Zhang G W, Zhang L, Long Y, Yang S W, Zhan Q, Wan F R 2016 Acta Phys. Sin. 65 066102

Google Scholar

Google Scholar

[18] 邓平, 孙晨, 彭群家, 韩恩厚, 柯伟 2015 中国腐蚀与防护学报 35 479

Deng P, Sun C, Peng Q J, Han E H, Ke W 2015 J. Chin. Soc. Corros. Prot. 35 479

[19] Gurrutxaga-Lerma B 2018 Int. J. Eng. Sci. 128 165

Google Scholar

Google Scholar

[20] Gupta J, Hure J, Tanguy B, Laffont L, Lafont M C, Andrieu E 2018 J. Nucl. Mater. 501 45

Google Scholar

Google Scholar

[21] Decelis B, Argon A S, Yip S 1983 J. Appl. Phys. 54 4864

Google Scholar

Google Scholar

[22] 董杰, 陈学东, 范志超, 江慧峰, 陆守香 2008 金属学报 44 1167

Google Scholar

Google Scholar

Dong J, Chen X D, Fan Z C, Jiang H F, Lu S X 2008 Acta Metall. Sin. 44 1167

Google Scholar

Google Scholar

[23] 赵芳欣, 张瑛洁, 张松, 赵祖欣, 尹绍奎, 李德成 1996 金属学报 32 1056

Zhao F X, Zhang Y J, Zhang S, Zhao Z X, Yin S K, Li D C 1996 Acta Metall. Sin. 32 1056

[24] 徐永波, 白以龙, 沈乐天, 薛青, 李环, 孔丹 1995 金属学报 31 485

Xu Y B, Bai Y L, Shen T L, Xue Q, Li H, Kong D 1995 Acta Metall. Sin. 31 485

[25] 陈奇志, 褚武扬, 乔利杰, 王燕斌, 肖纪美 1994 金属学报 30 248

Chen Q Z, Chu W Y, Qiao L J, Wang Y B, Xiao J M 1994 Acta Metall. Sin. 30 248

[26] Ackland G J, Mendelev M I, Srolovitz D J, Han S, Barashev A V 2004 J. Phys. Condens. Matter 16 S2629

Google Scholar

Google Scholar

[27] Mendelev M I, Han S, Srolovitz D J, Ackland G J, Sun D Y, Asta M 2003 Philos. Mag. 83 3977

Google Scholar

Google Scholar

[28] Plimpton S 1995 J. Comput. Phys. 117 1

Google Scholar

Google Scholar

[29] Stukowski A, Albe K 2010 Modell. Simul. Mater. Sci. Eng. 18 085001

Google Scholar

Google Scholar

-

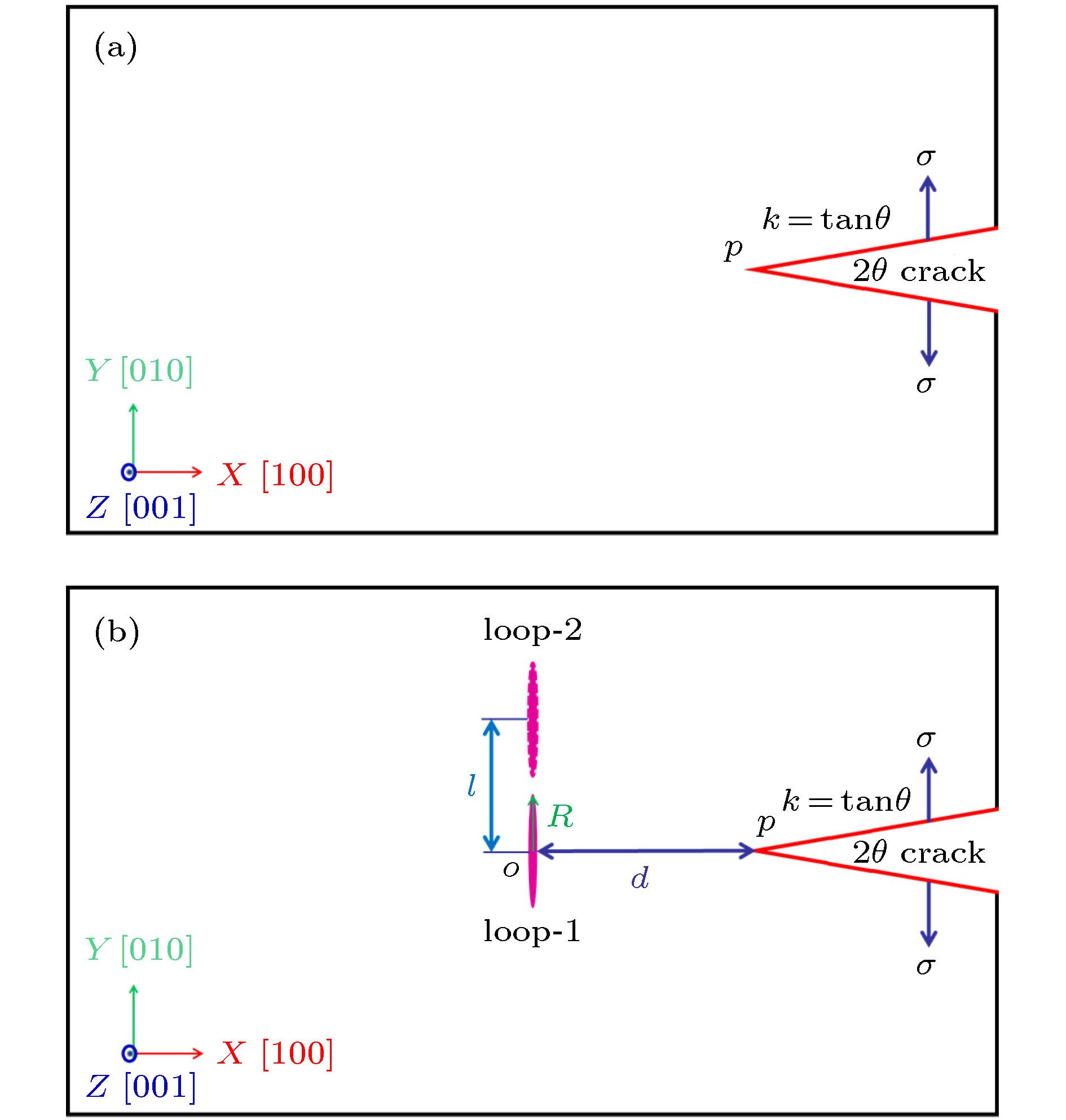

图 1 位错环与微裂纹扩展相互作用模型示意图 (a)无位错环时的微裂纹自由扩展; (b)存在不同位置的位错环时与裂纹扩展相互作用的模型

Figure 1. Schematic of interaction between the interstitial dislocation loop and expansion of micro-crack: (a) The model of micro-crack expansion without the effect of dislocation loop; (b) the model after including the effect of interstitial dislocation loop located at different positions.

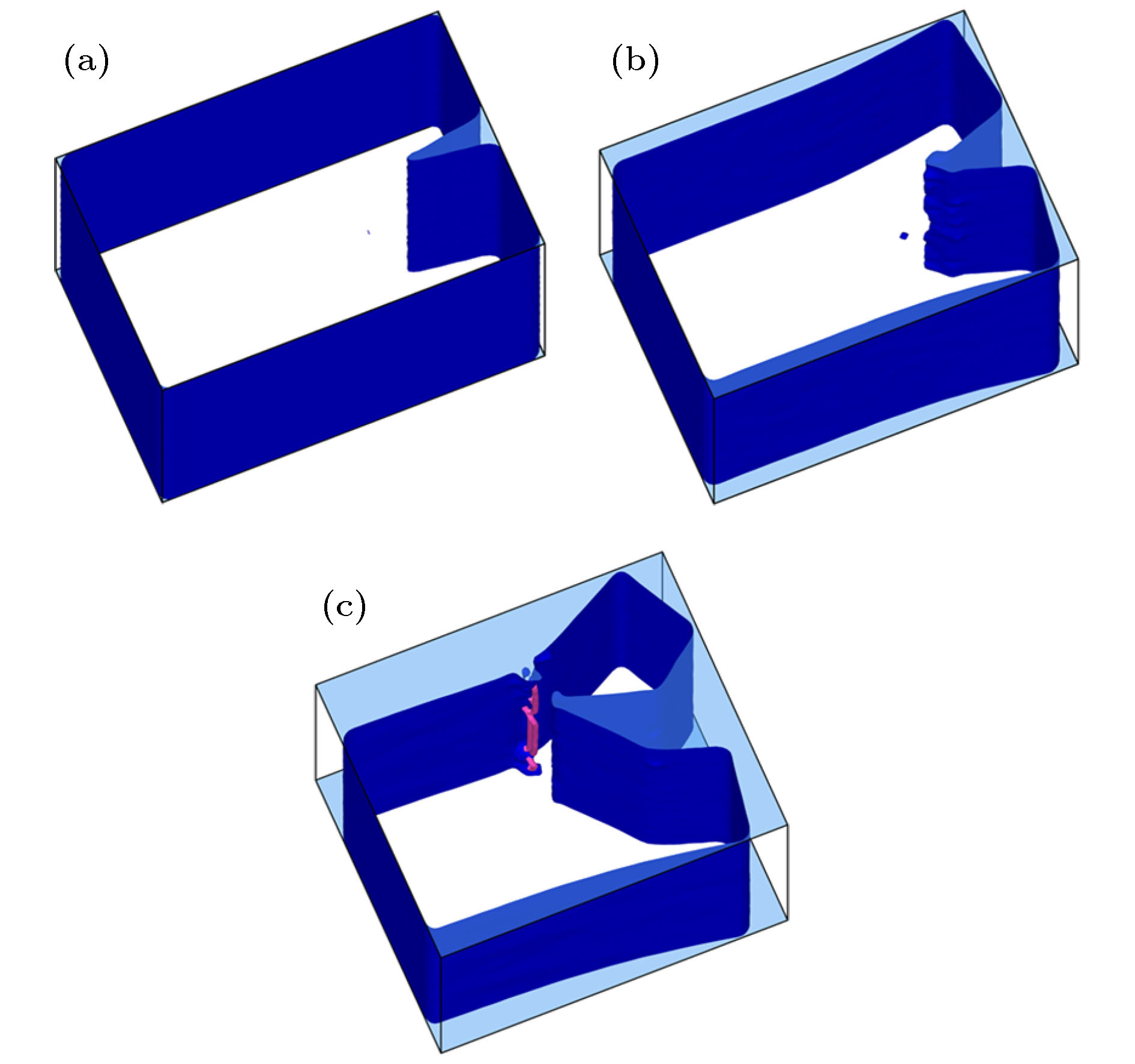

图 3 d = 1.5 nm, R = 1.5 nm, 位错环与微裂纹扩展的相互作用过程, (a)−(c)分别为15, 20和120 ps时的形貌 (a) 反应初始阶段在微裂纹尖端形成凹凸不平; (b)二者反应形成位错网络阶段; (c) 裂纹尖端被位错网络钉扎并保持在XOZ平面

Figure 3. Interaction between interstitial dislocation loop with radius R = 1.5 nm and micro-crack with distance to loop d = 1.5 nm. (a) to (c) are results at time of 15, 20, and 120 ps: (a) The initial stage with the formation of rugged crack tip; (b) the state with the formation of dislocation network after the interaction between loop and crack; (c) the final state with crack tip pinned by dislocation network located on XOZ plane.

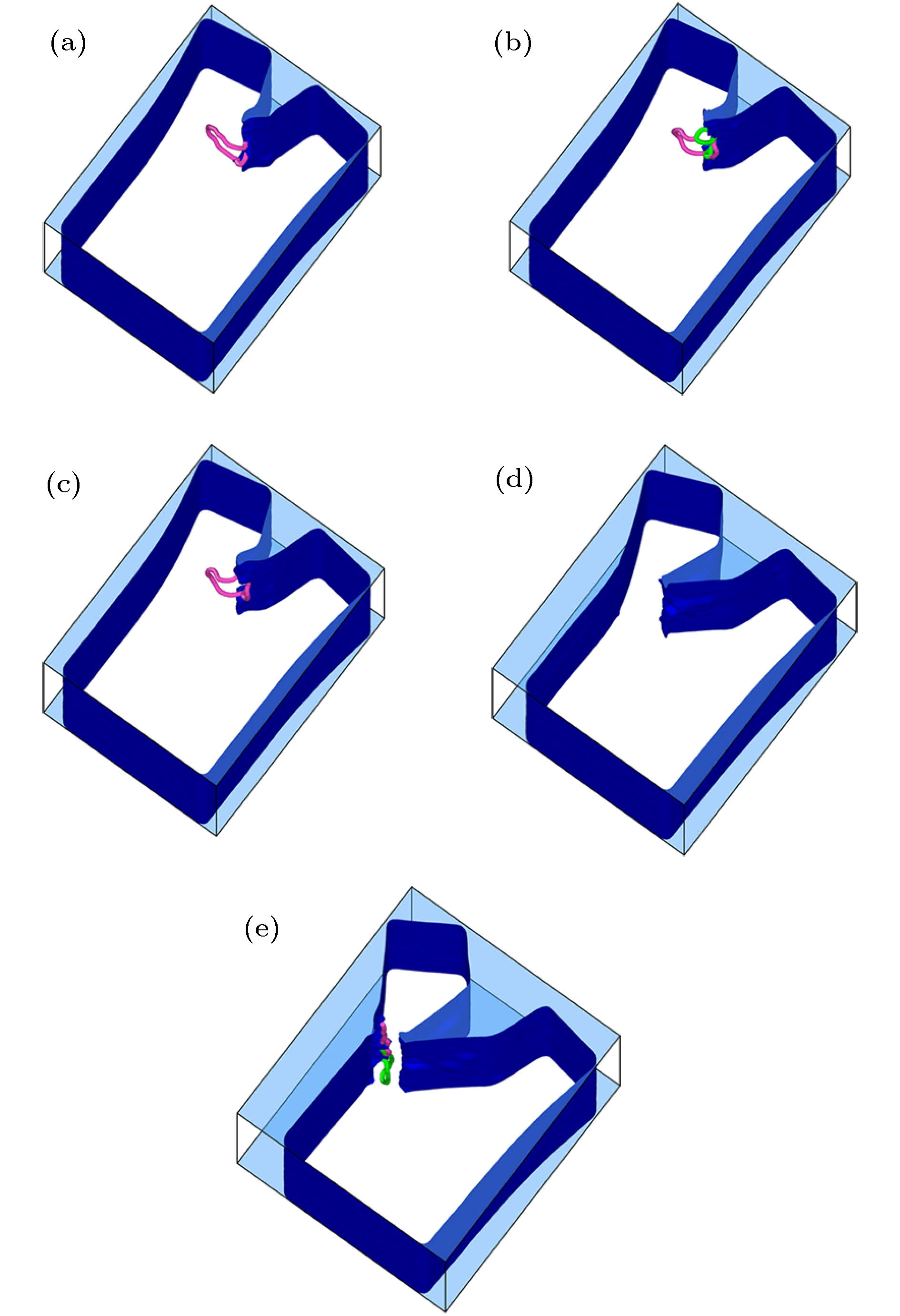

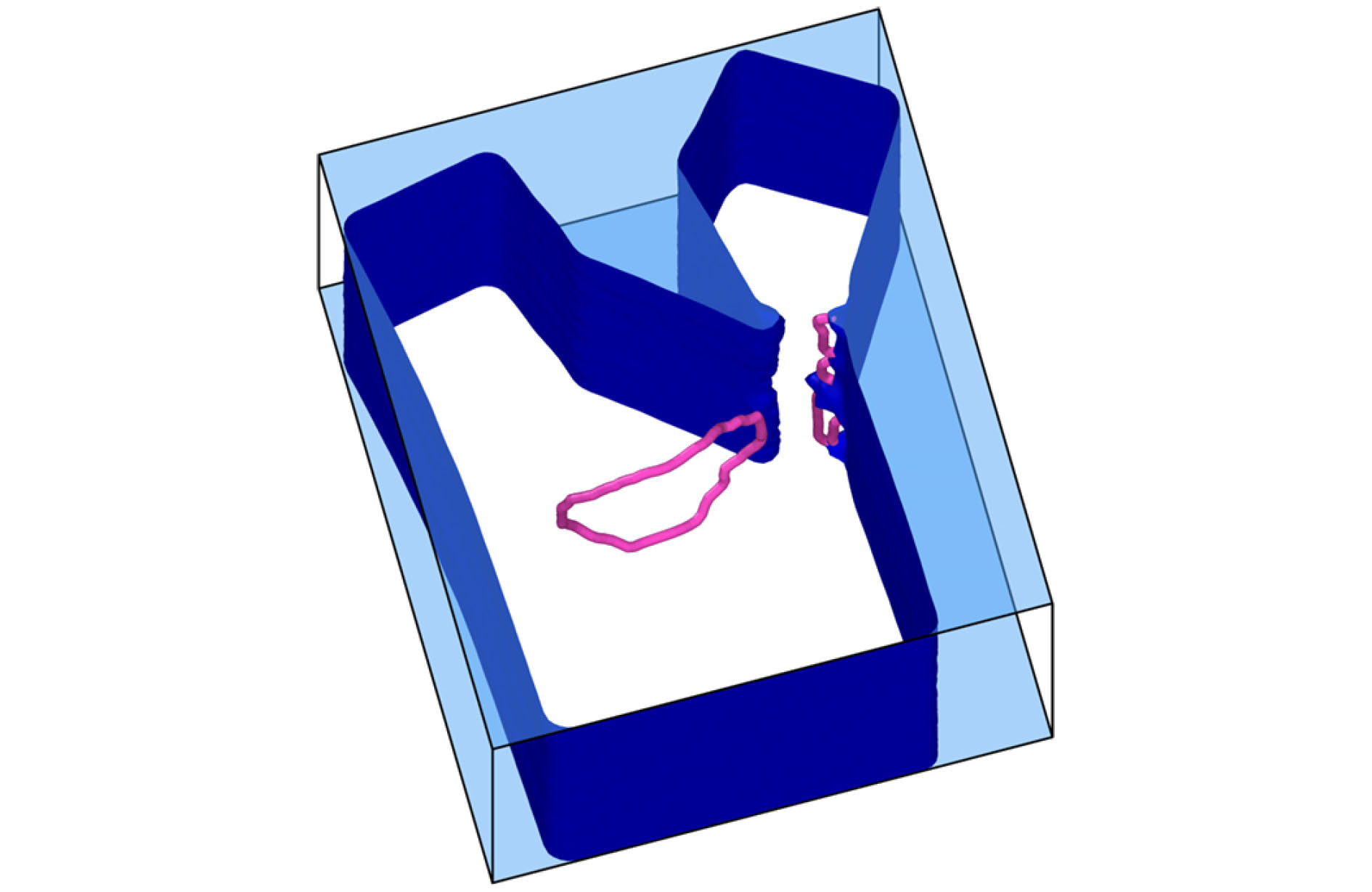

图 4 d = 3.0 nm, R = 1.5 nm, 位错环与微裂纹扩展的相互作用过程, (a)−(c)分别为46, 75和122.6 ps时的形貌 (a)微裂纹在滑移面上开始扩展的初始阶段; (b)形成以1/2

$\left\langle {111} \right\rangle $ 为主的位错网络阶段; (c)微裂纹沿滑移面扩展导致材料断裂的阶段Figure 4. Interaction between interstitial dislocation loop with radius R = 1.5 nm and micro-crack with distance d = 3.0 nm to loop. (a) to (c) are results at time of 46, 75, and 122.6 ps: (a) The stage at the beginning of crack on slip plane by changing the expansion direction; (b) the state with the formation of dislocation network and 1/2

$\left\langle {111} \right\rangle $ segments dominate the network; (c) the final state with crack expansion on slip plane, resulting in the fracture of material. -

[1] Rana M A 2012 Radit. Meas. 47 50

Google Scholar

Google Scholar

[2] Ascheron C, Schindler A, Flagmeyer R, Otto G 1989 Nucl. Instrum. Methods B 36 163

Google Scholar

Google Scholar

[3] Ascheron C, Schindler A, Flagmeyer R, Otto G 1986 Phys. Status Solidi A 96 555

Google Scholar

Google Scholar

[4] Mikkelson R C, Miller J W, Holland R E, Gemmell D S 1973 J. Appl. Phys. 44 935

Google Scholar

Google Scholar

[5] Kohyama A, Hishinuma A, Gelles D S, Klueh R L, Dietz W, Ehrlich K 1996 J. Nucl. Mater. 233–237 138

[6] Jung P 2002 J. Nucl. Mater. 301 15

Google Scholar

Google Scholar

[7] Beyerlein I J, Caro A, Demkowicz M J, Mara N A, Misra A, Uberuaga B P 2013 Mater. Today 16 443

Google Scholar

Google Scholar

[8] Litwa P, Kurpaska L, Varin R A, Perkowski K, Jagielski J, Jozwiak S, Czujko T 2017 J. Alloys Compd. 711 111

Google Scholar

Google Scholar

[9] Wei Y P, Liu P P, Zhu Y M, Wang Z Q, Wan F R, Zhan Q 2016 J. Alloys Compd. 676 481

Google Scholar

Google Scholar

[10] Masters B C 1965 Philos. Mag. 11 881

Google Scholar

Google Scholar

[11] Scott P 1994 J. Nucl. Mater. 211 101

Google Scholar

Google Scholar

[12] Was G S, Busby J T 2005 Philos. Mag. 85 443

Google Scholar

Google Scholar

[13] Fukuya K, Nakano M, Fujii K, Torimaru T, Kitsunai Y 2004 J. Nucl. Sci. Technol. 41 1218

Google Scholar

Google Scholar

[14] 梁晋洁, 高宁, 李玉红 2020 69 036101

Google Scholar

Google Scholar

Liang J J, Gao N, Li Y H 2020 Acta Phys. Sin. 69 036101

Google Scholar

Google Scholar

[15] 黄依娜, 万发荣, 焦治杰 2011 60 036802

Google Scholar

Google Scholar

Huang Y N, Wan F R, Jiao Z J 2011 Acta Phys. Sin. 60 036802

Google Scholar

Google Scholar

[16] 杜玉峰, 崔丽娟, 万发荣 2019 工程科学学报 41 1016

Google Scholar

Google Scholar

Du Y F, Cui L J, Wan F R 2019 Chin. J. Eng. 41 1016

Google Scholar

Google Scholar

[17] 崔丽娟, 高进, 杜玉峰, 张高伟, 张磊, 龙毅, 杨善武, 詹倩, 万发荣 2016 65 066102

Google Scholar

Google Scholar

Cui L J, Gao J, Du Y F, Zhang G W, Zhang L, Long Y, Yang S W, Zhan Q, Wan F R 2016 Acta Phys. Sin. 65 066102

Google Scholar

Google Scholar

[18] 邓平, 孙晨, 彭群家, 韩恩厚, 柯伟 2015 中国腐蚀与防护学报 35 479

Deng P, Sun C, Peng Q J, Han E H, Ke W 2015 J. Chin. Soc. Corros. Prot. 35 479

[19] Gurrutxaga-Lerma B 2018 Int. J. Eng. Sci. 128 165

Google Scholar

Google Scholar

[20] Gupta J, Hure J, Tanguy B, Laffont L, Lafont M C, Andrieu E 2018 J. Nucl. Mater. 501 45

Google Scholar

Google Scholar

[21] Decelis B, Argon A S, Yip S 1983 J. Appl. Phys. 54 4864

Google Scholar

Google Scholar

[22] 董杰, 陈学东, 范志超, 江慧峰, 陆守香 2008 金属学报 44 1167

Google Scholar

Google Scholar

Dong J, Chen X D, Fan Z C, Jiang H F, Lu S X 2008 Acta Metall. Sin. 44 1167

Google Scholar

Google Scholar

[23] 赵芳欣, 张瑛洁, 张松, 赵祖欣, 尹绍奎, 李德成 1996 金属学报 32 1056

Zhao F X, Zhang Y J, Zhang S, Zhao Z X, Yin S K, Li D C 1996 Acta Metall. Sin. 32 1056

[24] 徐永波, 白以龙, 沈乐天, 薛青, 李环, 孔丹 1995 金属学报 31 485

Xu Y B, Bai Y L, Shen T L, Xue Q, Li H, Kong D 1995 Acta Metall. Sin. 31 485

[25] 陈奇志, 褚武扬, 乔利杰, 王燕斌, 肖纪美 1994 金属学报 30 248

Chen Q Z, Chu W Y, Qiao L J, Wang Y B, Xiao J M 1994 Acta Metall. Sin. 30 248

[26] Ackland G J, Mendelev M I, Srolovitz D J, Han S, Barashev A V 2004 J. Phys. Condens. Matter 16 S2629

Google Scholar

Google Scholar

[27] Mendelev M I, Han S, Srolovitz D J, Ackland G J, Sun D Y, Asta M 2003 Philos. Mag. 83 3977

Google Scholar

Google Scholar

[28] Plimpton S 1995 J. Comput. Phys. 117 1

Google Scholar

Google Scholar

[29] Stukowski A, Albe K 2010 Modell. Simul. Mater. Sci. Eng. 18 085001

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 10901

- PDF Downloads: 132

- Cited By: 0

DownLoad:

DownLoad: