-

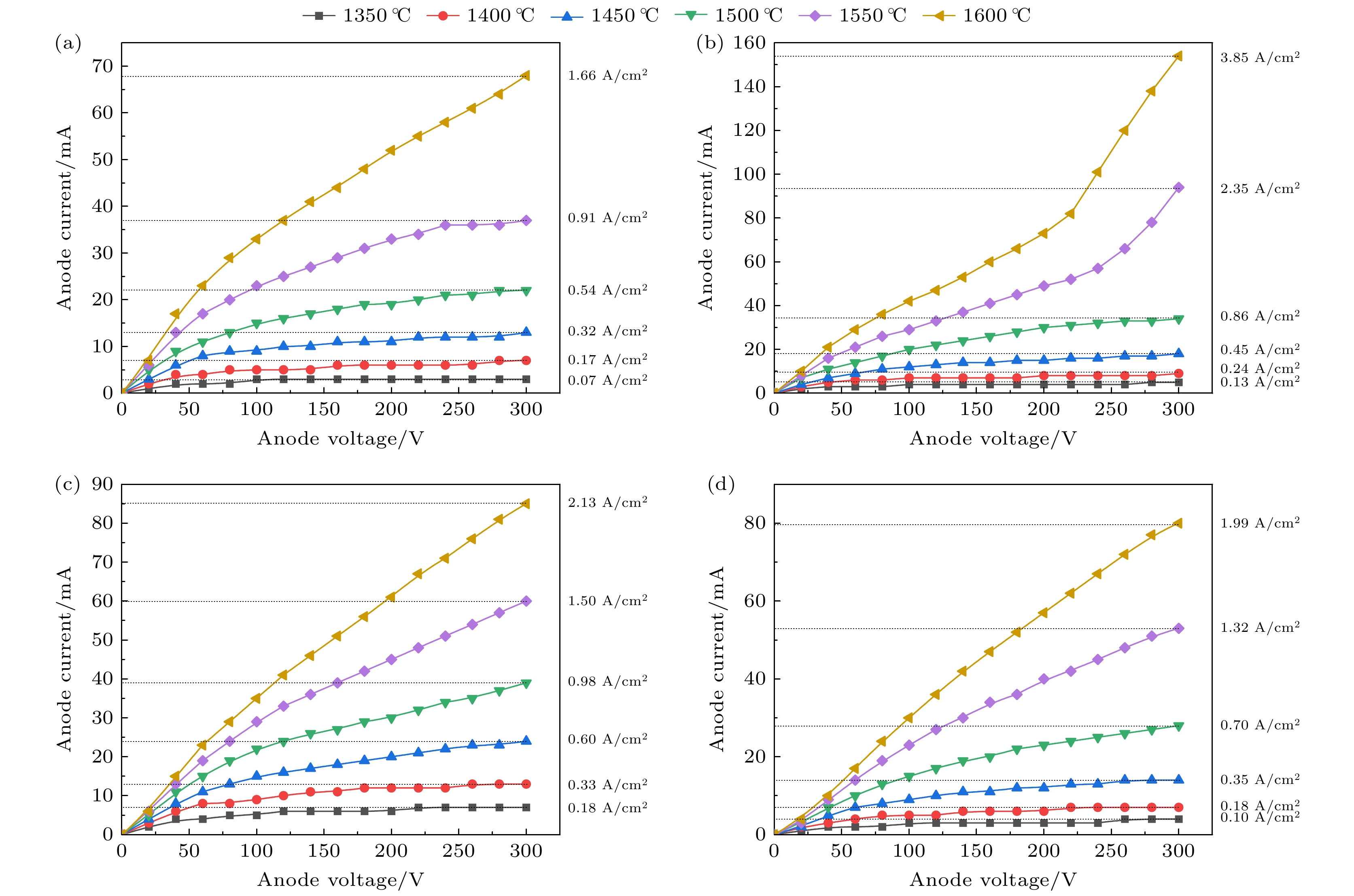

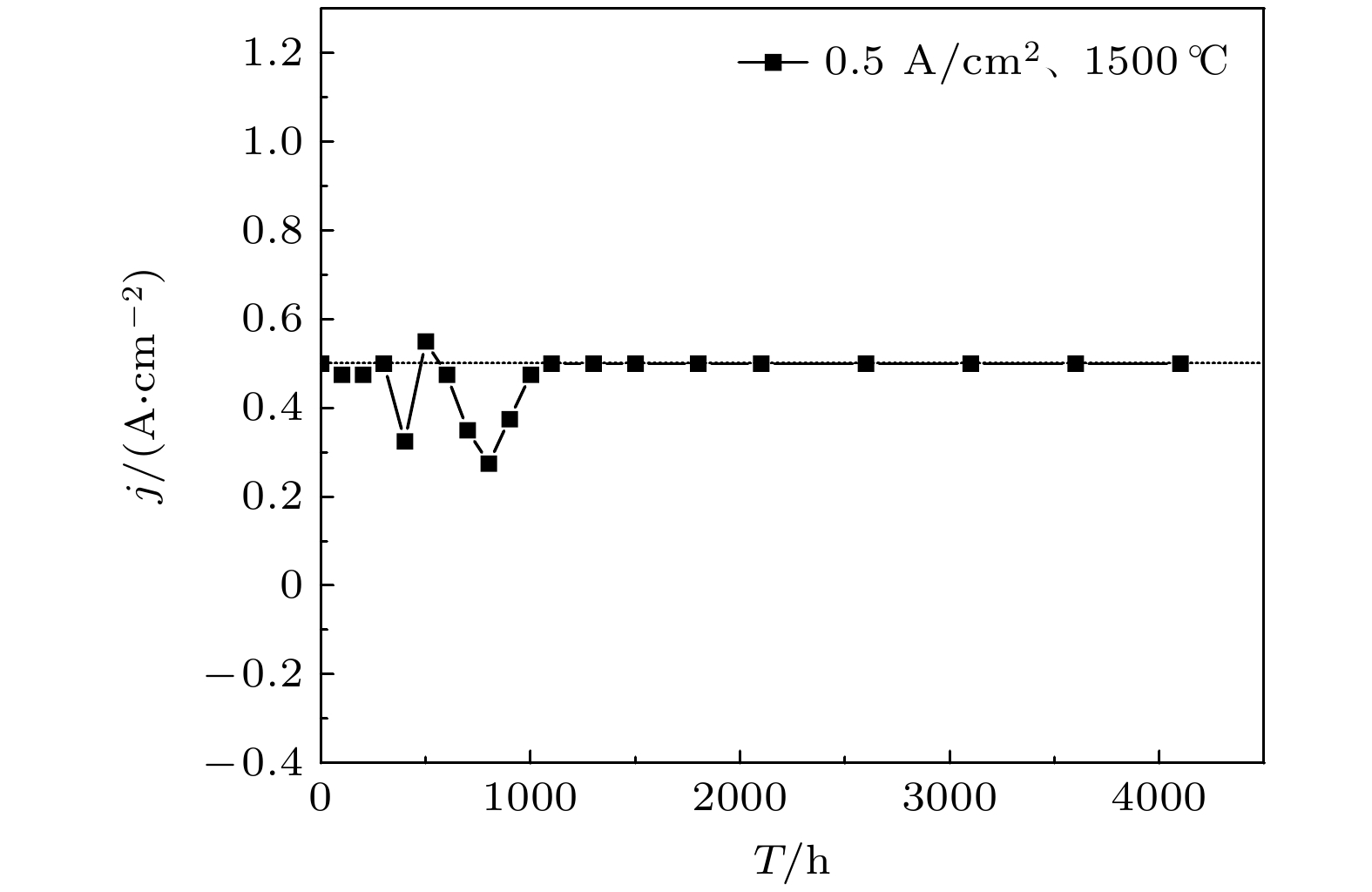

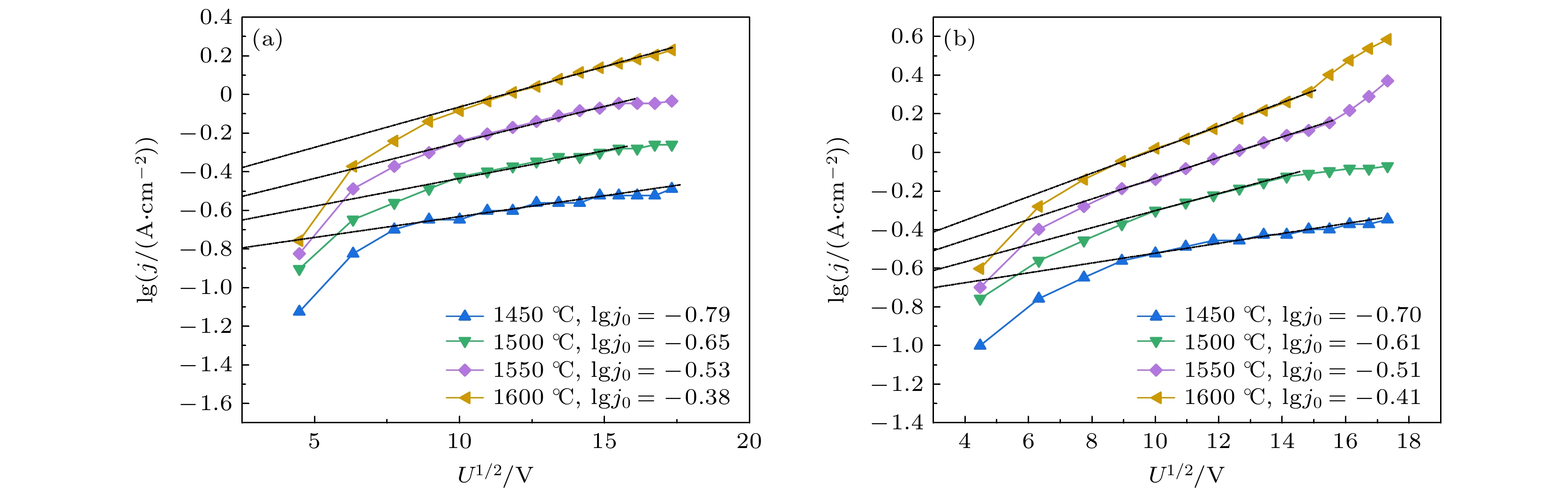

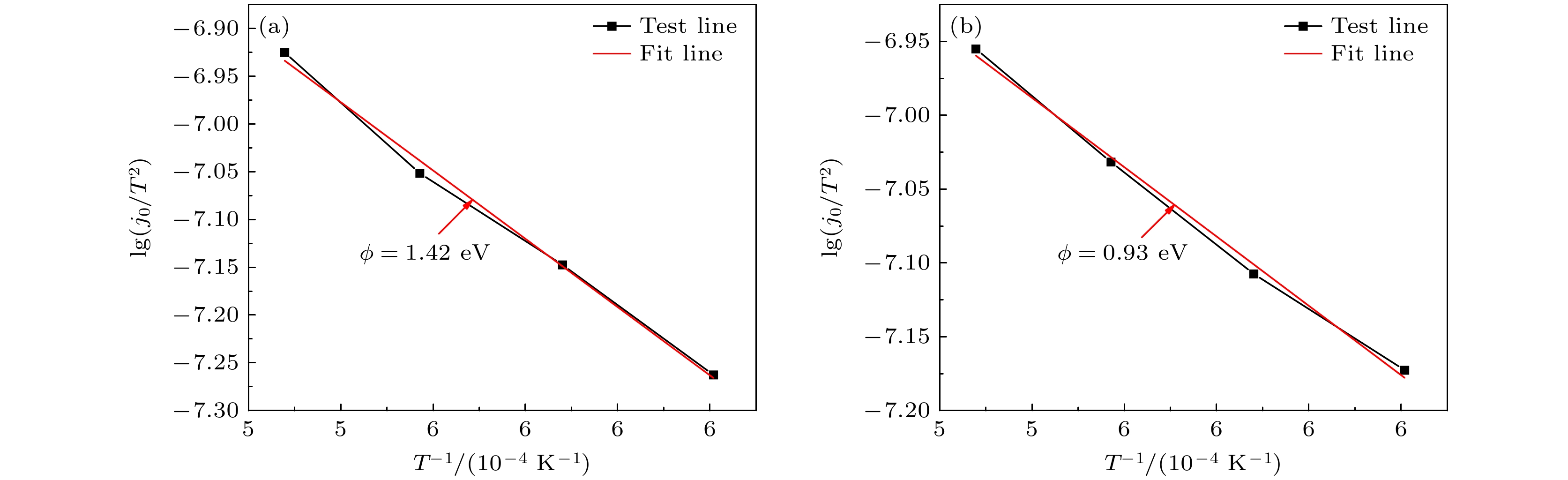

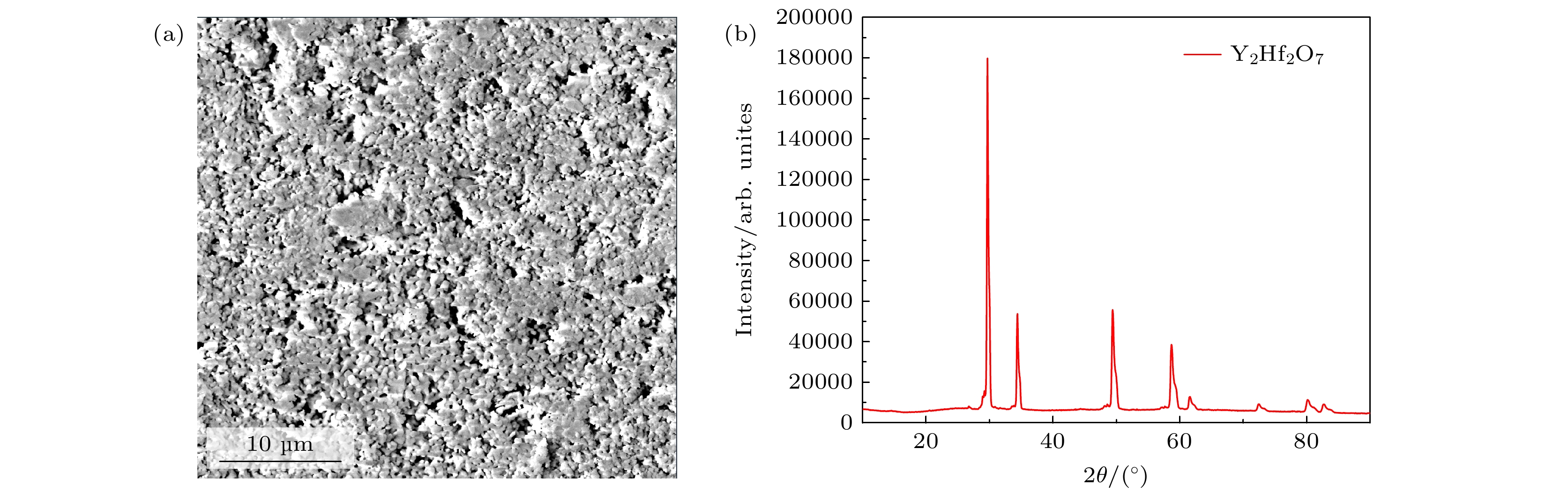

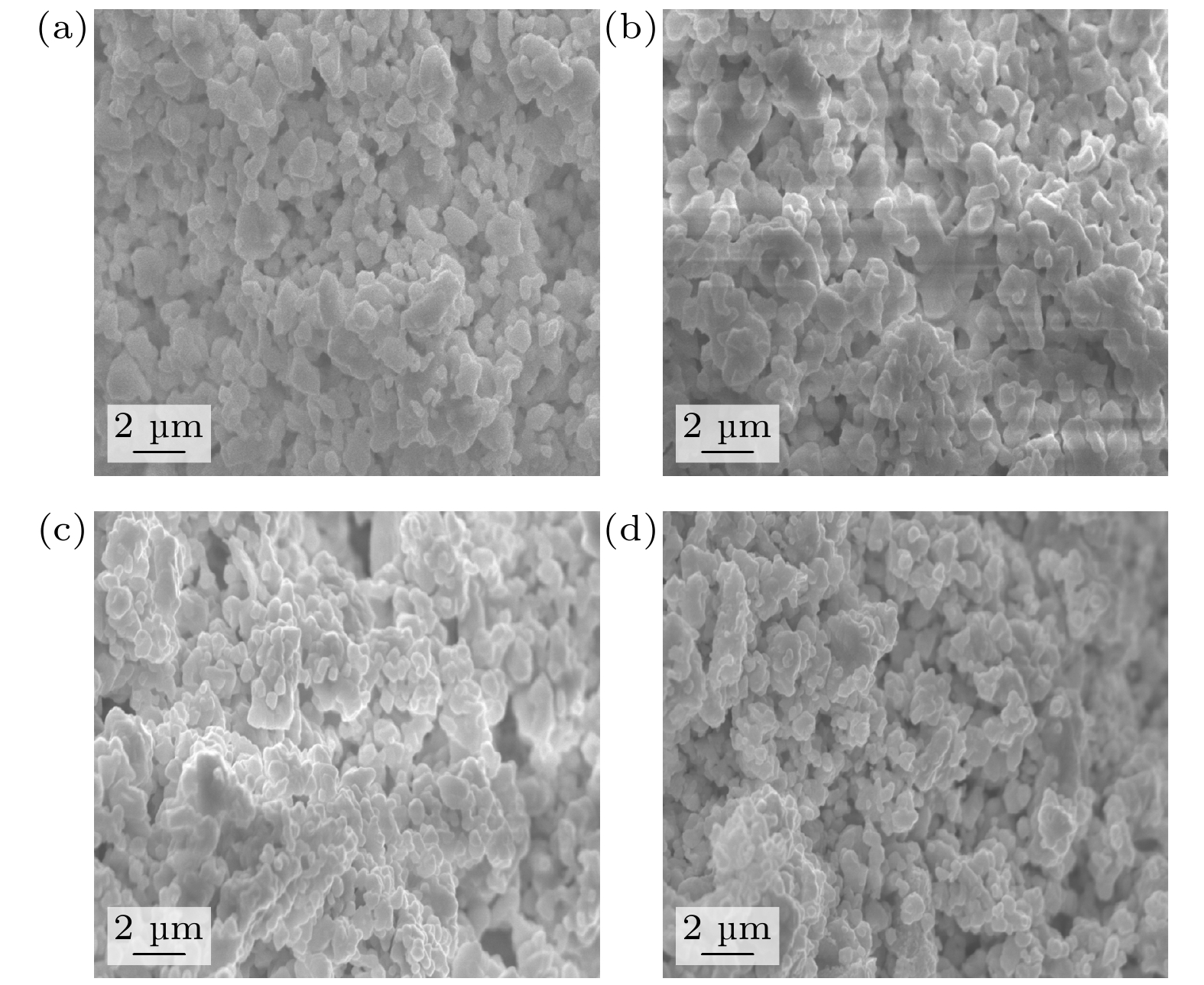

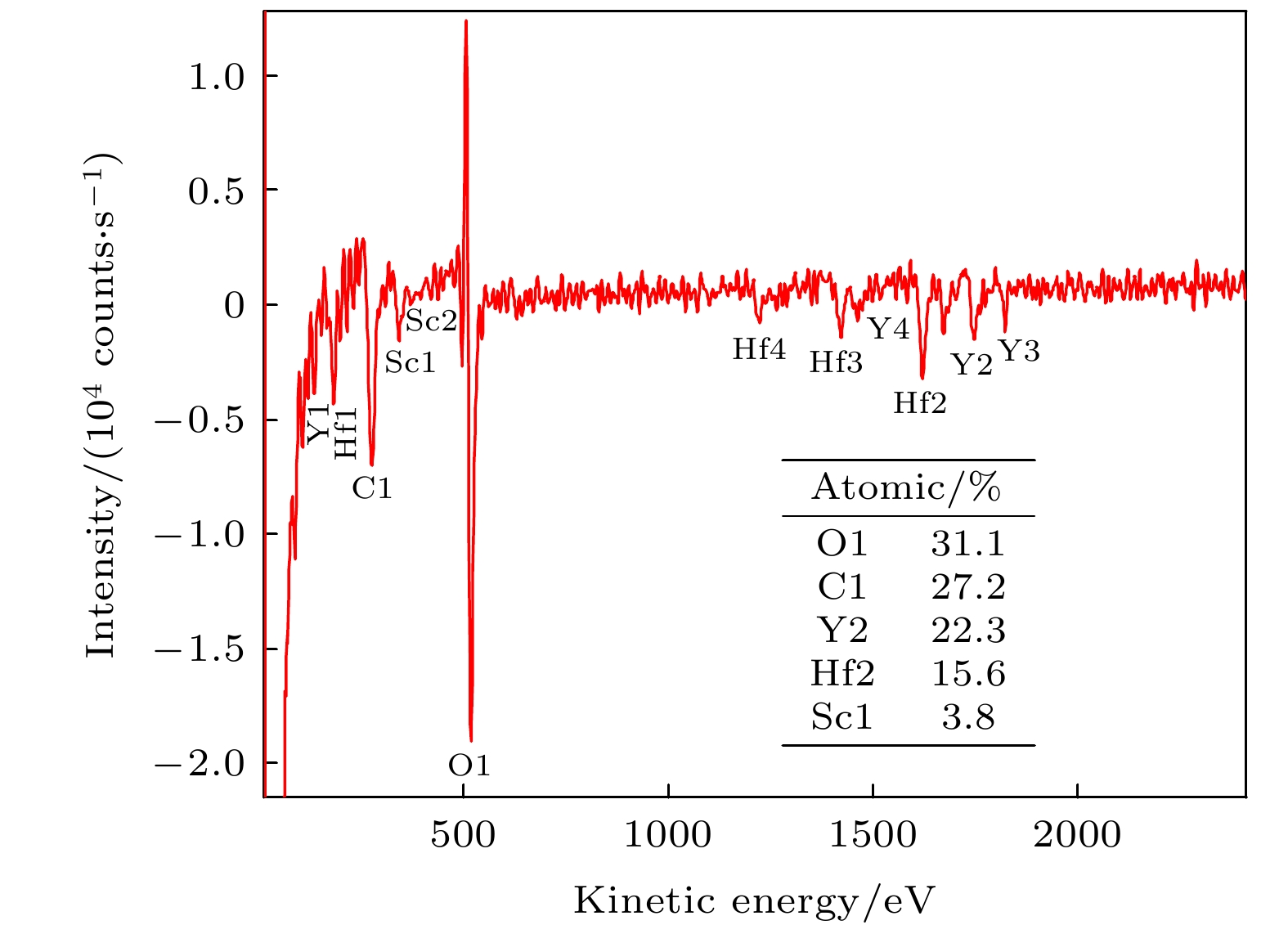

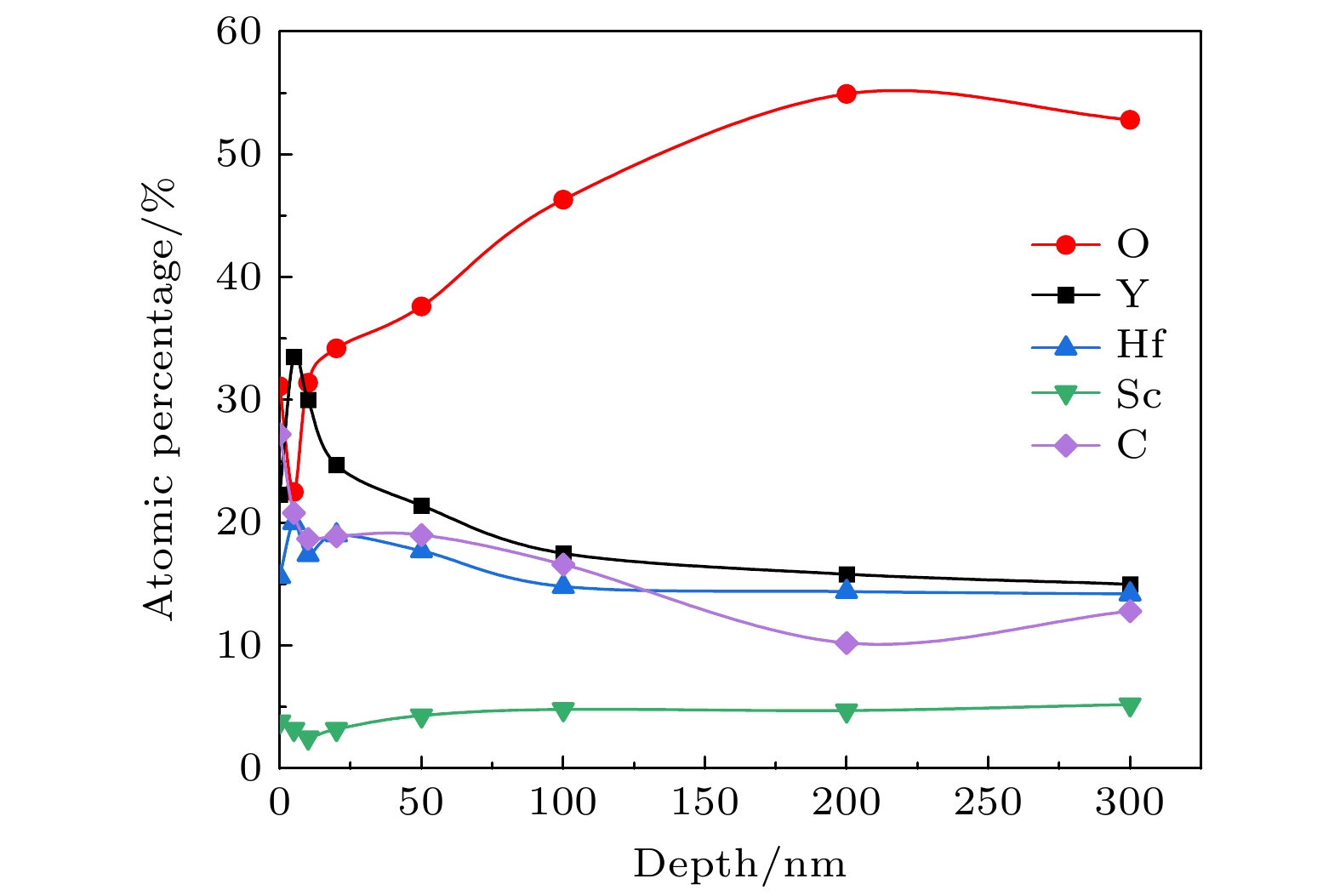

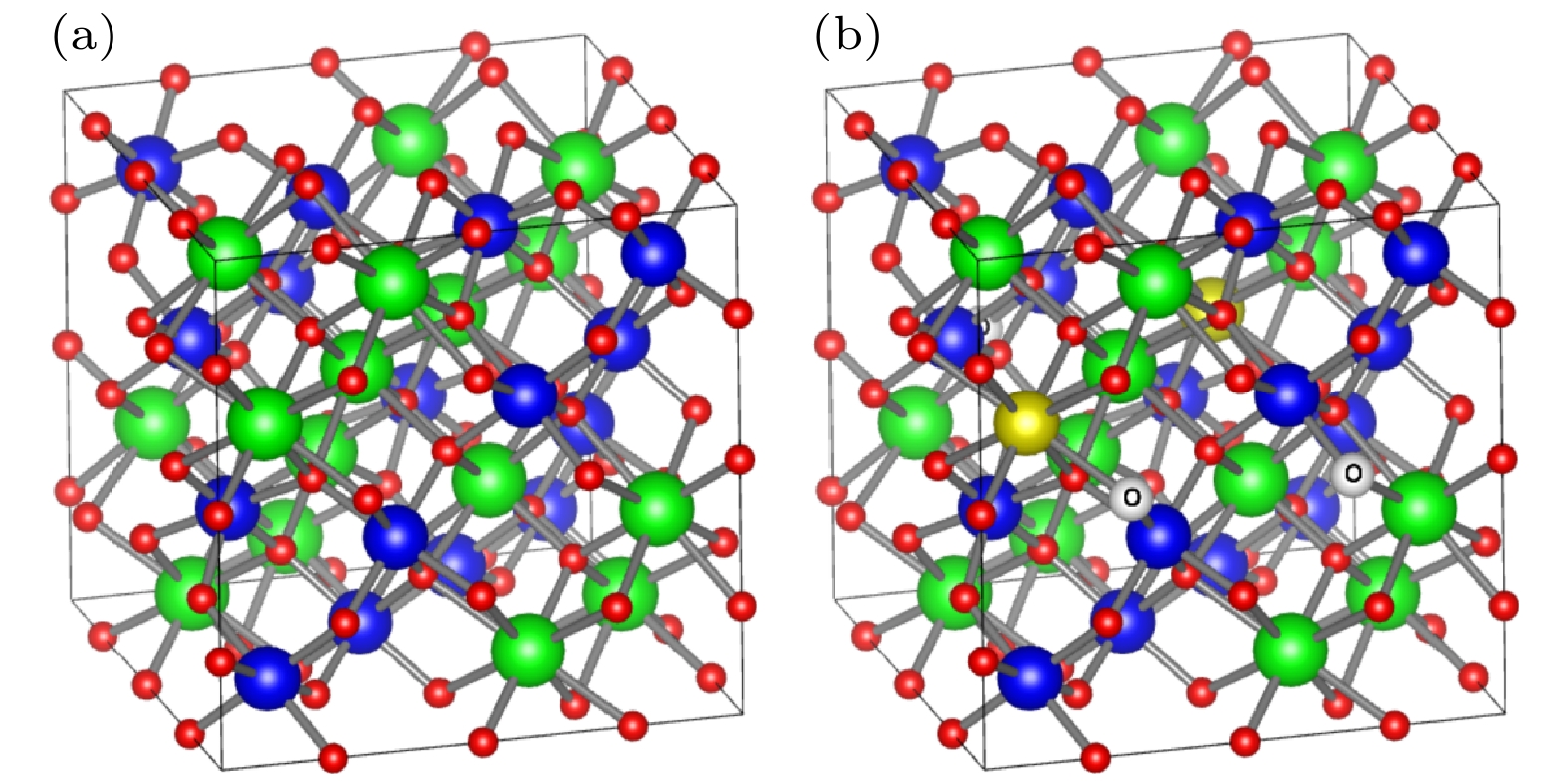

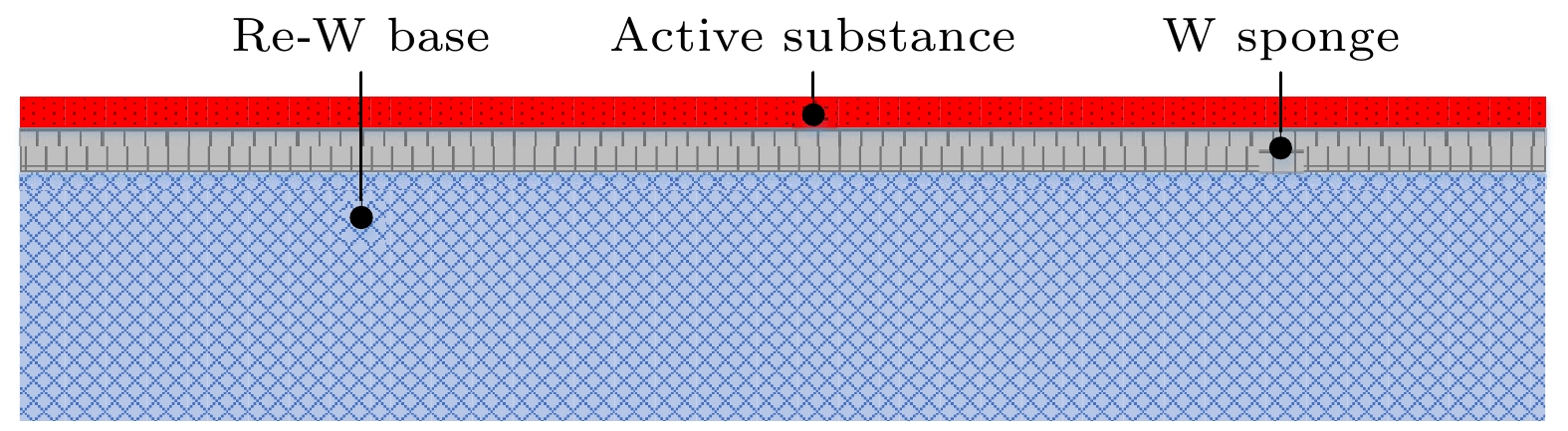

为了提高磁控管用稀土难熔钇盐阴极的热发射能力, 探索Sc2O3掺杂对稀土难熔钇盐阴极热发射性能的影响机理, 采用Sc2O3掺杂稀土难熔钇盐来制备阴极, 并测试该阴极的热发射性能. 热发射测试结果表明, Sc2O3掺杂能够有效地提高稀土难熔钇盐阴极的热发射能力. 其中, 3% Sc2O3 (3%为质量分数, 后同)掺杂能够最大程度地提高阴极的热发射能力, 当阳压为300 V, 温度为1600 ℃时, 3% Sc2O3掺杂阴极可以支取3.85 A/cm2的热发射电流. 而在相同条件下, 未掺杂Sc2O3阴极, 即稀土难熔钇盐阴极仅可以支取1.66 A/cm2的热发射电流, 3% Sc2O3掺杂能够将该阴极的热发射能力提升132%. 寿命试验结果表明, 当负载电流为0.5 A/cm2, 温度为1500 ℃时, 3% Sc2O3掺杂阴极的试验寿命已经超过4200 h, 且没有明显的衰减迹象. 最后, 利用扫描电子显微镜、能谱仪、X射线衍射仪、扫描俄歇纳米探针等对阴极进行详细分析. 结果表明, 热发射测试过程中, 一方面, 掺杂的Sc2O3和Y2Hf2O7发生了置换固溶反应, 生成了ScxY(2–x)Hf2O[7+(3/2)x]固溶体, 造成Y2Hf2O7晶格畸变, 导致晶格处于高能状态, 降低了阴极表面的逸出功, 与此同时, Sc2O3中的Sc置换掉了Y2Hf2O7晶胞中Y, 被置换出来的Y以金属单质形式存在, 改善了阴极表面的导电性. 另一方面, ScxY(2–x)Hf2O[7+(3/2)x]固溶体中会产生一定数量的Vo2+氧空位和自由电子, 也使得阴极表面的导电性能得到改善. 最终, 在这两方面的共同作用下, 阴极的热发射能力得到显著的提高.To improve the thermionic emission performance of the rare-earth refractory yttrium salt cathode used in the magnetron, the influence of Sc2O3 doping on its thermionic emission properties is investigated. Cathodes are fabricated by incorporating different weight percentages of Sc2O3 into the rare-earth refractory yttrium salt matrix, and their thermionic emission properties are systematically evaluated. The experimental findings reveal that the doping of Sc2O3 significantly enhances the thermionic emission capability of the cathode. Notably, Sc2O3 with a doping concentration of 3% has the most significant improvement in emission performance. The 3% Sc2O3-doped cathode can achieve a thermionic emission current density of 3.85 A/cm2 under an anode voltage of 300 V at 1600 ℃. In contrast, under the same conditions, the undoped cathode provides a current density of only 1.66 A/cm2, indicating a 132% increase in thermionic emission efficiency when doped with 3% Sc2O3. By using the Richardson line method coupled with data-fitting algorithms, the absolute zero work functions for undoped and Sc2O3-doped cathodes (3%, 7%, and 11%) are determined to be 1.42, 0.93, 0.98, and 1.11 eV, respectively. The lifespan assessment indicates that at 1400℃ the cathode doped with 3% Sc2O3 remains stable for over 4200 h under an initial load of 0.5 A/cm2 without significant degradation. Finally, those cathodes are analyzed by the XRD, SEM, EDS, AES respectively. The analyses show that during thermionic emission testing, the Sc2O3 and Y2Hf2O7 undergo substitutional solid solution reactions, forming the ScxY(2–x)Hf2O[7+(3/2)x] solid solution. This process causes lattice distortion in the Y2Hf2O7, which makes it in a high-energy state, thus reducing the work function on the cathode surface. At the same time, Sc from Sc2O3 displaces Y in the Y2Hf2O7 unit cells, with the displaced Y existing in the form of metal, which enhances the electrical conductivity of the cathode surface. Additionally, the ScxY(2–x)Hf2O[7+(3/2)x] solid solution generates a substantial number of Vo2+ oxygen vacancies and free electrons, thereby further augmenting surface conductivity. All in all, these mechanisms contribute to significantly improving the thermionic emission capability of the cathode.

-

Keywords:

- Sc2O3 doping /

- thermionic emission /

- emission mechanism /

- magnetron

[1] Vyas S K, Verma R K, Maurya S 2016 Frequenz 70 455

Google Scholar

Google Scholar

[2] Patibandla A, Dobbidi P, Tiwari T 2023 24th International Vacuum Electronics Conference (IVEC) Chengdu, China, April 25–28, 2023 p1

[3] Lim H, Jeong D H, Lee M, Ro S C 2017 IEEE Trans. Plasma. Sci. 45 2734

Google Scholar

Google Scholar

[4] Shang J H, Yang X Y, Wang Z Y, Hu M Y, Han C L, Zhang J X 2020 IEEE Trans. Elec. Dev. 67 2580

Google Scholar

Google Scholar

[5] Timofeev N A, Sukhomlinov V S, Georges Z 2021 IEEE Trans. Plasma Sci. 49 2387

Google Scholar

Google Scholar

[6] Bergner A, Scharf F H, Kühn G, Ruhrmann C, Hoebing T, Awakowicz P, Mentel J 2014 Plasma Sources Sci. T. 23 054005

Google Scholar

Google Scholar

[7] Makarov A P, Zemchikhin E M 2019 IEEE Proceedings of IVEC Busan, Korea (South), April 28–May 1, 2019 p112

[8] Djubua B C, Polivnikova O V 2003 Appl. Surf. Sci. 215 242

Google Scholar

Google Scholar

[9] Djubua B C, Kultashev O K, Kultashev A P, Polivnikova O V 2012 IEEE Proceedings of IVESC Monterey, CA, USA, April 24–26, 2012 p185

[10] Hu M W, Wang X X, Qi S K 2019 IEEE Trans. Elec. Dev. 66 3592

Google Scholar

Google Scholar

[11] Wang X X, Meng M F, Zhang R Q, Li Y, Zhang Q 2023 IEEE Proceedings of IVEC Chengdu, China, April 25-28, 2023 p1145

[12] Wang X X, Liu Y W, Luo J R, Zhan Q L, Li Y, Zhang Q 2014 IEEE Trans. Elec. Dev. 61 605

Google Scholar

Google Scholar

[13] Zhang R Q, Wang X X, Ren F, Yin S Y 2024 IEEE Trans. Elec. Dev. 71 2078

Google Scholar

Google Scholar

[14] Zhang R Q, Ding S X, Wang X X, Ren F, Yin S Y 2025 IEEE Trans. Elec. Dev. 72 1427

Google Scholar

Google Scholar

[15] Mujan N S, Zhou Q F, Liu X T, John B, Matthew J B 2022 IEEE Trans. Elec. Dev. 69 3513

Google Scholar

Google Scholar

[16] Wang J S, Dong L R, Liu W, Yang F 2017 Sci. China Technol. Sc. 60 1439

Google Scholar

Google Scholar

[17] Yang F, Wang J S, Liu W, Liu X, Zhou M L 2013 Appl Surface Sci. 270 746

Google Scholar

Google Scholar

[18] Yang F, Wang J S, Liu W, Zhou M L 2015 Mater. Chem. Phys. 149–150 288

Google Scholar

Google Scholar

[19] Wang X Q, Wang X X, Luo J R, Qi S K, Li Y 2023 IEEE Trans. Elec. Dev. 70 2883

Google Scholar

Google Scholar

[20] 漆世锴, 王小霞, 罗积润, 赵青兰, 李云 2016 65 057901

Google Scholar

Google Scholar

Qi S K, Wang X X, Luo J R, Zhao Q L, Li Y 2016 Acta Phys. Sin. 65 057901

Google Scholar

Google Scholar

[21] Sakharov K A, Simonenko E P, Simonenko N P 2018 Ceram. Int. 44 7647

Google Scholar

Google Scholar

[22] 周宏明, 易丹青 2008 无机材料学报 23 247

Google Scholar

Google Scholar

Zhou H M, Yi D Q 2008 J. Inorg. Mater. 23 247

Google Scholar

Google Scholar

[23] 袁志谦, 周增林, 李艳, 何学良, 陈文帅, 张婉婷 2024 材料导报 39 24100155

Yuan Z Q, Zhou Z L, Li Y, He X L, Chen W S, Zhang W T 2024 Materials Reports 39 24100155

[24] Prashar G, Vasudev H, Thakur L 2023 Prot. Met. Phys. Chem. Surf. 59 461

Google Scholar

Google Scholar

[25] Wang J S, Chen M D, Li C Z, Chen L Y, Yu Y S, Wang Y H, Liu B, Jing Q S 2021 Surf. Coat. Technol. 428 127879

Google Scholar

Google Scholar

[26] Guo Y Q, Guo L, Liu K Y, Qiu S Y, Guo H B, Xu H B 2024 J. Mater. Sci. Technol. 182 33

Google Scholar

Google Scholar

-

表 1 未掺杂、3%、7%、11% Sc2O3掺杂阴极表面元素成分及其原子百分比

Table 1. Element contents of the undoped, 3%, 7%, 11% Sc2O3 doped cathode and their atomic percentage.

Cathode type Element type/% Sc Y Hf O Undoped Sc2O3 0 19.88 25.23 54.89 3% Sc2O3 doped 0 22.03 26.35 51.62 7% Sc2O3 doped 6.37 16.99 18.25 58.39 11% Sc2O3 doped 15.10 12.81 18.98 53.11 表 2 O, Y, Hf, Sc, C元素原子百分比与氩离子蚀刻深度的关系

Table 2. O, Y, Hf, Sc, C atomic percentage as a function of the depth using argon ion etching method

Depth/nm O/% Y/% Hf/% Sc/% C/% 0 31.1 22.3 15.6 3.8 27.2 5 22.5 33.5 20.0 3.2 20.8 10 31.4 30.0 17.4 2.5 18.7 20 34.2 24.7 19.0 3.2 18.9 50 37.6 21.4 17.7 4.3 19.0 100 46.3 17.5 14.8 4.8 16.6 200 54.9 15.8 14.4 4.7 10.2 300 52.8 15.0 14.2 5.2 12.8 -

[1] Vyas S K, Verma R K, Maurya S 2016 Frequenz 70 455

Google Scholar

Google Scholar

[2] Patibandla A, Dobbidi P, Tiwari T 2023 24th International Vacuum Electronics Conference (IVEC) Chengdu, China, April 25–28, 2023 p1

[3] Lim H, Jeong D H, Lee M, Ro S C 2017 IEEE Trans. Plasma. Sci. 45 2734

Google Scholar

Google Scholar

[4] Shang J H, Yang X Y, Wang Z Y, Hu M Y, Han C L, Zhang J X 2020 IEEE Trans. Elec. Dev. 67 2580

Google Scholar

Google Scholar

[5] Timofeev N A, Sukhomlinov V S, Georges Z 2021 IEEE Trans. Plasma Sci. 49 2387

Google Scholar

Google Scholar

[6] Bergner A, Scharf F H, Kühn G, Ruhrmann C, Hoebing T, Awakowicz P, Mentel J 2014 Plasma Sources Sci. T. 23 054005

Google Scholar

Google Scholar

[7] Makarov A P, Zemchikhin E M 2019 IEEE Proceedings of IVEC Busan, Korea (South), April 28–May 1, 2019 p112

[8] Djubua B C, Polivnikova O V 2003 Appl. Surf. Sci. 215 242

Google Scholar

Google Scholar

[9] Djubua B C, Kultashev O K, Kultashev A P, Polivnikova O V 2012 IEEE Proceedings of IVESC Monterey, CA, USA, April 24–26, 2012 p185

[10] Hu M W, Wang X X, Qi S K 2019 IEEE Trans. Elec. Dev. 66 3592

Google Scholar

Google Scholar

[11] Wang X X, Meng M F, Zhang R Q, Li Y, Zhang Q 2023 IEEE Proceedings of IVEC Chengdu, China, April 25-28, 2023 p1145

[12] Wang X X, Liu Y W, Luo J R, Zhan Q L, Li Y, Zhang Q 2014 IEEE Trans. Elec. Dev. 61 605

Google Scholar

Google Scholar

[13] Zhang R Q, Wang X X, Ren F, Yin S Y 2024 IEEE Trans. Elec. Dev. 71 2078

Google Scholar

Google Scholar

[14] Zhang R Q, Ding S X, Wang X X, Ren F, Yin S Y 2025 IEEE Trans. Elec. Dev. 72 1427

Google Scholar

Google Scholar

[15] Mujan N S, Zhou Q F, Liu X T, John B, Matthew J B 2022 IEEE Trans. Elec. Dev. 69 3513

Google Scholar

Google Scholar

[16] Wang J S, Dong L R, Liu W, Yang F 2017 Sci. China Technol. Sc. 60 1439

Google Scholar

Google Scholar

[17] Yang F, Wang J S, Liu W, Liu X, Zhou M L 2013 Appl Surface Sci. 270 746

Google Scholar

Google Scholar

[18] Yang F, Wang J S, Liu W, Zhou M L 2015 Mater. Chem. Phys. 149–150 288

Google Scholar

Google Scholar

[19] Wang X Q, Wang X X, Luo J R, Qi S K, Li Y 2023 IEEE Trans. Elec. Dev. 70 2883

Google Scholar

Google Scholar

[20] 漆世锴, 王小霞, 罗积润, 赵青兰, 李云 2016 65 057901

Google Scholar

Google Scholar

Qi S K, Wang X X, Luo J R, Zhao Q L, Li Y 2016 Acta Phys. Sin. 65 057901

Google Scholar

Google Scholar

[21] Sakharov K A, Simonenko E P, Simonenko N P 2018 Ceram. Int. 44 7647

Google Scholar

Google Scholar

[22] 周宏明, 易丹青 2008 无机材料学报 23 247

Google Scholar

Google Scholar

Zhou H M, Yi D Q 2008 J. Inorg. Mater. 23 247

Google Scholar

Google Scholar

[23] 袁志谦, 周增林, 李艳, 何学良, 陈文帅, 张婉婷 2024 材料导报 39 24100155

Yuan Z Q, Zhou Z L, Li Y, He X L, Chen W S, Zhang W T 2024 Materials Reports 39 24100155

[24] Prashar G, Vasudev H, Thakur L 2023 Prot. Met. Phys. Chem. Surf. 59 461

Google Scholar

Google Scholar

[25] Wang J S, Chen M D, Li C Z, Chen L Y, Yu Y S, Wang Y H, Liu B, Jing Q S 2021 Surf. Coat. Technol. 428 127879

Google Scholar

Google Scholar

[26] Guo Y Q, Guo L, Liu K Y, Qiu S Y, Guo H B, Xu H B 2024 J. Mater. Sci. Technol. 182 33

Google Scholar

Google Scholar

计量

- 文章访问数: 414

- PDF下载量: 12

- 被引次数: 0

下载:

下载: