-

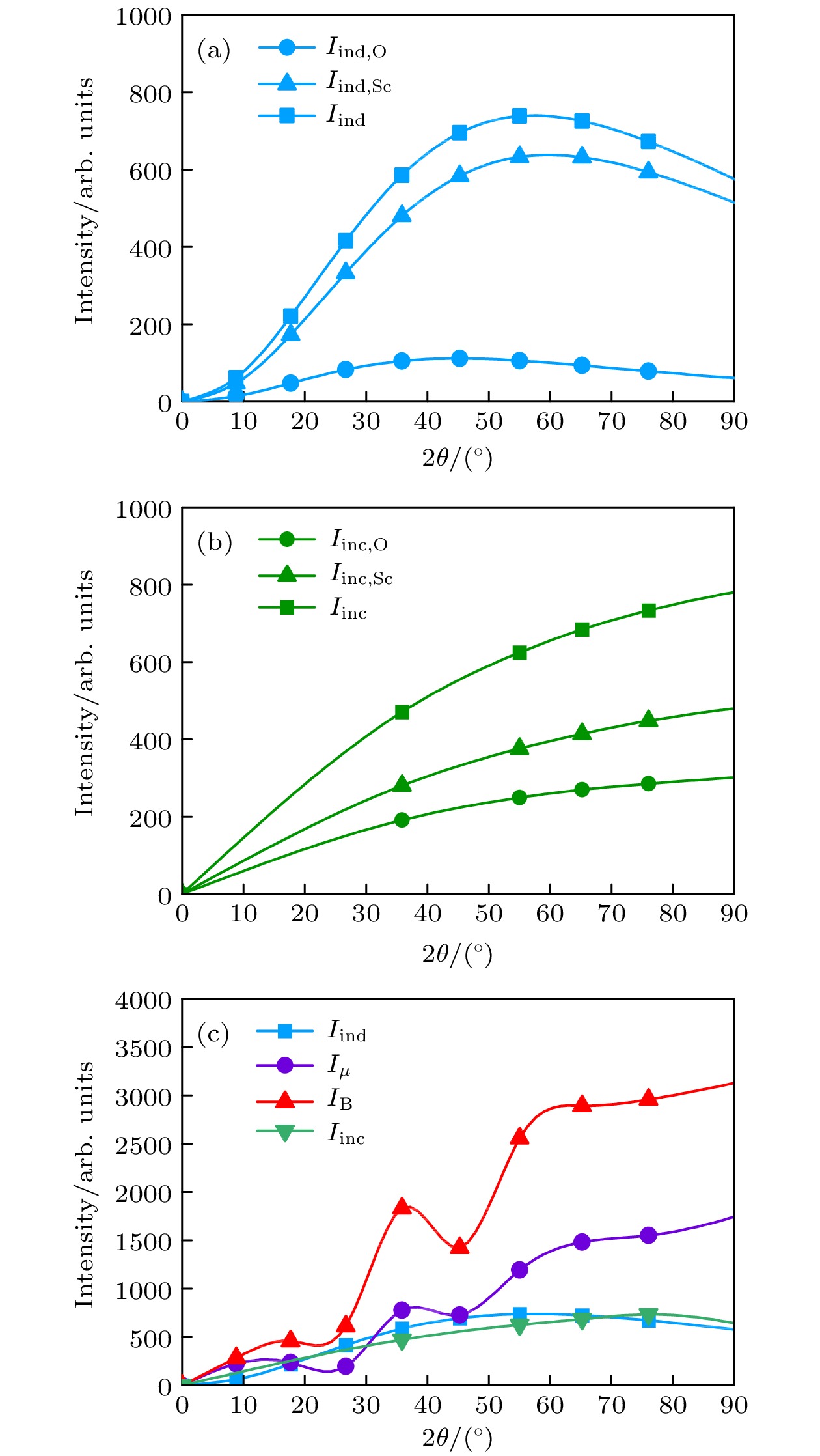

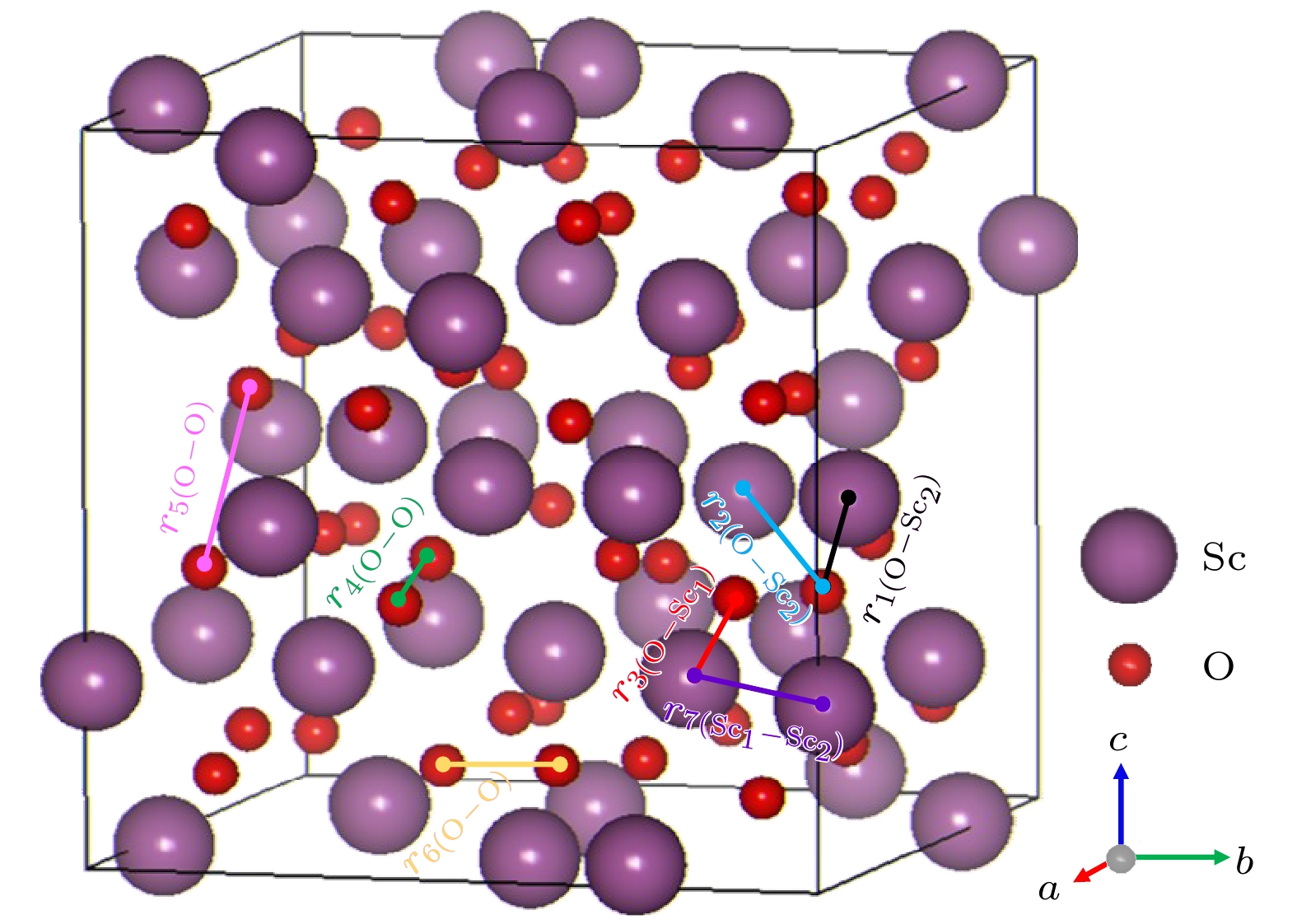

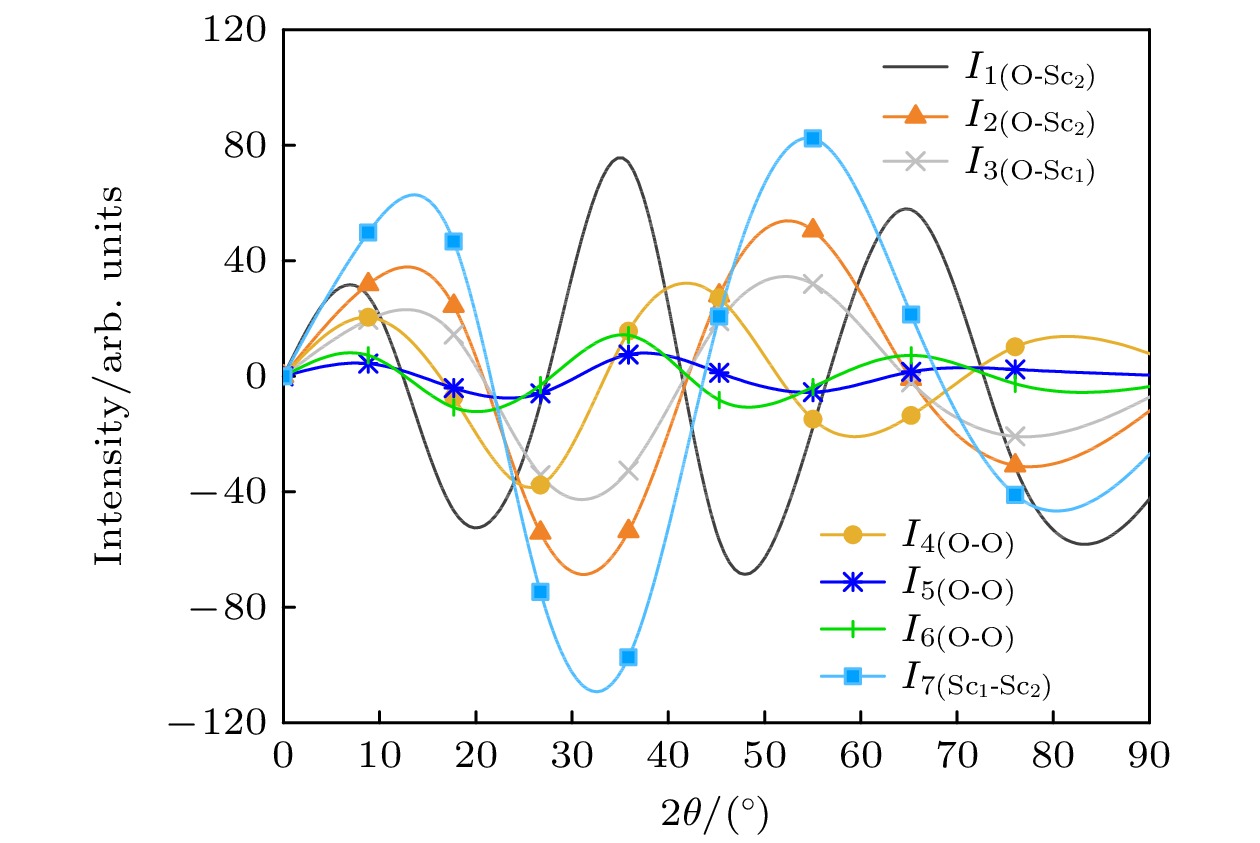

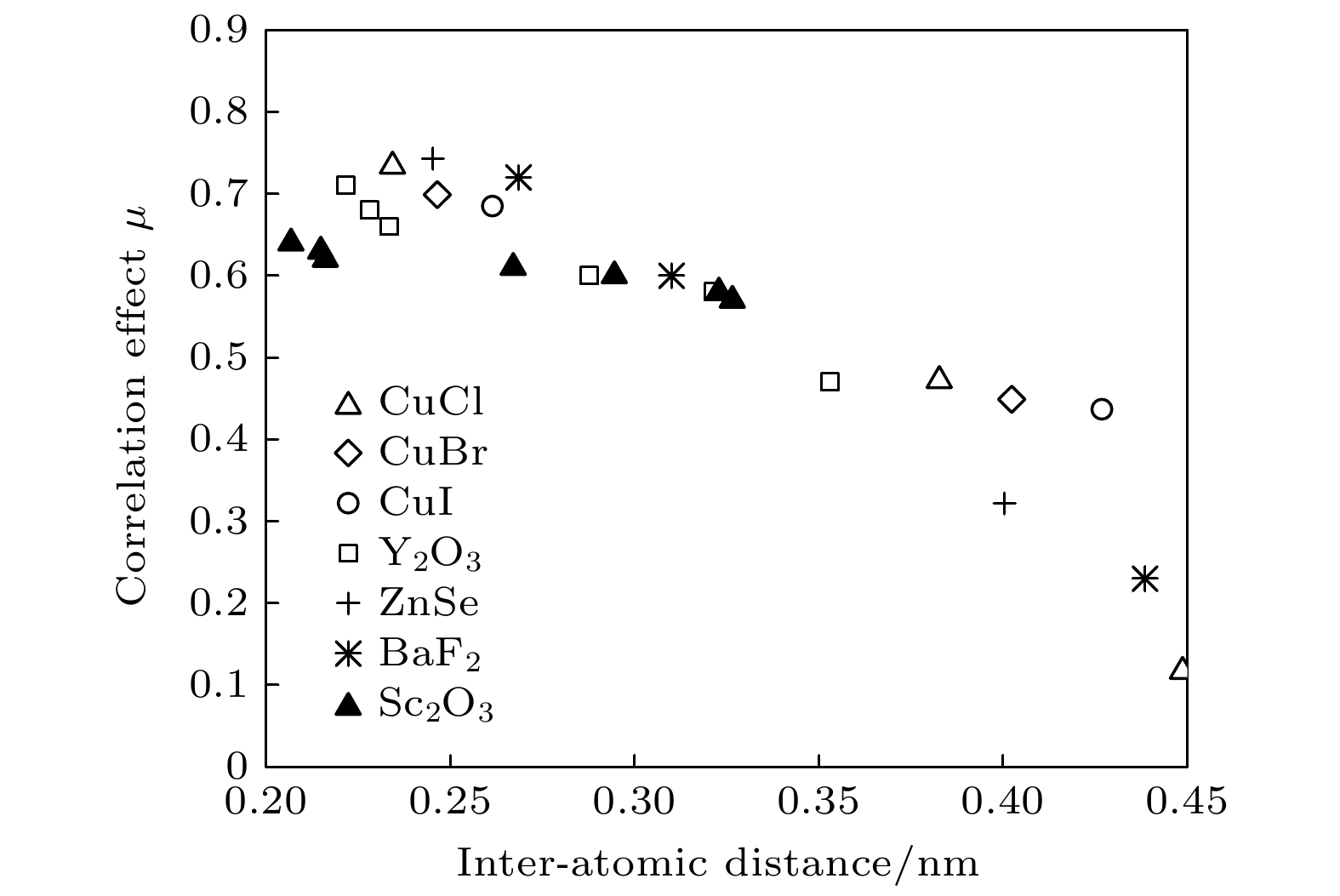

热漫散射分析在凝聚态物理和材料科学研究中具有巨大潜力与实用性. 氧化钪(Sc2O3)独特的物理化学性质, 使其具有较高的研究和应用价值. 在室温26 ℃下对Sc2O3进行了X射线衍射实验. 其热漫散射强度呈明显的振动形状, 将Sc2O3的全衍射背底强度方程展开, 并计算热漫散射强度的理论值, 直至计算到第14近邻原子(r为0.3816 nm)全衍射背底强度图谱. 将理论值与实验值拟合, 得到了最近邻原子至第7近邻原子所对应的原子间热振动相关效应值μ, 最近邻原子到第7近邻原子距离r的值分别为0.2067, 0.2148, 0.2161, 0.2671, 0.2945, 0.3229和0.3265 nm, 所对应的原子间热振动相关效应值μ分别为0.64, 0.63, 0.62, 0.61, 0.60, 0.58和0.57. 研究发现Sc2O3热漫散射强度大小与原子的热振动密切相关, 对热漫散射强度振动形状影响最大的是第7近邻原子Sc1-Sc2间的热振动相关效应μ, 原子间热振动相关效应值μ对研究材料的力热性质提供很重要的参数, 为下一步计算比热和原子间力常数打下基础, 其对于材料的力热方面的用途与发展有着至关重要的作用.

-

关键词:

- Sc2O3 /

- 热漫散射 /

- 原子间热振动相关效应值

Atoms in crystals will generate thermal diffuse scattering during thermal vibration. Thermal diffuse scattering analysis has great potential applications in condensed matter physics and material science research. Scandium oxide (Sc2O3) has unique physical and chemical properties, which make it have high research and application value. In this work, X-ray diffraction experiment is performed on Sc2O3 at room temperature of 26 ℃. The thermal diffuse scattering intensity exhibits a clear vibrational shape. The full diffraction back-based intensity equation of Sc2O3 is expanded, and the theoretical value of the thermal diffuse scattering intensity is calculated until the full diffraction back-based intensity spectrum of the 14th nearest atom (r = 0.3816 nm) is calculated. By fitting the theoretical value to the experimental value, we can see the inter-atomic thermal vibration correlation effect μ values corresponding to the nearest neighbor atom to the 7th nearest neighbor atom, the values of distance r from the nearest neighbor atom to the 7th nearest neighbor atom are 0.2067, 0.2148, 0.2161, 0.2671, 0.2945, 0.3229 and 0.3265nm, respectively, corresponding to their inter-atomic thermal vibration correlation effect μ values of 0.64, 0.63, 0.62, 0.61, 0.60, 0.58 and 0.57. Research result shows that the intensity of thermal diffuse scattering in Sc2O3 is closely related to the atomic thermal vibration, the most significant influence on the vibration shape of thermal diffuse scattering intensity is the thermal vibration correlation effect between the 7th nearest atom Sc1-Sc2. Inter-atomic thermal vibration correlation effect μ values will provide important parameters for studying the mechanical and thermal properties of materials, laying the foundation for the next-step calculating specific heat and interatomic force constant, and thus playing a crucial role in the use and development of materials.-

Keywords:

- Sc2O3 /

- thermal diffuse scattering /

- inter-atomic thermal vibration correlation effect values

[1] Kulikov B P, Baranov V N, Bezrukikh A I, Deev V B, Motkov M M 2018 Metallurgist 61 1115

Google Scholar

Google Scholar

[2] 唐冲冲, 常化强, 包晓刚, 刘贵清, 刘奎仁 2012 中国稀土学报 30 680

Tang C C, Chang H Q, Bao X G, Liu G Q, Liu K R 2012 CJCR 30 680

[3] Masanori H, Kouji Y, Hiromasa Y, Toru H O 2008 J. Alloys Compd. 474 124

Google Scholar

Google Scholar

[4] Zhigachev A O, Rodaev V V, Zhigacheva D V, Lyskov N V, Shchukina M A 2021 Ceram. Int. 47 32490

Google Scholar

Google Scholar

[5] Pu Y C, Li S R, Yan S, Huang X, Wang D, Ye Y Y, Liu Y Q 2019 Fuel 241 607

Google Scholar

Google Scholar

[6] Nakazono K, Takahashi R, Yamada Y, Sato S 2021 Mol. Catal. 516 111996

Google Scholar

Google Scholar

[7] Sha H Y, He Z Z, Li C, Wang X Y, Jiang Q, Zeng F M, Su Z M 2019 Opt. Mater. 93 39

Google Scholar

Google Scholar

[8] Xue J M, Li F, Liu Y Q, Yang F, Hou Z X 2023 Appl. Surf. Sci. 613 155984

Google Scholar

Google Scholar

[9] Zhang C, Zhou Z X, Tang Z M, Ballo D, Wang C, Jian G 2022 J. Alloys Compd. 889 161622

Google Scholar

Google Scholar

[10] Poirot N, Bregiroux D, Boy P, Autret-Lambert C, Belleville P, Bianchi L 2015 Ceram. Int. 41 3879

Google Scholar

Google Scholar

[11] Toshiyuki M T I J L 2005 J. Am. Ceram. Soc. 88 817

Google Scholar

Google Scholar

[12] Jiang B X, Hu C, Li J, Kou H, Shi Y, Liu W B, Pan Y B 2011 J. Rare Earths 29 951

Google Scholar

Google Scholar

[13] Lu S Z, Yang Q H 2012 Chin. Phys. B 21 047801

Google Scholar

Google Scholar

[14] Lu X, Jiang B X, Li J, Liu W B, Wang L, Ba X B, Hu C, Liu B L, Pan Y B 2013 Ceram. Int. 39 4695

Google Scholar

Google Scholar

[15] Ma M Z, Dong L L, Jing W, Xu T, Kang B, Hou F 2019 Proceedings of the 11th International Conference on High-Performance Ceramics Kunming, China, May 25–29, 2019 p012080

[16] Dai Z F, Liu Q, Hrenia D, Dai J W, Wang W, Li J 2018 Opt. Mater. 75 673

Google Scholar

Google Scholar

[17] Wang Y, Sun X D, Qiu G M 2007 J. Rare Earths 25 68

Google Scholar

Google Scholar

[18] Jacobsohn L G, Serivalsatit K, Quarles C A, Ballato J 2015 J. Mater. Sci. 50 3183

Google Scholar

Google Scholar

[19] 杨丛松, 陈博, 王芳, 郑剑平, 赵建翔 2017 稀有金属 41 163

Google Scholar

Google Scholar

Yang C S, Chen B, Wang F, Zheng J P, Zhao J X 2017 Chin. Rare Metals 41 163

Google Scholar

Google Scholar

[20] Kong P F, Pu Y T, Ma P, Zhu J L 2020 Thin Solid Films 714 138357

Google Scholar

Google Scholar

[21] Sakuma T, Shimoyama T, Basar K, Xianglian, Takahashi H, Arai M, Ishii Y 2005 Solid State Ion 176 2689

Google Scholar

Google Scholar

[22] Arai M, Sakuma T 2001 J. Phys. Soc. Jpn. 70 144

Google Scholar

Google Scholar

[23] Beni G, Platzman P M 1976 Phys. Rev. B 14 1514

[24] Basar K, Xianglian, Sakuma T, Takahashi H, Igawa N 2009 ITB J. Sci. (Bdg.) 41 50

Google Scholar

Google Scholar

[25] Sakuma T, Makhsun, Sakai R, Xianglian, Takahashi H, Basar K, Igawa N, Sergey A D 2015 AIP Conf. Proc. 1656 020002

Google Scholar

Google Scholar

[26] Wada T, Sakuma T, Sakai R, Uehara H, Xianglian, Takahashi H, Kamishima O, Igawa N, Sergey A D 2012 Solid State Ion 225 18

Google Scholar

Google Scholar

[27] Sakuma T, Mohapatra S R, Uehara H, Sakai R, Xianglian, Takahashi H, Igawa N, Basar K 2011 Atom Indonesia 36 121

Google Scholar

Google Scholar

[28] Sakuma T, Xianglian, Shimizu N, Mohapatra S R, Isozaki N, Uehara H, Takahashi H, Basar K, Igawa N, Kamishima O 2010 Solid State Ion 192 54

Google Scholar

Google Scholar

[29] Sakuma T, Xianglian, Siagian S, Basar K, Takahashi H, Igawa N, Kamishima O 2010 J. Therm. Anal. Calorim. 99 173

Google Scholar

Google Scholar

[30] Basar K, Siagian S, Xianglian, Sakuma T, Takahashi H, Igawa N 2008 Nucl. Instrum. Methods Phys. Res. A 600 237

Google Scholar

Google Scholar

[31] 香莲, 赵敏兰, 佐久间隆, 井川直樹 2015 原子与分子 32 499

Google Scholar

Google Scholar

Xianglian, Zhao M L, Sakuma T, Igawa N 2015 J. at. Mol. Sci. 32 499

Google Scholar

Google Scholar

[32] Xianglian, Sakuma T, Mohapatra S R, Uehara H, Takahashi H, Kamishima O, Igawa N 2012 Mol. Simul. 38 448

Google Scholar

Google Scholar

[33] Xianglian, Basar K, Honda H, Siagian S, Ohara K, Sakuma T, Takahashi H, Igawa N, Ishii Y 2007 Solid State Ion 179 776

Google Scholar

Google Scholar

[34] 郭田田, 香莲, 包文秀, 包桂芝 2018 光散射学报 30 182

Google Scholar

Google Scholar

Guo T T, Xianglian, Bao W X, Bao G Z 2018 J. Light Scatter. 30 182

Google Scholar

Google Scholar

[35] Sakuma T 1992 J. Phys. Soc. Jpn. 61 4041

Google Scholar

Google Scholar

[36] 刘泽朋, 王瑞刚, 香莲, 包桂芝 2023 内蒙古民族大学学报(自然科学版) 38 199

Google Scholar

Google Scholar

Liu Z P, Wang R G, Xianglian, Bao G Z 2023 J. Inner Mongolia Minzu Univ. (Nat. Sci.) 38 199

Google Scholar

Google Scholar

[37] Rietveld H M 1967 Acta Cryst. 22 151

Google Scholar

Google Scholar

[38] Izumi F, Ikeda T 2000 Mater. Sci. Forum 399 198

Google Scholar

Google Scholar

[39] Lonsdale K 1962 International Tables for X-Ray Crystallography (Vol. III) (United Kingdo: Published by International Union of Crystallography) pp72–103

-

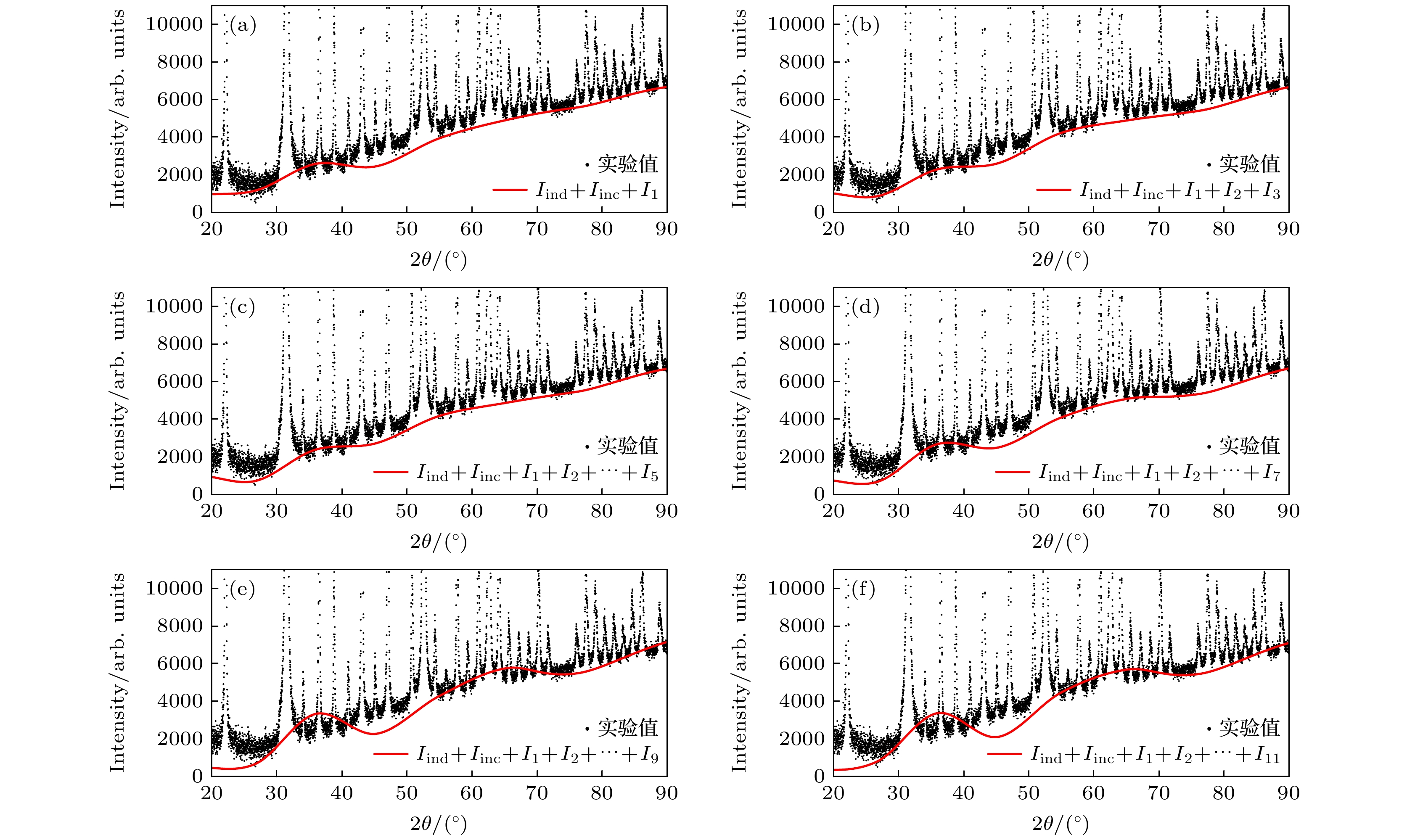

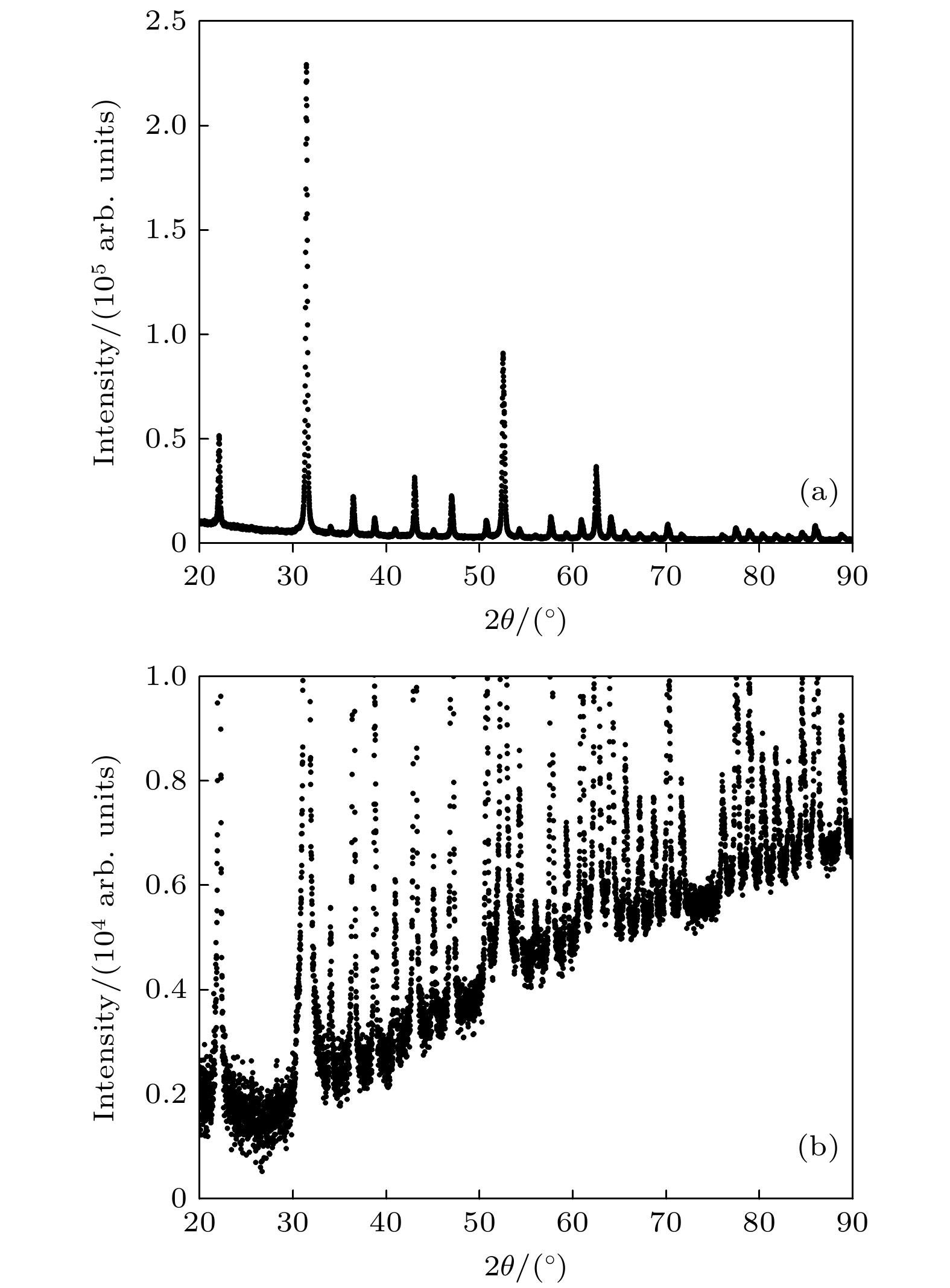

图 3 Sc2O3的全衍射背底强度的计算结果和实验结果的对比 (a)最近邻原子; (b)第1—3近邻原子; (c)第1—5近邻原子; (d) 第1—7近邻原子; (e)第1—9近邻原子; (f)第1—11近邻原子

Fig. 3. Comparison between calculated and experimental results of the total diffraction back-base intensity of Sc2O3: (a) The nearest neighbor atom; (b) the 1–3 nearest neighbor atomic; (c) the 1–5 nearest neighbor atomic; (d) the 1–7 nearest neighbor atomic; (e) the 1–9 nearest neighbor atom; (f) the 1–11 nearest neighbor atom.

参数 物理意义 参数 物理意义 $k$ 仪器参数 $ {N_0} $ 晶体内晶胞数 ${u_i}$ 单位晶胞内i原子数 ${Z_{{r_{s\left( i \right)s'\left( j \right)}}}}$ 配位数 ${f_i}$ i原子散射因子 ${r_{s\left( i \right)s'\left( j \right)}}$ 晶胞内i原子与j原子间距 ${B_i}$ i原子各向同性温度因子 ${\sigma _{{\text{incoh}}}}$ 非干涉性的原子散射截面 Ie 单个电子散射强度 θ 散射角 λ 入射光线波长 表 2 Sc2O3的晶体结构参数

Table 2. Crystal structure parameters of Sc2O3.

x y z B/nm2 Sc1 0.2500 0.2500 0.2500 0.003329 Sc2 0.4649 0 0.2500 0.011085 O 0.3928 0.1528 0.3802 0.009657 表 3 Sc2O3的原子间热振动相关效应值μ

Table 3. Interatomic thermal vibration related effect values of Sc2O3.

原子间距离r/nm 配位数Z 原子间相关效应值$ \mu $ O-Sc2 0.2067 2 0.64 O-Sc2 0.2148 1 0.63 O-Sc1 0.2161 1 0.62 O-O 0.2671 4 0.61 O-O 0.2945 1 0.60 O-O 0.3229 2 0.58 Sc1-Sc2 0.3265 6 0.57 -

[1] Kulikov B P, Baranov V N, Bezrukikh A I, Deev V B, Motkov M M 2018 Metallurgist 61 1115

Google Scholar

Google Scholar

[2] 唐冲冲, 常化强, 包晓刚, 刘贵清, 刘奎仁 2012 中国稀土学报 30 680

Tang C C, Chang H Q, Bao X G, Liu G Q, Liu K R 2012 CJCR 30 680

[3] Masanori H, Kouji Y, Hiromasa Y, Toru H O 2008 J. Alloys Compd. 474 124

Google Scholar

Google Scholar

[4] Zhigachev A O, Rodaev V V, Zhigacheva D V, Lyskov N V, Shchukina M A 2021 Ceram. Int. 47 32490

Google Scholar

Google Scholar

[5] Pu Y C, Li S R, Yan S, Huang X, Wang D, Ye Y Y, Liu Y Q 2019 Fuel 241 607

Google Scholar

Google Scholar

[6] Nakazono K, Takahashi R, Yamada Y, Sato S 2021 Mol. Catal. 516 111996

Google Scholar

Google Scholar

[7] Sha H Y, He Z Z, Li C, Wang X Y, Jiang Q, Zeng F M, Su Z M 2019 Opt. Mater. 93 39

Google Scholar

Google Scholar

[8] Xue J M, Li F, Liu Y Q, Yang F, Hou Z X 2023 Appl. Surf. Sci. 613 155984

Google Scholar

Google Scholar

[9] Zhang C, Zhou Z X, Tang Z M, Ballo D, Wang C, Jian G 2022 J. Alloys Compd. 889 161622

Google Scholar

Google Scholar

[10] Poirot N, Bregiroux D, Boy P, Autret-Lambert C, Belleville P, Bianchi L 2015 Ceram. Int. 41 3879

Google Scholar

Google Scholar

[11] Toshiyuki M T I J L 2005 J. Am. Ceram. Soc. 88 817

Google Scholar

Google Scholar

[12] Jiang B X, Hu C, Li J, Kou H, Shi Y, Liu W B, Pan Y B 2011 J. Rare Earths 29 951

Google Scholar

Google Scholar

[13] Lu S Z, Yang Q H 2012 Chin. Phys. B 21 047801

Google Scholar

Google Scholar

[14] Lu X, Jiang B X, Li J, Liu W B, Wang L, Ba X B, Hu C, Liu B L, Pan Y B 2013 Ceram. Int. 39 4695

Google Scholar

Google Scholar

[15] Ma M Z, Dong L L, Jing W, Xu T, Kang B, Hou F 2019 Proceedings of the 11th International Conference on High-Performance Ceramics Kunming, China, May 25–29, 2019 p012080

[16] Dai Z F, Liu Q, Hrenia D, Dai J W, Wang W, Li J 2018 Opt. Mater. 75 673

Google Scholar

Google Scholar

[17] Wang Y, Sun X D, Qiu G M 2007 J. Rare Earths 25 68

Google Scholar

Google Scholar

[18] Jacobsohn L G, Serivalsatit K, Quarles C A, Ballato J 2015 J. Mater. Sci. 50 3183

Google Scholar

Google Scholar

[19] 杨丛松, 陈博, 王芳, 郑剑平, 赵建翔 2017 稀有金属 41 163

Google Scholar

Google Scholar

Yang C S, Chen B, Wang F, Zheng J P, Zhao J X 2017 Chin. Rare Metals 41 163

Google Scholar

Google Scholar

[20] Kong P F, Pu Y T, Ma P, Zhu J L 2020 Thin Solid Films 714 138357

Google Scholar

Google Scholar

[21] Sakuma T, Shimoyama T, Basar K, Xianglian, Takahashi H, Arai M, Ishii Y 2005 Solid State Ion 176 2689

Google Scholar

Google Scholar

[22] Arai M, Sakuma T 2001 J. Phys. Soc. Jpn. 70 144

Google Scholar

Google Scholar

[23] Beni G, Platzman P M 1976 Phys. Rev. B 14 1514

[24] Basar K, Xianglian, Sakuma T, Takahashi H, Igawa N 2009 ITB J. Sci. (Bdg.) 41 50

Google Scholar

Google Scholar

[25] Sakuma T, Makhsun, Sakai R, Xianglian, Takahashi H, Basar K, Igawa N, Sergey A D 2015 AIP Conf. Proc. 1656 020002

Google Scholar

Google Scholar

[26] Wada T, Sakuma T, Sakai R, Uehara H, Xianglian, Takahashi H, Kamishima O, Igawa N, Sergey A D 2012 Solid State Ion 225 18

Google Scholar

Google Scholar

[27] Sakuma T, Mohapatra S R, Uehara H, Sakai R, Xianglian, Takahashi H, Igawa N, Basar K 2011 Atom Indonesia 36 121

Google Scholar

Google Scholar

[28] Sakuma T, Xianglian, Shimizu N, Mohapatra S R, Isozaki N, Uehara H, Takahashi H, Basar K, Igawa N, Kamishima O 2010 Solid State Ion 192 54

Google Scholar

Google Scholar

[29] Sakuma T, Xianglian, Siagian S, Basar K, Takahashi H, Igawa N, Kamishima O 2010 J. Therm. Anal. Calorim. 99 173

Google Scholar

Google Scholar

[30] Basar K, Siagian S, Xianglian, Sakuma T, Takahashi H, Igawa N 2008 Nucl. Instrum. Methods Phys. Res. A 600 237

Google Scholar

Google Scholar

[31] 香莲, 赵敏兰, 佐久间隆, 井川直樹 2015 原子与分子 32 499

Google Scholar

Google Scholar

Xianglian, Zhao M L, Sakuma T, Igawa N 2015 J. at. Mol. Sci. 32 499

Google Scholar

Google Scholar

[32] Xianglian, Sakuma T, Mohapatra S R, Uehara H, Takahashi H, Kamishima O, Igawa N 2012 Mol. Simul. 38 448

Google Scholar

Google Scholar

[33] Xianglian, Basar K, Honda H, Siagian S, Ohara K, Sakuma T, Takahashi H, Igawa N, Ishii Y 2007 Solid State Ion 179 776

Google Scholar

Google Scholar

[34] 郭田田, 香莲, 包文秀, 包桂芝 2018 光散射学报 30 182

Google Scholar

Google Scholar

Guo T T, Xianglian, Bao W X, Bao G Z 2018 J. Light Scatter. 30 182

Google Scholar

Google Scholar

[35] Sakuma T 1992 J. Phys. Soc. Jpn. 61 4041

Google Scholar

Google Scholar

[36] 刘泽朋, 王瑞刚, 香莲, 包桂芝 2023 内蒙古民族大学学报(自然科学版) 38 199

Google Scholar

Google Scholar

Liu Z P, Wang R G, Xianglian, Bao G Z 2023 J. Inner Mongolia Minzu Univ. (Nat. Sci.) 38 199

Google Scholar

Google Scholar

[37] Rietveld H M 1967 Acta Cryst. 22 151

Google Scholar

Google Scholar

[38] Izumi F, Ikeda T 2000 Mater. Sci. Forum 399 198

Google Scholar

Google Scholar

[39] Lonsdale K 1962 International Tables for X-Ray Crystallography (Vol. III) (United Kingdo: Published by International Union of Crystallography) pp72–103

计量

- 文章访问数: 2993

- PDF下载量: 51

- 被引次数: 0

下载:

下载: