-

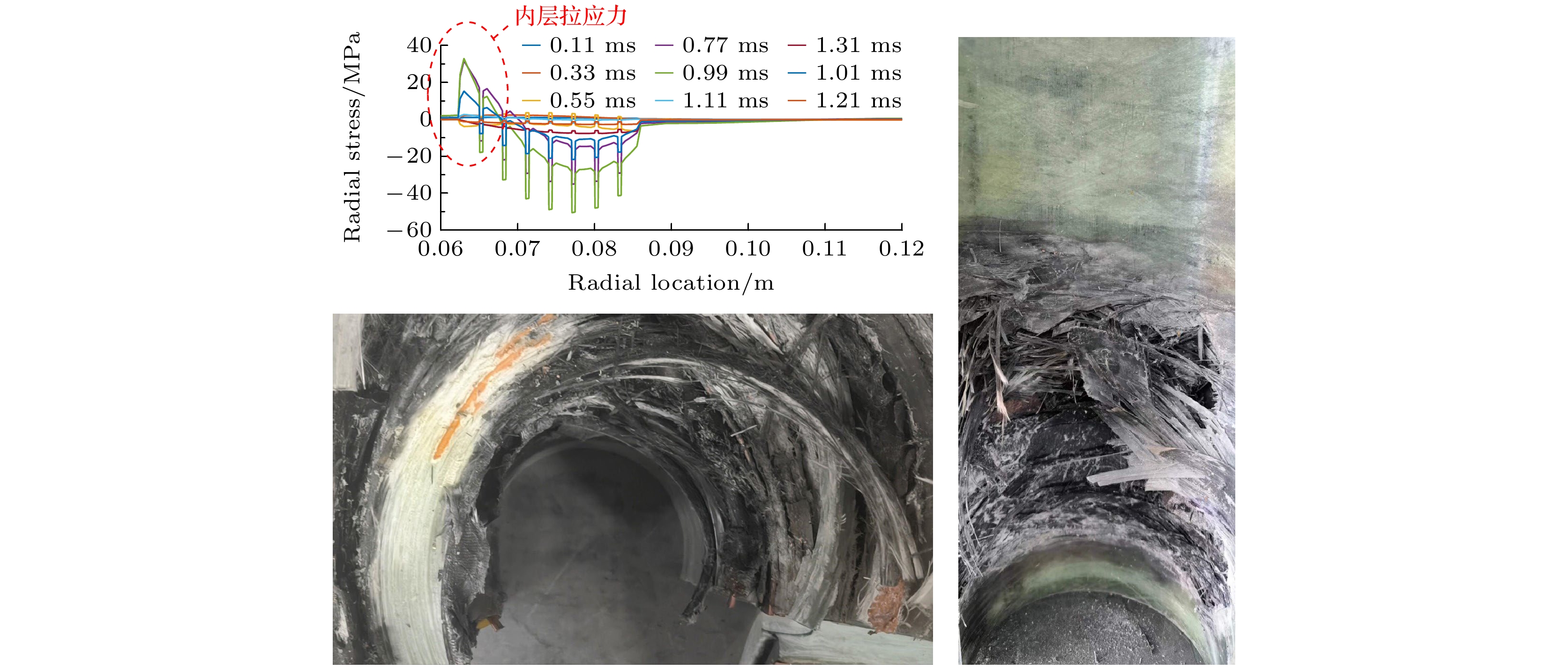

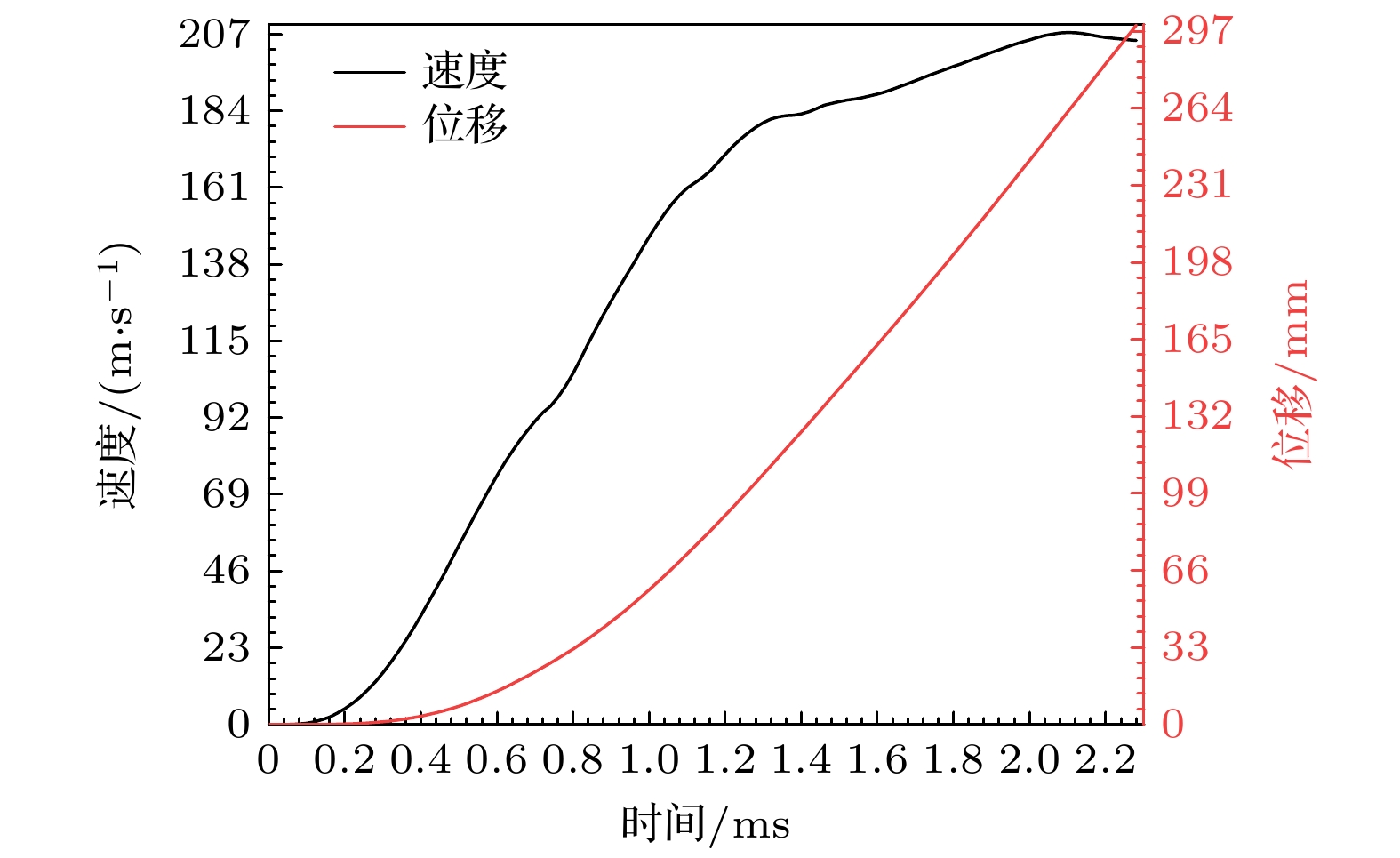

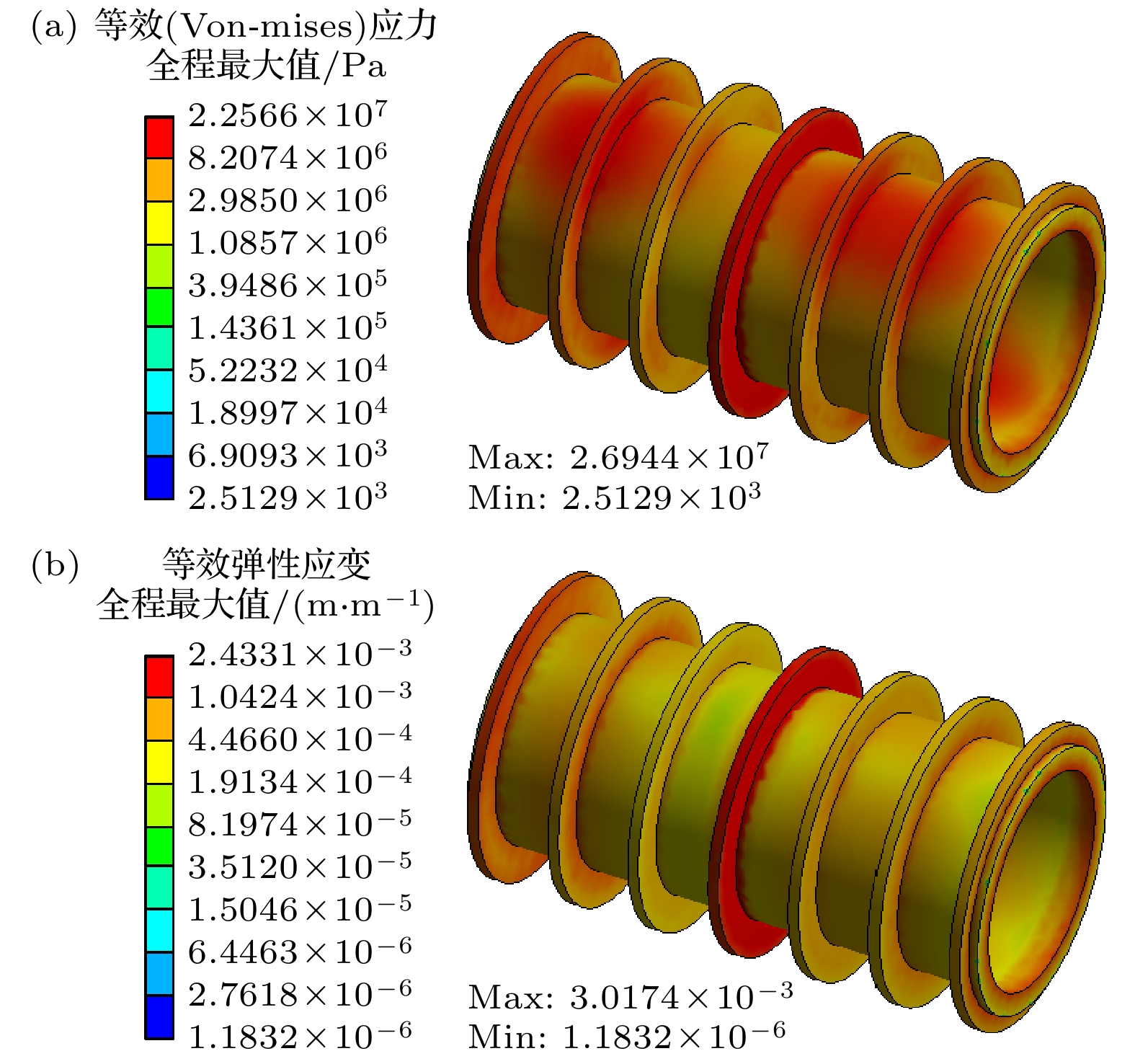

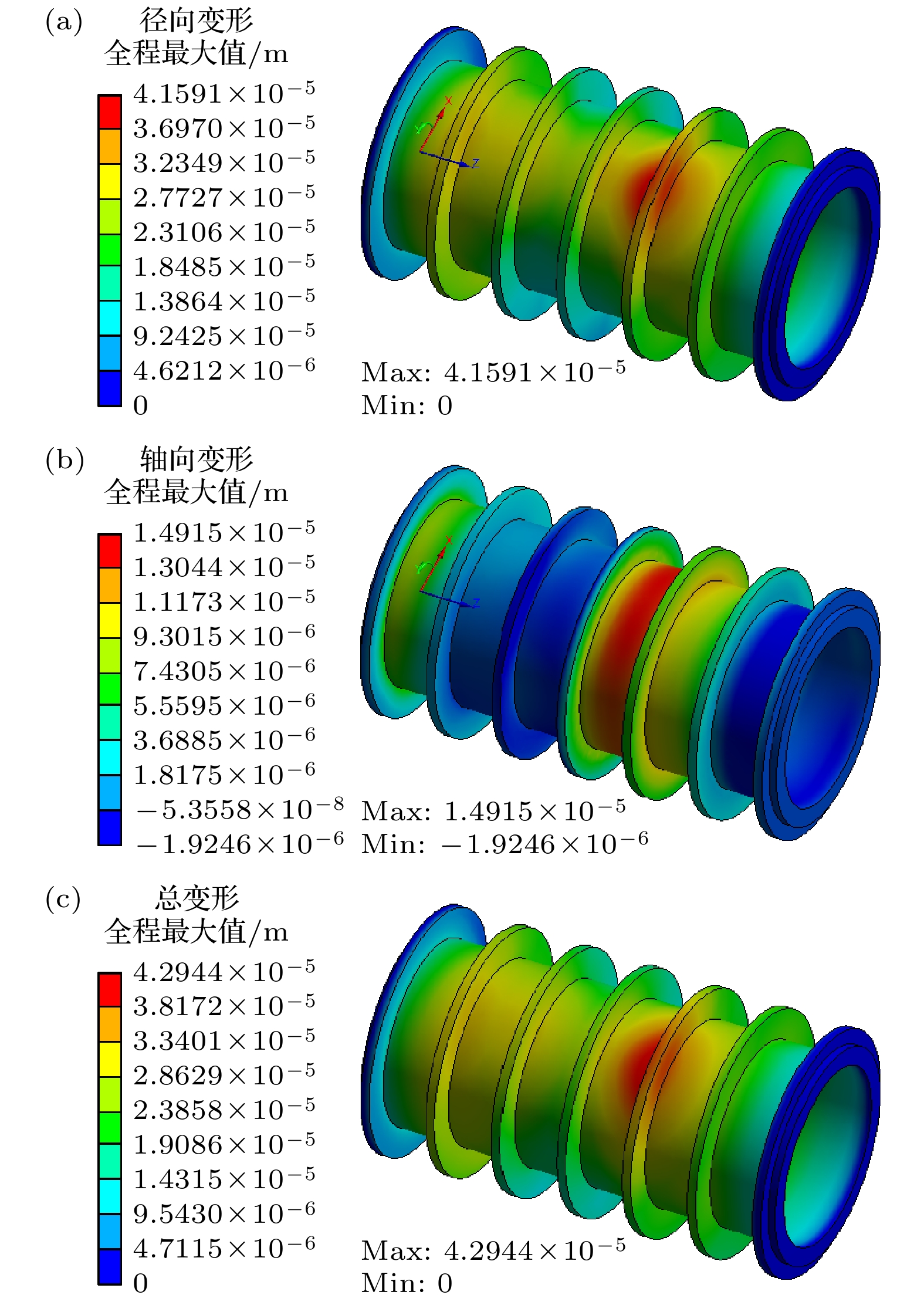

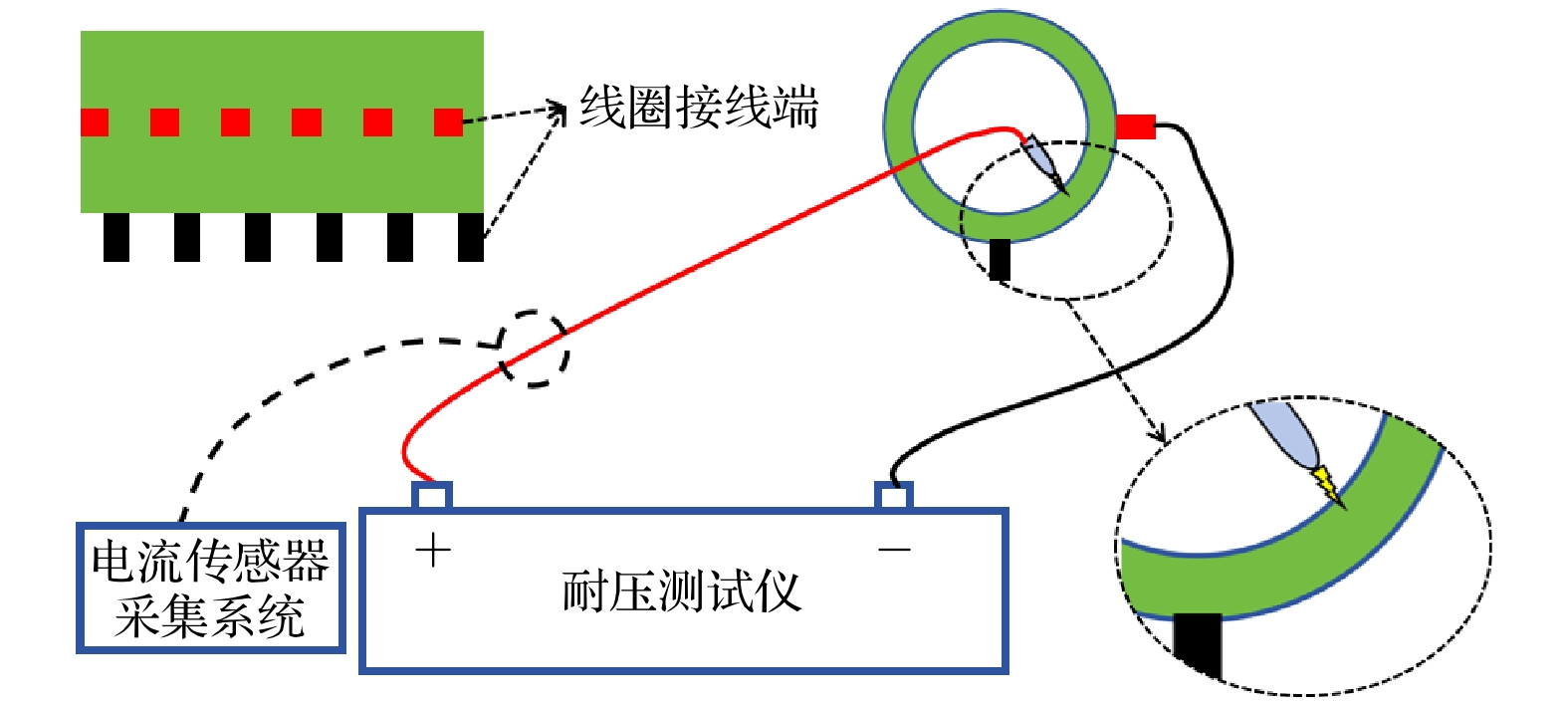

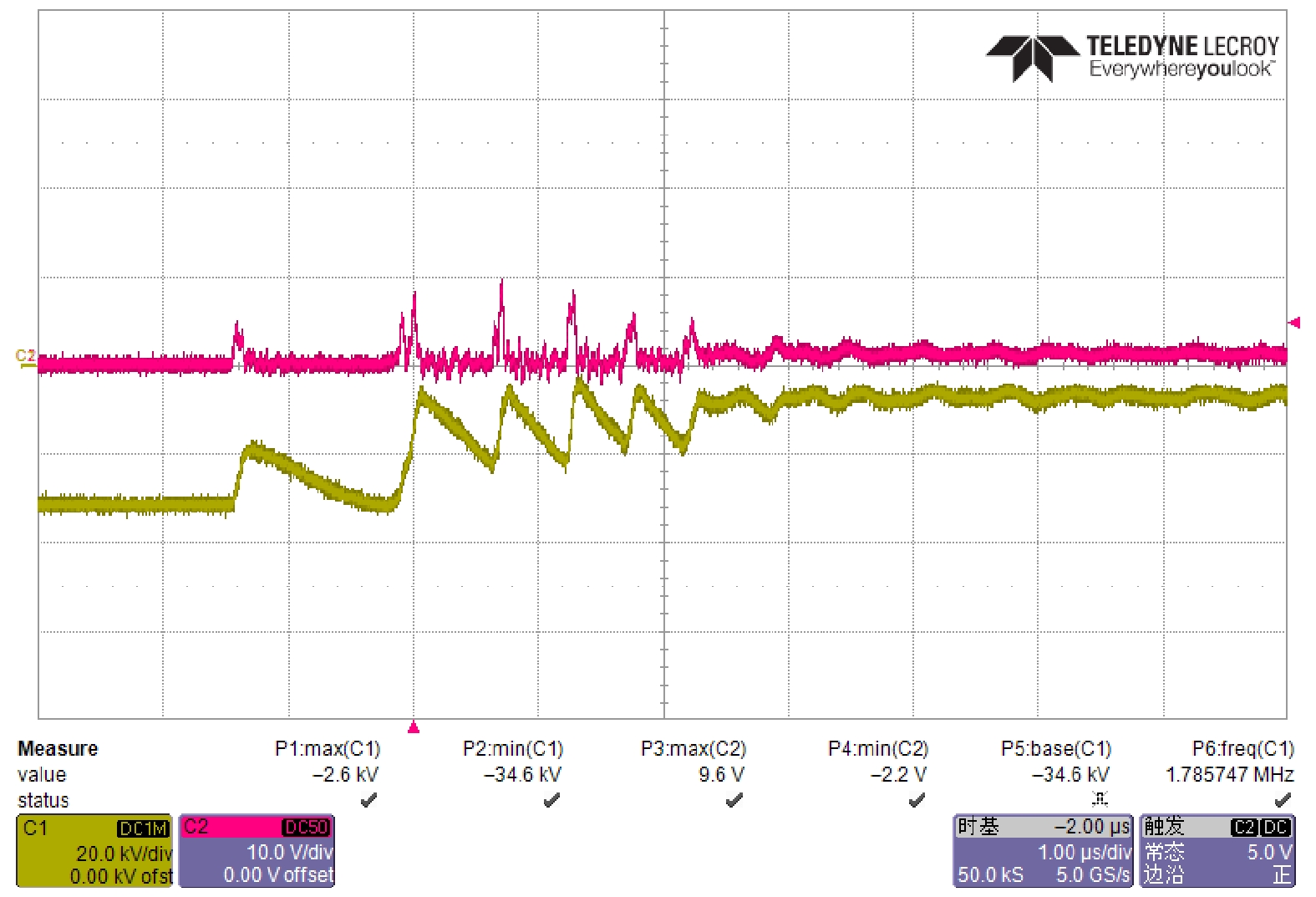

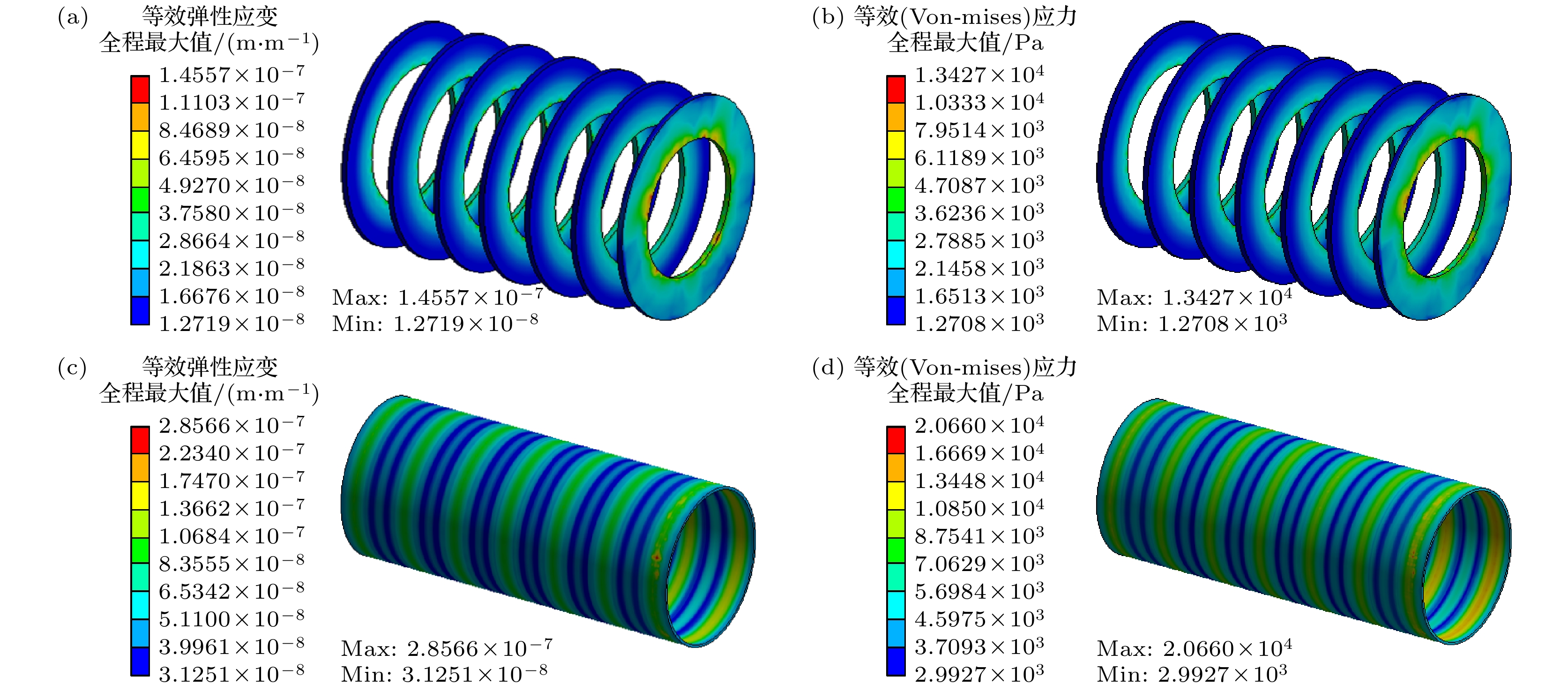

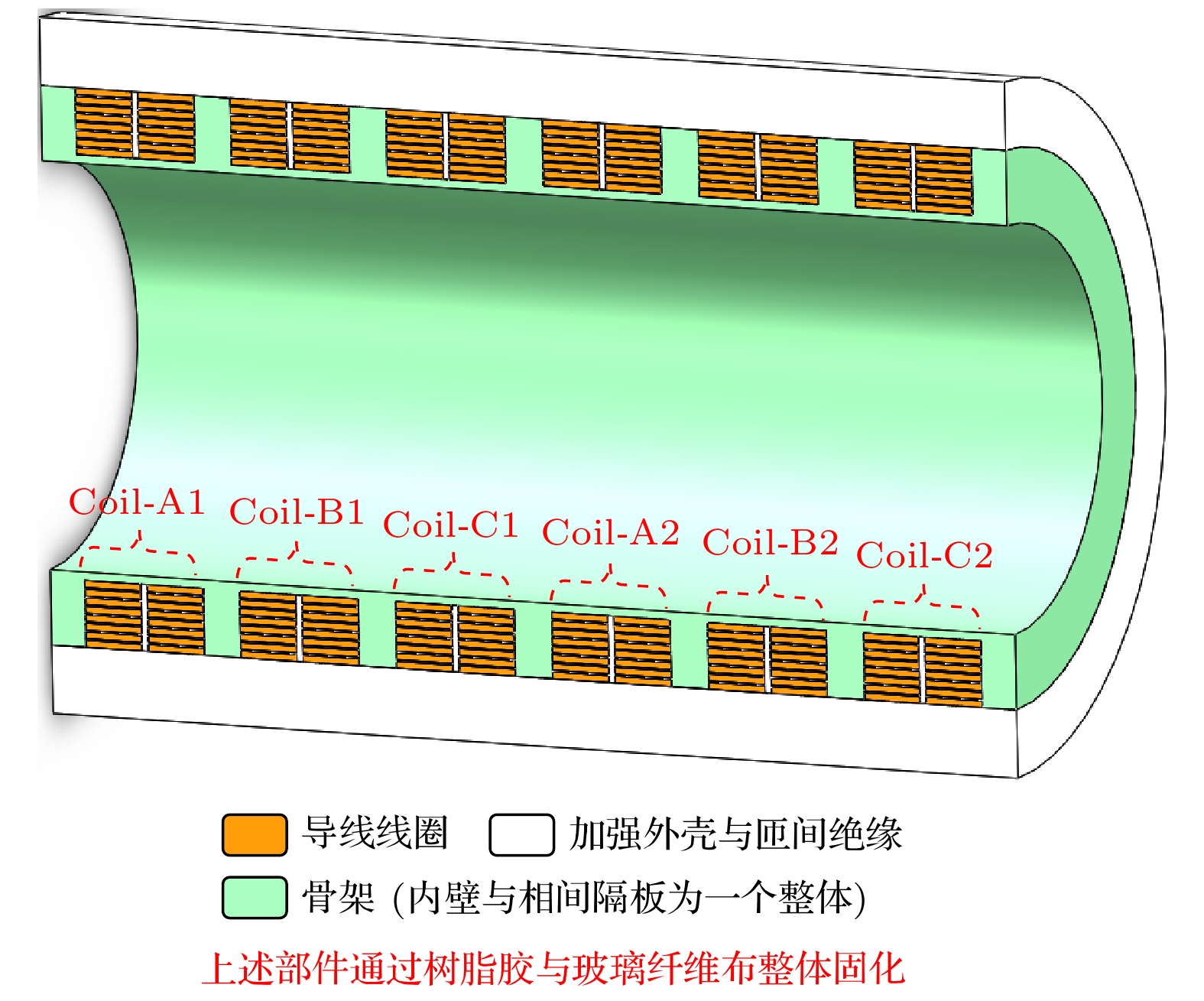

为了避免传统一体化驱动结构在运行过程中容易出现骨架断裂失效等不稳定现象. 本文根据典型一体化驱动结构在运行过程中的应力应变, 结合加速实验后出现内壁裂痕的一体化驱动结构的耐压放电测试, 分析确定一体化驱动结构存在的不稳定因素, 初步设计了一种轴径双向分离式模块化的新型驱动结构, 对新结构在运行过程中的电磁及结构响应等展开有限元仿真分析. 在相同激励条件下, 新型驱动结构内壁上的应力应变远小于一体化结构, 同时一体化驱动结构的内壁上的最大形变约为10–2 m量级, 而新型驱动结构在运行过程中内壁上的最大形变降低至10–5—10–6 m量级. 结果表明新结构能够在保证推进性能的前提下, 降低内壁和相间隔板的应力应变及变形程度, 提高了结构的可靠性, 能够为电磁线圈驱动结构的设计优化提供一定参考和借鉴.In order to alleviate the common problems of skeleton fracture and failure in traditional propulsion systems, the insulation degradation and structural instability existing in integrated drive structures during operation are investigated in this work. By using stress-strain calculations of a typical integrated drive structure and voltage-withstanding discharge tests after acceleration experiments, key factors are identified, and it is believed that the tensile stress inside the driving structure is one of the reasons for structural instability. Owing to the electromagnetic force acting on the coil, the integrated driving structure exhibits high tensile stress and strain on the inner wall and interphase partition, accompanied by significant deformation, which is not conducive to the overall structural stability. Based on the above calculation results, a novel modular drive structure with bidirectional separation is proposed, which can realize the radial separation between the phase partition and the skeleton inner cylinder, as well as axial separation between different driving coils. Finite element simulation analysis is conducted to evaluate its acceleration performance and structural response during operation. The results indicate that under the same excitation conditions, the new driving structure greatly reduces the interaction between the coil and the inner wall during operation, so the stress-strain on the inner wall of the new driving structure is much smaller than that of the integrated structure. The maximum deformation decreases from approximately 10–2 m in the integrated structure to about 10–5 m to 10–6 m in the new design. These findings emphasize the potential of new structure to improve reliability while ensuring propulsion performance, providing valuable insights for optimizing electromagnetic coil drive structures. For this new structure, there will be plans to conduct high-pressure propulsion experiments in the future to verify its reliability.

-

Keywords:

- electromagnetic propulsion /

- coil propulsion /

- structural response /

- finite element analysis

[1] Song M G, Park S W, Le D V, Go B S, Park M 2023 IEEE Trans. Plasma Sci. 51 3611

Google Scholar

Google Scholar

[2] Tosun N, Polat H, Ceylan D, Karagoz M, Yıldırım B, Güngen İbrahim, Keysan O 2020 IEEE Trans. Plasma Sci. 48 3220

Google Scholar

Google Scholar

[3] 马伟明, 鲁军勇 2023 电工技术学报 38 3943

Google Scholar

Google Scholar

Ma W M, Lu J Y 2023 Trans. China Electrotech. So. 38 3943

Google Scholar

Google Scholar

[4] 王秋良, 王厚生, 李献, 陈顺中 2015 高电压技术 41 2489

Google Scholar

Google Scholar

Wang Q L, Wang H S, Li X, Chen S Z 2015 High Volt. Eng. 41 2489

Google Scholar

Google Scholar

[5] Lu J Y, Ma W M 2011 IEEE Trans. Plasma Sci. 39 116

Google Scholar

Google Scholar

[6] 王湘 2020 硕士学位论文 (湖南: 国防科技大学)

Wang X 2020 M. S. Thesis (Hunan: National Unversity of Defense Technology

[7] 苏子舟, 张博, 国伟, 刘学超, 屈武斌 2011 火炮发射与控制学报 121 93

Google Scholar

Google Scholar

Su Z Z, Zhang B, Guo W, Liu X C, Qu W B 2011 J. Gun Launch Contr. 121 93

Google Scholar

Google Scholar

[8] 王禹晨, 刘晓艳, 黄懿赟, 管锐, 江加福 2022 强激光与粒子束 34 81

Google Scholar

Google Scholar

Wang Y C, Liu X Y, Huang Y Y, Guan R, Jiang J F 2022 High Power Laser Partic. Beams 34 81

Google Scholar

Google Scholar

[9] Cong Y T, Cheng J S, Xiong L, Wang Y C, Sun J 2021 IEEE Trans. Plasma Sci. 49 914

Google Scholar

Google Scholar

[10] Cong Y T, Cheng J S, Wang Q L, Xiong L, Sun J, Wang Y C 2021 IEEE Trans. Plasma Sci. 49 4002

Google Scholar

Google Scholar

[11] Kaye R J, Shokair I R, Wavrik R W, Dempsey J F, Honey W E, Shimp K J, Douglas G M 1995 IEEE Trans. Magn. 31 478

Google Scholar

Google Scholar

[12] Kaye R J, Mann G A 2003 Sandia National Laboratories

[13] Lockner T, Kaye R, Turman B 2004 Conference Record of the Twenty-Sixth International Power Modulator Symposium San Francisco, California, USA, May 23–26, 2004 p119

[14] 关晓存, 雷彬, 李治源 2012 固体力学学报 33 209

Google Scholar

Google Scholar

Guan X C, Lei B, Li Z Y 2012 Acta Mech. Solida Sin. 33 209

Google Scholar

Google Scholar

[15] Zhang Y J, Qin W N, Zhang Y D 2016 Electrical Mach. Contr. 20 77 [张宇娇, 秦威南, 张亚东 2016 电机与控制学报 20 77]

Google Scholar

Google Scholar

Zhang Y J, Qin W N, Zhang Y D 2016 Electrical Mach. Contr. 20 77

Google Scholar

Google Scholar

[16] Zhang Y J, Qin W N, Ruan J J 2015 IEEE Trans. Plasma Sci. 43 1288

Google Scholar

Google Scholar

[17] 秦威南 2015 硕士学位论文(宜昌: 三峡大学)

Qin W N 2015 M. S. Thesis (Yichang: China Three Gorges University

[18] 贺亚男, 关晓存, 孟庆云, 管少华, 郭灯华 2021 火炮发射与控制学报 42 1

Google Scholar

Google Scholar

He Y N, Guan X C, Meng Q Y, Guan S H, Guo D H 2021 J. Gun Launch Contr. 42 1

Google Scholar

Google Scholar

[19] 李睿杰, 程军胜, 熊玲, 陈功轩, 邓兆哲, 何湘宁 2023 兵器装备工程学报 44 103

Google Scholar

Google Scholar

Li R J, Cheng J S, Xiong L, Chen G X, Deng Z Z, He X N 2023 J. Ordn. Equip. Eng. 44 103

Google Scholar

Google Scholar

[20] 李伟, 李首德, 刘世亮, 熊玲, 程军胜 2023 兵器装备工程学报 44 157

Google Scholar

Google Scholar

Li W, Li S D, Liu S L, Xiong L, Cheng J S 2023 J. Ordn. Equip. Eng. 44 157

Google Scholar

Google Scholar

-

表 1 驱动结构尺寸和材料性能参数

Table 1. Drive structure dimensions and material performance parameters.

参数 值 电枢质量/kg 2 骨架内半径/mm 60 导线径向厚度/mm 2.5 线圈轴向宽度/mm 40 匝间绝缘厚度/mm 0.5 相间隔板轴向宽度/mm 5 绕组径向匝数 8 骨架内壁厚度/mm 2.5 绝缘材料杨氏模量 Ej/GPa 100 绝缘材料泊松比 vj 0.22 铜导体杨氏模量 Ec/GPa 110 铜导体泊松比 vc 0.34 -

[1] Song M G, Park S W, Le D V, Go B S, Park M 2023 IEEE Trans. Plasma Sci. 51 3611

Google Scholar

Google Scholar

[2] Tosun N, Polat H, Ceylan D, Karagoz M, Yıldırım B, Güngen İbrahim, Keysan O 2020 IEEE Trans. Plasma Sci. 48 3220

Google Scholar

Google Scholar

[3] 马伟明, 鲁军勇 2023 电工技术学报 38 3943

Google Scholar

Google Scholar

Ma W M, Lu J Y 2023 Trans. China Electrotech. So. 38 3943

Google Scholar

Google Scholar

[4] 王秋良, 王厚生, 李献, 陈顺中 2015 高电压技术 41 2489

Google Scholar

Google Scholar

Wang Q L, Wang H S, Li X, Chen S Z 2015 High Volt. Eng. 41 2489

Google Scholar

Google Scholar

[5] Lu J Y, Ma W M 2011 IEEE Trans. Plasma Sci. 39 116

Google Scholar

Google Scholar

[6] 王湘 2020 硕士学位论文 (湖南: 国防科技大学)

Wang X 2020 M. S. Thesis (Hunan: National Unversity of Defense Technology

[7] 苏子舟, 张博, 国伟, 刘学超, 屈武斌 2011 火炮发射与控制学报 121 93

Google Scholar

Google Scholar

Su Z Z, Zhang B, Guo W, Liu X C, Qu W B 2011 J. Gun Launch Contr. 121 93

Google Scholar

Google Scholar

[8] 王禹晨, 刘晓艳, 黄懿赟, 管锐, 江加福 2022 强激光与粒子束 34 81

Google Scholar

Google Scholar

Wang Y C, Liu X Y, Huang Y Y, Guan R, Jiang J F 2022 High Power Laser Partic. Beams 34 81

Google Scholar

Google Scholar

[9] Cong Y T, Cheng J S, Xiong L, Wang Y C, Sun J 2021 IEEE Trans. Plasma Sci. 49 914

Google Scholar

Google Scholar

[10] Cong Y T, Cheng J S, Wang Q L, Xiong L, Sun J, Wang Y C 2021 IEEE Trans. Plasma Sci. 49 4002

Google Scholar

Google Scholar

[11] Kaye R J, Shokair I R, Wavrik R W, Dempsey J F, Honey W E, Shimp K J, Douglas G M 1995 IEEE Trans. Magn. 31 478

Google Scholar

Google Scholar

[12] Kaye R J, Mann G A 2003 Sandia National Laboratories

[13] Lockner T, Kaye R, Turman B 2004 Conference Record of the Twenty-Sixth International Power Modulator Symposium San Francisco, California, USA, May 23–26, 2004 p119

[14] 关晓存, 雷彬, 李治源 2012 固体力学学报 33 209

Google Scholar

Google Scholar

Guan X C, Lei B, Li Z Y 2012 Acta Mech. Solida Sin. 33 209

Google Scholar

Google Scholar

[15] Zhang Y J, Qin W N, Zhang Y D 2016 Electrical Mach. Contr. 20 77 [张宇娇, 秦威南, 张亚东 2016 电机与控制学报 20 77]

Google Scholar

Google Scholar

Zhang Y J, Qin W N, Zhang Y D 2016 Electrical Mach. Contr. 20 77

Google Scholar

Google Scholar

[16] Zhang Y J, Qin W N, Ruan J J 2015 IEEE Trans. Plasma Sci. 43 1288

Google Scholar

Google Scholar

[17] 秦威南 2015 硕士学位论文(宜昌: 三峡大学)

Qin W N 2015 M. S. Thesis (Yichang: China Three Gorges University

[18] 贺亚男, 关晓存, 孟庆云, 管少华, 郭灯华 2021 火炮发射与控制学报 42 1

Google Scholar

Google Scholar

He Y N, Guan X C, Meng Q Y, Guan S H, Guo D H 2021 J. Gun Launch Contr. 42 1

Google Scholar

Google Scholar

[19] 李睿杰, 程军胜, 熊玲, 陈功轩, 邓兆哲, 何湘宁 2023 兵器装备工程学报 44 103

Google Scholar

Google Scholar

Li R J, Cheng J S, Xiong L, Chen G X, Deng Z Z, He X N 2023 J. Ordn. Equip. Eng. 44 103

Google Scholar

Google Scholar

[20] 李伟, 李首德, 刘世亮, 熊玲, 程军胜 2023 兵器装备工程学报 44 157

Google Scholar

Google Scholar

Li W, Li S D, Liu S L, Xiong L, Cheng J S 2023 J. Ordn. Equip. Eng. 44 157

Google Scholar

Google Scholar

计量

- 文章访问数: 3817

- PDF下载量: 198

- 被引次数: 0

下载:

下载: