-

以钙钛矿为代表的共点配位多面体晶体(CSCPC)具有独特而丰富的光、电、磁性质, 在多铁材料、快离子导体、光电催化等方面具有广阔的应用前景. 在众多CSCPC中, 具有优异理化性质的相只是极少数. 因此, 如何通过结构调控获得这些相, 一直是相关领域的研究热点和“卡脖子”问题. 受此启发, 本文从相结构的角度评述了近年来高性能CSCPC的合成研究, 以期明确相转变的内在规律, 并揭示其中所蕴藏的相调控机制. 首先系统地总结了CSCPC中常见的多面体和晶格骨架的类型, 并将多面体畸变大致分为偏移、转动、变形三大类. 以此为基础, 对各类材料合成方案进行分析和归纳, 发现传统的合成方案多依赖于宏观尺度上对温度、压力、组分等外部物理条件的改变. 近年来, 新兴的合成方案聚焦于对多面体几何和拓扑结构的微观调控, 如利用容忍因子和基板趋近效应来构造相结构. 它们在本质上都遵循着共同的相调控机制, 即通过引发多面体的畸变来诱导晶体转变成具有目标属性的相结构. 不同的是, 后者具有更强的目标导向性, 但其适用面还局限在配位八面体的转动体系, 如何拓展其应用范围尚存挑战性. 此外, “明确引发畸变的根源及各畸变间相互作用” 以及“基于计算机科学的定制化指导”都是优化合成方案的未来方向. 本文所做的调研和评述以期为高性能CSCPC材料的设计和制备提供一些思路和启发.Corner-shared coordination polyhedral crystals (CSCPCs) represented by perovskites have unique and various properties in optics, electrics, and magnetism, leading to their broad applications such as in serving as ferroelectric material, fast ionic conductors, and electro/photo-catalysts. However, the excellent properties are owned only by a very small fraction of CSCPS phases. How to obtain such phases through structural operation has always been a research hotspot and a bottleneck in related fields. Herein, we review the recent research progress of the synthesis of high-performance CSCPC materials from the perspective of phase structure, in order to clarify the intrinsic rules of phase evolution and reveal the mechanism behind the phase manipulation. We first systematically summarize the types of polyhedra and crystal frameworks in CSCPCs and classify the polyhedral distortions as three main types, i.e. cation displacements, polyhedral rotations, and deformations. Based on that, we further analyze and conclude different material synthesis methods. We find that most traditional synthesis methods rely on the phase transitions induced by the change of external physical conditions at a macroscopic level, such as composition, temperature, and pressure. Recently, there was an emerging synthesis method focusing on the microscopic manipulation of polyhedral geometry and topology, such as phase constructions according to tolerance-factor and substrate-proximity effects. The macroscopic synthesis methods and the microscopic synthesis methods share the same phase manipulation mechanism: making crystals transit into the structure-specified phases by inducing polyhedral distortions. The only difference is that the latter is more target-oriented, but its applications are currently limited to octahedral coordination tilt/rotation systems. Expanding its application scope is still a challenge. In addition, we propose two aspects that may be useful in optimizing the synthesis method: one is to clarify the origin of induced distortions and the interaction between different distortions, and the other is to customize the guidelines based on computer science. We hope that the research progress reviewed in this article can provide some valuable references and inspirations for designing and synthesizing the high-performance CSCPC materials.

-

Keywords:

- corner-shared coordination polyhedral crystal /

- polyhedral distortion /

- phase evolution /

- property manipulation /

- synthesis method

[1] Koegel A A, Mozur E M, Oswald I W H, Jalarvo N H, Prisk T R, Tyagi M, Neilson J R 2022 J. Am. Chem. Soc. 144 1313

Google Scholar

Google Scholar

[2] Gao J, Li W, Liu J, Li Q, Li J F 2022 Research 2022 9782343

[3] Surta T W, Whittle T A, Wright M A, Niu H J, Gamon J, Gibson Q D, Daniels L M, Thomas W J, Zanella M, Shepley P M, Li Y, Goetzee-Barral A, Bell A J, Alaria J, Claridge J B, Rosseinsky M J 2021 J. Am. Chem. Soc. 143 1386

Google Scholar

Google Scholar

[4] Retuerto M, Li M R, Ignatov A, Croft M, Ramanujachary K V, Chi S, Hodges J P, Dachraoui W, Hadermann J, Tran T T, Halasyamani P S, Grams C P, Hemberger J, Greenblatt M 2013 Inorg. Chem. 52 12482

Google Scholar

Google Scholar

[5] Chi L, Swainson I, Cranswick L, Her J H, Stephens P, Knop O 2005 J. Solid State Chem. 178 1376

Google Scholar

Google Scholar

[6] Slater P R, Irvine J T S, Ishihara T, Takita Y 1998 Solid State Ionics 107 319

Google Scholar

Google Scholar

[7] García-Martín S, Alario-Franco M A, Ehrenberg H, Rodríguez-Carvajal J, Amador U 2004 J. Am. Chem. Soc. 126 3587

Google Scholar

Google Scholar

[8] Dachraoui W, Hadermann J, Abakumov A M, Tsirlin A A, Batuk D, Glazyrin K, McCammon C, Dubrovinsky L, Tendeloo G V 2012 Chem. Mater. 24 1378

Google Scholar

Google Scholar

[9] Lanfredi S, Gênova D H M, Brito I A O, Lima A R F, Nobre M A L 2011 J. Solid State Chem. 184 990

Google Scholar

Google Scholar

[10] Megaw H D, Darlington C N W 1975 Acta Cryst. A31 161

[11] King G, Woodward P M 2010 J. Mater. Chem. 20 5785

Google Scholar

Google Scholar

[12] Haumont R, Kornev I A, Lisenkov S, Bellaiche L, Kreisel J, Dkhil B 2008 Phys. Rev. B 78 134108

Google Scholar

Google Scholar

[13] Moriyama T, Kan A, Ogawa H 2013 Mater. Sci. Eng. B 178 875

Google Scholar

Google Scholar

[14] Bechtel J S, Van der Ven A 2018 Phys. Rev. Mater. 2 025401

Google Scholar

Google Scholar

[15] Drathen C, Nakagawa T, Crichton W A, Hill A H, Ohishi Y, Margadonna S 2015 J. Mater. Chem. C 3 4321

Google Scholar

Google Scholar

[16] Vailionis A, Boschker H, Siemons W, Houwman E P, Blank D H A, Rijnders G, Koster G 2011 Phys. Rev. B 83 064101

[17] Barnes P W, Lufaso M W, Woodward P M 2006 Acta Cryst. B62 384

[18] Zhang Y R, Motohashi T, Masubuchi Y, Kikkawa S 2011 J. Ceram. Soc. Jpn. 119 581

Google Scholar

Google Scholar

[19] Fischer P, Polomska M, Sosnowska I, Szymański M 1980 J. Phys. C Solid St. Phys. 13 1931

Google Scholar

Google Scholar

[20] Haumont R, Bouvier P, Pashkin A, Rabia K, Frank S, Dkhil B, Crichton W A, Kuntscher C A, Kreisel J 2009 Phys. Rev. B 79 184110

Google Scholar

Google Scholar

[21] Gómez-Salces S, Aguado F, Rodríguez F, Valiente R, González J, Haumont R, Kreisel J 2012 Phys. Rev. B 85 144109

Google Scholar

Google Scholar

[22] Huband S, Keeble D S, Zhang N, Glazer A M, Bartasyte A, Thomas P A 2017 J. Appl. Phys. 121 024102

Google Scholar

Google Scholar

[23] Adem U, Nugroho A A, Meetsma A, Palstra T T M 2007 Phys. Rev. B 75 014108

Google Scholar

Google Scholar

[24] Graetsch H A, Schreuer J, Burianek M, Mühlberg M 2012 J. Solid State Chem. 196 255

Google Scholar

Google Scholar

[25] Kahlenberg V 1998 Z. Krist. 213 13

[26] Iwata Y, Shibuya I, Wada M, Sawada A, Ishibashi Y 1985 Jpn. J. Appl. Phys. 24 597

Google Scholar

Google Scholar

[27] Woodward P M, Sleight A W, Vogt T 1997 J. Solid State Chem. 131 9

Google Scholar

Google Scholar

[28] Gerand B, Nowogrocki G, Guenot J, Figlarz M 1979 J. Solid State Chem. 29 429

Google Scholar

Google Scholar

[29] Knight K S 2022 Mineral. Mag. 86 87

Google Scholar

Google Scholar

[30] Labbé P, Leligny H, Raveau B, Schneck J, Tolédano J C 1989 J. Phys. Condens. Matter 2 25

[31] Valdez M N, Spaldin N A 2019 Polyhedron 171 181

Google Scholar

Google Scholar

[32] Oh Y S, Luo X, Huang F T, Wang Y Z, Cheong S W 2015 Nat. Mater. 14 407

Google Scholar

Google Scholar

[33] Zhang B H, Liu X Q, Chen X M 2022 J. Phys. D Appl. Phys. 55 113001

Google Scholar

Google Scholar

[34] Theobald F, Laarif A, Hewat A W 1984 Ferroelectrics 56 219

Google Scholar

Google Scholar

[35] Vogt T, Woodward P M, Hunter B A 1999 J. Solid State Chem. 144 209

Google Scholar

Google Scholar

[36] Dong Y Q, Ma Z Y, Luo Z L, Zhou H, Fong D D, Wu W B, Gao C 2019 Adv. Mater. Interfaces 6 1900644

Google Scholar

Google Scholar

[37] Kim T H, Puggioni D, Yuan Y, Xie L, Zhou H, Campbell N, Ryan P J, Choi Y, Kim J W, Patzner J R, Ryu S, Podkaminer J P, Irwin J, Ma Y, Fennie C J, Rzchowski M S, Pan X Q, Gopalan V, Rondinelli J M, Eom C B 2016 Nature 533 68

Google Scholar

Google Scholar

[38] Glazer A M 1972 Acta Cryst. B28 3384

[39] Glazer A M, Megaw H D 1973 Acta Cryst. A29 489

[40] Chang H Y, Sivakumar T, Ok K M, Shiv Halasyamani P 2008 Inorg. Chem. 47 8511

Google Scholar

Google Scholar

[41] Gao B T, Liu H, Zhou Z Y, Deng S Q, Sun J L, Chen J 2021 Inorg. Chem. 60 3232

Google Scholar

Google Scholar

[42] Xia W R, Wu H, Xue P J, Zhu X H 2018 Nanoscale Res. Lett. 13 135

Google Scholar

Google Scholar

[43] Graetsch H A 2002 Acta Cryst. C58 i18

[44] Li Z Y, Cho Y J, Li X, Li X Y, Aimi A, Inaguma Y, Alonso J A, Fernandez-Diaz M T, Yan J Q, Downer M C, Henkelman G, Goodenough J B, Zhou J S 2018 J. Am. Chem. Soc. 140 2214

Google Scholar

Google Scholar

[45] Darlington C N W, Knight K S 1999 Acta Cryst. B55 24

[46] Ahn K H, Lookman T, Bishop A R 2004 Nature 428 401

Google Scholar

Google Scholar

[47] Chakhmouradian A R, Ross K, Mitchell R H, Swainson I 2001 Phys. Chem. Miner. 28 277

Google Scholar

Google Scholar

[48] Morita K, Davies D W, Butler K T, Walsh A 2022 Chem. Mater. 34 562

Google Scholar

Google Scholar

[49] Lin K, Gong P F, Sun J, Ma H Q, Wang Y, You L, Deng J X, Chen J, Lin Z S, Kato K C, Wu H, Huang Q Z, Xing X R 2016 Inorg. Chem. 55 2864

Google Scholar

Google Scholar

[50] Jones G O, Thomas P A 2002 Acta Cryst. B58 168

[51] Peng B, Hu Y C, Murakami S C, Zhang T T, Monserrat B 2020 Sci. Adv. 6 eabd1618

Google Scholar

Google Scholar

[52] Yoshida S, Akamatsu H, Hayashi K 2021 Phys. Rev. Lett. 127 215701

Google Scholar

Google Scholar

[53] 方成, 汪洪, 施思齐 2016 65 168201

Google Scholar

Google Scholar

Fang C, Wang H, Shi S Q 2016 Acta Phys. Sin. 65 168201

Google Scholar

Google Scholar

[54] Goldschmidt V M 1926 Naturwiss 14 477

Google Scholar

Google Scholar

[55] Prasanna R, Gold-Parker A, Leijtens T, Conings B, Babayigit A, Boyen H G, Toney M F, McGehee M D 2017 J. Am. Chem. Soc. 139 11117

Google Scholar

Google Scholar

[56] Ming C, Yang K, Zeng H, Zhang S B, Sun Y Y 2020 Mater. Horiz. 7 2985

Google Scholar

Google Scholar

[57] Zhong Q, Dahn J R, Colbow K 1992 Phys. Rev. B 46 2554

Google Scholar

Google Scholar

[58] Min T, Choi W, Seo J, Han G, Song K, Ryu S, Lee H, Lee J, Eom K, Eom C B, Jeong H Y, Kim Y M, Lee J, Oh S H 2021 Sci. Adv. 7 eabe9053

Google Scholar

Google Scholar

[59] Zhang Y, Xu X J 2021 Solid State Sci. 113 106541

Google Scholar

Google Scholar

[60] Jarin S, Yuan Y F, Zhang M X, Hu M W, Rana M, Wang S, Knibbe R 2022 Crystals 12 1570

Google Scholar

Google Scholar

[61] Guo Z M, Lin B 2021 Sol. Energy 228 689

Google Scholar

Google Scholar

[62] Talapatra A, Uberuaga B P, Stanek C R, Pilania G 2021 Chem. Mater. 33 845

Google Scholar

Google Scholar

[63] Li Z Z, Xu Q C, Sun Q D, Hou Z F, Yin W J 2019 Adv. Funct. Mater. 29 1807280

Google Scholar

Google Scholar

[64] Park H, Ali A, Mall R, Bensmail H, Sanvito S, El-Mellouhi F 2021 Mach. Learn. Sci. Technol. 2 025030

Google Scholar

Google Scholar

[65] Priyadarshini R, Joardar H, Bisoy S K, Badapanda T 2023 Solid State Commun. 361 115062

Google Scholar

Google Scholar

[66] Behara S, Poonawala T, Thomas T 2021 Comp. Mater. Sci. 188 110191

Google Scholar

Google Scholar

[67] Ghosh A, Palanichamy G, Trujillo D P, Shaikh M, Ghosh S 2022 Chem. Mater. 34 7563

Google Scholar

Google Scholar

[68] Pilania G, Balachandran P V, Gubernatis J E, Lookman T 2015 Acta Cryst. B71 507

-

图 1 部分CSCPC的结构、晶格骨架和畸变类型的示意图 (a)由配位八面体构成的类钙钛矿结构和(b)由配位四面体构成的方钠石结构, 以及根据二者分别推演出的(d)简立方的(三维)晶格骨架和(e)球状的(高维度)晶格骨架; (c) 拉伸状的Jahn-Teller畸变和 (f) C4类型的二阶Jahn-Teller畸变. 黄球、蓝球和红球分别代表A, B和X位的原子/离子

Fig. 1. Demonstration examples of some CSCPC structures, crystal frameworks and distortion types: (a) Perovskite-like structure constructed by coordination octahedra; (b) sodalite structure constructed by coordination tetrahedra; (d) simple cubic framework (three dimensions, derived from (a)); (e) globular framework (more than three dimensions, derived from (b)); (c) octahedral elongation of Jahn-Teller distortion; (f) C4 type of second-order Jahn-Teller distortion. Atoms/Ions at A, B and X sites are represented by yellow, blue and red spheres, respectively.

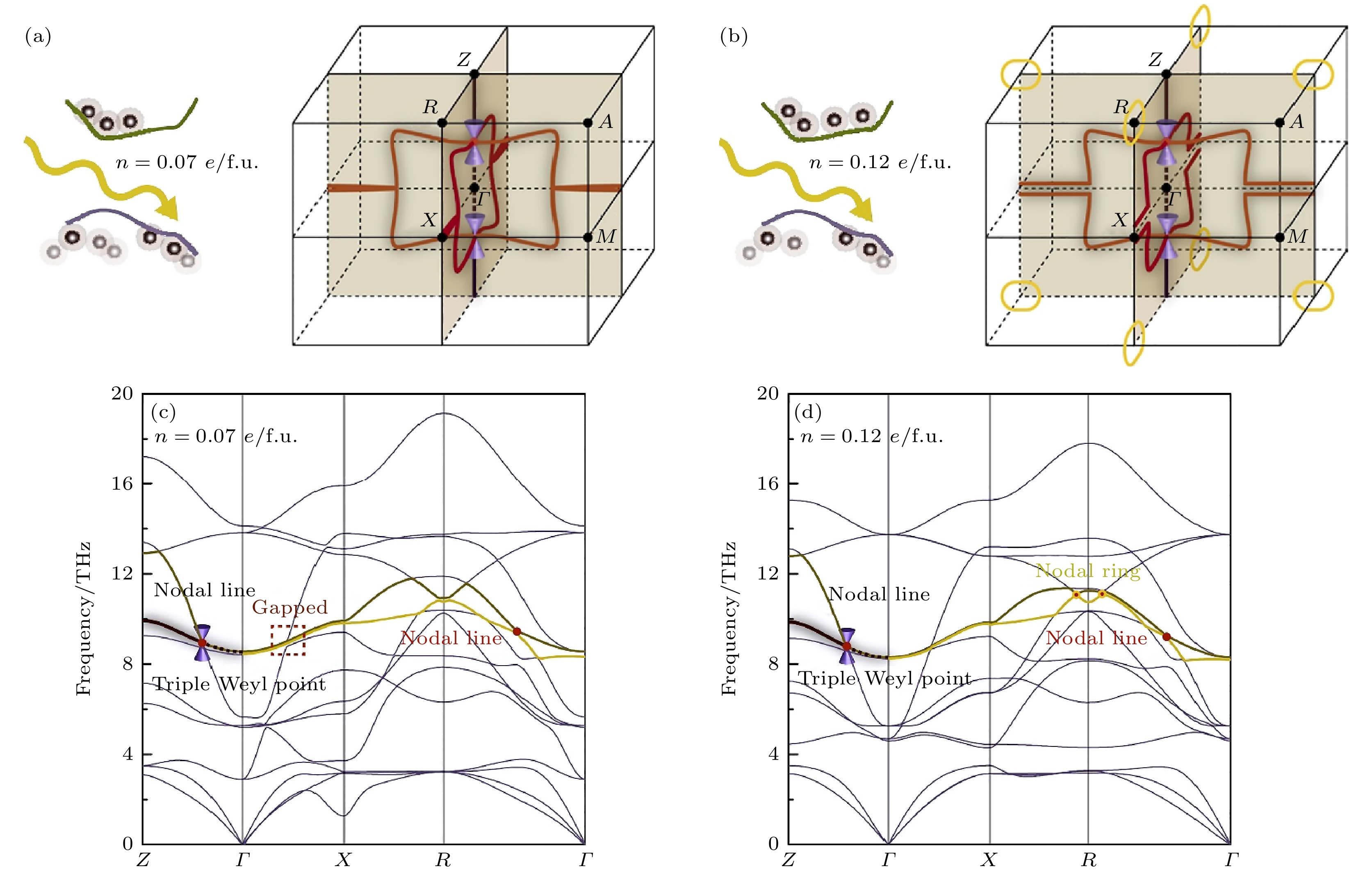

图 2 BaTiO3在光载流子浓度n分别为(a) 0.07 e/f.u.和(b) 0.12 e/f.u.时的体布里渊区中由第十和第十一声子分支形成的节线和节环, 以及两种光载流子浓度n下分别对应的声子色散(c)和(d), 引用自文献[51]

Fig. 2. Nodal lines and nodal rings formed by the 10th and 11th phonon branches in the bulk Brillouin zone for photoexcited carrier concentrations n of (a) 0.07 and (b) 0.12 e/f.u. in BaTiO3; The corresponding phonon dispersions are shown in (c) and (d), respectively. Four images are cited from Ref. [51].

图 4 (a) 中心对称的NdNiO3生长在LaAlO3的(111)面上形成的Au偏移(蓝线)和Bu偏移(红线)的体系的中心声子模随八面体倾斜角度Θ变化的函数图, 其中转动体系为a– a– c0且同相位转角ξ = 0°; (b)—(d) 不稳定的Au偏移和Bu偏移模式下八面体的倾斜角度Θ和转动角度ξ的变化导致的能量增加; (e) 用于测量Nd偏移幅度δ的电子密度图; (f) 用于测量八面体倾斜角度Θ的STEM-ABF图; 引用自文献[37]中的6幅图

Fig. 4. (a) Calculated zone-centre phonon modes with Au (blue line) and Bu (red line) symmetry for a centrosymmetric NdNiO3 on LaAlO3 (111) with varying degree of the a– a– c0 tilt angle Θ with the in-phase rotation angle ξ = 0°; (b)–(d) energetic gain for varying octahedral tilt Θ and rotation ξ angles with the unstable Au or Bu modes; (e) image of electron density map for measuring Nd displacement δ; (f) STEM-ABF image for measuring octahedral tilt angle (Θ). Six images are cited from Ref. [37]

图 3 (a) 无畸变的立方、(b) 存在八面体倾斜、(c) 出现晶格收缩时的钙钛矿晶格图; (d) 含铅和锡的钙钛矿FA1–xCsxMI3 (M = Sn, Pb)的光学带隙随铯含量变化的函数; 引用自文献[55]

Fig. 3. Perovskite lattice diagrams: (a) Undistorted cubic; (b) with octahedral tilting; (c) with lattice contraction. (d) Optical band gap of lead- and tin-based perovskites FA1–xCsxMI3 (M = Sn, Pb) as a function of cesium content. Four images are cited from Ref. [55]

-

[1] Koegel A A, Mozur E M, Oswald I W H, Jalarvo N H, Prisk T R, Tyagi M, Neilson J R 2022 J. Am. Chem. Soc. 144 1313

Google Scholar

Google Scholar

[2] Gao J, Li W, Liu J, Li Q, Li J F 2022 Research 2022 9782343

[3] Surta T W, Whittle T A, Wright M A, Niu H J, Gamon J, Gibson Q D, Daniels L M, Thomas W J, Zanella M, Shepley P M, Li Y, Goetzee-Barral A, Bell A J, Alaria J, Claridge J B, Rosseinsky M J 2021 J. Am. Chem. Soc. 143 1386

Google Scholar

Google Scholar

[4] Retuerto M, Li M R, Ignatov A, Croft M, Ramanujachary K V, Chi S, Hodges J P, Dachraoui W, Hadermann J, Tran T T, Halasyamani P S, Grams C P, Hemberger J, Greenblatt M 2013 Inorg. Chem. 52 12482

Google Scholar

Google Scholar

[5] Chi L, Swainson I, Cranswick L, Her J H, Stephens P, Knop O 2005 J. Solid State Chem. 178 1376

Google Scholar

Google Scholar

[6] Slater P R, Irvine J T S, Ishihara T, Takita Y 1998 Solid State Ionics 107 319

Google Scholar

Google Scholar

[7] García-Martín S, Alario-Franco M A, Ehrenberg H, Rodríguez-Carvajal J, Amador U 2004 J. Am. Chem. Soc. 126 3587

Google Scholar

Google Scholar

[8] Dachraoui W, Hadermann J, Abakumov A M, Tsirlin A A, Batuk D, Glazyrin K, McCammon C, Dubrovinsky L, Tendeloo G V 2012 Chem. Mater. 24 1378

Google Scholar

Google Scholar

[9] Lanfredi S, Gênova D H M, Brito I A O, Lima A R F, Nobre M A L 2011 J. Solid State Chem. 184 990

Google Scholar

Google Scholar

[10] Megaw H D, Darlington C N W 1975 Acta Cryst. A31 161

[11] King G, Woodward P M 2010 J. Mater. Chem. 20 5785

Google Scholar

Google Scholar

[12] Haumont R, Kornev I A, Lisenkov S, Bellaiche L, Kreisel J, Dkhil B 2008 Phys. Rev. B 78 134108

Google Scholar

Google Scholar

[13] Moriyama T, Kan A, Ogawa H 2013 Mater. Sci. Eng. B 178 875

Google Scholar

Google Scholar

[14] Bechtel J S, Van der Ven A 2018 Phys. Rev. Mater. 2 025401

Google Scholar

Google Scholar

[15] Drathen C, Nakagawa T, Crichton W A, Hill A H, Ohishi Y, Margadonna S 2015 J. Mater. Chem. C 3 4321

Google Scholar

Google Scholar

[16] Vailionis A, Boschker H, Siemons W, Houwman E P, Blank D H A, Rijnders G, Koster G 2011 Phys. Rev. B 83 064101

[17] Barnes P W, Lufaso M W, Woodward P M 2006 Acta Cryst. B62 384

[18] Zhang Y R, Motohashi T, Masubuchi Y, Kikkawa S 2011 J. Ceram. Soc. Jpn. 119 581

Google Scholar

Google Scholar

[19] Fischer P, Polomska M, Sosnowska I, Szymański M 1980 J. Phys. C Solid St. Phys. 13 1931

Google Scholar

Google Scholar

[20] Haumont R, Bouvier P, Pashkin A, Rabia K, Frank S, Dkhil B, Crichton W A, Kuntscher C A, Kreisel J 2009 Phys. Rev. B 79 184110

Google Scholar

Google Scholar

[21] Gómez-Salces S, Aguado F, Rodríguez F, Valiente R, González J, Haumont R, Kreisel J 2012 Phys. Rev. B 85 144109

Google Scholar

Google Scholar

[22] Huband S, Keeble D S, Zhang N, Glazer A M, Bartasyte A, Thomas P A 2017 J. Appl. Phys. 121 024102

Google Scholar

Google Scholar

[23] Adem U, Nugroho A A, Meetsma A, Palstra T T M 2007 Phys. Rev. B 75 014108

Google Scholar

Google Scholar

[24] Graetsch H A, Schreuer J, Burianek M, Mühlberg M 2012 J. Solid State Chem. 196 255

Google Scholar

Google Scholar

[25] Kahlenberg V 1998 Z. Krist. 213 13

[26] Iwata Y, Shibuya I, Wada M, Sawada A, Ishibashi Y 1985 Jpn. J. Appl. Phys. 24 597

Google Scholar

Google Scholar

[27] Woodward P M, Sleight A W, Vogt T 1997 J. Solid State Chem. 131 9

Google Scholar

Google Scholar

[28] Gerand B, Nowogrocki G, Guenot J, Figlarz M 1979 J. Solid State Chem. 29 429

Google Scholar

Google Scholar

[29] Knight K S 2022 Mineral. Mag. 86 87

Google Scholar

Google Scholar

[30] Labbé P, Leligny H, Raveau B, Schneck J, Tolédano J C 1989 J. Phys. Condens. Matter 2 25

[31] Valdez M N, Spaldin N A 2019 Polyhedron 171 181

Google Scholar

Google Scholar

[32] Oh Y S, Luo X, Huang F T, Wang Y Z, Cheong S W 2015 Nat. Mater. 14 407

Google Scholar

Google Scholar

[33] Zhang B H, Liu X Q, Chen X M 2022 J. Phys. D Appl. Phys. 55 113001

Google Scholar

Google Scholar

[34] Theobald F, Laarif A, Hewat A W 1984 Ferroelectrics 56 219

Google Scholar

Google Scholar

[35] Vogt T, Woodward P M, Hunter B A 1999 J. Solid State Chem. 144 209

Google Scholar

Google Scholar

[36] Dong Y Q, Ma Z Y, Luo Z L, Zhou H, Fong D D, Wu W B, Gao C 2019 Adv. Mater. Interfaces 6 1900644

Google Scholar

Google Scholar

[37] Kim T H, Puggioni D, Yuan Y, Xie L, Zhou H, Campbell N, Ryan P J, Choi Y, Kim J W, Patzner J R, Ryu S, Podkaminer J P, Irwin J, Ma Y, Fennie C J, Rzchowski M S, Pan X Q, Gopalan V, Rondinelli J M, Eom C B 2016 Nature 533 68

Google Scholar

Google Scholar

[38] Glazer A M 1972 Acta Cryst. B28 3384

[39] Glazer A M, Megaw H D 1973 Acta Cryst. A29 489

[40] Chang H Y, Sivakumar T, Ok K M, Shiv Halasyamani P 2008 Inorg. Chem. 47 8511

Google Scholar

Google Scholar

[41] Gao B T, Liu H, Zhou Z Y, Deng S Q, Sun J L, Chen J 2021 Inorg. Chem. 60 3232

Google Scholar

Google Scholar

[42] Xia W R, Wu H, Xue P J, Zhu X H 2018 Nanoscale Res. Lett. 13 135

Google Scholar

Google Scholar

[43] Graetsch H A 2002 Acta Cryst. C58 i18

[44] Li Z Y, Cho Y J, Li X, Li X Y, Aimi A, Inaguma Y, Alonso J A, Fernandez-Diaz M T, Yan J Q, Downer M C, Henkelman G, Goodenough J B, Zhou J S 2018 J. Am. Chem. Soc. 140 2214

Google Scholar

Google Scholar

[45] Darlington C N W, Knight K S 1999 Acta Cryst. B55 24

[46] Ahn K H, Lookman T, Bishop A R 2004 Nature 428 401

Google Scholar

Google Scholar

[47] Chakhmouradian A R, Ross K, Mitchell R H, Swainson I 2001 Phys. Chem. Miner. 28 277

Google Scholar

Google Scholar

[48] Morita K, Davies D W, Butler K T, Walsh A 2022 Chem. Mater. 34 562

Google Scholar

Google Scholar

[49] Lin K, Gong P F, Sun J, Ma H Q, Wang Y, You L, Deng J X, Chen J, Lin Z S, Kato K C, Wu H, Huang Q Z, Xing X R 2016 Inorg. Chem. 55 2864

Google Scholar

Google Scholar

[50] Jones G O, Thomas P A 2002 Acta Cryst. B58 168

[51] Peng B, Hu Y C, Murakami S C, Zhang T T, Monserrat B 2020 Sci. Adv. 6 eabd1618

Google Scholar

Google Scholar

[52] Yoshida S, Akamatsu H, Hayashi K 2021 Phys. Rev. Lett. 127 215701

Google Scholar

Google Scholar

[53] 方成, 汪洪, 施思齐 2016 65 168201

Google Scholar

Google Scholar

Fang C, Wang H, Shi S Q 2016 Acta Phys. Sin. 65 168201

Google Scholar

Google Scholar

[54] Goldschmidt V M 1926 Naturwiss 14 477

Google Scholar

Google Scholar

[55] Prasanna R, Gold-Parker A, Leijtens T, Conings B, Babayigit A, Boyen H G, Toney M F, McGehee M D 2017 J. Am. Chem. Soc. 139 11117

Google Scholar

Google Scholar

[56] Ming C, Yang K, Zeng H, Zhang S B, Sun Y Y 2020 Mater. Horiz. 7 2985

Google Scholar

Google Scholar

[57] Zhong Q, Dahn J R, Colbow K 1992 Phys. Rev. B 46 2554

Google Scholar

Google Scholar

[58] Min T, Choi W, Seo J, Han G, Song K, Ryu S, Lee H, Lee J, Eom K, Eom C B, Jeong H Y, Kim Y M, Lee J, Oh S H 2021 Sci. Adv. 7 eabe9053

Google Scholar

Google Scholar

[59] Zhang Y, Xu X J 2021 Solid State Sci. 113 106541

Google Scholar

Google Scholar

[60] Jarin S, Yuan Y F, Zhang M X, Hu M W, Rana M, Wang S, Knibbe R 2022 Crystals 12 1570

Google Scholar

Google Scholar

[61] Guo Z M, Lin B 2021 Sol. Energy 228 689

Google Scholar

Google Scholar

[62] Talapatra A, Uberuaga B P, Stanek C R, Pilania G 2021 Chem. Mater. 33 845

Google Scholar

Google Scholar

[63] Li Z Z, Xu Q C, Sun Q D, Hou Z F, Yin W J 2019 Adv. Funct. Mater. 29 1807280

Google Scholar

Google Scholar

[64] Park H, Ali A, Mall R, Bensmail H, Sanvito S, El-Mellouhi F 2021 Mach. Learn. Sci. Technol. 2 025030

Google Scholar

Google Scholar

[65] Priyadarshini R, Joardar H, Bisoy S K, Badapanda T 2023 Solid State Commun. 361 115062

Google Scholar

Google Scholar

[66] Behara S, Poonawala T, Thomas T 2021 Comp. Mater. Sci. 188 110191

Google Scholar

Google Scholar

[67] Ghosh A, Palanichamy G, Trujillo D P, Shaikh M, Ghosh S 2022 Chem. Mater. 34 7563

Google Scholar

Google Scholar

[68] Pilania G, Balachandran P V, Gubernatis J E, Lookman T 2015 Acta Cryst. B71 507

计量

- 文章访问数: 6068

- PDF下载量: 114

- 被引次数: 0

下载:

下载: