-

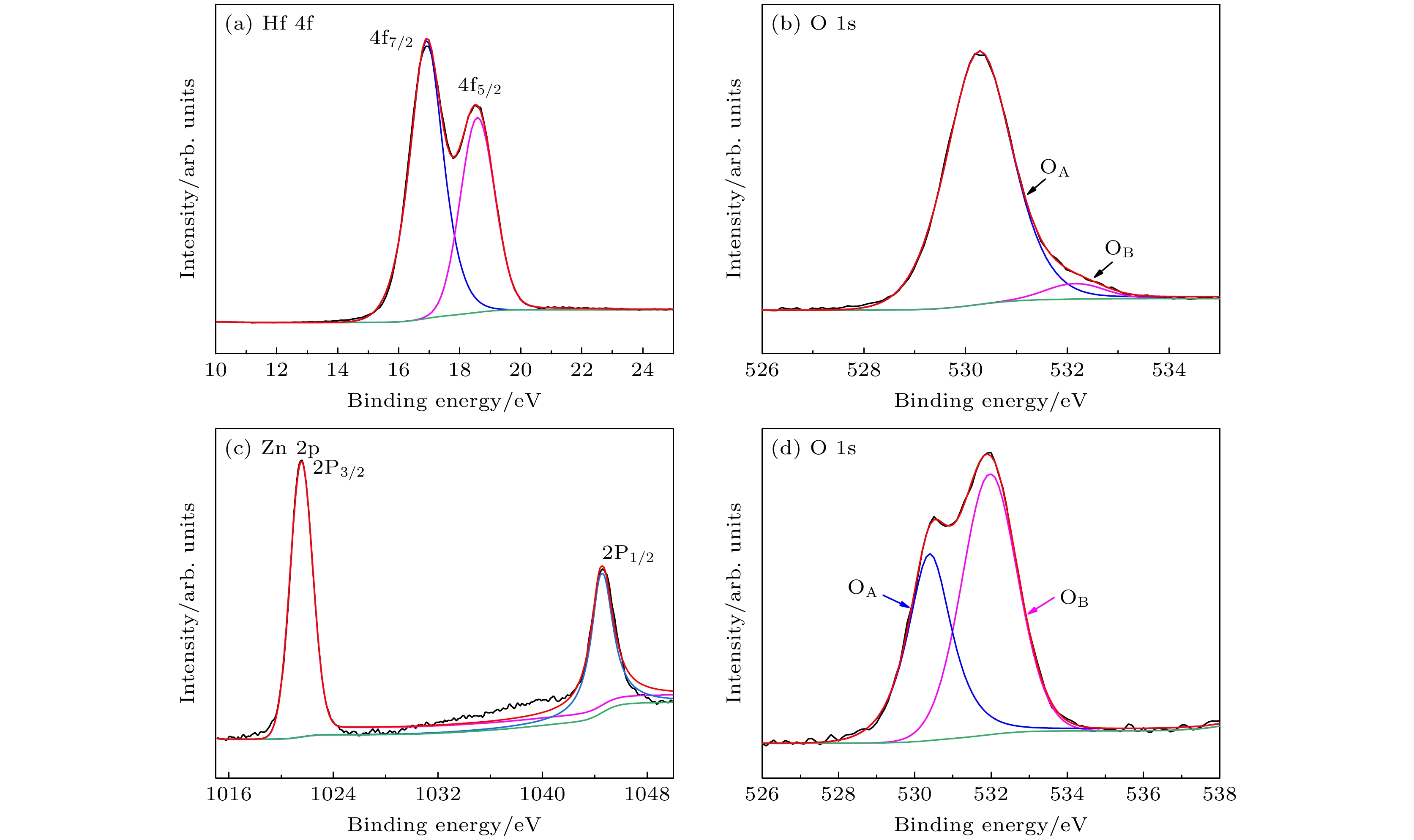

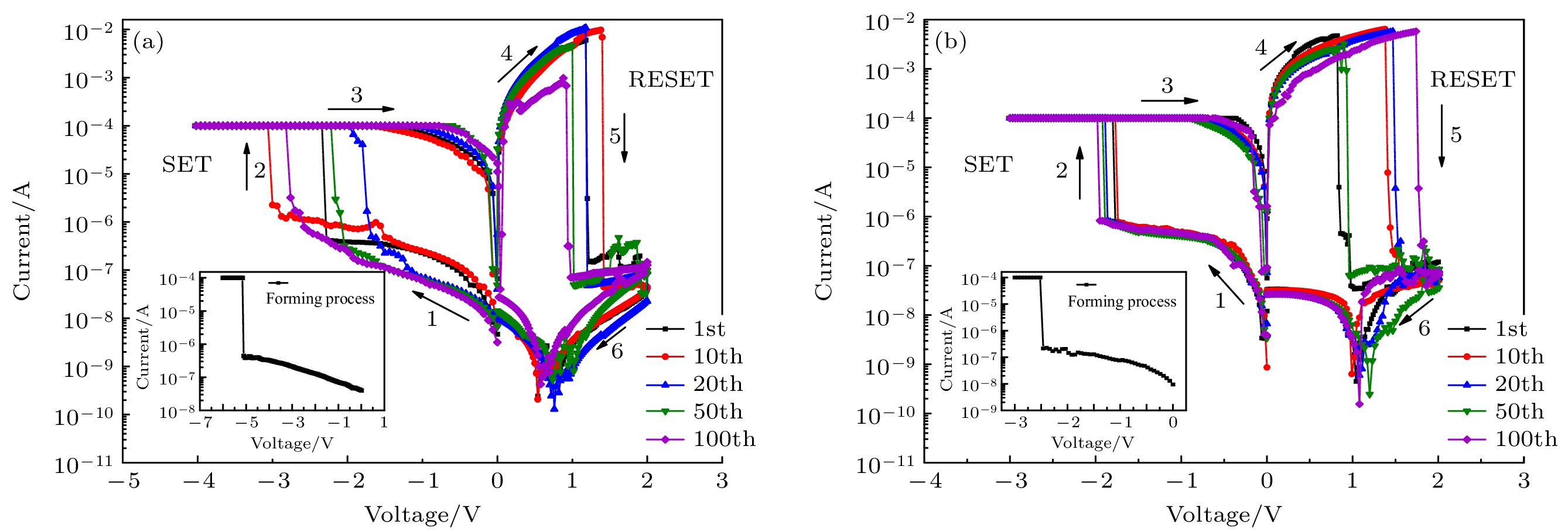

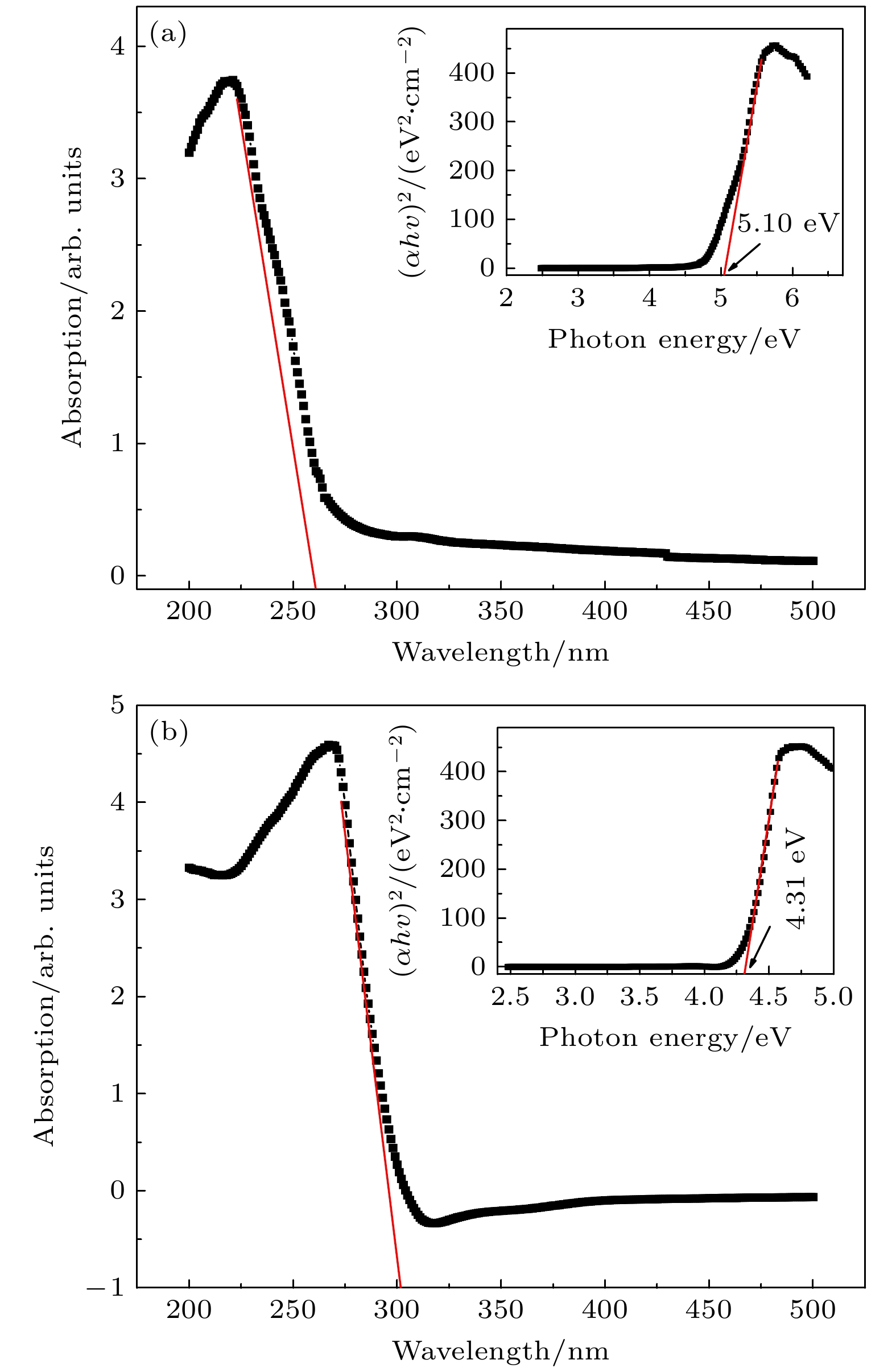

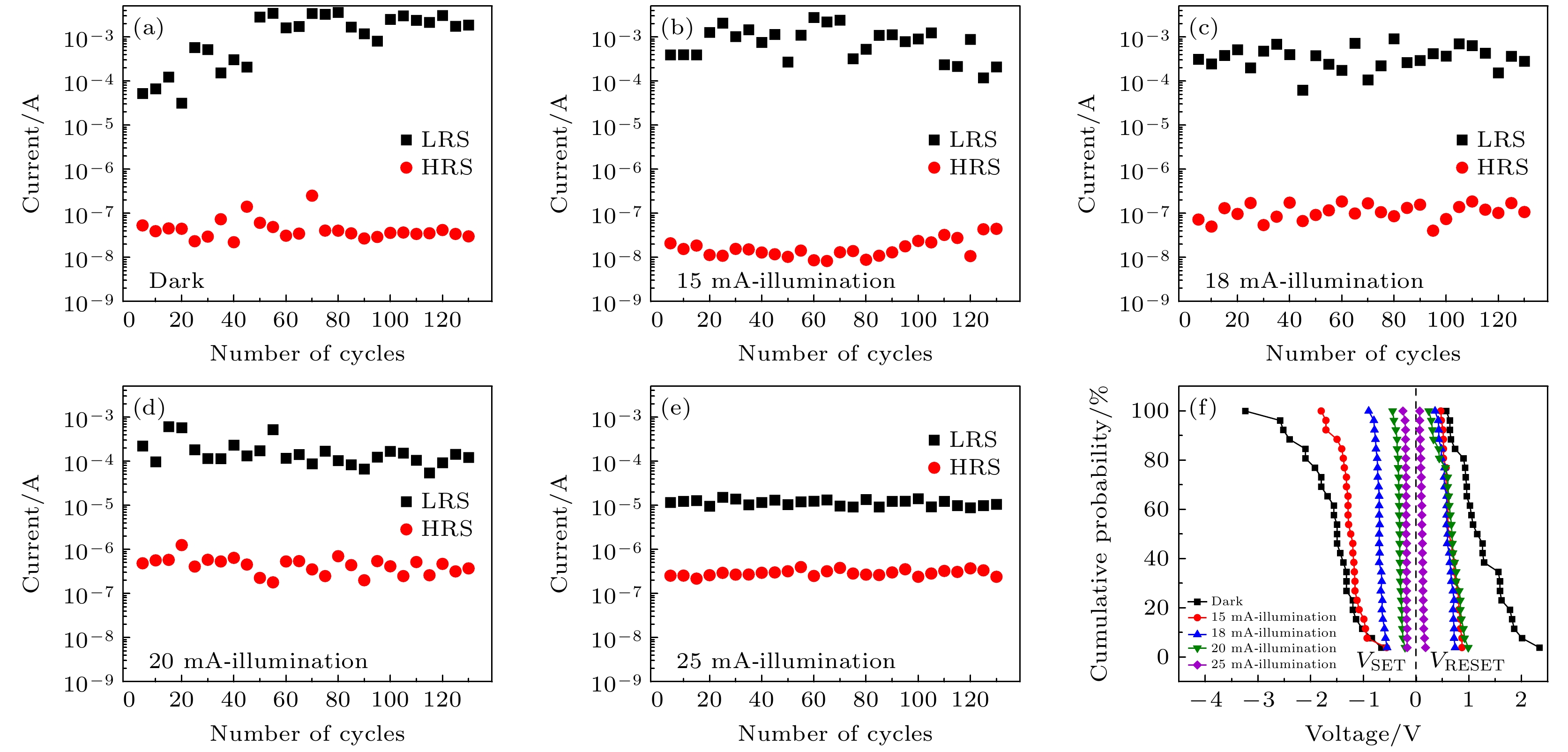

利用磁控溅射法制备了Cu/HfOx/Pt和Cu/HfOx-ZnO/Pt器件. HfOx器件和HfOx-ZnO器件都表现出双极性阻变特性以及具有良好的保持性, 但HfOx-ZnO器件具有更加优异的阻变性能, 例如均一性、耐受性和重复性. 研究表明, 通过增加ZnO富氧层有利于提高器件的阻变性能. 另外, HfOx薄膜的禁带宽度约为5.10 eV, 对255 nm波长的光照没有响应. 而HfOx-ZnO薄膜的禁带宽度减小为4.31 eV, 该器件在波长255 nm的光照作用下, 不仅可以提高器件的阻变性能, 还可以通过设置不同强度的光照使器件具有多级存储的能力. 研究发现, 器件在有无光照作用下的阻变行为都与薄膜中的氧空位有关, 所以本文提出了氧空位导电细丝物理模型来解释器件的阻变行为. 本文使用光电协同的方法为研制出低功耗、高存储密度的阻变存储器提供了新思路.Cu/HfOx/Pt and Cu/HfOx-ZnO/Pt resistance random access memory (RRAM) devices are prepared by magnetron sputtering. The results show that the Cu/HfOx/Pt device has the stable bipolar resistive switching characteristics, good retention (as long as 104 s), and a switching ratio greater than 103. The current conduction mechanism of HfOx device is ohmic conduction at low resistance, while space charge limited current (SCLC) mechanism dominates at high resistance, and the conductive filament is composed of oxygen vacancies. Owing to the low content and random distribution of oxygen defects in the HfOx film, the endurance and uniformity of the device are poor. Compared with HfOx device, HfOx-ZnO device exhibits lower operating voltage and better uniformity and stability. The main reason is that ZnO material has smaller formation energy of oxygen vacancy, which can produce more oxygen defects under electric field to participate in the resistive switching behavior of the device, thereby reducing the operating voltage and improving the uniformity of the device. In addition, owing to the existence of the interface between HfOx and ZnO film, the random distribution of oxygen defects is inhibited, that is, the random fracture and formation of conductive filament are inhibited, which is beneficial to improving the uniformity of the device. In addition, the resistive switching behaviors of Cu/HfOx/Pt and Cu/HfOx-ZnO/Pt RRAM devices under different intensities of 255 nm ultraviolet illumination are studied. For Cu/HfOx/Pt device, the light of 255 nm wavelength shows little effect on its resistive switching characteristics. For the Cu/HfOx-ZnO/Pt RRAM device, the operating voltage and stability of the device can be improved by increasing the light intensity. Although the switching ratio of the device decreases with the increase of light intensity, the device can exhibit multiple resistance states by adjusting different light intensities to achieve multi-level storage. Finally, the analysis of the I-V curves of the devices indicates that the two types of devices show similar resistive switching mechanisms under the illumination of light or no light, which can be explained by the resistive switching mechanism of oxygen vacancy conductive filament. Therefore, a physical model based on the oxygen vacancy conductive filament is established to explain the resistive switching behavior of the device in this paper.

-

Keywords:

- resistance random access memory /

- oxygen vacancies /

- photoelectric modulation /

- multilevel memory

[1] Guo T, Elshekh H, Yu Z, Yu B, Wang D, Kadhim M S, Chen Y Z, Hou W T, Sun B 2019 Mater. Today Commun. 20 100540

Google Scholar

Google Scholar

[2] Yoo S J, Agbenyeke R E, Choi H, Jeon K, Ryu J J, Eom T, Park B K, Chung T M, Jeong D S, Song W 2022 Appl. Surf. Sci. 577 151936

Google Scholar

Google Scholar

[3] Killedar S T, Ahir N A, Morankar P J, Tiwari A P, Kim D K 2020 Opt. Mater. 109 110333

Google Scholar

Google Scholar

[4] 龚少康, 周静, 王志青, 朱茂聪, 沈杰, 吴智, 陈文 2021 70 197301

Google Scholar

Google Scholar

Gong S K, Zhou J, Wang Z Q, Zhu M C, Shen J, Wu Z, Chen W 2021 Acta Phys. Sin. 70 197301

Google Scholar

Google Scholar

[5] Guo T T, Huang H X, Huang X L, Wang Y, Duan L, Xu Z 2022 J. Alloys Compd. 921 166218

Google Scholar

Google Scholar

[6] More K D, Narwade V N, Halge D I, Dadge J W, Bogle K A 2020 Physica B 595 412339

Google Scholar

Google Scholar

[7] He H K, Yang R, Zhou W, Huang H M, Xiong J, Gan L, Zhai T Y, Guo X 2018 Small 14 1800079

Google Scholar

Google Scholar

[8] Zhou H, Wei X D, Wei W, Ye C, Zhang R L, Zhang L, Xia Q, Huang H, Wang B 2019 Surf. Coat. Tech. 359 150

Google Scholar

Google Scholar

[9] 张娇娇, 周龙, 王洪强, 董广志, 樊慧庆 2023 铸造技术 44 23

Google Scholar

Google Scholar

Zhang J J, Zhou L, Wang H Q, Dong G Z, Fan H Q 2023 Foundry Technology 44 23

Google Scholar

Google Scholar

[10] Wang Y H, He Z Q, Lai X B, Liu B Y, Chen Y B, Zhang L W, Wang F P 2021 J. Alloys Compd. 873 159809

Google Scholar

Google Scholar

[11] Strukov D B, Snider G S, Stewart D R, Williams R S 2008 Nature 453 80

Google Scholar

Google Scholar

[12] Zhang L, Huang H, Ye C, Chang K C, Zhang R L, Xia Q, Wei X D, Wei W, Wang W F 2018 Semicond. Sci. Tech. 33 085013

Google Scholar

Google Scholar

[13] 代月花, 潘志勇, 陈真, 王菲菲, 李宁, 金波, 李晓风 2016 65 073101

Google Scholar

Google Scholar

Dai Y H, Pan Z Y, Chen Z, Wang F F, Li N, Jin B, Li X F 2016 Acta Phys. Sin. 65 073101

Google Scholar

Google Scholar

[14] Leydecker T, Herder M, Pavlica E, Bratina G, Hecht S, Orgiu E, Samorì P 2016 Nat Nanotechnol. 11 769

Google Scholar

Google Scholar

[15] Lee Y J, Liu K H, Peng Y, Yen M C, Tamada K 2020 Nat. Commun. 12 4460

Google Scholar

Google Scholar

[16] 曾凡菊, 谭永前, 唐孝生, 张小梅, 尹海峰 2021 70 157301

Google Scholar

Google Scholar

Zeng F J, Tan Y Q, Tang X S, Zhang X M, Yin H F 2021 Acta Phys. Sin. 70 157301

Google Scholar

Google Scholar

[17] Ge N N, Gong C H, Yuan X C, Zeng H Z, Wei X H 2018 RSC Adv. 8 29499

Google Scholar

Google Scholar

[18] Kao M C, Chen H Z, Chen K H, Shi J B, Chen K P 2020 Thin Solid Films 697 137816

Google Scholar

Google Scholar

[19] Chen Z L, Yu Y, Jin L F, Li Y F, Li Q Y, Li T T, Li J, Zhao H L, Zhang Y T, Dai H T 2021 J. Mater Chem. C 8 2178

Google Scholar

Google Scholar

[20] Singh L, Kaushik V, Rajput S, Kumar M 2021 J. Lightwave Technol. 39 5869

Google Scholar

Google Scholar

[21] Ungureanu M, Zazpe R, Golmar F, Stoliar P, Llopis R, Casanova F, Hueso L E 2012 Adv. Mater. 24 2496

Google Scholar

Google Scholar

[22] Zhu X J, Lu W D 2018 Acs Nano 12 1242

Google Scholar

Google Scholar

[23] Russo P, Xiao M, Liang R, Zhou N Y 2018 Adv Funct. Mater. 28 17062301

Google Scholar

Google Scholar

[24] Xie S, Pei L, Li M Y, Zhu Y D, Cheng X Y, Ding H Q, Xiong R 2018 J. Alloys Compd. 778 141

Google Scholar

Google Scholar

[25] Xue W H, Ci W J, Xu X H, Liu G 2020 Chin. Phys. B. 29 048401

Google Scholar

Google Scholar

[26] Sharath S U, Bertaud T, Kurian J, Hildebrandt E, Walczyk C, Calka P, Zaumseil P, Sowinska M, Walczyk D, Gloskovskii A, Schroeder T, Alff L 2014 Appl. Phys. Lett. 104 063502

Google Scholar

Google Scholar

[27] Guo T T, Wang Y X, Duan L, Fan J B, Wang Z Z 2021 Vacuum 189 110224

Google Scholar

Google Scholar

[28] Bon C Y, Kim D, Lee K, Choi S, Yoo S I 2020 AIP Adv. 10 115117

Google Scholar

Google Scholar

[29] Kannadasan N, Shanmugam N, Cholan S, Sathishkumar K, Viruthagiri G, Poonguzhali R 2014 Current Appl. Phys. 14 1760

Google Scholar

Google Scholar

[30] Pereira L, Barquinha P, Fortunato E, Martins R 2005 Mater. Sci Engineer B 118 210

Google Scholar

Google Scholar

[31] Praksgh R, Sharma S, Kumar A, Kaur D 2019 Appl. Phys. Lett. 115 052108

Google Scholar

Google Scholar

[32] Wu P, Zhang J, Lu J G, Li X F, Wu C J, Sun R J, Feng L S, Jiang Q J, Lu B, Pan X H 2014 IEEE T Electron. Dev. 61 1431

Google Scholar

Google Scholar

[33] Liu P, She G W, Liao Z L, Wang Y, Wang Z Z, Shi W S, Zhang X H, Lee S T, Chen D M 2009 Appl. Phys. Lett. 94 635

Google Scholar

Google Scholar

[34] Laiho R, Poloskin D S, Stepanov Y P, Vlasenko M P, Vlasenko L S, Zakhvalinskii V S 2009 J Appl. Phys. 106 56

Google Scholar

Google Scholar

[35] Wang X J, Wang Y Y, Feng M, Wang K Y, Tian Y M 2020 Current Appl. Phys. 20 261104

Google Scholar

Google Scholar

[36] Tan T T, Du Y H, Sun Y L, Zhang H, Cao A, Zha G Q 2019 J. Mater. Sci. 30 13445

Google Scholar

Google Scholar

-

-

[1] Guo T, Elshekh H, Yu Z, Yu B, Wang D, Kadhim M S, Chen Y Z, Hou W T, Sun B 2019 Mater. Today Commun. 20 100540

Google Scholar

Google Scholar

[2] Yoo S J, Agbenyeke R E, Choi H, Jeon K, Ryu J J, Eom T, Park B K, Chung T M, Jeong D S, Song W 2022 Appl. Surf. Sci. 577 151936

Google Scholar

Google Scholar

[3] Killedar S T, Ahir N A, Morankar P J, Tiwari A P, Kim D K 2020 Opt. Mater. 109 110333

Google Scholar

Google Scholar

[4] 龚少康, 周静, 王志青, 朱茂聪, 沈杰, 吴智, 陈文 2021 70 197301

Google Scholar

Google Scholar

Gong S K, Zhou J, Wang Z Q, Zhu M C, Shen J, Wu Z, Chen W 2021 Acta Phys. Sin. 70 197301

Google Scholar

Google Scholar

[5] Guo T T, Huang H X, Huang X L, Wang Y, Duan L, Xu Z 2022 J. Alloys Compd. 921 166218

Google Scholar

Google Scholar

[6] More K D, Narwade V N, Halge D I, Dadge J W, Bogle K A 2020 Physica B 595 412339

Google Scholar

Google Scholar

[7] He H K, Yang R, Zhou W, Huang H M, Xiong J, Gan L, Zhai T Y, Guo X 2018 Small 14 1800079

Google Scholar

Google Scholar

[8] Zhou H, Wei X D, Wei W, Ye C, Zhang R L, Zhang L, Xia Q, Huang H, Wang B 2019 Surf. Coat. Tech. 359 150

Google Scholar

Google Scholar

[9] 张娇娇, 周龙, 王洪强, 董广志, 樊慧庆 2023 铸造技术 44 23

Google Scholar

Google Scholar

Zhang J J, Zhou L, Wang H Q, Dong G Z, Fan H Q 2023 Foundry Technology 44 23

Google Scholar

Google Scholar

[10] Wang Y H, He Z Q, Lai X B, Liu B Y, Chen Y B, Zhang L W, Wang F P 2021 J. Alloys Compd. 873 159809

Google Scholar

Google Scholar

[11] Strukov D B, Snider G S, Stewart D R, Williams R S 2008 Nature 453 80

Google Scholar

Google Scholar

[12] Zhang L, Huang H, Ye C, Chang K C, Zhang R L, Xia Q, Wei X D, Wei W, Wang W F 2018 Semicond. Sci. Tech. 33 085013

Google Scholar

Google Scholar

[13] 代月花, 潘志勇, 陈真, 王菲菲, 李宁, 金波, 李晓风 2016 65 073101

Google Scholar

Google Scholar

Dai Y H, Pan Z Y, Chen Z, Wang F F, Li N, Jin B, Li X F 2016 Acta Phys. Sin. 65 073101

Google Scholar

Google Scholar

[14] Leydecker T, Herder M, Pavlica E, Bratina G, Hecht S, Orgiu E, Samorì P 2016 Nat Nanotechnol. 11 769

Google Scholar

Google Scholar

[15] Lee Y J, Liu K H, Peng Y, Yen M C, Tamada K 2020 Nat. Commun. 12 4460

Google Scholar

Google Scholar

[16] 曾凡菊, 谭永前, 唐孝生, 张小梅, 尹海峰 2021 70 157301

Google Scholar

Google Scholar

Zeng F J, Tan Y Q, Tang X S, Zhang X M, Yin H F 2021 Acta Phys. Sin. 70 157301

Google Scholar

Google Scholar

[17] Ge N N, Gong C H, Yuan X C, Zeng H Z, Wei X H 2018 RSC Adv. 8 29499

Google Scholar

Google Scholar

[18] Kao M C, Chen H Z, Chen K H, Shi J B, Chen K P 2020 Thin Solid Films 697 137816

Google Scholar

Google Scholar

[19] Chen Z L, Yu Y, Jin L F, Li Y F, Li Q Y, Li T T, Li J, Zhao H L, Zhang Y T, Dai H T 2021 J. Mater Chem. C 8 2178

Google Scholar

Google Scholar

[20] Singh L, Kaushik V, Rajput S, Kumar M 2021 J. Lightwave Technol. 39 5869

Google Scholar

Google Scholar

[21] Ungureanu M, Zazpe R, Golmar F, Stoliar P, Llopis R, Casanova F, Hueso L E 2012 Adv. Mater. 24 2496

Google Scholar

Google Scholar

[22] Zhu X J, Lu W D 2018 Acs Nano 12 1242

Google Scholar

Google Scholar

[23] Russo P, Xiao M, Liang R, Zhou N Y 2018 Adv Funct. Mater. 28 17062301

Google Scholar

Google Scholar

[24] Xie S, Pei L, Li M Y, Zhu Y D, Cheng X Y, Ding H Q, Xiong R 2018 J. Alloys Compd. 778 141

Google Scholar

Google Scholar

[25] Xue W H, Ci W J, Xu X H, Liu G 2020 Chin. Phys. B. 29 048401

Google Scholar

Google Scholar

[26] Sharath S U, Bertaud T, Kurian J, Hildebrandt E, Walczyk C, Calka P, Zaumseil P, Sowinska M, Walczyk D, Gloskovskii A, Schroeder T, Alff L 2014 Appl. Phys. Lett. 104 063502

Google Scholar

Google Scholar

[27] Guo T T, Wang Y X, Duan L, Fan J B, Wang Z Z 2021 Vacuum 189 110224

Google Scholar

Google Scholar

[28] Bon C Y, Kim D, Lee K, Choi S, Yoo S I 2020 AIP Adv. 10 115117

Google Scholar

Google Scholar

[29] Kannadasan N, Shanmugam N, Cholan S, Sathishkumar K, Viruthagiri G, Poonguzhali R 2014 Current Appl. Phys. 14 1760

Google Scholar

Google Scholar

[30] Pereira L, Barquinha P, Fortunato E, Martins R 2005 Mater. Sci Engineer B 118 210

Google Scholar

Google Scholar

[31] Praksgh R, Sharma S, Kumar A, Kaur D 2019 Appl. Phys. Lett. 115 052108

Google Scholar

Google Scholar

[32] Wu P, Zhang J, Lu J G, Li X F, Wu C J, Sun R J, Feng L S, Jiang Q J, Lu B, Pan X H 2014 IEEE T Electron. Dev. 61 1431

Google Scholar

Google Scholar

[33] Liu P, She G W, Liao Z L, Wang Y, Wang Z Z, Shi W S, Zhang X H, Lee S T, Chen D M 2009 Appl. Phys. Lett. 94 635

Google Scholar

Google Scholar

[34] Laiho R, Poloskin D S, Stepanov Y P, Vlasenko M P, Vlasenko L S, Zakhvalinskii V S 2009 J Appl. Phys. 106 56

Google Scholar

Google Scholar

[35] Wang X J, Wang Y Y, Feng M, Wang K Y, Tian Y M 2020 Current Appl. Phys. 20 261104

Google Scholar

Google Scholar

[36] Tan T T, Du Y H, Sun Y L, Zhang H, Cao A, Zha G Q 2019 J. Mater. Sci. 30 13445

Google Scholar

Google Scholar

计量

- 文章访问数: 4978

- PDF下载量: 139

- 被引次数: 0

下载:

下载: