-

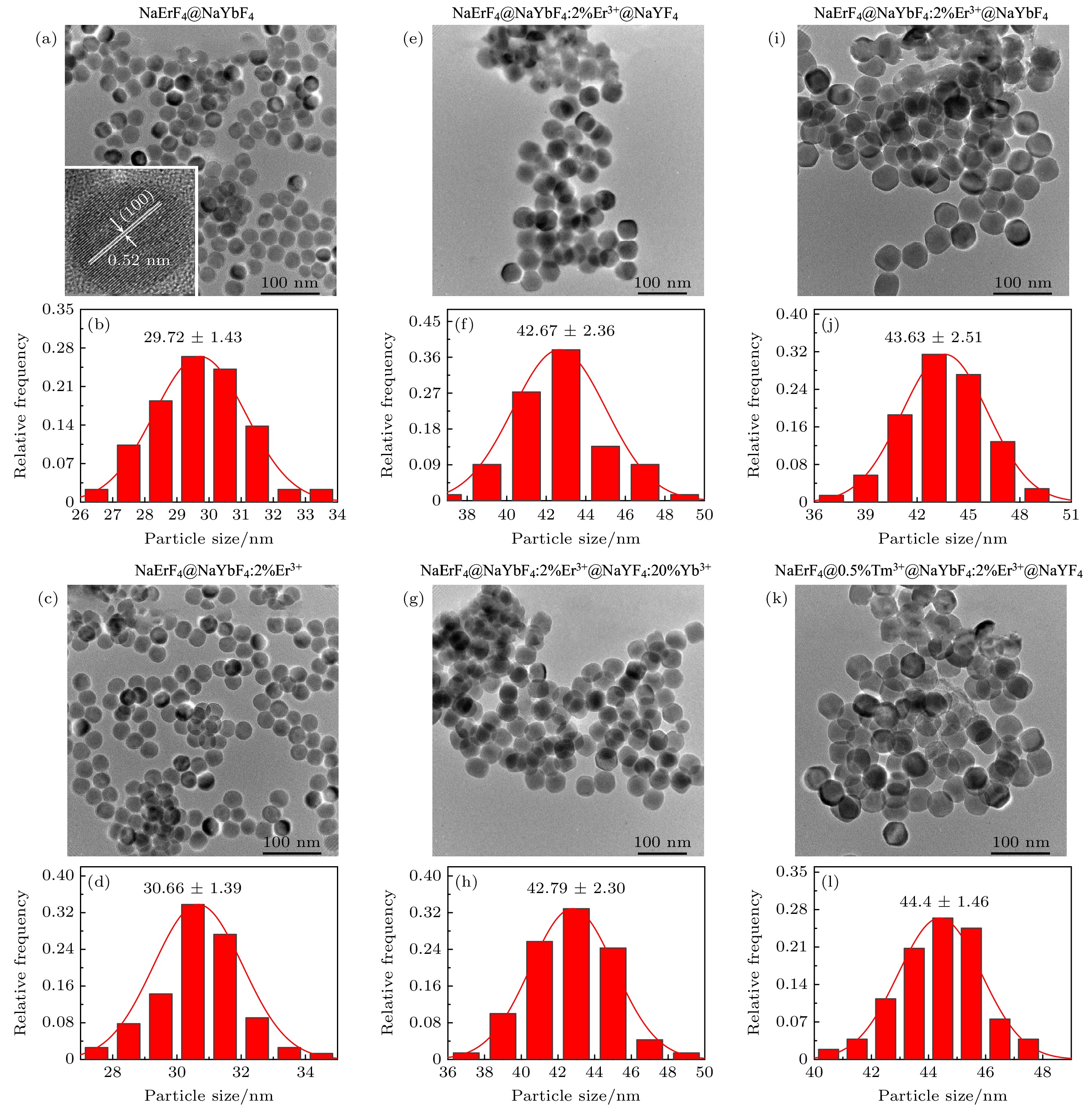

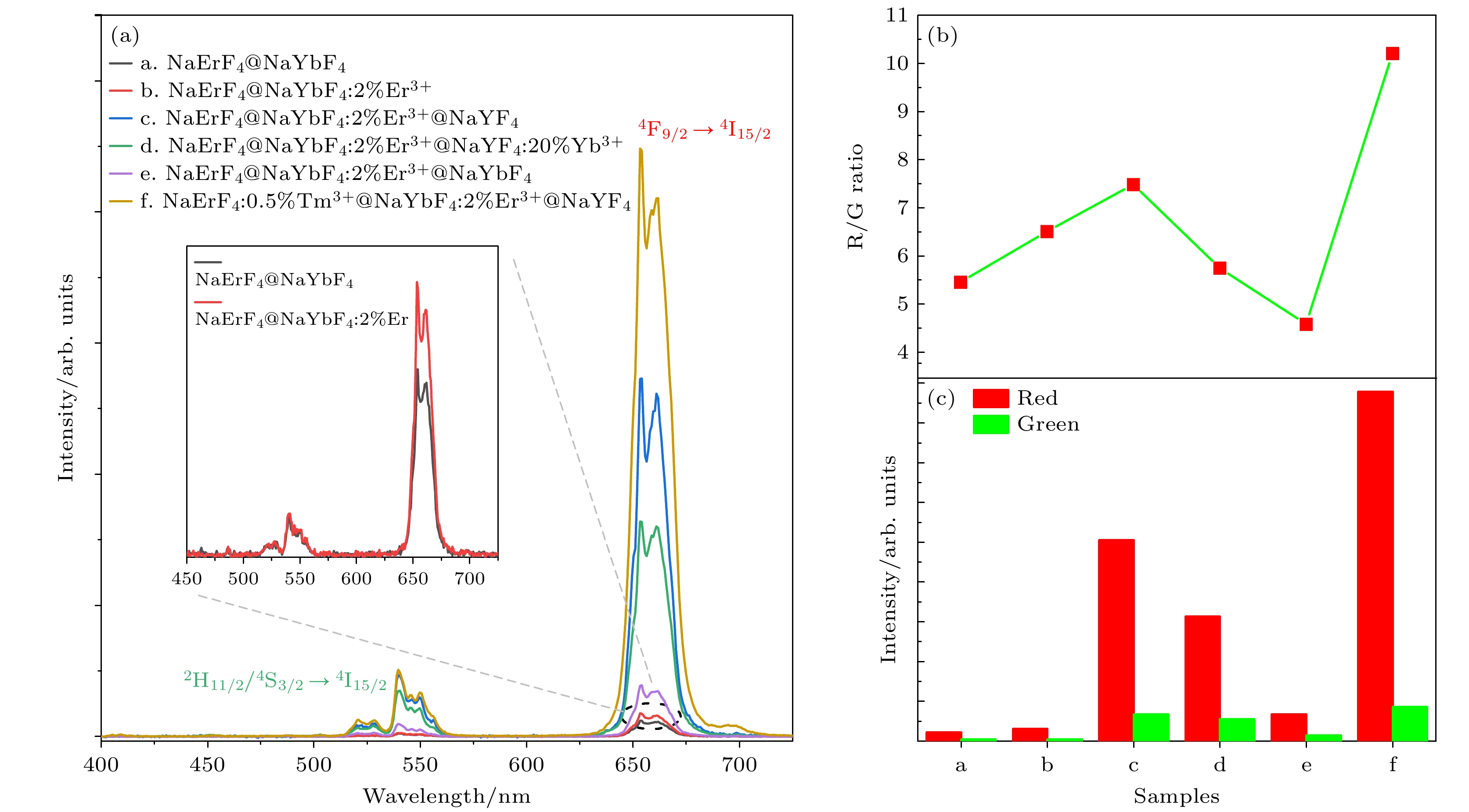

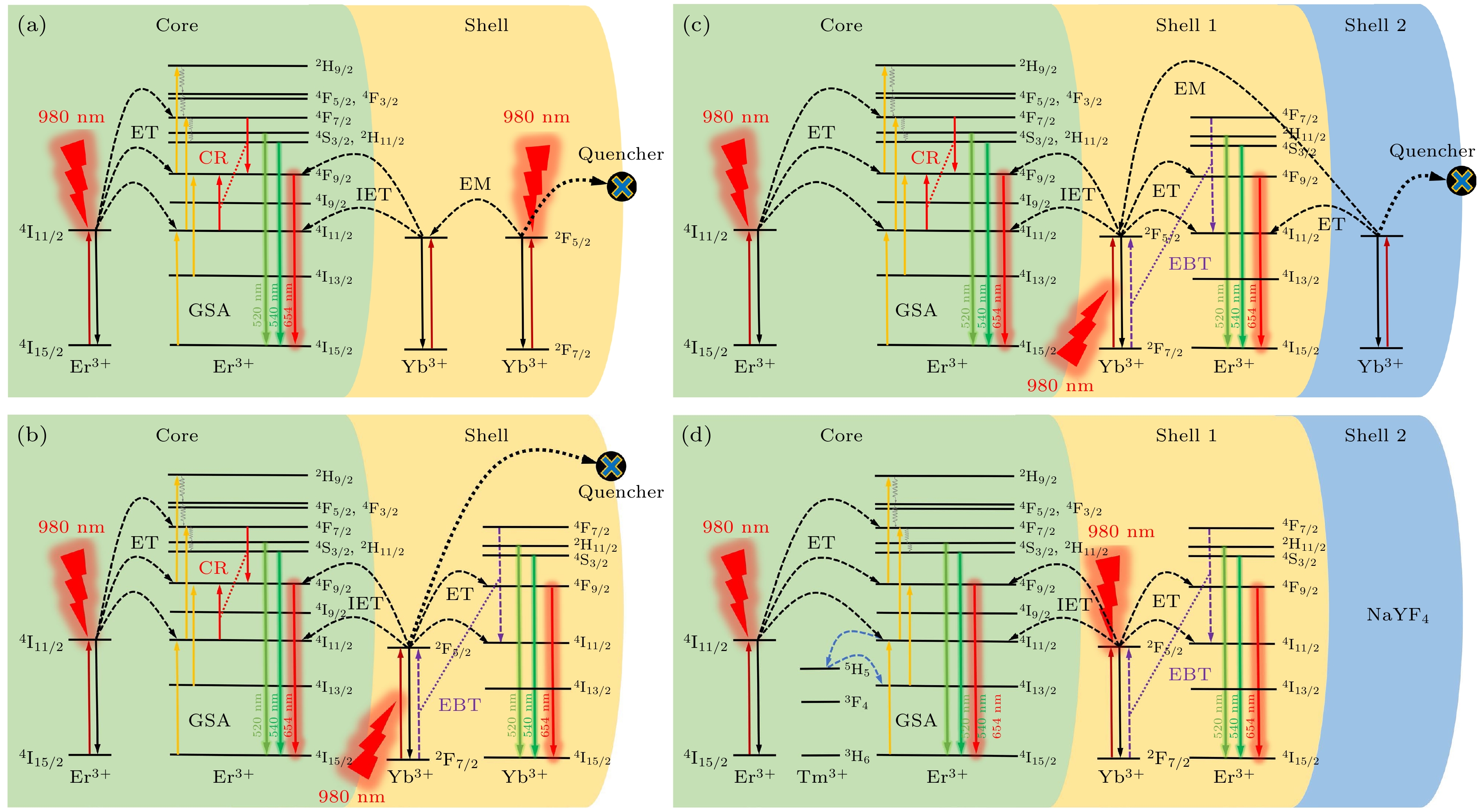

构建核壳结构已被广泛应用于增强及调控稀土掺杂微/纳材料的发光性能. 本工作旨在通过构建NaErF4@NaYbF4:2%Er3+纳米核壳晶体, 实现了Er3+离子的红光发射增强. 实验结果表明: 当NaErF4纳米晶体包覆NaYbF4:2%Er3+活性壳时, 在980 nm激光激发下, 其Er3+离子的红光发射强度相比NaErF4@NaYbF4核壳晶体增强了1.4倍, 且红绿比由5.4提高至6.5. 同时, 当NaErF4@ NaYbF4:2%Er3+ 核壳晶体再次包覆NaYF4惰性壳及引入微量Tm3+离子时, 其Er3+离子的红光发射强度相比于NaErF4@NaYbF4核壳结构分别增强了23.2和40.3倍, 且红绿比分别提高到7.5和10.2. 基于不同核壳晶体的光谱特性、离子间能量传递过程及其发光动力学, 对不同核壳晶体中Er3+离子的红光增强机理进行了讨论. 结果表明Er3+离子的红光增强主要借助高浓度Yb3+离子的双向能量传递及Tm3+离子的能量俘获效应所致, 同时NaYF4惰性壳的包覆也有效降低纳米晶体表面猝灭效应. 本文所构建的具有高效红光发射的NaErF4@NaYbF4:2%Er3+@NaYF4核壳纳米晶体在多彩防伪、 显示及生物成像等领域中具有巨大的应用潜力.Building core-shell structures are widely used to enhance and regulate the luminescence properties of rare-earth-doped micro/nano materials. In this work, a variety of different NaErF4 core-shell and core-shell-shell nanocrystals are successfully constructed based on high temperature co-precipitation method by epitaxial growth technology. The upconversion red emission intensities of Er3+ ions in different core-shell structures are effectively enhanced by regulating their structures and doping ions. The experimental structures show that the constructed core-shell nanocrystals each have a hexagonal phase structure, and core-shell structure of about 40 nm. In the near infrared 980 nm laser excitation, the NaErF4 core-shell nanocrystal shows a strong single-band red emission. And the single-band red emission intensity of Er3+ ions is enhanced through constructing the NaErF4@NaYbF4:2%Er3+ core-shell structure. The experimental results show that red emission intensity of Er3+ ions is about 1.4 times higher than that of the NaErF4@NaYbF4 core-shell structure by constructing the NaErF4@NaYbF4:2%Er3+ core-shell structures under 980 nm excitation, and its red/green emission intensity ratio increases from 5.4 to 6.5. Meanwhile, when NaErF4@NaYbF4:2%Er3+ core-shell structure recoats the NaYF4 inert shell and is added with a small quantity of Tm3+ ions, their red emission intensities of Er3+ ions are 23.2 times and 40.3 times that of NaErF4@NaYbF4 core-shell structures, and their red/green emission intensity ratios reach 7.5 and 10.2, respectively. The red emission enhancement of Er3+ ions is mainly caused by bidirectional energy transfer process of high excitation energy of Yb3+ ions and energy trapping center of Tm3+ ions which effectively change the density of population of luminescent energy levels of Er3+ ions. Furthermore, the coated NaYF4 inert shell also effectively weakens the surface quenching effect of nanocrystals. The mechanisms of red enhancement in different core-shell structures are discussed based on the spectral properties, the process of interion energy transfer, and luminescence kinetics. The constructed NaErF4@NaYbF4:2%Er3+@NaYF4 core-shell structures with high-efficiency red emission in this work have great potential applications in the fields of colorful anti-counterfeiting, display and biological imaging.

-

Keywords:

- nano core-shell structure /

- upconversion luminescence /

- red emission regulation /

- bidirectional energy transmission

[1] Alkahtani M, Alsofyani N, Alfahd A, Almuqhim A A, Almuqhim F A, Alshehri A A, Qasem H, Hemmer P R 2021 Nanomaterials 11 284

Google Scholar

Google Scholar

[2] Sun T Y, Li Y H, Ho W L, Zhu Q, Chen X, Jin L M, Zhu H M, Huang B L, Lin J, Little B E, Chu S T, Wang F 2019 Nat. Commun. 10 1811

Google Scholar

Google Scholar

[3] Wang F, Deng R R, Wang J, Wang Q X, Han Y, Zhu H M, Chen X Y, Liu X G 2011 Nat. Mater. 10 968

Google Scholar

Google Scholar

[4] Wang Y B, Lei L, Ye R G, Jia G H, Hua Y J, Deng D G, Xu S Q 2021 ACS Appl. Mater. Interfaces 13 23951

Google Scholar

Google Scholar

[5] Bao H Q, Wang W, Li X, Liu X M, Zhang L, Yan X, Wang Y H, Wang C G, Jia X T, Sun P, Kong X G, Zhnag H, Lu G Y 2022 Adv. Optical Mater. 10 2101702

Google Scholar

Google Scholar

[6] 严学文, 王朝晋, 王博扬, 孙泽煜, 张晨雪, 韩庆艳, 祁建霞, 董军, 高伟 2019 68 174204

Google Scholar

Google Scholar

Yan X W, Wang C J, Wang B Y, Sun Z Y, Zhang C X, Han Q Y, Qi J X, Dong J, Gao W 2019 Acta Phys. Sin. 68 174204

Google Scholar

Google Scholar

[7] Meng Z P, Zhang S F, Wu S L 2020 J. Lumin. 227 117566

Google Scholar

Google Scholar

[8] Tang M, Zhu X H, Zhang Y H, Zhang Z P, Zhang Z M, Mei Q S, Zhang J, Wu M H, Liu J L, Zhang Y 2019 ACS Nano 13 10405

Google Scholar

Google Scholar

[9] Wang W, Feng Z, Li B, Chang Y L, Li X, Yan X, Chen R Z, Yu X M, Zhao H Y, Lu G Y, Kong X G, Qian J, Liu X M 2021 J. Mater. Chem. B 9 2899

Google Scholar

Google Scholar

[10] Xu F, Sun Y, Gao H P, Jin S Y, Zhang Z L, Zhang H F, Pan G C, Kang M, Ma X Q, Mao Y L 2021 ACS Appl. Mater. Interfaces 13 2674

Google Scholar

Google Scholar

[11] Tan M L, Li F, Wang X, Fan R W, Chen G Y 2020 ACS Nano 14 6532

Google Scholar

Google Scholar

[12] Zhang H B, Chen Z H, He Y R, Yang S Y, Wei J 2021 ACS Appl. Mater. Interfaces 4 4340

[13] Lin H, Xu D K, Li A M, Teng D D, Yang S H, Zhang Y L 2016 Sci. Rep. 6 28051

Google Scholar

Google Scholar

[14] Lin H, Xu D K, Li A M, Qiu Z R, Yang S H, Zhang Y L 2017 New J. Chem. 41 1193

Google Scholar

Google Scholar

[15] Seki K, Uematsu K, Toda K, Sato M 2014 Chem. Lett. 43 1213

Google Scholar

Google Scholar

[16] Lin H, Xu D K, Li Y J, Yao L, Xu L Q, Ma Y, Yang S H, Zhang Y L 2018 Inorg. Chem. 57 15361

Google Scholar

Google Scholar

[17] Joshi R, Perala R S, Shelar S B, Ballal A, Singh B P, Ningthoujam S 2021 ACS Appl. Mater. Interfaces 13 3481

Google Scholar

Google Scholar

[18] Cheng Q, Sui J H, Cai W 2012 Nanoscale 4 779

Google Scholar

Google Scholar

[19] Lin H, Cheng Z Y, Xu D K, Zhang X G, Ge J, Xu L Q, Ma Y, Yang S H, Zhang Y L 2021 J. Mater. Chem. C 9 4385

Google Scholar

Google Scholar

[20] Lin H, Xu D K, Cheng Z Y, Li Y G, Xu L Q, Ma Y, Yang S H, Zhang Y L 2020 Appl. Surf. Sci. 514 146074

Google Scholar

Google Scholar

[21] Ren P, Zheng X L, Zhang J, Camillis S D, Jia J G, Wang H, Liao X Z, Piper J A, Lu Y Q 2022 ACS Photonics 9 758

[22] Fu X, Fu S, Lu Q, Zhang J, Wan P P, Liu J L, Zhang Y, Chen C, Li W, Wang H D, Mei Q S 2022 Nat. Commun. 13 4741

Google Scholar

Google Scholar

[23] Gong G, Song Y, Tan H H, Xie S W, Zhang C F, Xu L J, Xu J X, Zheng J 2019 Compos. Part B 179 107504

Google Scholar

Google Scholar

[24] Jia H, Li D G, Zhang D, Dong Y H, Ma S T, Zhou M, Di W H, Qin W P 2021 ACS Appl. Mater. Interfaces 13 4402

Google Scholar

Google Scholar

[25] Shang Y F, Hao S W, Lv W Q, Chen T, Tian L, Lei Z T, Yang C H 2018 J. Mater. Chem. C 6 3869

Google Scholar

Google Scholar

[26] Choi J E, Kim D, Jang H S 2019 Chem. Commun. 55 2261

Google Scholar

Google Scholar

[27] Huang J S, Yan L, Liu S B, Song N, Zhang Q Y, Zhou B 2021 Adv. Funct. Mater. 31 2009796

Google Scholar

Google Scholar

[28] Xie X Y, Li Q Q, Chen H R, Wang W, Wu F X, Tu L P, Zhang Y L, Kong X G, Chang Y L 2022 Nano Lett. 22 5339

Google Scholar

Google Scholar

[29] Li D, Wen S H, Kong M Y, Liu Y T, Hu W, Shi B Y, Shi X Y, Jin D Y 2020 Anal. Chem. 92 10913

Google Scholar

Google Scholar

[30] Szczeszak A, Jurga N, Lis S 2020 Ceram. Int. 46 26382

Google Scholar

Google Scholar

[31] Tong L M, Lu E, Pichaandi J, Zhao G Y, Winnik M A 2016 J. Phys. Chem. C 120 6269

Google Scholar

Google Scholar

[32] Chen Q S, Xie X J, Huang B L, Liang L L, Han S Y, Yi Z G, Wang Y, Li Y, Fan D Y, Huang L, Liu X G 2017 Angew. Chem. Int. Ed. 56 7605

Google Scholar

Google Scholar

[33] Gao W, Zheng H R, Han Q Y, He E J, Gao F Q, Wang R B 2014 J. Mater. Chem. C 2 5327

Google Scholar

Google Scholar

[34] Cui X S, Cheng Y, Lin H, Wu Q P, Xu J, Wang Y S 2019 J. Rare Earths 37 573

Google Scholar

Google Scholar

[35] Qiao Y F, Qiao S Q, Yu X, Min Q H, Pi C J, Qiu J B, Ma H Q, Yi J H, Zhan Q Q, Xu X H 2021 Nanoscale 13 8181

Google Scholar

Google Scholar

[36] Gao W, Xing Y, Chen B H, Shao L, Zhang J J, Yan X W, Han Q Y, Zhang C Y, Liu L, Dong J 2023 J. Alloys Compd. 936 168371

Google Scholar

Google Scholar

[37] Wu Q X, Xu Z, Wageh S, Al-Ghamdi A, Zhao S L 2021 J. Alloys Compd. 891 162067

[38] Yan L, Huang J S, An Z C, Zhang Q Y, Zhou B 2022 Nano Lett. 22 7042

Google Scholar

Google Scholar

[39] Gao W, Zhang C X, Han Q Y, Lu Y R, Yan X W, Wang Y K, Yang Y, Liu J H, Dong J 2022 J. Lumin. 241 118501

Google Scholar

Google Scholar

[40] Gao D L, Zhang X Y, Chong B, Xiao G Q, Tian D P 2017 Phys. Chem. Chem. Phys. 19 4288

Google Scholar

Google Scholar

[41] 董军, 张晨雪, 程小同, 邢宇, 韩庆艳, 严学文, 祁建霞, 刘继红, 杨祎, 高伟 2021 70 154208

Google Scholar

Google Scholar

Dong J, Zhang C X, Cheng X T, Xing Y, Han Q Y, Yan X W, Qi J X, Liu J H, Yang Y, Gao W 2021 Acta Phys. Sin. 70 154208

Google Scholar

Google Scholar

-

图 4 在980 nm不同激发功率下 (a)NaErF4:0.5%Tm3+@NaYbF4:2%Er3+@NaYF4 C-S晶体的上转换发射光谱; (b)红、绿光发射与泵浦功率依赖关系; (c)红、绿光发射强度对比(插图为其对应的红绿比)

Fig. 4. (a) The UC emission spectra , (b) power density dependence of red and green emission, and (c) comparison of red and green emission intensity of NaErF4:0.5%Tm3+@NaYbF4:2%Er3+ @ NaYF4 C-S structure under different excitation powers of 980 nm (The insert is corresponding R/G ratio).

-

[1] Alkahtani M, Alsofyani N, Alfahd A, Almuqhim A A, Almuqhim F A, Alshehri A A, Qasem H, Hemmer P R 2021 Nanomaterials 11 284

Google Scholar

Google Scholar

[2] Sun T Y, Li Y H, Ho W L, Zhu Q, Chen X, Jin L M, Zhu H M, Huang B L, Lin J, Little B E, Chu S T, Wang F 2019 Nat. Commun. 10 1811

Google Scholar

Google Scholar

[3] Wang F, Deng R R, Wang J, Wang Q X, Han Y, Zhu H M, Chen X Y, Liu X G 2011 Nat. Mater. 10 968

Google Scholar

Google Scholar

[4] Wang Y B, Lei L, Ye R G, Jia G H, Hua Y J, Deng D G, Xu S Q 2021 ACS Appl. Mater. Interfaces 13 23951

Google Scholar

Google Scholar

[5] Bao H Q, Wang W, Li X, Liu X M, Zhang L, Yan X, Wang Y H, Wang C G, Jia X T, Sun P, Kong X G, Zhnag H, Lu G Y 2022 Adv. Optical Mater. 10 2101702

Google Scholar

Google Scholar

[6] 严学文, 王朝晋, 王博扬, 孙泽煜, 张晨雪, 韩庆艳, 祁建霞, 董军, 高伟 2019 68 174204

Google Scholar

Google Scholar

Yan X W, Wang C J, Wang B Y, Sun Z Y, Zhang C X, Han Q Y, Qi J X, Dong J, Gao W 2019 Acta Phys. Sin. 68 174204

Google Scholar

Google Scholar

[7] Meng Z P, Zhang S F, Wu S L 2020 J. Lumin. 227 117566

Google Scholar

Google Scholar

[8] Tang M, Zhu X H, Zhang Y H, Zhang Z P, Zhang Z M, Mei Q S, Zhang J, Wu M H, Liu J L, Zhang Y 2019 ACS Nano 13 10405

Google Scholar

Google Scholar

[9] Wang W, Feng Z, Li B, Chang Y L, Li X, Yan X, Chen R Z, Yu X M, Zhao H Y, Lu G Y, Kong X G, Qian J, Liu X M 2021 J. Mater. Chem. B 9 2899

Google Scholar

Google Scholar

[10] Xu F, Sun Y, Gao H P, Jin S Y, Zhang Z L, Zhang H F, Pan G C, Kang M, Ma X Q, Mao Y L 2021 ACS Appl. Mater. Interfaces 13 2674

Google Scholar

Google Scholar

[11] Tan M L, Li F, Wang X, Fan R W, Chen G Y 2020 ACS Nano 14 6532

Google Scholar

Google Scholar

[12] Zhang H B, Chen Z H, He Y R, Yang S Y, Wei J 2021 ACS Appl. Mater. Interfaces 4 4340

[13] Lin H, Xu D K, Li A M, Teng D D, Yang S H, Zhang Y L 2016 Sci. Rep. 6 28051

Google Scholar

Google Scholar

[14] Lin H, Xu D K, Li A M, Qiu Z R, Yang S H, Zhang Y L 2017 New J. Chem. 41 1193

Google Scholar

Google Scholar

[15] Seki K, Uematsu K, Toda K, Sato M 2014 Chem. Lett. 43 1213

Google Scholar

Google Scholar

[16] Lin H, Xu D K, Li Y J, Yao L, Xu L Q, Ma Y, Yang S H, Zhang Y L 2018 Inorg. Chem. 57 15361

Google Scholar

Google Scholar

[17] Joshi R, Perala R S, Shelar S B, Ballal A, Singh B P, Ningthoujam S 2021 ACS Appl. Mater. Interfaces 13 3481

Google Scholar

Google Scholar

[18] Cheng Q, Sui J H, Cai W 2012 Nanoscale 4 779

Google Scholar

Google Scholar

[19] Lin H, Cheng Z Y, Xu D K, Zhang X G, Ge J, Xu L Q, Ma Y, Yang S H, Zhang Y L 2021 J. Mater. Chem. C 9 4385

Google Scholar

Google Scholar

[20] Lin H, Xu D K, Cheng Z Y, Li Y G, Xu L Q, Ma Y, Yang S H, Zhang Y L 2020 Appl. Surf. Sci. 514 146074

Google Scholar

Google Scholar

[21] Ren P, Zheng X L, Zhang J, Camillis S D, Jia J G, Wang H, Liao X Z, Piper J A, Lu Y Q 2022 ACS Photonics 9 758

[22] Fu X, Fu S, Lu Q, Zhang J, Wan P P, Liu J L, Zhang Y, Chen C, Li W, Wang H D, Mei Q S 2022 Nat. Commun. 13 4741

Google Scholar

Google Scholar

[23] Gong G, Song Y, Tan H H, Xie S W, Zhang C F, Xu L J, Xu J X, Zheng J 2019 Compos. Part B 179 107504

Google Scholar

Google Scholar

[24] Jia H, Li D G, Zhang D, Dong Y H, Ma S T, Zhou M, Di W H, Qin W P 2021 ACS Appl. Mater. Interfaces 13 4402

Google Scholar

Google Scholar

[25] Shang Y F, Hao S W, Lv W Q, Chen T, Tian L, Lei Z T, Yang C H 2018 J. Mater. Chem. C 6 3869

Google Scholar

Google Scholar

[26] Choi J E, Kim D, Jang H S 2019 Chem. Commun. 55 2261

Google Scholar

Google Scholar

[27] Huang J S, Yan L, Liu S B, Song N, Zhang Q Y, Zhou B 2021 Adv. Funct. Mater. 31 2009796

Google Scholar

Google Scholar

[28] Xie X Y, Li Q Q, Chen H R, Wang W, Wu F X, Tu L P, Zhang Y L, Kong X G, Chang Y L 2022 Nano Lett. 22 5339

Google Scholar

Google Scholar

[29] Li D, Wen S H, Kong M Y, Liu Y T, Hu W, Shi B Y, Shi X Y, Jin D Y 2020 Anal. Chem. 92 10913

Google Scholar

Google Scholar

[30] Szczeszak A, Jurga N, Lis S 2020 Ceram. Int. 46 26382

Google Scholar

Google Scholar

[31] Tong L M, Lu E, Pichaandi J, Zhao G Y, Winnik M A 2016 J. Phys. Chem. C 120 6269

Google Scholar

Google Scholar

[32] Chen Q S, Xie X J, Huang B L, Liang L L, Han S Y, Yi Z G, Wang Y, Li Y, Fan D Y, Huang L, Liu X G 2017 Angew. Chem. Int. Ed. 56 7605

Google Scholar

Google Scholar

[33] Gao W, Zheng H R, Han Q Y, He E J, Gao F Q, Wang R B 2014 J. Mater. Chem. C 2 5327

Google Scholar

Google Scholar

[34] Cui X S, Cheng Y, Lin H, Wu Q P, Xu J, Wang Y S 2019 J. Rare Earths 37 573

Google Scholar

Google Scholar

[35] Qiao Y F, Qiao S Q, Yu X, Min Q H, Pi C J, Qiu J B, Ma H Q, Yi J H, Zhan Q Q, Xu X H 2021 Nanoscale 13 8181

Google Scholar

Google Scholar

[36] Gao W, Xing Y, Chen B H, Shao L, Zhang J J, Yan X W, Han Q Y, Zhang C Y, Liu L, Dong J 2023 J. Alloys Compd. 936 168371

Google Scholar

Google Scholar

[37] Wu Q X, Xu Z, Wageh S, Al-Ghamdi A, Zhao S L 2021 J. Alloys Compd. 891 162067

[38] Yan L, Huang J S, An Z C, Zhang Q Y, Zhou B 2022 Nano Lett. 22 7042

Google Scholar

Google Scholar

[39] Gao W, Zhang C X, Han Q Y, Lu Y R, Yan X W, Wang Y K, Yang Y, Liu J H, Dong J 2022 J. Lumin. 241 118501

Google Scholar

Google Scholar

[40] Gao D L, Zhang X Y, Chong B, Xiao G Q, Tian D P 2017 Phys. Chem. Chem. Phys. 19 4288

Google Scholar

Google Scholar

[41] 董军, 张晨雪, 程小同, 邢宇, 韩庆艳, 严学文, 祁建霞, 刘继红, 杨祎, 高伟 2021 70 154208

Google Scholar

Google Scholar

Dong J, Zhang C X, Cheng X T, Xing Y, Han Q Y, Yan X W, Qi J X, Liu J H, Yang Y, Gao W 2021 Acta Phys. Sin. 70 154208

Google Scholar

Google Scholar

计量

- 文章访问数: 5426

- PDF下载量: 121

- 被引次数: 0

下载:

下载: