-

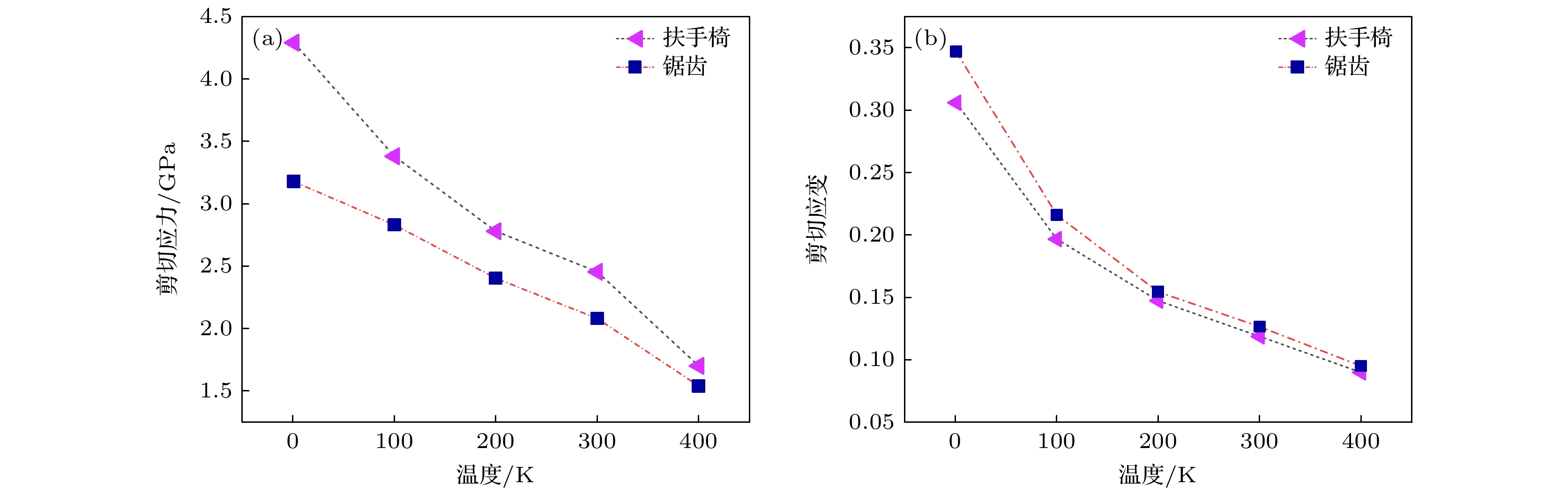

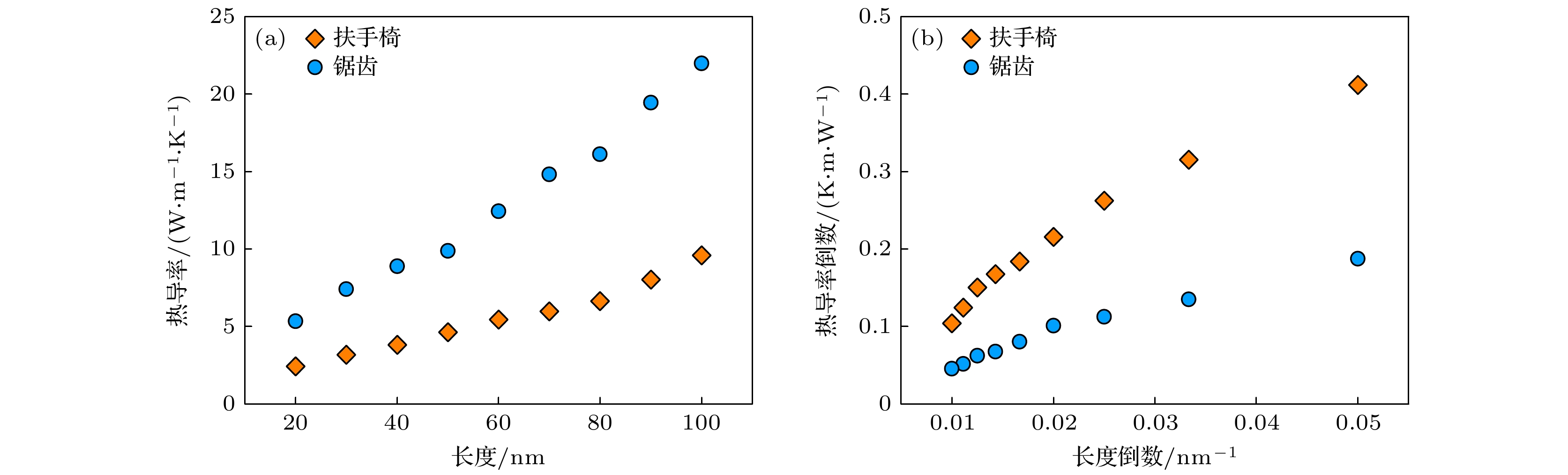

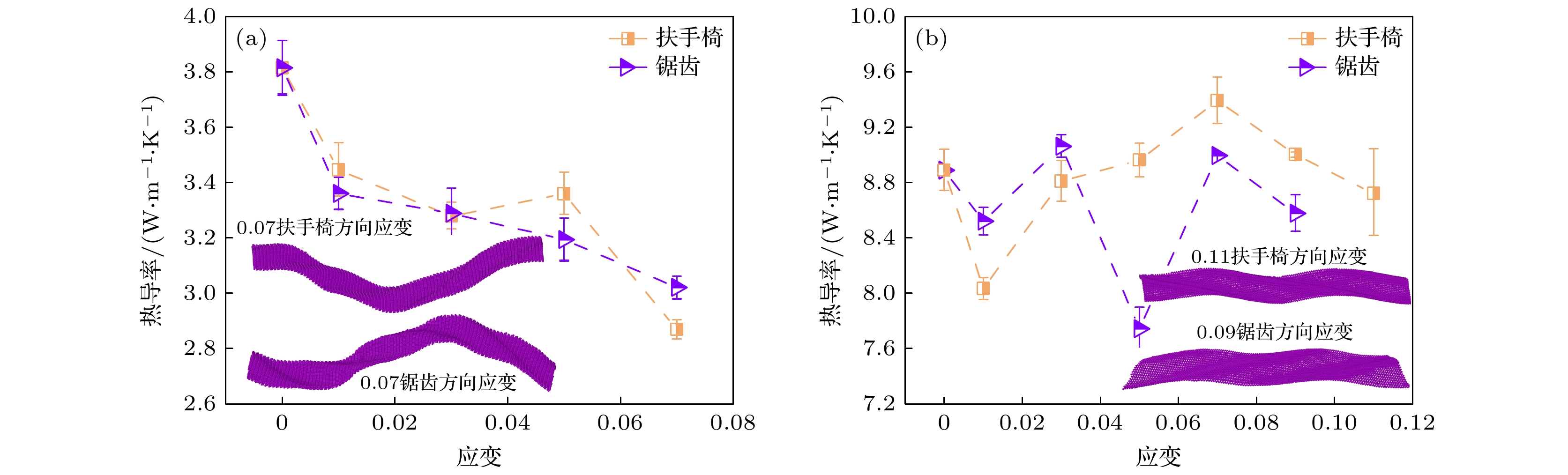

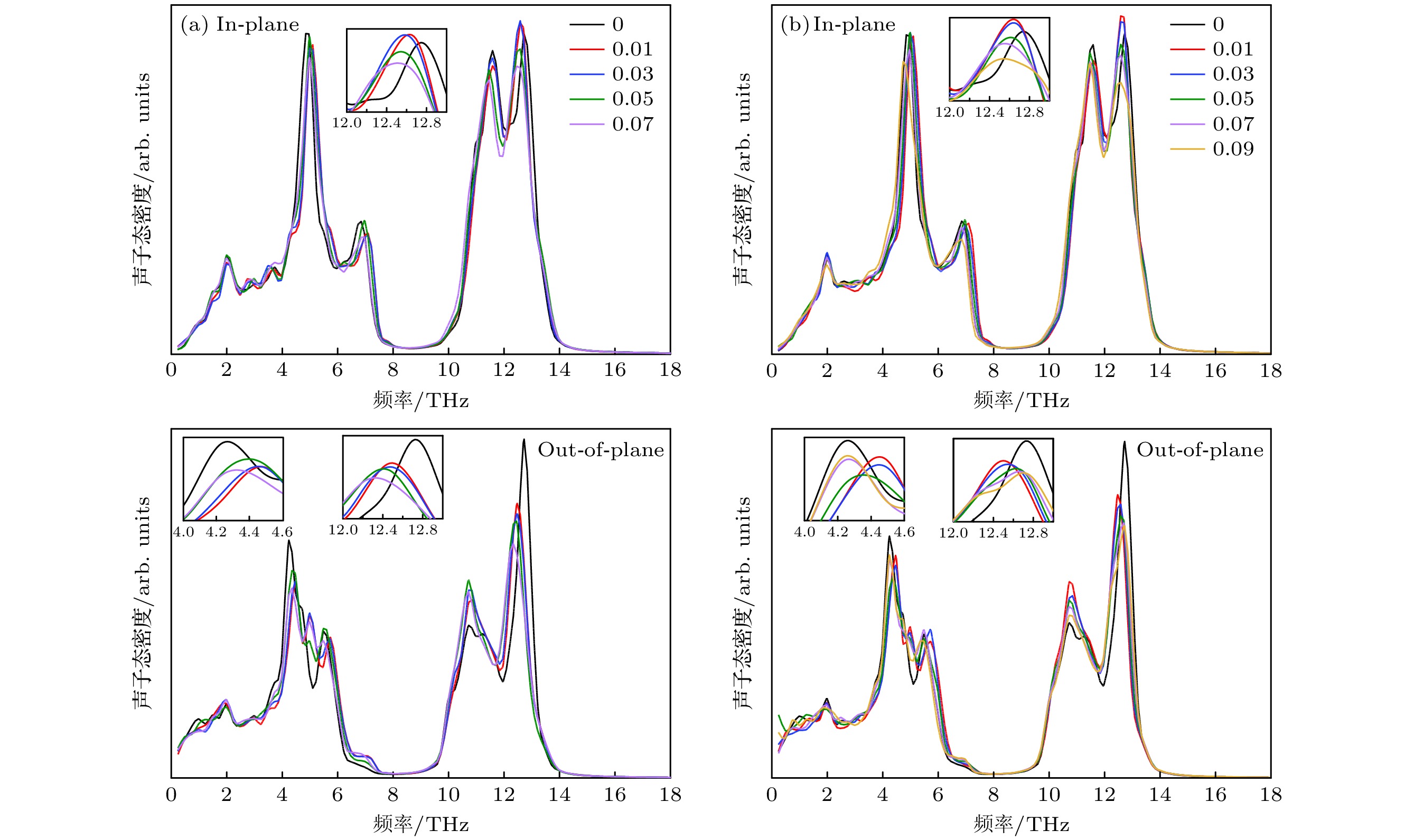

磷烯是一种新型的二维半导体材料, 近年来得到了研究者们的广泛关注. 通过分子动力学模拟对磷烯在剪切形变下的力学和热学性能进行了系统探究. 磷烯的剪切力学呈现出各向同性的特点, 沿扶手椅与锯齿方向的剪切模量均约为22 GPa. 磷烯的断裂强度和极限应变对温度十分敏感, 高温会显著削弱磷烯抗剪切形变的能力. 无应变时磷烯沿锯齿与扶手椅方向热导率的各向异性比为2.83. 当对磷烯施加剪切应变时, 磷烯沿扶手椅方向的热导率随着剪切应变的增大而减小, 但是剪切应变对磷烯锯齿方向热导率的影响则相对较弱. 通过对磷烯的声子态密度分析发现, 剪切形变主要对其柔性声子模式的振动特性具有显著影响, 使高频声子发生了红移. 同时, 剪切形变的存在会严重改变晶格的非简谐振动, 继而在不同程度上对磷烯声子间的散射产生重要的影响. 磷烯声子态密度的改变以及声子散射通道的变化共同决定了其在剪切形变下的导热特性.Phosphorene, a new two-dimensional material beyond graphene, has received increasing attention in recent years owing to its superior physical properties of significant utility. Herein we carry out molecular dynamics simulations to systematically study the mechanical and thermal properties of phosphorene under shear loadings. It is found that the shear modulus of phosphorene is about 22 GPa in both the armchair direction and zigzag direction. The fracture strength and ultimate strain of phosphorene can be significantly reduced owing to stronger thermal vibrations of atoms at a higher temperature. The thermal conductivity of pristine phosphorene at room temperature is obtained, specifically, it is 18.57 W·m–1·K–1 along the armchair direction and 52.52 W·m–1·K–1 in the zigzag direction. When either an armchair- or a zigzag-oriented shear strain is applied, the armchair-oriented thermal conductivity decreases monotonically with the strain increasing. Whereas the zigzag-oriented thermal conductivity exhibits a non-monotonic behavior. The strain-induced redshift occurs in the high-frequency phonons of out-of-plane flexural modes in the phonon density of states of the sheared phosphorene. In addition, the buckled structure of phosphorene will lead the deformation characteristics under the shear strain differ from those of the planar structure such as graphene, which has a significant influence on the lattice anharmonicity and phonon scattering. It is believed that the interplay between the shift of phonon density of states and the change of phonon scattering channels results in the unique thermal transport behavior of phosphorene under shear deformation. The findings provide an insight into the understanding of the mechanical and thermal properties of phosphorene, and have significance for the future applications in phosphorene-based novel devices.

-

Keywords:

- phosphorene /

- shear deformation /

- thermal conductivity /

- molecular dynamics

[1] Geim A K 2009 Science 324 1530

Google Scholar

Google Scholar

[2] Xu M, Liang T, Shi M, Chen H 2013 Chem. Rev. 113 3766

Google Scholar

Google Scholar

[3] Cai Z, Liu B, Zou X, Cheng H M 2018 Chem. Rev. 118 6091

Google Scholar

Google Scholar

[4] Lin Y, Connellb J W 2012 Nanoscale 4 6908

Google Scholar

Google Scholar

[5] Manzeli S, Ovchinnikov D, Pasquier D, Yazyev O V, Kis A 2017 Nat. Rev. Mater. 2 17033

Google Scholar

Google Scholar

[6] Balendhran S, Walia S, Nili H, Sriram S, Bhaskaran M 2015 Small 11 640

Google Scholar

Google Scholar

[7] Carvalho A, Wang M, Zhu X, Rodin A S, Su H, Neto A H C 2016 Nat. Rev. Mater. 1 16061

Google Scholar

Google Scholar

[8] Batmunkh M, Bat-Erdene M, Shapter J G 2016 Adv. Mater. 28 8586

Google Scholar

Google Scholar

[9] Akinwande D, Petrone N, Hone J 2014 Nat. Commun. 5 5678

Google Scholar

Google Scholar

[10] Novoselov K S, Mishchenko A, Carvalho A, Neto A H C 2016 Science 353 aac9439

Google Scholar

Google Scholar

[11] Bonaccorso F, Colombo L, Yu G, Stoller M, Tozzini V, Ferrari A C, Ruoff R S, Pellegrini V 2015 Science 347 1246501

Google Scholar

Google Scholar

[12] Jia P Z, Xie Z X, Deng Y X, Zhang Y, Tang L M, Zhou W X, Chen K Q 2022 Appl. Phys. Lett. 121 043901

Google Scholar

Google Scholar

[13] Zhou W X, Cheng Y, Chen K Q, Xie G, Wang T, Zhang G 2020 Adv. Funct. Mater. 30 1903829

Google Scholar

Google Scholar

[14] Liu H, Neal A T, Zhu Z, Luo Z, Xu X, Tománek D, Ye P D 2014 ACS Nano 8 4033

Google Scholar

Google Scholar

[15] Khandelwal A, Mani K, Karigerasi M H, Lahiri I 2017 Mater. Sci. Eng. B 221 17

Google Scholar

Google Scholar

[16] Li L, Yu Y, Ye G J, Ge Q, Ou X, Wu H, Feng D, Chen X H, Zhang Y 2014 Nat. Nanotech. 9 372

Google Scholar

Google Scholar

[17] Fei R, Faghaninia A, Soklaski R, Yan J A, Lo C, Yang L 2014 Nano Lett. 14 6393

Google Scholar

Google Scholar

[18] Qiao J, Kong X, Hu Z X, Yang F, Ji W 2014 Nat. Commun. 5 4475

Google Scholar

Google Scholar

[19] Tran V, Soklaski R, Liang Y, Yang L 2014 Phys. Rev. B 89 235319

Google Scholar

Google Scholar

[20] Jiang J W, Park H S 2014 J. Phys. D:Appl. Phys. 47 385304

Google Scholar

Google Scholar

[21] Sha Z D, Pei Q X, Ding Z, Jiang J W, Zhang Y W 2015 J. Phys. D: Appl. Phys. 48 395303

Google Scholar

Google Scholar

[22] Sha Z D, Pei Q X, Zhang Y Y, Zhang Y W 2016 Nanotech. 27 315704

Google Scholar

Google Scholar

[23] Li L, Yang J 2017 Nanotech. 28 475701

Google Scholar

Google Scholar

[24] Qin G, Hu M 2018 Small 14 1702465

Google Scholar

Google Scholar

[25] Hong Y, Zhang J, Zeng X C 2018 Chin. Phys. B 27 036501

Google Scholar

Google Scholar

[26] Qin G, Yan Q B, Qin Z, Yue S Y, Hu M, Su G 2015 Phys. Chem. Chem. Phys. 17 4854

Google Scholar

Google Scholar

[27] Hong Y, Zhang J, Huang X, Zeng X C 2015 Nanoscale 7 18716

Google Scholar

Google Scholar

[28] Ong Z Y, Cai Y, Zhang G, Zhang Y W 2014 J. Phys. Chem. C 118 25272

Google Scholar

Google Scholar

[29] Zhang Y Y, Pei Q X, Jiang J W, Wei N, Zhang Y W 2016 Nanoscale 8 483

Google Scholar

Google Scholar

[30] Liu B, Bai L, Korznikova E A, Dmitriev S V, Law A W K, Zhou K 2017 J. Phys. Chem. C 121 13876

Google Scholar

Google Scholar

[31] Wei Q, Peng X 2014 Appl. Phys. Lett. 104 251915

Google Scholar

Google Scholar

[32] Yang Z, Zhao J, Wei N 2015 Appl. Phys. Lett. 107 023107

Google Scholar

Google Scholar

[33] Gamil M, Zeng Q H, Zhang Y Y 2020 Phys. Lett. A 384 126784

Google Scholar

Google Scholar

[34] Hatam-Lee S M, Peer-Mohammadi H, Rajabpour A 2021 Mater. Today Commun. 26 101796

Google Scholar

Google Scholar

[35] Mahnama M, Meshkinghalam M, Ozmaian M 2022 J. Phys.: Condens. Matter 34 075403

Google Scholar

Google Scholar

[36] Li T 2021 Physica E 131 114761

Google Scholar

Google Scholar

[37] Plimpton S 1995 J. Comput. Phys. 117 1

Google Scholar

Google Scholar

[38] Jiang J W 2015 Nanotech. 26 315706

Google Scholar

Google Scholar

[39] Kheirkhah A H, Iranizad E S, Raeisi M, Rajabpour A 2014 Solid State Commun. 177 98

Google Scholar

Google Scholar

[40] Zhang C, Hao X L, Wang C X, Wei N, Rabczuk T 2017 Sci. Rep. 7 41398

Google Scholar

Google Scholar

[41] Zhao J, Jiang J W, Rabczuk T 2013 Appl. Phys. Lett. 103 231913

Google Scholar

Google Scholar

[42] Li T, Tang Z, Huang Z, Yu J 2017 Physica E 85 137

Google Scholar

Google Scholar

[43] Xu K, Fan Z, Zhang J, Wei N, Ala-Nissila T 2018 Modell. Simul. Mater. Sci. Eng. 26 085001

Google Scholar

Google Scholar

[44] Smith B, Vermeersch B, Carrete J, Ou E, Kim J, Mingo N, Akinwande D, Shi L 2017 Adv. Mater. 29 1603756

Google Scholar

Google Scholar

[45] Hu M, Zhang X, Poulikakos D 2013 Phys. Rev. B 87 195417

Google Scholar

Google Scholar

-

表 1 磷烯的剪切力学性能

Table 1. Mechanical properties of phosphorene under shear loading.

-

[1] Geim A K 2009 Science 324 1530

Google Scholar

Google Scholar

[2] Xu M, Liang T, Shi M, Chen H 2013 Chem. Rev. 113 3766

Google Scholar

Google Scholar

[3] Cai Z, Liu B, Zou X, Cheng H M 2018 Chem. Rev. 118 6091

Google Scholar

Google Scholar

[4] Lin Y, Connellb J W 2012 Nanoscale 4 6908

Google Scholar

Google Scholar

[5] Manzeli S, Ovchinnikov D, Pasquier D, Yazyev O V, Kis A 2017 Nat. Rev. Mater. 2 17033

Google Scholar

Google Scholar

[6] Balendhran S, Walia S, Nili H, Sriram S, Bhaskaran M 2015 Small 11 640

Google Scholar

Google Scholar

[7] Carvalho A, Wang M, Zhu X, Rodin A S, Su H, Neto A H C 2016 Nat. Rev. Mater. 1 16061

Google Scholar

Google Scholar

[8] Batmunkh M, Bat-Erdene M, Shapter J G 2016 Adv. Mater. 28 8586

Google Scholar

Google Scholar

[9] Akinwande D, Petrone N, Hone J 2014 Nat. Commun. 5 5678

Google Scholar

Google Scholar

[10] Novoselov K S, Mishchenko A, Carvalho A, Neto A H C 2016 Science 353 aac9439

Google Scholar

Google Scholar

[11] Bonaccorso F, Colombo L, Yu G, Stoller M, Tozzini V, Ferrari A C, Ruoff R S, Pellegrini V 2015 Science 347 1246501

Google Scholar

Google Scholar

[12] Jia P Z, Xie Z X, Deng Y X, Zhang Y, Tang L M, Zhou W X, Chen K Q 2022 Appl. Phys. Lett. 121 043901

Google Scholar

Google Scholar

[13] Zhou W X, Cheng Y, Chen K Q, Xie G, Wang T, Zhang G 2020 Adv. Funct. Mater. 30 1903829

Google Scholar

Google Scholar

[14] Liu H, Neal A T, Zhu Z, Luo Z, Xu X, Tománek D, Ye P D 2014 ACS Nano 8 4033

Google Scholar

Google Scholar

[15] Khandelwal A, Mani K, Karigerasi M H, Lahiri I 2017 Mater. Sci. Eng. B 221 17

Google Scholar

Google Scholar

[16] Li L, Yu Y, Ye G J, Ge Q, Ou X, Wu H, Feng D, Chen X H, Zhang Y 2014 Nat. Nanotech. 9 372

Google Scholar

Google Scholar

[17] Fei R, Faghaninia A, Soklaski R, Yan J A, Lo C, Yang L 2014 Nano Lett. 14 6393

Google Scholar

Google Scholar

[18] Qiao J, Kong X, Hu Z X, Yang F, Ji W 2014 Nat. Commun. 5 4475

Google Scholar

Google Scholar

[19] Tran V, Soklaski R, Liang Y, Yang L 2014 Phys. Rev. B 89 235319

Google Scholar

Google Scholar

[20] Jiang J W, Park H S 2014 J. Phys. D:Appl. Phys. 47 385304

Google Scholar

Google Scholar

[21] Sha Z D, Pei Q X, Ding Z, Jiang J W, Zhang Y W 2015 J. Phys. D: Appl. Phys. 48 395303

Google Scholar

Google Scholar

[22] Sha Z D, Pei Q X, Zhang Y Y, Zhang Y W 2016 Nanotech. 27 315704

Google Scholar

Google Scholar

[23] Li L, Yang J 2017 Nanotech. 28 475701

Google Scholar

Google Scholar

[24] Qin G, Hu M 2018 Small 14 1702465

Google Scholar

Google Scholar

[25] Hong Y, Zhang J, Zeng X C 2018 Chin. Phys. B 27 036501

Google Scholar

Google Scholar

[26] Qin G, Yan Q B, Qin Z, Yue S Y, Hu M, Su G 2015 Phys. Chem. Chem. Phys. 17 4854

Google Scholar

Google Scholar

[27] Hong Y, Zhang J, Huang X, Zeng X C 2015 Nanoscale 7 18716

Google Scholar

Google Scholar

[28] Ong Z Y, Cai Y, Zhang G, Zhang Y W 2014 J. Phys. Chem. C 118 25272

Google Scholar

Google Scholar

[29] Zhang Y Y, Pei Q X, Jiang J W, Wei N, Zhang Y W 2016 Nanoscale 8 483

Google Scholar

Google Scholar

[30] Liu B, Bai L, Korznikova E A, Dmitriev S V, Law A W K, Zhou K 2017 J. Phys. Chem. C 121 13876

Google Scholar

Google Scholar

[31] Wei Q, Peng X 2014 Appl. Phys. Lett. 104 251915

Google Scholar

Google Scholar

[32] Yang Z, Zhao J, Wei N 2015 Appl. Phys. Lett. 107 023107

Google Scholar

Google Scholar

[33] Gamil M, Zeng Q H, Zhang Y Y 2020 Phys. Lett. A 384 126784

Google Scholar

Google Scholar

[34] Hatam-Lee S M, Peer-Mohammadi H, Rajabpour A 2021 Mater. Today Commun. 26 101796

Google Scholar

Google Scholar

[35] Mahnama M, Meshkinghalam M, Ozmaian M 2022 J. Phys.: Condens. Matter 34 075403

Google Scholar

Google Scholar

[36] Li T 2021 Physica E 131 114761

Google Scholar

Google Scholar

[37] Plimpton S 1995 J. Comput. Phys. 117 1

Google Scholar

Google Scholar

[38] Jiang J W 2015 Nanotech. 26 315706

Google Scholar

Google Scholar

[39] Kheirkhah A H, Iranizad E S, Raeisi M, Rajabpour A 2014 Solid State Commun. 177 98

Google Scholar

Google Scholar

[40] Zhang C, Hao X L, Wang C X, Wei N, Rabczuk T 2017 Sci. Rep. 7 41398

Google Scholar

Google Scholar

[41] Zhao J, Jiang J W, Rabczuk T 2013 Appl. Phys. Lett. 103 231913

Google Scholar

Google Scholar

[42] Li T, Tang Z, Huang Z, Yu J 2017 Physica E 85 137

Google Scholar

Google Scholar

[43] Xu K, Fan Z, Zhang J, Wei N, Ala-Nissila T 2018 Modell. Simul. Mater. Sci. Eng. 26 085001

Google Scholar

Google Scholar

[44] Smith B, Vermeersch B, Carrete J, Ou E, Kim J, Mingo N, Akinwande D, Shi L 2017 Adv. Mater. 29 1603756

Google Scholar

Google Scholar

[45] Hu M, Zhang X, Poulikakos D 2013 Phys. Rev. B 87 195417

Google Scholar

Google Scholar

计量

- 文章访问数: 4241

- PDF下载量: 58

- 被引次数: 0

下载:

下载: