-

自从2004年首次制备出石墨烯以来, 机械解理技术被广泛用于制备过渡金属二硫族化合物、黑磷等各种二维材料. 在多种二维材料制备技术中, 机械解理技术具有制备方法简单、普适性好等优点, 最重要的是解理得到的晶体质量高, 是研究很多新奇物性的理想选择. 本文介绍了机械解理技术的产生背景, 总结了常规机械解理技术在二维材料研究过程中的瓶颈. 为了解决常规机械解理技术制备效率低、样品尺寸小的问题, 一些新型机械解理技术近年来不断发展起来, 如氧气等离子体辅助法和金膜辅助法等. 作为自上而下的二维材料制备方法, 新的解理技术在未来二维材料基础研究和应用中仍然充满生机. 未来解理技术将朝更大尺寸, 更高质量方向发展.Since the monolayer graphene was first obtained in the year of 2004, mechanical exfoliation technique has been widely used to prepare various two-dimensional materials such as transition metal dichalcogenides and black phosphorus. Among a variety of preparation techniques of two-dimensional materials, mechanical exfoliation technique shows advantages in its simplicity and universality. More importantly, the exfoliated two-dimensional samples are the ideal ones for many novel phenomena. This paper introduces the background of mechanical exfoliation technique and summarizes the problems of conventional mechanical exfoliation technique in the development of two-dimensional materials. In order to solve the problems of low efficiency and small sample size of conventional mechanical exfoliation technique, some modified mechanical exfoliation techniques have been developed, such as oxygen-plasma-assisted exfoliation method and gold-film-assisted exfoliation method. As a commonly used “top-down” preparation method, the new exfoliation technology is still full of vitality in basic research and application of two-dimensional materials. In the future, larger size and higher quality will be the development direction of exfoliation technology.

-

Keywords:

- two-dimensional materials /

- mechanical exfoliation /

- graphene /

- MoS2

[1] Kroto H W, Heath J R, O'Brien S C, Curl R F, Smalley R E 1985 Nature 318 162

Google Scholar

Google Scholar

[2] Iijima S 1991 Nature 354 56

Google Scholar

Google Scholar

[3] Lu X K, Yu M F, Huang H, Ruoff R S 1999 Nanotechnology 10 269

Google Scholar

Google Scholar

[4] Chen H, Zhang X L, Zhang Y Y, Wang D F, Bao D L, Que Y D, Xiao W D, Du S X, Ouyang M, Pantelides S T, Gao H J 2019 Science 365 1036

Google Scholar

Google Scholar

[5] Novoselov K S, Geim A K, Morozov S V, Jiang D, Zhang Y, Dubonos S V, Grigorieva I V, Firsov A A 2004 Science 306 666

Google Scholar

Google Scholar

[6] Gu Y Y, Wang Y F, Xia J, Meng X M 2020 Chin. Phys. Lett. 37 048101

Google Scholar

Google Scholar

[7] 王铄, 王文辉, 吕俊鹏, 倪振华 2021 70 026802

Google Scholar

Google Scholar

Wang S, Wang W H, Lv J P, Ni Z H 2021 Acta Phys. Sin. 70 026802

Google Scholar

Google Scholar

[8] Zhang D L, Yi C, Ge C H, Shu W N, Li B, Duan X D, Pan A L, Wang X 2021 Chin. Phys. B 30 097601

Google Scholar

Google Scholar

[9] Zhang S, Song Y, Li H, Li J M, Qian K, Liu C, Wang J O, Qian T, Zhang Y Y, Lu J C, Ding H, Lin X, Pan J B, Du S X, Gao H J 2020 Chin. Phys. Lett. 37 068103

Google Scholar

Google Scholar

[10] Tan C L, Cao X H, Wu X J, He Q Y, Yang J, Zhang X, Chen J Z, Zhao W, Han S K, Nam G H, Sindoro M, Zhang H 2017 Chem. Rev. 117 6225

Google Scholar

Google Scholar

[11] Zhang Y B, Tan Y W, Stormer H L, Kim P 2005 Nature 438 201

Google Scholar

Google Scholar

[12] Novoselov K S, Geim A K, Morozov S V, Jiang D, Katsnelson M I, Grigorieva I V, Dubonos S V, Firsov A A 2005 Nature 438 197

Google Scholar

Google Scholar

[13] Cao Y, Fatemi V, Fang S, Watanabe K, Taniguchi T, Kaxiras E, Jarillo-Herrero P 2018 Nature 556 43

Google Scholar

Google Scholar

[14] Radisavljevic B, Radenovic A, Brivio J, Giacometti V, Kis A 2011 Nat. Nanotech. 6 147

Google Scholar

Google Scholar

[15] Castro Neto A H, Guinea F, Peres N M R, Novoselov K S, Geim A K 2009 Rev. Mod. Phys. 81 109

Google Scholar

Google Scholar

[16] Mak K F, Lee C, Hone J, Shan J, Heinz T F 2010 Phys. Rev. Lett. 105 136805

Google Scholar

Google Scholar

[17] Wang Q H, Kalantar-Zadeh K, Kis A, Coleman J N, Strano M S 2012 Nat. Nanotech. 7 699

Google Scholar

Google Scholar

[18] Li L K, Yu Y J, Ye G J, Ge Q Q, Ou X D, Wu H, Feng D L, Chen X H, Zhang Y B 2014 Nat. Nanotech. 9 372

Google Scholar

Google Scholar

[19] Cao Y, Fatemi V, Demir A, Fang S, Tomarken S L, Luo J Y, Sanchez-Yamagishi J D, Watanabe K, Taniguchi T, Kaxiras E, Ashoori R C, Jarillo-Herrero P 2018 Nature 556 80

Google Scholar

Google Scholar

[20] Cao Y, Fatemi V, Fang S, Watanabe K, Taniguchi T, Kaxiras E, Jarillo-Herrero P 2018 Natures 556 43

[21] Lisi S, Lu X B, Benschop T, de Jong T A, Stepanov P, Duran J R, Margot F, Cucchi I, Cappelli E, Hunter A, Tamai A, Kandyba V, Giampietri A, Barinov A, Jobst J, Stalman V, Leeuwenhoek M, Watanabe K, Taniguchi T, Rademaker L, van der Molen S J, Allan M P, Efetov D K, Baumberger F 2021 Nat. Phys. 17 189

Google Scholar

Google Scholar

[22] 季怡汝, 褚衍邦, 冼乐德, 杨威, 张广宇 2021 70 118101

Google Scholar

Google Scholar

Ji Y R, Chu Y B, Xian L D, Yang W, Zhang G Y 2021 Acta Phys. Sin. 70 118101

Google Scholar

Google Scholar

[23] Huang Y, Sutter E, Shi N N, Zheng J B, Yang T Z, Englund D, Gao H J, Sutter P 2015 ACS Nano 9 10612

Google Scholar

Google Scholar

[24] Yu Y J, Ma L G, Cai P, Zhong R D, Ye C, Shen J, Gu G D, Chen X H, Zhang Y B 2019 Nature 575 156

Google Scholar

Google Scholar

[25] 许宏, 孟蕾, 李杨, 杨天中, 鲍丽宏, 刘国东, 赵林, 刘天生, 邢杰, 高鸿钧, 周兴江, 黄元 2018 67 218201

Google Scholar

Google Scholar

Xu H, Meng L, Li Y, Yang T Z, Bao L H, Liu G D, Zhao L, Liu T S, Xing J, Gao H J, Zhou X J, Huang Y 2018 Acta Phys. Sin. 67 218201

Google Scholar

Google Scholar

[26] Huang Y, Pan Y H, Yang R, et al. 2020 Nat. Commun. 11 2453

Google Scholar

Google Scholar

[27] Magda G Z, Peto J, Dobrik G, Hwang C, Biro L P, Tapaszto L 2015 Sci. Rep. 5 14714

Google Scholar

Google Scholar

[28] Desai S B, Madhvapathy S R, Amani M, Kiriya D, Hettick M, Tosun M, Zhou Y Z, Dubey M, Ager J W, Chrzan D, Javey A 2016 Adv. Mater. 28 4053

Google Scholar

Google Scholar

[29] Velicky M, Donnelly G E, Hendren W R, McFarland S, Scullion D, DeBenedetti W J I, Correa G C, Han Y M, Wain A J, Hines M A, Muller D A, Novoselov K S, Abruna H D, Bowman R M, Santos E J G, and Huang F M 2018 ACS Nano 12 10463

Google Scholar

Google Scholar

[30] Yang S Q, Xu X L, Zhu Y Z, Niu R R, Xu C Q, Peng Y X, Cheng X, Jia X H, Huang Y, Xu X F, Lu J M, Ye Y 2021 Phys. Rev. X 11 011003

Google Scholar

Google Scholar

[31] Zang Z H, Zhu Y Z, Xi M, et al. 2022 Phys. Rev. Lett. 128 017201

Google Scholar

Google Scholar

[32] Liu F, Wu W J, Bai Y S, Chae S H, Li Q Y, Wang J, Hone J, Zhu X Y 2020 Science 367 903

Google Scholar

Google Scholar

[33] Huang Y, Wang Y K, Huang X Y, Zhang G H, Han X, Yang Y, Gao Y N, Meng L, Wang Y S, Geng G Z, Liu L W, Zhao L, Cheng Z H, Liu X F, Ren Z F, Yang H X, Hao Y F, Gao H J, Zhou X J, Ji W, Wang Y L 2021 Infomat 4 e12274

Google Scholar

Google Scholar

[34] Huang X Y, Zhang L, Liu L W, Qin Y, Fu Q, Wu Q, Yang R, Lv J P, Ni Z H, Liu L, Ji W, Wang Y L, Zhou X J, Huang Y. 2021 Sci. China Inf. Sci. 64 140406

Google Scholar

Google Scholar

[35] Deng Y J, Yu Y J, Song Y C, Zhang J Z, Wang N Z, Sun Z Y, Yi Y F, Wu Y Z, Wu S W, Zhu J Y, Wang J, Chen X H, Zhang Y B. 2018 Nature 563 94

Google Scholar

Google Scholar

-

图 1 (a)(b)美国华盛顿大学的Ruoff等利用AFM针尖在石墨烯柱上将石墨烯推开[3]; (c)英国曼切斯特大学Geim课题组利用胶带解理的薄层石墨烯[5]; (d)利用STM针尖实现了对石墨烯的折叠和展开[4] .

Fig. 1. (a)(b) Ruoff et al. from the University of Washington in the United States used AFM tip to push graphene away on a graphene column[3]; (c) The thin layers of graphene was exfoliated from tape, which reported from Geim's group at the University of Manchester in the UK[5]; (d) folding and unfolding graphene using STM tips[4].

图 2 (a)第1个单层MoS2材料中观察到的荧光光谱[16]; (b)单层MoS2的场效应晶体管中观察到高开关比电流响应[14]; (c)薄层黑磷器件在电场调控下的输运特性[18]

Fig. 2. (a) Fluorescence spectra was observed in the first monolayer MoS2 material[16]; (b) high switching ratio current response was observed in monolayer MoS2 FET[14]; (c) transport characteristics of thin layer black phosphorus devices under electric field regulation[18] .

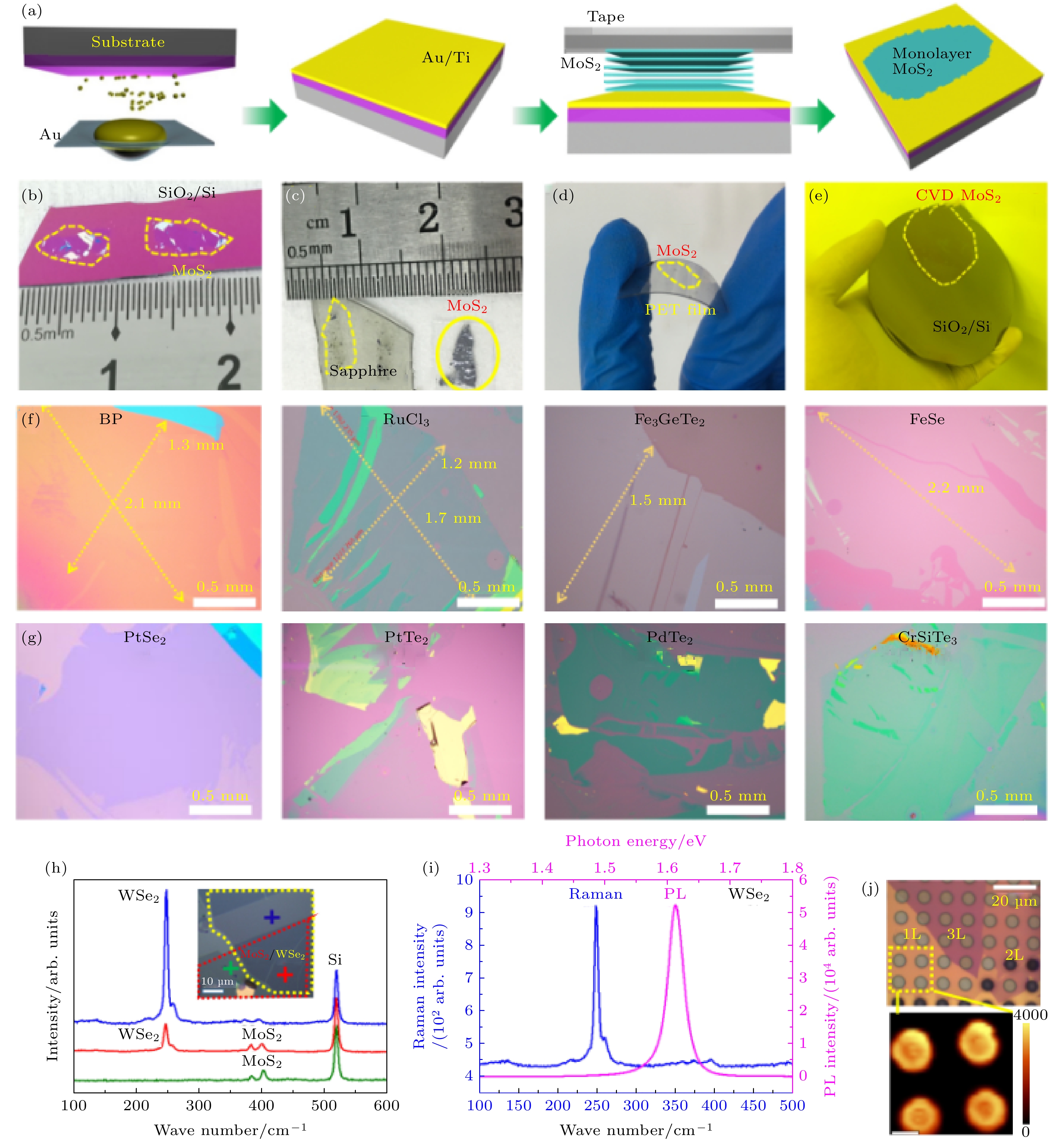

图 5 普适性解理技术制备的多种二维材料及表征 (a) 新型机械解理的步骤; (b)—(e)不同基底上解理得到的大面积MoS2; (f)(g)解理得到的多种大面积二维材料; (h)—(j)异质结及悬空二维材料的拉曼光谱及荧光光谱[26]

Fig. 5. Mechanical exfoliation of different monolayer materials with macroscopic size: (a) Illustration of the modified exfoliation process; (b)–(e) optical images of large-area MoS2 exfoliated on different substrates; (f)(g) a variety of large-area two-dimensional materials obtained by exfoliation; (h)–(j) Raman and photoluminescence (PL) spectra of heterostructure and suspended 2D material[26].

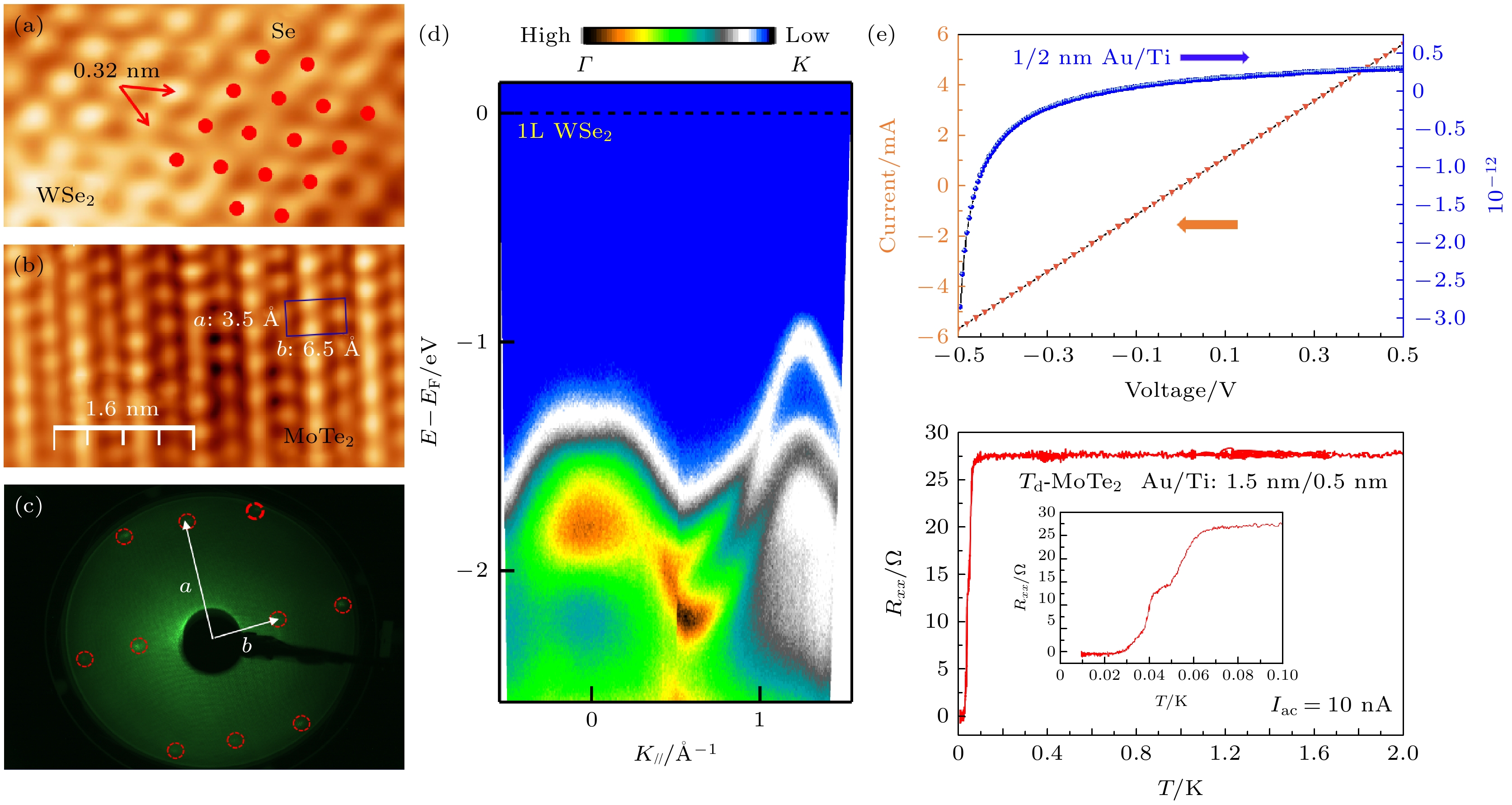

图 6 (a)(b)解理在金膜上的单层WSe2和MoTe2的STM图像; (c)单层MoTe2的低能电子衍射斑点; (d)利用ARPES测得的单层WSe2能带结构; (e)金属膜导电性测试, 以及在薄层金属膜上观察到的MoTe2超导电性[26]

Fig. 6. (a)(b) STM images of monolayer WSe2 and MoTe2 exfoliated onto Au layer; (c) LEED pattern of monolayer MoTe2; (d) ARPES band structure of monolayer WSe2; (e) electrical measurements of metal films and superconductivity of MoTe2 observed on thin metal films[26].

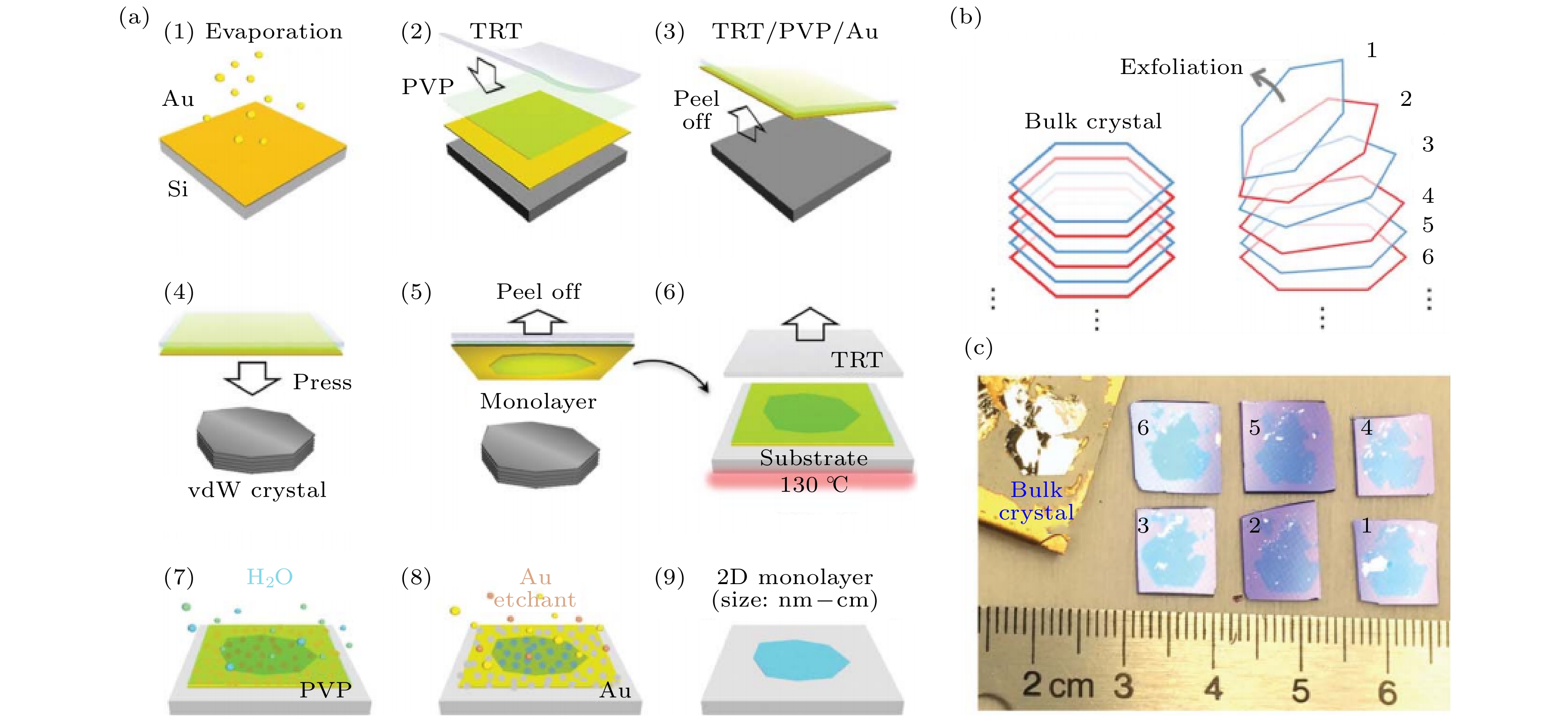

图 7 块状TMDs单晶的逐层解理过程示意图(a)方法(1)在超平整的硅晶圆上沉积金膜; (2)在表面悬涂一层PVP; (3)使用热敏胶带(TRT)提取PVP和金膜; (4)将超平整的金膜压在块状vdW晶体的表面上; (5)解理单层并转移到衬底上; (6)加热去除TRT; (7)将PVP溶解在水中; (8)将金溶解在I2/I–蚀刻剂溶液中; (9)获得具有宏观尺寸的单晶单层. (b)从AB堆垛的TMDs晶体产生偶数层和奇数层的逐层解理技术示意图. (c)从左上角所示的厘米大小的WSe2单晶中依次解理的6个单层样品(在SiO2/Si衬底上)的光学图像[32]

Fig. 7. Schematic illustration of the layer-by-layer exfoliation procedure of bulk TMDs single crystals. (a) Method: (1) Depositing gold on ultraflat silicon wafer; (2) spin-coating the surface with a layer of PVP; (3) using thermal release tape (TRT) to pick up the PVP and gold; (4) pressing the ultraflat gold onto the surface of a bulk vdW crystal; (5) peeling off a monolayer and transferring onto a substrate; (6) removing the TRT with heat; (7) dissolving PVP in water; (8) dissolving gold in an I2/I– etchant solution; and (9) obtaining the single-crystal monolayer with macroscopic dimensions. (b) Schematic of the layer-by-layer exfoliation technique to yield even and odd layers from an AB stacked TMDs crystals. (c) Optical images of six monolayer samples (on SiO2/Si substrate) sequentially exfoliated from a centimeter-size WSe2 single crystal shown at the upper left corner[32].

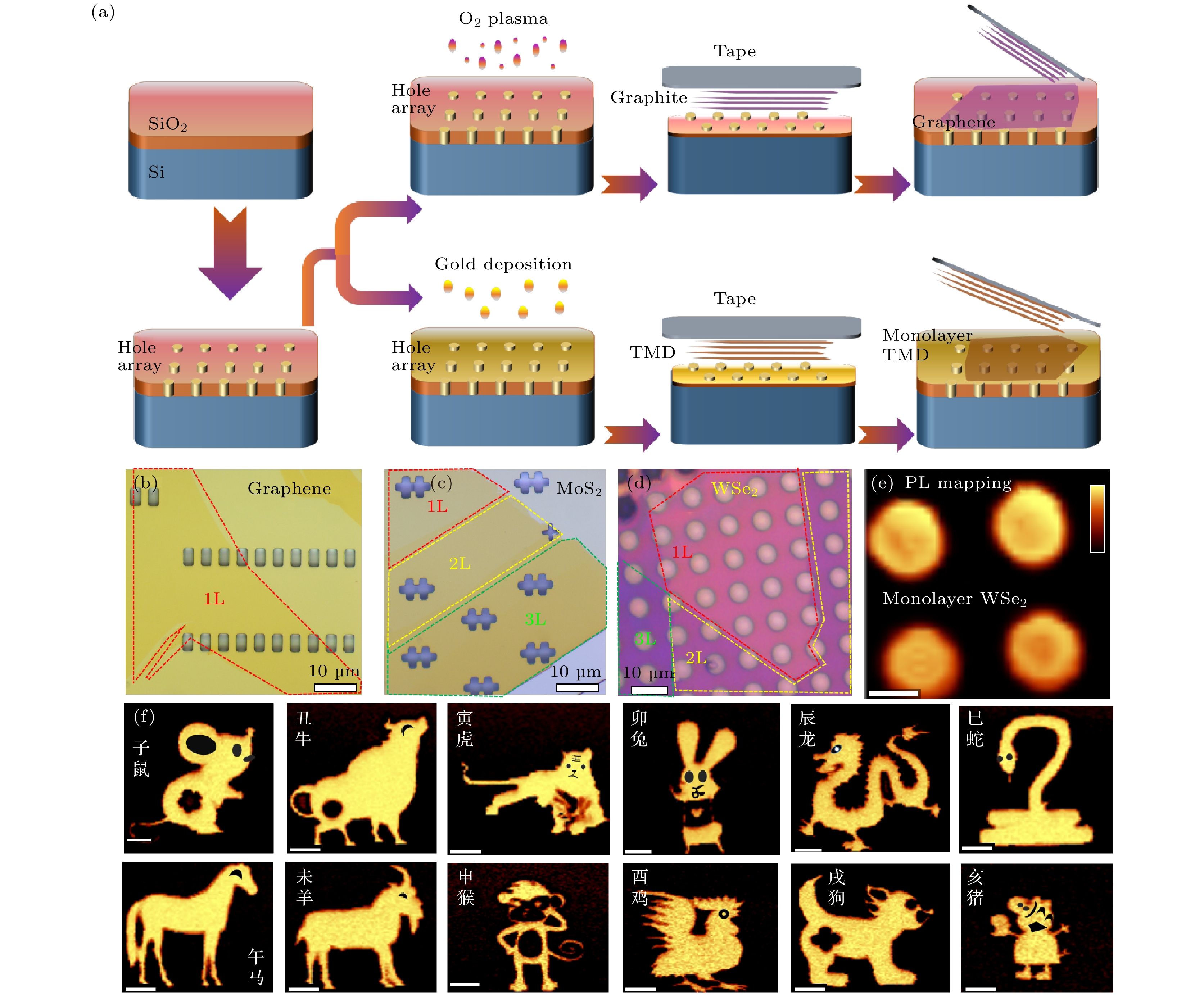

图 8 二维材料悬浮结构的制备路线图(a)及解理后的二维材料(b)—(d); 解理后的悬浮WSe2展现出良好的荧光特性(e); (f)是将衬底图案化(十二生肖图案)加工后, 通过优化解理工艺制备的悬浮WSe2荧光成像图片, 比例尺为4 μm[33]

Fig. 8. Fabrication process and characterization of suspended 2D materials. (a) Schematic images for preparing suspended samples. (b)–(d) Optical images of exfoliated graphene, MoS2 and WSe2 on different patterned substrates, including rectangle, Hall bar and circular hole structures. (e) PL mapping image of suspended monolayer WSe2. (f) PL mapping images of Chinese zodiac signs, which were collected on suspended WSe2 flakes. Some details are added artificially, such as eyes and mouths. The scale bar is 4 μm[33]

-

[1] Kroto H W, Heath J R, O'Brien S C, Curl R F, Smalley R E 1985 Nature 318 162

Google Scholar

Google Scholar

[2] Iijima S 1991 Nature 354 56

Google Scholar

Google Scholar

[3] Lu X K, Yu M F, Huang H, Ruoff R S 1999 Nanotechnology 10 269

Google Scholar

Google Scholar

[4] Chen H, Zhang X L, Zhang Y Y, Wang D F, Bao D L, Que Y D, Xiao W D, Du S X, Ouyang M, Pantelides S T, Gao H J 2019 Science 365 1036

Google Scholar

Google Scholar

[5] Novoselov K S, Geim A K, Morozov S V, Jiang D, Zhang Y, Dubonos S V, Grigorieva I V, Firsov A A 2004 Science 306 666

Google Scholar

Google Scholar

[6] Gu Y Y, Wang Y F, Xia J, Meng X M 2020 Chin. Phys. Lett. 37 048101

Google Scholar

Google Scholar

[7] 王铄, 王文辉, 吕俊鹏, 倪振华 2021 70 026802

Google Scholar

Google Scholar

Wang S, Wang W H, Lv J P, Ni Z H 2021 Acta Phys. Sin. 70 026802

Google Scholar

Google Scholar

[8] Zhang D L, Yi C, Ge C H, Shu W N, Li B, Duan X D, Pan A L, Wang X 2021 Chin. Phys. B 30 097601

Google Scholar

Google Scholar

[9] Zhang S, Song Y, Li H, Li J M, Qian K, Liu C, Wang J O, Qian T, Zhang Y Y, Lu J C, Ding H, Lin X, Pan J B, Du S X, Gao H J 2020 Chin. Phys. Lett. 37 068103

Google Scholar

Google Scholar

[10] Tan C L, Cao X H, Wu X J, He Q Y, Yang J, Zhang X, Chen J Z, Zhao W, Han S K, Nam G H, Sindoro M, Zhang H 2017 Chem. Rev. 117 6225

Google Scholar

Google Scholar

[11] Zhang Y B, Tan Y W, Stormer H L, Kim P 2005 Nature 438 201

Google Scholar

Google Scholar

[12] Novoselov K S, Geim A K, Morozov S V, Jiang D, Katsnelson M I, Grigorieva I V, Dubonos S V, Firsov A A 2005 Nature 438 197

Google Scholar

Google Scholar

[13] Cao Y, Fatemi V, Fang S, Watanabe K, Taniguchi T, Kaxiras E, Jarillo-Herrero P 2018 Nature 556 43

Google Scholar

Google Scholar

[14] Radisavljevic B, Radenovic A, Brivio J, Giacometti V, Kis A 2011 Nat. Nanotech. 6 147

Google Scholar

Google Scholar

[15] Castro Neto A H, Guinea F, Peres N M R, Novoselov K S, Geim A K 2009 Rev. Mod. Phys. 81 109

Google Scholar

Google Scholar

[16] Mak K F, Lee C, Hone J, Shan J, Heinz T F 2010 Phys. Rev. Lett. 105 136805

Google Scholar

Google Scholar

[17] Wang Q H, Kalantar-Zadeh K, Kis A, Coleman J N, Strano M S 2012 Nat. Nanotech. 7 699

Google Scholar

Google Scholar

[18] Li L K, Yu Y J, Ye G J, Ge Q Q, Ou X D, Wu H, Feng D L, Chen X H, Zhang Y B 2014 Nat. Nanotech. 9 372

Google Scholar

Google Scholar

[19] Cao Y, Fatemi V, Demir A, Fang S, Tomarken S L, Luo J Y, Sanchez-Yamagishi J D, Watanabe K, Taniguchi T, Kaxiras E, Ashoori R C, Jarillo-Herrero P 2018 Nature 556 80

Google Scholar

Google Scholar

[20] Cao Y, Fatemi V, Fang S, Watanabe K, Taniguchi T, Kaxiras E, Jarillo-Herrero P 2018 Natures 556 43

[21] Lisi S, Lu X B, Benschop T, de Jong T A, Stepanov P, Duran J R, Margot F, Cucchi I, Cappelli E, Hunter A, Tamai A, Kandyba V, Giampietri A, Barinov A, Jobst J, Stalman V, Leeuwenhoek M, Watanabe K, Taniguchi T, Rademaker L, van der Molen S J, Allan M P, Efetov D K, Baumberger F 2021 Nat. Phys. 17 189

Google Scholar

Google Scholar

[22] 季怡汝, 褚衍邦, 冼乐德, 杨威, 张广宇 2021 70 118101

Google Scholar

Google Scholar

Ji Y R, Chu Y B, Xian L D, Yang W, Zhang G Y 2021 Acta Phys. Sin. 70 118101

Google Scholar

Google Scholar

[23] Huang Y, Sutter E, Shi N N, Zheng J B, Yang T Z, Englund D, Gao H J, Sutter P 2015 ACS Nano 9 10612

Google Scholar

Google Scholar

[24] Yu Y J, Ma L G, Cai P, Zhong R D, Ye C, Shen J, Gu G D, Chen X H, Zhang Y B 2019 Nature 575 156

Google Scholar

Google Scholar

[25] 许宏, 孟蕾, 李杨, 杨天中, 鲍丽宏, 刘国东, 赵林, 刘天生, 邢杰, 高鸿钧, 周兴江, 黄元 2018 67 218201

Google Scholar

Google Scholar

Xu H, Meng L, Li Y, Yang T Z, Bao L H, Liu G D, Zhao L, Liu T S, Xing J, Gao H J, Zhou X J, Huang Y 2018 Acta Phys. Sin. 67 218201

Google Scholar

Google Scholar

[26] Huang Y, Pan Y H, Yang R, et al. 2020 Nat. Commun. 11 2453

Google Scholar

Google Scholar

[27] Magda G Z, Peto J, Dobrik G, Hwang C, Biro L P, Tapaszto L 2015 Sci. Rep. 5 14714

Google Scholar

Google Scholar

[28] Desai S B, Madhvapathy S R, Amani M, Kiriya D, Hettick M, Tosun M, Zhou Y Z, Dubey M, Ager J W, Chrzan D, Javey A 2016 Adv. Mater. 28 4053

Google Scholar

Google Scholar

[29] Velicky M, Donnelly G E, Hendren W R, McFarland S, Scullion D, DeBenedetti W J I, Correa G C, Han Y M, Wain A J, Hines M A, Muller D A, Novoselov K S, Abruna H D, Bowman R M, Santos E J G, and Huang F M 2018 ACS Nano 12 10463

Google Scholar

Google Scholar

[30] Yang S Q, Xu X L, Zhu Y Z, Niu R R, Xu C Q, Peng Y X, Cheng X, Jia X H, Huang Y, Xu X F, Lu J M, Ye Y 2021 Phys. Rev. X 11 011003

Google Scholar

Google Scholar

[31] Zang Z H, Zhu Y Z, Xi M, et al. 2022 Phys. Rev. Lett. 128 017201

Google Scholar

Google Scholar

[32] Liu F, Wu W J, Bai Y S, Chae S H, Li Q Y, Wang J, Hone J, Zhu X Y 2020 Science 367 903

Google Scholar

Google Scholar

[33] Huang Y, Wang Y K, Huang X Y, Zhang G H, Han X, Yang Y, Gao Y N, Meng L, Wang Y S, Geng G Z, Liu L W, Zhao L, Cheng Z H, Liu X F, Ren Z F, Yang H X, Hao Y F, Gao H J, Zhou X J, Ji W, Wang Y L 2021 Infomat 4 e12274

Google Scholar

Google Scholar

[34] Huang X Y, Zhang L, Liu L W, Qin Y, Fu Q, Wu Q, Yang R, Lv J P, Ni Z H, Liu L, Ji W, Wang Y L, Zhou X J, Huang Y. 2021 Sci. China Inf. Sci. 64 140406

Google Scholar

Google Scholar

[35] Deng Y J, Yu Y J, Song Y C, Zhang J Z, Wang N Z, Sun Z Y, Yi Y F, Wu Y Z, Wu S W, Zhu J Y, Wang J, Chen X H, Zhang Y B. 2018 Nature 563 94

Google Scholar

Google Scholar

计量

- 文章访问数: 14082

- PDF下载量: 870

- 被引次数: 0

下载:

下载: