-

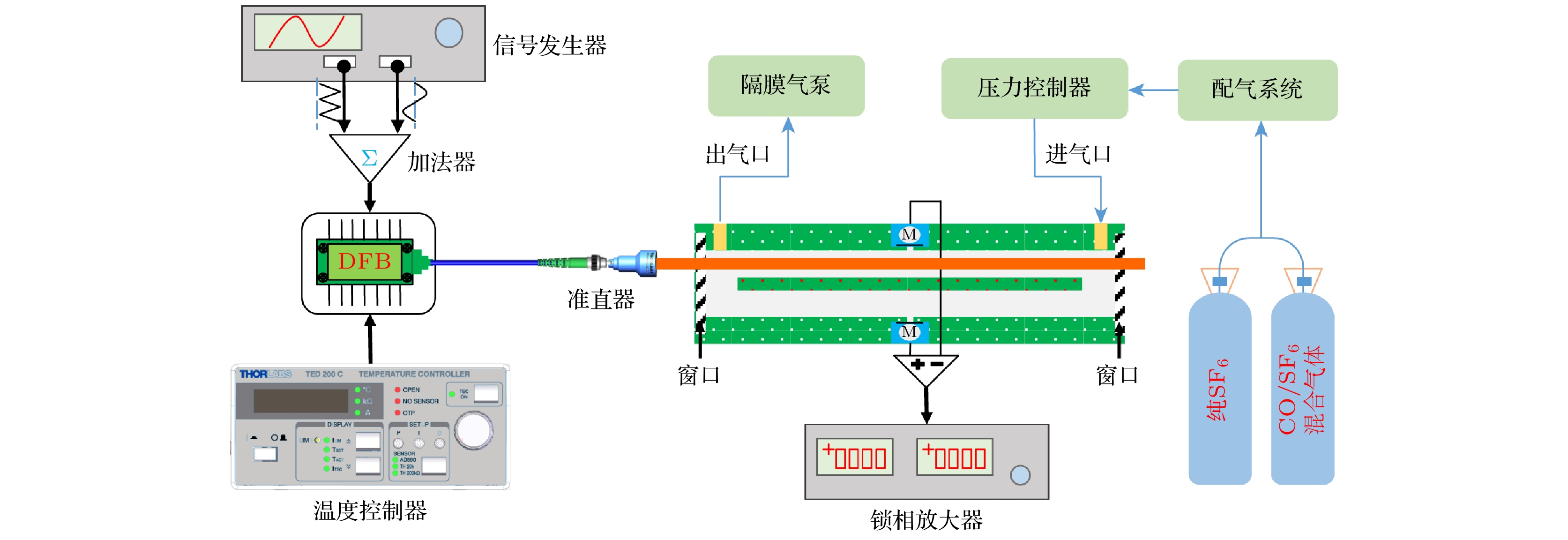

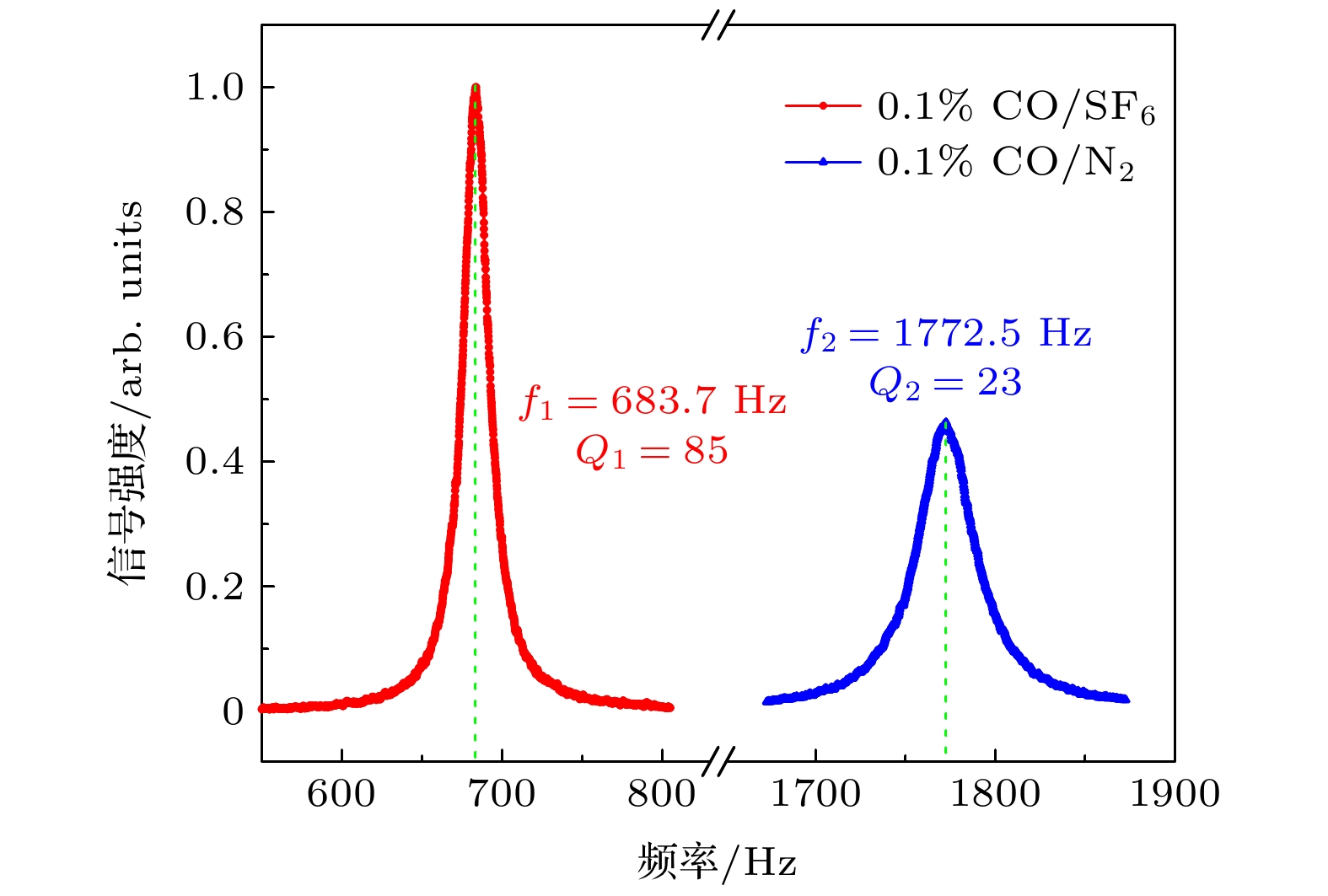

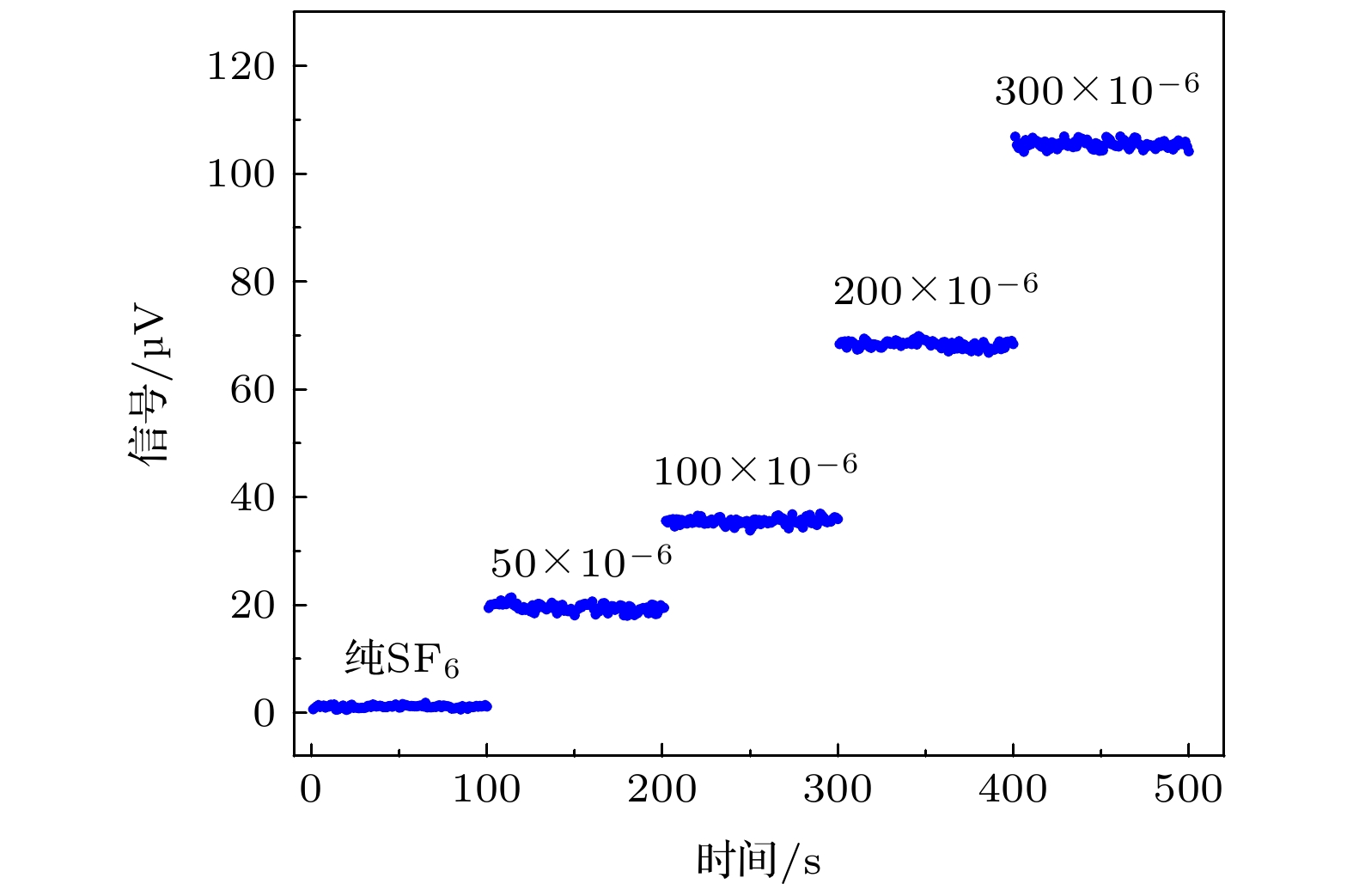

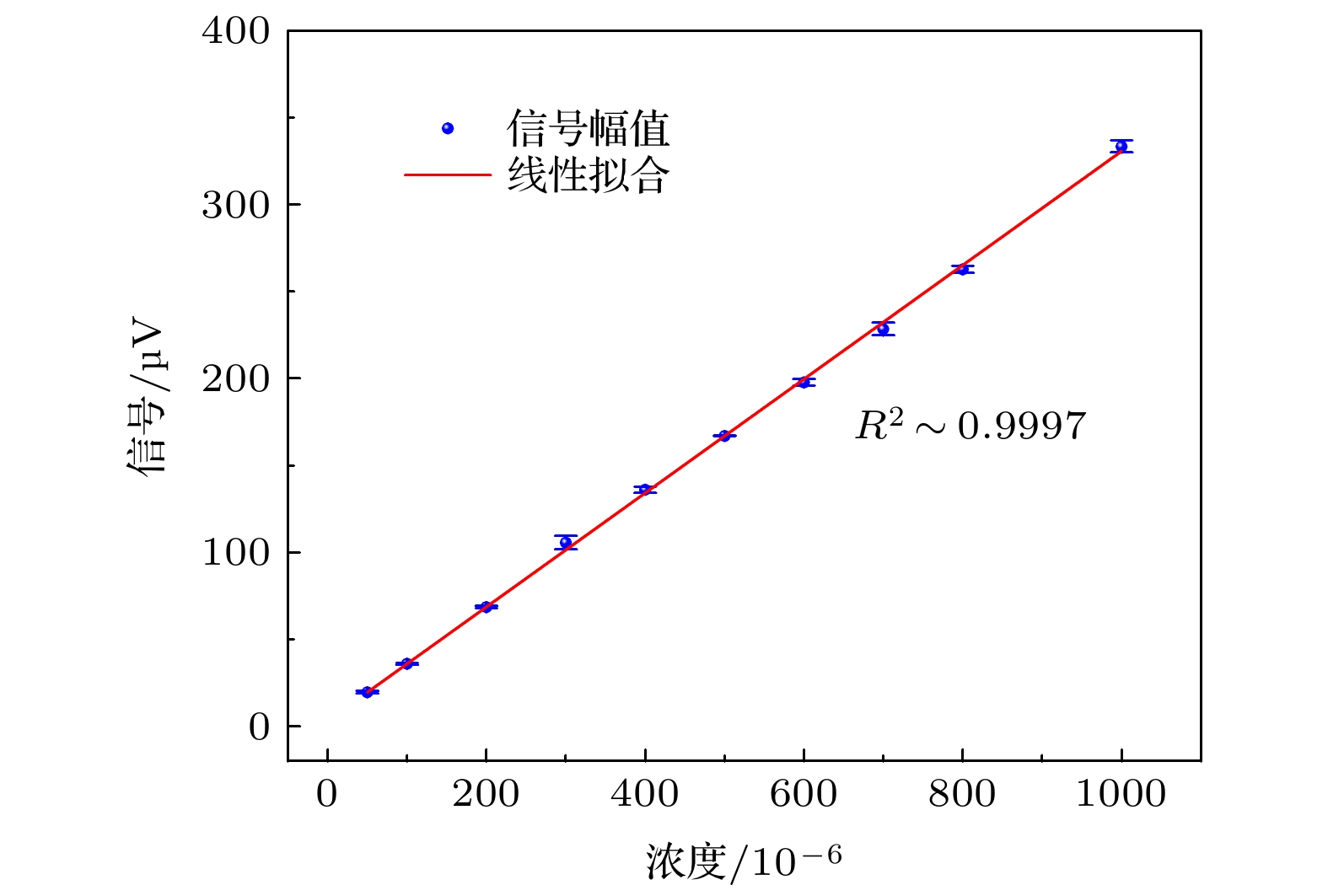

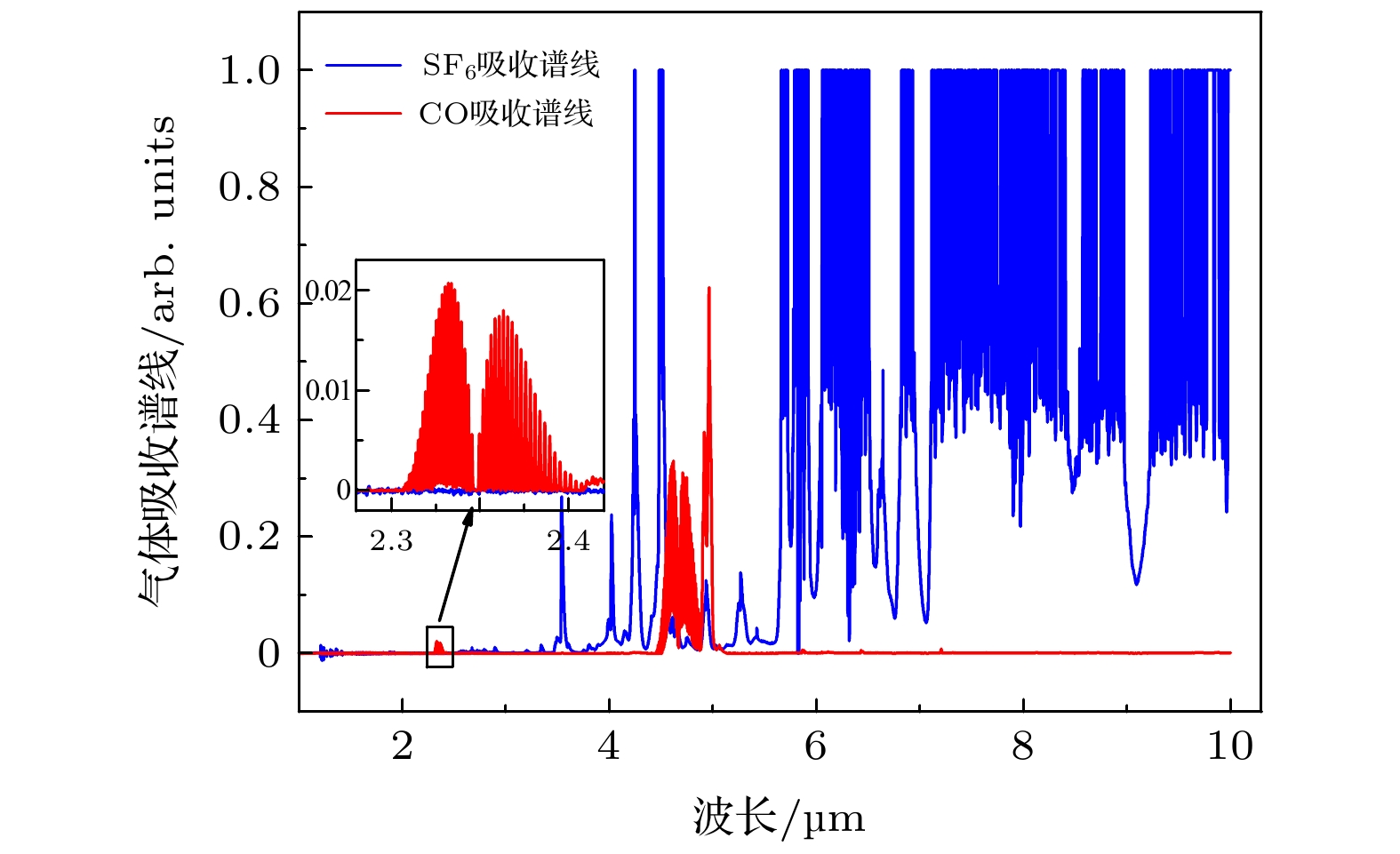

针对电力系统对六氟化硫电气绝缘设备中气体衍生物的在线高精度探测需要, 提出了差分双通道结构的光声池作为光声探测模块, 并使用中心波长为2.3 μm的分布式反馈(distributed feedback laser, DFB)激光器作为激励光源, 搭建了一款工作在高浓度六氟化硫背景气体中的一氧化碳气体传感器. 通过光声共振理论模拟和设计, 在纯六氟化硫气体中光声池的品质因子为84, 相对于在氮气载气中的品质因子提高了约4倍. 经实验验证, 差分结构光声池的最大气体流速较单共振腔光声池提高了6倍, 且具有较强的噪声免疫能力. 在对传感器系统的共振频率、气流速度和工作压强等参数优化后, 在1 s的积分时间下, 获得一氧化碳气体的探测灵敏度为体积分数1.18 × 10–6, 对应的归一化噪声等效浓度(1σ)为3.68 × 10–8 cm–1·W·Hz–1/2. 该传感器的灵敏度高, 选择性好且噪声免疫能力强, 可以为电力系统中潜在性绝缘故障诊断提供一种在线探测技术, 具有重要的应用前景.Trace gas analysis for SF6 decomposition is a powerful diagnostic method to identify partial discharge problem occurring in electrical equipment. In particular, it is recognized that the SF6 decomposition gases (such as CO, H2S, SO2 and CF4) can effectively determine the inner insulation condition of the electrical equipment. Currently, most of researches of diagnostic methods cannot meet the online high-precision detection of gas derivatives in SF6 electrical insulation equipment. Therefore, there is a need of developing a sensitive, selective and cost-effective sensor system for CO detection in an SF6 buffer gas environment due to the fact that the power system is filled with pure SF6 as the dielectric gas, which means that the concentration of SF6 is usually > 99.8%. The traditional photoacoustic CO gas sensors cannot be directly used in power system, since several SF6 physical constants strongly differ from those of N2 or air. In addition, SF6 molecule reveals uninterrupted and strong absorption lines in the mid-infrared spectral region. In this work, a CO gas sensor working in high concentration SF6 background gas is designed by using a distributed feedback (DFB) laser as an excitation source with a center wavelength of 2.3 μm. The absorption line strength of 2.3 μm is ~ two orders of magnitude higher than the absorption line strength around 1.56 μm, which can improve the sensor detection performance. A background-gas-induced high-Q differential photoacoustic cell is simulated numerically and tested experimentally. The quality factor of the designed photoacoustic cell in pure SF6 gas is 85, which is ~ 4 times higher than that in N2 carrier gas. The experimental results show that the maximum gas flow rate of the differential structure photoacoustic cell is ~ 6 times higher than that of the single resonant cavity photoacoustic cell. After optimizing the resonance frequency, gas velocity and working pressure of the sensor system, the detection sensitivity of the volume fraction of 1.85 × 10–6 is achieved. In the case of the volume fraction of 50 × 10–6 CO/SF6 gas mixture, the maximum photoacoustic signal amplitude of 19.6 μV is obtained, the corresponding normalized noise equivalent concentration (1σ) is 3.68 × 10–8 cm–1·W·Hz1/2 in 1 s integration time. A linear fitting is implemented to evaluate the response of the sensor from 50 × 10–6 to 1000 × 10–6, resulting in an R square value of 0.9997. The CO photoacoustic gas sensor has high sensitivity, good selectivity and strong noise immunity, which can provide an on-line detection technology for potential insulation fault diagnosis in the power system. The capability of CO gas sensor can be improved by using a higher excitation optical output power and/or reducing the PAC resonator volume to increase the cell constant.

-

Keywords:

- pohotoacoustic spectroscopy /

- trace gas sensors /

- electrical equipment insulation diagnosis

[1] 张晓星, 孟凡生, 唐炬, 杨冰 2012 61 156101

Google Scholar

Google Scholar

Zhang X X, Meng F S, Tang J, Yang B 2012 Acta Phys. Sin. 61 156101

Google Scholar

Google Scholar

[2] Kurte R, Beyer C, Heise H, Klockow D 2002 Anal. Bioanal. Chem. 373 639

Google Scholar

Google Scholar

[3] Yin X K, Dong L, Wu H P, Ma W G, Zhang L, Yin W B, Xiao L T, Jia S T, Tittel F K 2017 Appl. Phys. Lett. 111 031109

Google Scholar

Google Scholar

[4] Yin X K, Dong L, Wu H P, et al. 2017 Opt. Express 25 32581

Google Scholar

Google Scholar

[5] Zhang X X, Liu H, Ren J B, Li J, Li X 2015 Spectrochim. Acta, Part A 136 884

Google Scholar

Google Scholar

[6] Heise H M, Kurte R, Fischer P, Klockow D, Janissek P R 1997 Fresenius J. Anal. Chem. 358 793

Google Scholar

Google Scholar

[7] Wang P Y, Chen W G, Wang J X, Tang J, Shi Y L, Wan F 2020 Anal. Chem. 92 5969

Google Scholar

Google Scholar

[8] Cui R Y, Dong L, Wu H P, et al. 2018 Opt. Express 26 24318

Google Scholar

Google Scholar

[9] Zheng H D, Liu Y H, Lin H Y, et al. 2020 Photoacoustics 17 100158

Google Scholar

Google Scholar

[10] 周彧, 曹渊, 朱公栋, 刘锟, 谈图, 王利军, 高晓明 2018 57 084201

Google Scholar

Google Scholar

Zhou Y, Cao Y, Zhu G D, Liu K, Tan T, Wang L J, Gao X M 2018 Acta Phys. Sin. 57 084201

Google Scholar

Google Scholar

[11] Ma Y F, Yu X, Yu G, Li X D, Zhang J B, Cheng D Y, Sun R, Titttel F K 2015 Appl. Phys. Lett. 107 021106

Google Scholar

Google Scholar

[12] 尹旭坤, 郑华丹, 董磊, 武红鹏, 刘小利, 马维光, 张雷, 尹王保, 贾锁堂 2015 64 130701

Google Scholar

Google Scholar

Yin X K, Zheng H D, Dong L, Wu H P, Liu X L, Ma W G, Zhang L, Yin W B, Jia S T 2015 Acta Phys. Sin. 64 130701

Google Scholar

Google Scholar

[13] Hu L, Zheng C T, Zheng J, Wang Y D, Tittel F K 2019 Opt. Lett. 44 2562

Google Scholar

Google Scholar

[14] Wang Z, Wang Q, Ching J Y, Wu J C, Zhang G F, Ren W 2017 Sens. Actuators, B 246 710

Google Scholar

Google Scholar

[15] 陈珂, 袁帅, 宫振峰, 于清旭 2018 中国激光 45 0911012

Google Scholar

Google Scholar

Chen K, Yuan S, Gong Z F, Yu Q X 2018 Chin. J. Las. 45 0911012

Google Scholar

Google Scholar

[16] Zhang X, Cheng Z, Li X 2016 Infrared Phys. Technol. 78 31

Google Scholar

Google Scholar

[17] Luo J, Fang Y, Zhao Y, Wang A, Li D, Li Y, Liu Y, Cui F, Wu J, Liu J 2015 Anal. Methods 7 1200

Google Scholar

Google Scholar

[18] Sun B, Zifarelli A, Wu H P, Russo S D, Li S Z, Patimisco P, Dong L, Spagnolo V 2020 Anal. Chem. 92 13922

Google Scholar

Google Scholar

[19] Yin X K, Wu H P, Dong L, et al. 2019 Sens. Actuators, B 282 567

Google Scholar

Google Scholar

[20] Li Z L, Wang Z, Qi Y, Jin W, Ren W 2017 Sens. Actuators, B 248 1023

Google Scholar

Google Scholar

[21] He Y, Ma Y F, Tong Y, Yu X, Tittel F K 2019 Opt. Laser Technol. 115 129

Google Scholar

Google Scholar

[22] Li S Z, Dong L, Wu H P, Sampaolo A, Patimisco P, Spagnolo V, Tittel F K 2019 Anal. Chem. 91 5834

Google Scholar

Google Scholar

[23] Yin X K, Wu H P, Dong L, Li B, Ma W G, Zhang L, Yin W B, Xiao L T, Jia S T, Tittel F K 2020 ACS Sens. 5 549

Google Scholar

Google Scholar

[24] Wu H P, Dong L, Zheng H D, et al. 2017 Nat. Commun. 8 15331

Google Scholar

Google Scholar

[25] Gong Z F, Gao T L, Mei L, Chen K, Chen Y W, Zhang B, Peng W, Yu Q X 2021 Photoacoustics 21 100216

Google Scholar

Google Scholar

[26] Cao Y, Liu K, Wang R F, Chen W D, Gao X M 2021 Opt. Express 29 2258

Google Scholar

Google Scholar

-

-

[1] 张晓星, 孟凡生, 唐炬, 杨冰 2012 61 156101

Google Scholar

Google Scholar

Zhang X X, Meng F S, Tang J, Yang B 2012 Acta Phys. Sin. 61 156101

Google Scholar

Google Scholar

[2] Kurte R, Beyer C, Heise H, Klockow D 2002 Anal. Bioanal. Chem. 373 639

Google Scholar

Google Scholar

[3] Yin X K, Dong L, Wu H P, Ma W G, Zhang L, Yin W B, Xiao L T, Jia S T, Tittel F K 2017 Appl. Phys. Lett. 111 031109

Google Scholar

Google Scholar

[4] Yin X K, Dong L, Wu H P, et al. 2017 Opt. Express 25 32581

Google Scholar

Google Scholar

[5] Zhang X X, Liu H, Ren J B, Li J, Li X 2015 Spectrochim. Acta, Part A 136 884

Google Scholar

Google Scholar

[6] Heise H M, Kurte R, Fischer P, Klockow D, Janissek P R 1997 Fresenius J. Anal. Chem. 358 793

Google Scholar

Google Scholar

[7] Wang P Y, Chen W G, Wang J X, Tang J, Shi Y L, Wan F 2020 Anal. Chem. 92 5969

Google Scholar

Google Scholar

[8] Cui R Y, Dong L, Wu H P, et al. 2018 Opt. Express 26 24318

Google Scholar

Google Scholar

[9] Zheng H D, Liu Y H, Lin H Y, et al. 2020 Photoacoustics 17 100158

Google Scholar

Google Scholar

[10] 周彧, 曹渊, 朱公栋, 刘锟, 谈图, 王利军, 高晓明 2018 57 084201

Google Scholar

Google Scholar

Zhou Y, Cao Y, Zhu G D, Liu K, Tan T, Wang L J, Gao X M 2018 Acta Phys. Sin. 57 084201

Google Scholar

Google Scholar

[11] Ma Y F, Yu X, Yu G, Li X D, Zhang J B, Cheng D Y, Sun R, Titttel F K 2015 Appl. Phys. Lett. 107 021106

Google Scholar

Google Scholar

[12] 尹旭坤, 郑华丹, 董磊, 武红鹏, 刘小利, 马维光, 张雷, 尹王保, 贾锁堂 2015 64 130701

Google Scholar

Google Scholar

Yin X K, Zheng H D, Dong L, Wu H P, Liu X L, Ma W G, Zhang L, Yin W B, Jia S T 2015 Acta Phys. Sin. 64 130701

Google Scholar

Google Scholar

[13] Hu L, Zheng C T, Zheng J, Wang Y D, Tittel F K 2019 Opt. Lett. 44 2562

Google Scholar

Google Scholar

[14] Wang Z, Wang Q, Ching J Y, Wu J C, Zhang G F, Ren W 2017 Sens. Actuators, B 246 710

Google Scholar

Google Scholar

[15] 陈珂, 袁帅, 宫振峰, 于清旭 2018 中国激光 45 0911012

Google Scholar

Google Scholar

Chen K, Yuan S, Gong Z F, Yu Q X 2018 Chin. J. Las. 45 0911012

Google Scholar

Google Scholar

[16] Zhang X, Cheng Z, Li X 2016 Infrared Phys. Technol. 78 31

Google Scholar

Google Scholar

[17] Luo J, Fang Y, Zhao Y, Wang A, Li D, Li Y, Liu Y, Cui F, Wu J, Liu J 2015 Anal. Methods 7 1200

Google Scholar

Google Scholar

[18] Sun B, Zifarelli A, Wu H P, Russo S D, Li S Z, Patimisco P, Dong L, Spagnolo V 2020 Anal. Chem. 92 13922

Google Scholar

Google Scholar

[19] Yin X K, Wu H P, Dong L, et al. 2019 Sens. Actuators, B 282 567

Google Scholar

Google Scholar

[20] Li Z L, Wang Z, Qi Y, Jin W, Ren W 2017 Sens. Actuators, B 248 1023

Google Scholar

Google Scholar

[21] He Y, Ma Y F, Tong Y, Yu X, Tittel F K 2019 Opt. Laser Technol. 115 129

Google Scholar

Google Scholar

[22] Li S Z, Dong L, Wu H P, Sampaolo A, Patimisco P, Spagnolo V, Tittel F K 2019 Anal. Chem. 91 5834

Google Scholar

Google Scholar

[23] Yin X K, Wu H P, Dong L, Li B, Ma W G, Zhang L, Yin W B, Xiao L T, Jia S T, Tittel F K 2020 ACS Sens. 5 549

Google Scholar

Google Scholar

[24] Wu H P, Dong L, Zheng H D, et al. 2017 Nat. Commun. 8 15331

Google Scholar

Google Scholar

[25] Gong Z F, Gao T L, Mei L, Chen K, Chen Y W, Zhang B, Peng W, Yu Q X 2021 Photoacoustics 21 100216

Google Scholar

Google Scholar

[26] Cao Y, Liu K, Wang R F, Chen W D, Gao X M 2021 Opt. Express 29 2258

Google Scholar

Google Scholar

计量

- 文章访问数: 9618

- PDF下载量: 146

- 被引次数: 0

下载:

下载: