-

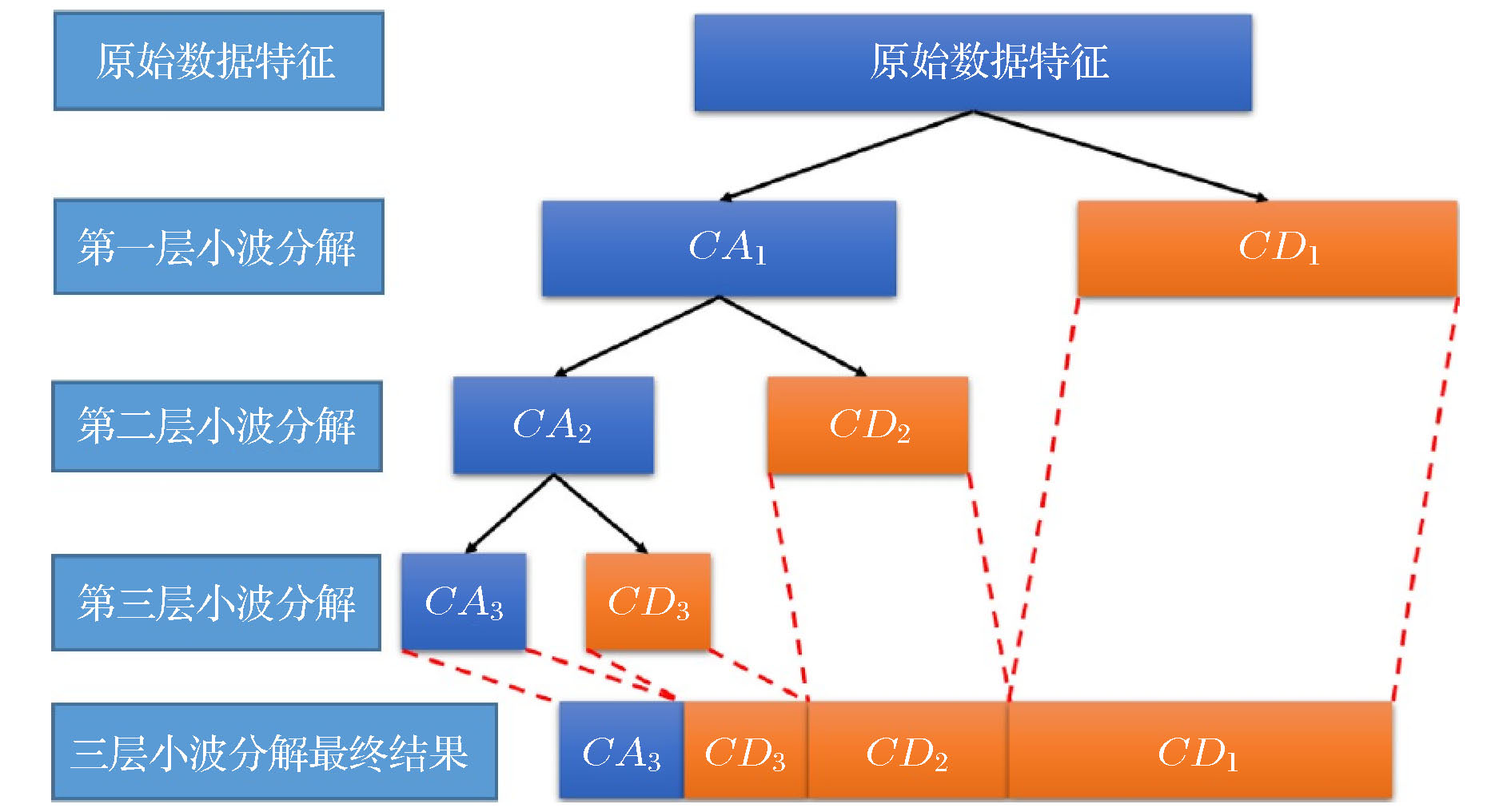

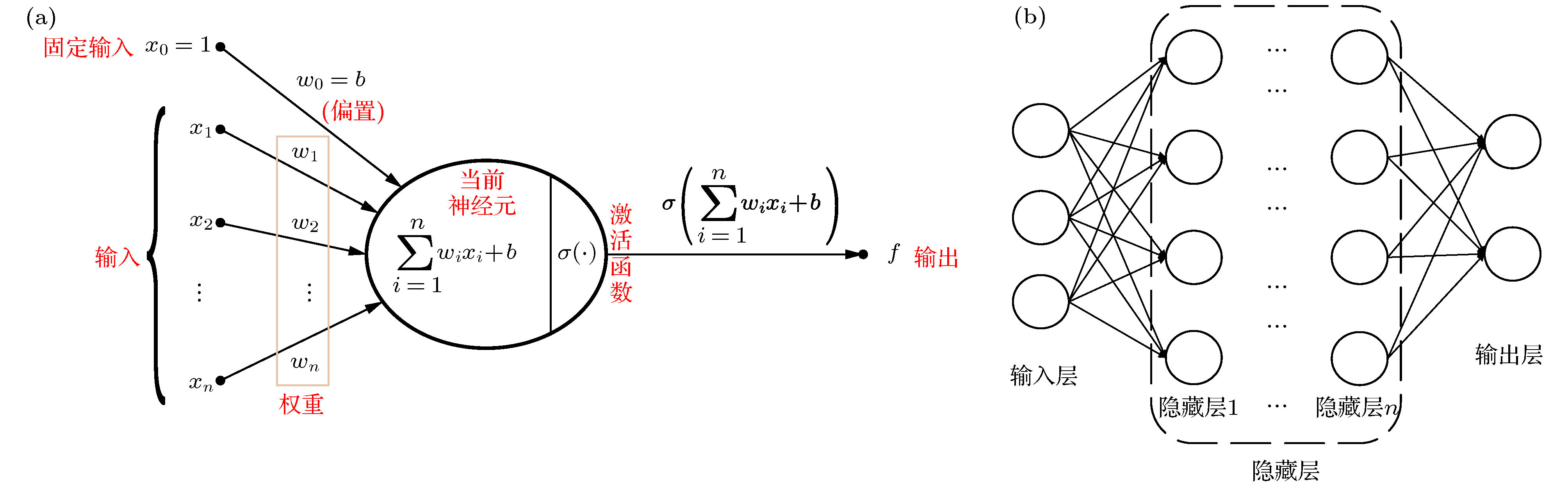

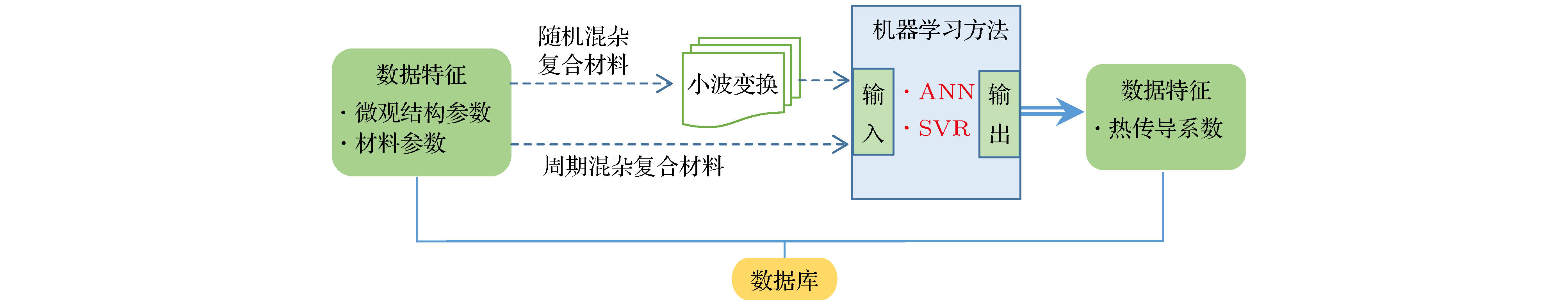

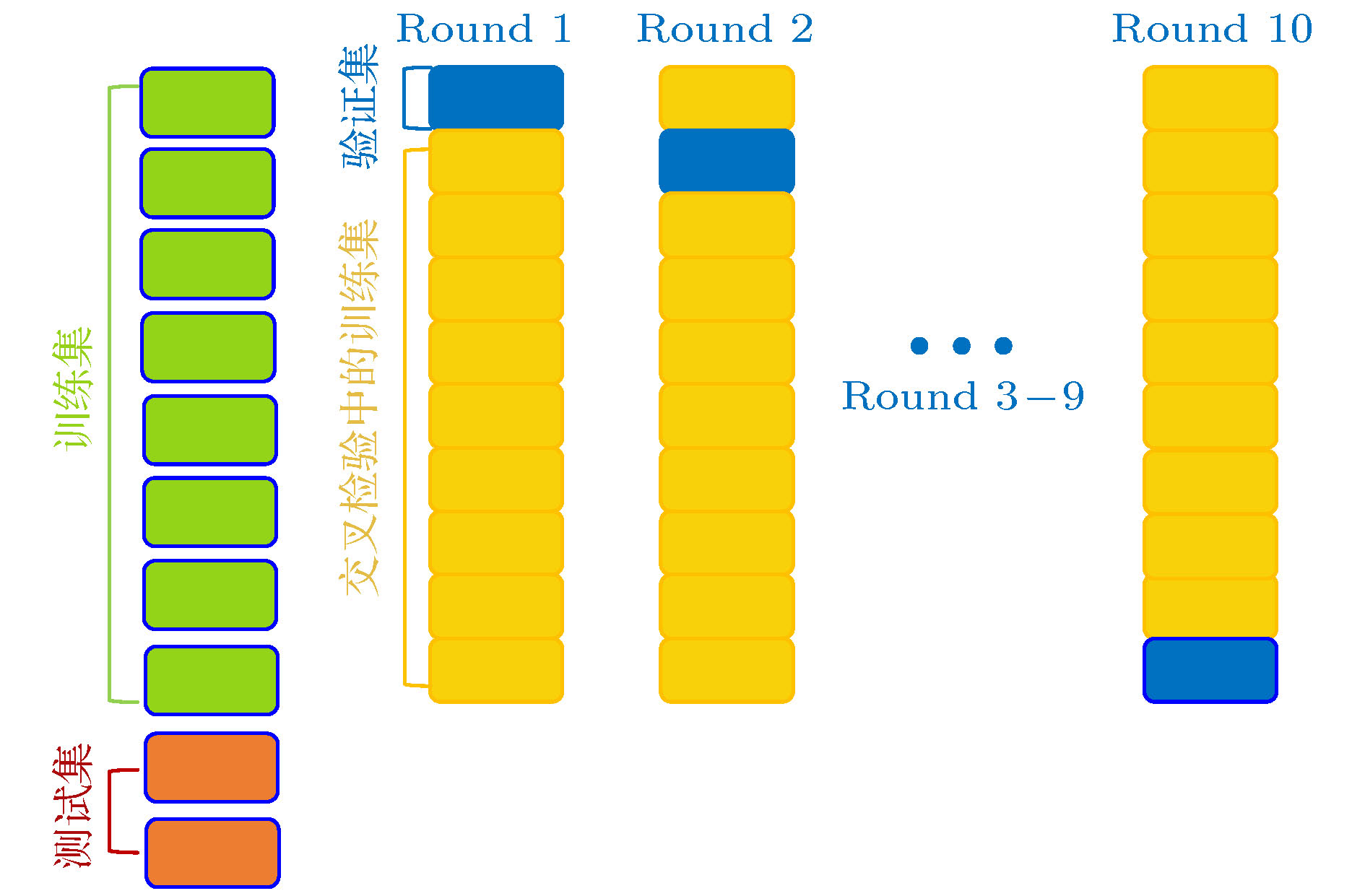

混杂复合材料是一种新型复合材料, 其复杂的细观结构导致预测其等效热传导性能极富挑战性. 本文结合渐近均匀化方法、小波变换方法和机器学习方法发展了一种新的可以有效预测混杂复合材料等效热传导性能的小波-机器学习混合方法. 该方法主要包括离线多尺度建模和在线机器学习两部分. 首先借助渐近均匀化方法通过离线多尺度建模建立了混杂复合材料的热传导性能材料数据库, 然后利用小波变换方法对离线的材料数据库进行预处理, 接下来分别运用人工神经网络和支持向量回归方法建立混杂复合材料等效热传导性能预测的在线机器学习模型. 最后通过对周期和随机混杂复合材料进行数值实验, 验证了小波-机器学习混合方法的有效性, 数值实验结果表明小波-神经网络混合方法具有最优的预测效果和抗噪能力. 此外, 需要强调的是对于具有高维大规模数据特征的随机混杂复合材料, 小波-机器学习混合方法不仅可以提取离线材料数据库的重要特征, 还可以显著减少在线监督学习的输入数据规模并提高机器学习模型的训练效率及抗噪性能. 本文建立的小波-机器学习混合方法不仅适用于混杂复合材料等效热传导性能的预测, 还可进一步推广应用于复合材料等效物理、力学性能的预测.The hybrid composite materials are a new type of composite material. Due to their complex microscopic structures, it is very challenging to predict the equivalent thermal conductivities of hybrid composites. In this paper, an innovative hybrid wavelet-based learning method assisted multiscale analysis is developed to predict the effective thermal conductivities of hybrid composite materials with heterogeneous conductivity by the asymptotic homogenization method, wavelet transform method, and machine learning method. This innovative approach mainly includes two parts: off-line multi-scale modeling and on-line machine learning. Firstly, the material database about thermal transfer performance of hybrid composites is established by the asymptotic homogenization method and off-line multi-scale modeling, and then the off-line material database is preprocessed by the wavelet transform method. Secondly, the artificial neural network and support vector regression method are employed to establish the on-line machine learning model for predicting the equivalent heat conduction properties of hybrid composites. Finally, the effectiveness of the proposed hybrid wavelet-based learning method is verified by numerical experiments on the periodic and random hybrid composites. The numerical results show that the hybrid wavelet-based artificial neural network method owns the optimal capability of parameter prediction and anti-noise. Furthermore, it should be emphasized that the hybrid wavelet-based learning method can not only extract the important features of off-line material database for random hybrid composites with high-dimensional large-scale data features, but also significantly reduce the quantity of input data for ensuring the successful on-line supervised learning and improve the training efficiency and anti-noise performance of the machine learning model. The established hybrid wavelet-based learning method in this paper can not only be used to evaluate the equivalent thermal conductivities of hybrid composite materials, but also further extend to the predicting of the equivalent physical and mechanical properties of composite materials.

-

Keywords:

- hybrid composite materials /

- effective thermal conductivities /

- machine learning method /

- wavelet transform

[1] 沈观林, 胡更开, 刘彬 2013 复合材料力学 (第2版) (北京: 清华大学出版社) 第159−161页

Shen G L, Hu G K, Liu B 2013 Mechanics of Composite Materials (2nd Ed.) (Beijing: Tsinghua University Press) pp159−161 (in Chinese)

[2] Hashin Z 1983 Int. J. Appl. Mech. 50 481

Google Scholar

Google Scholar

[3] Levin V M 1967 Mech. Solids 2 58

[4] Yang Q, Becker W 2004 CMES-Comput. Model. Eng. 6 319

Google Scholar

Google Scholar

[5] Islam M R, Pramila A 1999 J. Compos. Mater. 33 1699

Google Scholar

Google Scholar

[6] Yu Y, Cui J, Han F, Chen Y 2008 Comput. Exp. Simul. Eng. Sci. 2 19

[7] Yu Y, Cui J, Han F 2009 Comput. Mater. Sci. 46 151

Google Scholar

Google Scholar

[8] Ernesto I R, Manuel E C, Julián B C 2016 J. Braz. Soc. Mech. Sci. 38 1333

Google Scholar

Google Scholar

[9] Eduardo S N, Manuel E C, Julián B C 2017 Int. J. Eng. Sci. 119 205

Google Scholar

Google Scholar

[10] Bensoussan A, Lions J L, Papanicolaou G 2011 Asymptotic Analysis for Periodic Structures (2nd Ed.) (Vol. 374) (Rhode Island: American Mathematical Society) pp13−19

[11] Sundararaghavan V, Nicholas Z 2005 Comput. Mater. Sci. 32 223

Google Scholar

Google Scholar

[12] Liu R, Yabansu Y C, Agrawal A, Kalidindi S R, Choudhary A N 2015 Integr. Mater. Manuf. Innov. 4 1

Google Scholar

Google Scholar

[13] Sun Y, Bai H, Li M, Wang W 2017 J. Phys. Chem. Lett. 8 3434

Google Scholar

Google Scholar

[14] Kondo R, Yamakawa S, Masuoka Y, Tajima S, Asahi R 2017 Acta Mater. 141 29

Google Scholar

Google Scholar

[15] Cang R, Li H, Yao H, Jiao Y, Ren Y 2018 Comput. Mater. Sci. 150 212

Google Scholar

Google Scholar

[16] Bessa M A, Bostanabad R, Liu Z, Hu A, Apley D W, Brinson C, Chen W, Liu W K 2017 Comput. Meth. Appl. Mech. 320 633

Google Scholar

Google Scholar

[17] Benyelloul K, Aourag H 2013 Comput. Mater. Sci. 77 330

Google Scholar

Google Scholar

[18] Li X, Liu Z, Cui S, Luo C, Li C, Zhuang Z 2019 Comput. Meth. Appl. Mech. 347 735

Google Scholar

Google Scholar

[19] Balokas G, Czichon S, Rolfes R 2018 Compos. Struct. 183 550

Google Scholar

Google Scholar

[20] Liu Z, Wu C 2019 J. Mech. Phys. Solids 127 20

[21] Rong Q, Wei H, Huang X, Bao H 2019 Compos. Sci. Technol. 184 107861

Google Scholar

Google Scholar

[22] Li Y, Cui J 2004 Chin. J. Comput. Mech. 21 540

Google Scholar

Google Scholar

[23] 李友云 2004 博士学位论文 (北京: 中国科学院数学与系统科学研究院)

Li Y Y 2004 Ph. D. Dissertation (Beijing: Academy of mathematics and Systems Sciences, Chinese Academy of Sciences) (in Chinese)

[24] Zhang Y, Wong Y S, Deng J, Anton C, Gabos S, Zhang W, et al. 2016 Biodata Min. 9 19

Google Scholar

Google Scholar

[25] Wong Y, Lee B, Wong T 2001 Intell. Data Anal. 5 59

Google Scholar

Google Scholar

[26] Mallat S G 1989 IEEE Trans. Pattern. Anal. 11 674

Google Scholar

Google Scholar

[27] Alemohammad M, Stroud J R, Bosworth B T, Foster M A 2017 Opt. Express 25 9802

Google Scholar

Google Scholar

[28] Pathak R S 2009 The Wavelet Transform (1st Ed.) (Vol. 4) (Singapore: World Scientific) pp21−37

[29] 周志华 2016 机器学习 (第1版) (北京: 清华大学出版社) 第97−107页

Zhou Z H 2016 Machine Learning (1st Ed.) (Beijing: Tsinghua University Press) pp97−107 (in Chinese)

[30] Smola A J, Schölkopf B 2004 Stat. Comput. 1 4

Google Scholar

Google Scholar

-

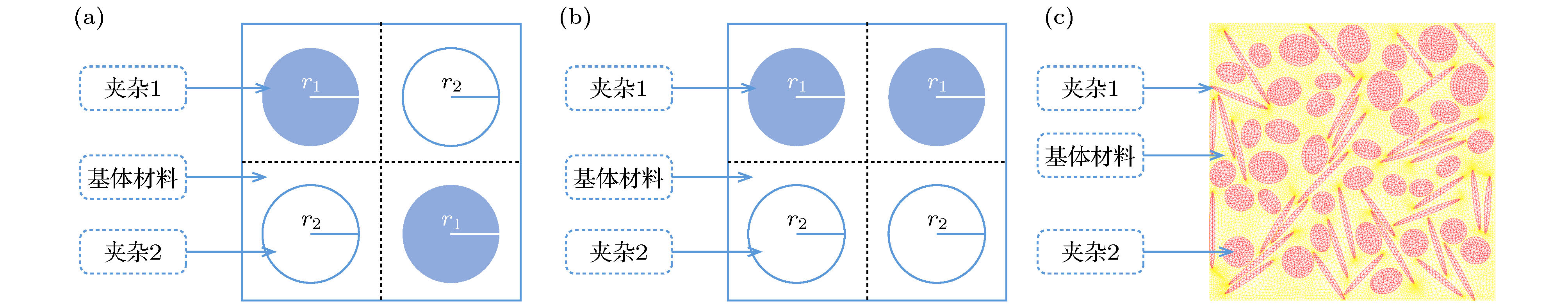

图 5 三种混杂复合材料1000个随机样本的等效热传导系数分布图 (a) 周期混杂复合材料I; (b) 周期混杂复合材料II; (c) 随机混杂复合材料

Fig. 5. Effective thermal conductivity distribution of 1000 RVE samples of three kinds of hybrid composite materials: (a) Periodic hybrid composite material I; (b) periodic hybrid composite material II; (c) random hybrid composite material.

图 7 三种混杂复合材料训练集误差和验证集误差随迭代次数变化曲线图 (a) 周期混杂复合材料I; (b) 周期混杂复合材料II; (c) 随机混杂复合材料

Fig. 7. Training error and cross-validation error descend as the training iteration increases for three kinds of hybrid composite materials: (a) Periodic hybrid composite material I; (b) periodic hybrid composite material II; (c) random hybrid composite material

图 8 三种混杂复合材料训练集和测试集上的相对误差分布图 (a) 周期混杂复合材料I; (b) 周期混杂复合材料II; (c) 随机混杂复合材料

Fig. 8. Frequency distribution of training error and test error of three kinds of hybrid composite materials: (a) Periodic hybrid composite material I; (b) periodic hybrid composite material II; (c) random hybrid composite material.

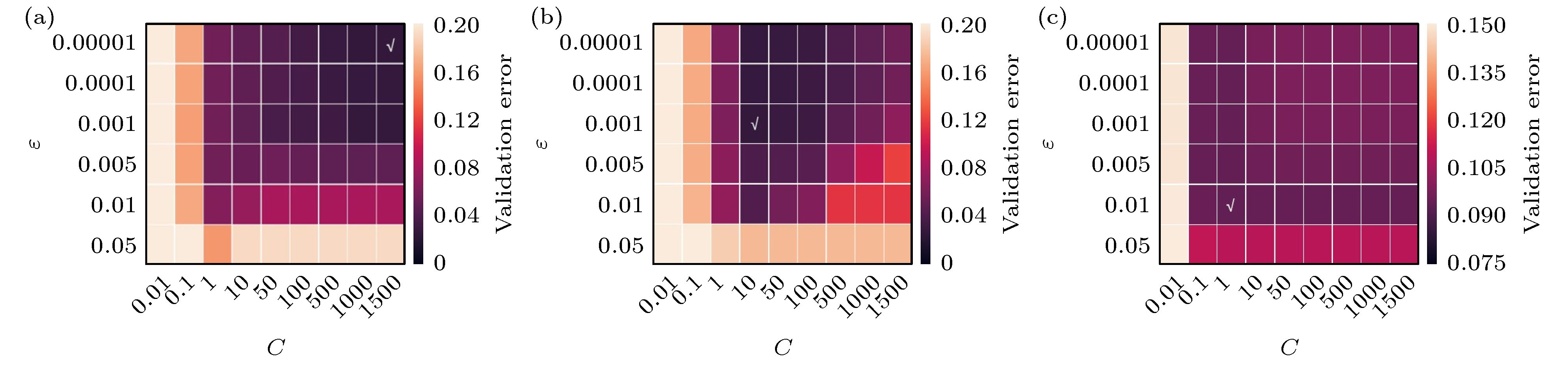

图 9 三种混杂复合材料参数网格搜索示意图, 其中标记√处为最终确定的最优参数组合 (a) 周期混杂复合材料I; (b) 周期混杂复合材料II; (c) 随机混杂复合材料

Fig. 9. Grid search diagram of three kinds of hybrid composite materials’ parameters, where the final optimal combination of parameters is marked with √: (a) Periodic hybrid composite material I; (b) periodic hybrid composite material II; (c) random hybrid composite material.

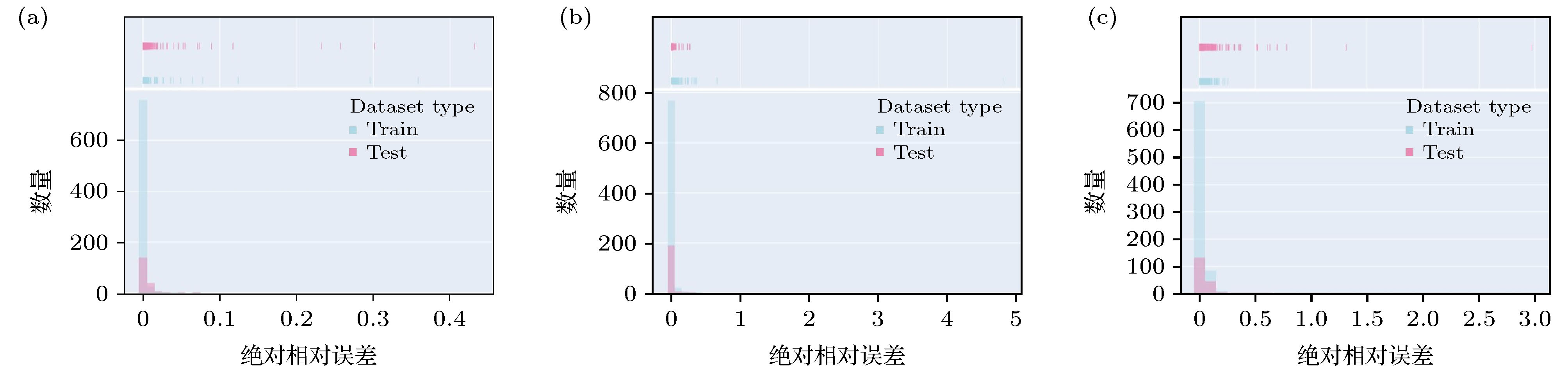

图 10 三种混杂复合材料训练集和测试集上的相对误差分布图 (a) 周期混杂复合材料I; (b) 周期混杂复合材料II; (c) 随机混杂复合材料

Fig. 10. Frequency distribution of training error and test error of three kinds of hybrid composite materials: (a) Periodic hybrid composite material I; (b) periodic hybrid composite material II; (c) random hybrid composite material.

表 1 周期型混杂复合材料的材料数据库

Table 1. Database for periodic hybrid composite material

样本编号 数据特征 数据标签 样本1 $kc_1$ $kc_2$ $km$ $r_1$ $r_2$ $\widehat k$ $\cdots$ $\cdots$ $\cdots$ $\cdots$ $\cdots$ $\cdots$ $\cdots$ 样本n $kc_1$ $kc_2$ $km$ $r_1$ $r_2$ $\widehat k$ 表 2 随机型混杂复合材料的材料数据库

Table 2. Database for random hybrid composite material

样本编号 数据特征 数据标签 样本1 $k^1_{x_1 x_2}$ $k^2_{x_1 x_2}$ $\cdots$ $k^m_{x_1 x_2}$ $\widehat k$ $\cdots$ $\cdots$ $\cdots$ $\cdots$ $\cdots$ $\cdots$ 样本n $k^1_{x_1 x_2}$ $k^2_{x_1 x_2}$ $\cdots$ $k^m_{x_1 x_2}$ $\widehat k$ 表 3 随机型混杂复合材料新的材料数据库

Table 3. New database for random hybrid composite material.

样本编号 数据特征 数据标签 样本1 $CA_3$ $\widehat k$ $\cdots$ $\cdots$ $\cdots$ 样本n $CA_3$ $\widehat k$ 表 4 两种小波-机器学习混合方法抗噪性能分析

Table 4. Anti-noise performance analysis of two kinds of hybrid wavelet-based learning methods.

方法 模型参数 Cv训练误差 Cv验证误差 训练误差 测试误差 训练时间/s 测试时间/s ANN 1250-1024-512-512-256-1 1.708% 5.760% 1.360% 3.973% 100.345 0.061 ANN-I 1250-1024-512-512-256-1 1.516% 5.948% 1.671% 4.496% 100.517 0.089 ANN-II 1250-1024-512-512-256-1 1.349% 5.404% 1.683% 4.427% 101.160 0.071 ANN-III 1250-1024-512-512-256-1 1.550% 5.862% 1.285% 4.810% 100.270 0.059 SVR C = 1和$\varepsilon=10^{-2}$ 2.658% 9.257% 2.664% 8.156% 0.780 0.171 SVR-I C = 1和$\varepsilon=10^{-2}$ 2.664% 9.268% 2.660% 8.160% 0.710 0.187 SVR-II C = 1和$\varepsilon=10^{-2}$ 2.659% 9.265% 2.673% 8.150% 0.696 0.159 SVR-III C = 1和$\varepsilon=10^{-2}$ 2.677% 9.124% 2.675% 8.099% 0.694 0.166 -

[1] 沈观林, 胡更开, 刘彬 2013 复合材料力学 (第2版) (北京: 清华大学出版社) 第159−161页

Shen G L, Hu G K, Liu B 2013 Mechanics of Composite Materials (2nd Ed.) (Beijing: Tsinghua University Press) pp159−161 (in Chinese)

[2] Hashin Z 1983 Int. J. Appl. Mech. 50 481

Google Scholar

Google Scholar

[3] Levin V M 1967 Mech. Solids 2 58

[4] Yang Q, Becker W 2004 CMES-Comput. Model. Eng. 6 319

Google Scholar

Google Scholar

[5] Islam M R, Pramila A 1999 J. Compos. Mater. 33 1699

Google Scholar

Google Scholar

[6] Yu Y, Cui J, Han F, Chen Y 2008 Comput. Exp. Simul. Eng. Sci. 2 19

[7] Yu Y, Cui J, Han F 2009 Comput. Mater. Sci. 46 151

Google Scholar

Google Scholar

[8] Ernesto I R, Manuel E C, Julián B C 2016 J. Braz. Soc. Mech. Sci. 38 1333

Google Scholar

Google Scholar

[9] Eduardo S N, Manuel E C, Julián B C 2017 Int. J. Eng. Sci. 119 205

Google Scholar

Google Scholar

[10] Bensoussan A, Lions J L, Papanicolaou G 2011 Asymptotic Analysis for Periodic Structures (2nd Ed.) (Vol. 374) (Rhode Island: American Mathematical Society) pp13−19

[11] Sundararaghavan V, Nicholas Z 2005 Comput. Mater. Sci. 32 223

Google Scholar

Google Scholar

[12] Liu R, Yabansu Y C, Agrawal A, Kalidindi S R, Choudhary A N 2015 Integr. Mater. Manuf. Innov. 4 1

Google Scholar

Google Scholar

[13] Sun Y, Bai H, Li M, Wang W 2017 J. Phys. Chem. Lett. 8 3434

Google Scholar

Google Scholar

[14] Kondo R, Yamakawa S, Masuoka Y, Tajima S, Asahi R 2017 Acta Mater. 141 29

Google Scholar

Google Scholar

[15] Cang R, Li H, Yao H, Jiao Y, Ren Y 2018 Comput. Mater. Sci. 150 212

Google Scholar

Google Scholar

[16] Bessa M A, Bostanabad R, Liu Z, Hu A, Apley D W, Brinson C, Chen W, Liu W K 2017 Comput. Meth. Appl. Mech. 320 633

Google Scholar

Google Scholar

[17] Benyelloul K, Aourag H 2013 Comput. Mater. Sci. 77 330

Google Scholar

Google Scholar

[18] Li X, Liu Z, Cui S, Luo C, Li C, Zhuang Z 2019 Comput. Meth. Appl. Mech. 347 735

Google Scholar

Google Scholar

[19] Balokas G, Czichon S, Rolfes R 2018 Compos. Struct. 183 550

Google Scholar

Google Scholar

[20] Liu Z, Wu C 2019 J. Mech. Phys. Solids 127 20

[21] Rong Q, Wei H, Huang X, Bao H 2019 Compos. Sci. Technol. 184 107861

Google Scholar

Google Scholar

[22] Li Y, Cui J 2004 Chin. J. Comput. Mech. 21 540

Google Scholar

Google Scholar

[23] 李友云 2004 博士学位论文 (北京: 中国科学院数学与系统科学研究院)

Li Y Y 2004 Ph. D. Dissertation (Beijing: Academy of mathematics and Systems Sciences, Chinese Academy of Sciences) (in Chinese)

[24] Zhang Y, Wong Y S, Deng J, Anton C, Gabos S, Zhang W, et al. 2016 Biodata Min. 9 19

Google Scholar

Google Scholar

[25] Wong Y, Lee B, Wong T 2001 Intell. Data Anal. 5 59

Google Scholar

Google Scholar

[26] Mallat S G 1989 IEEE Trans. Pattern. Anal. 11 674

Google Scholar

Google Scholar

[27] Alemohammad M, Stroud J R, Bosworth B T, Foster M A 2017 Opt. Express 25 9802

Google Scholar

Google Scholar

[28] Pathak R S 2009 The Wavelet Transform (1st Ed.) (Vol. 4) (Singapore: World Scientific) pp21−37

[29] 周志华 2016 机器学习 (第1版) (北京: 清华大学出版社) 第97−107页

Zhou Z H 2016 Machine Learning (1st Ed.) (Beijing: Tsinghua University Press) pp97−107 (in Chinese)

[30] Smola A J, Schölkopf B 2004 Stat. Comput. 1 4

Google Scholar

Google Scholar

计量

- 文章访问数: 8143

- PDF下载量: 162

- 被引次数: 0

下载:

下载: