-

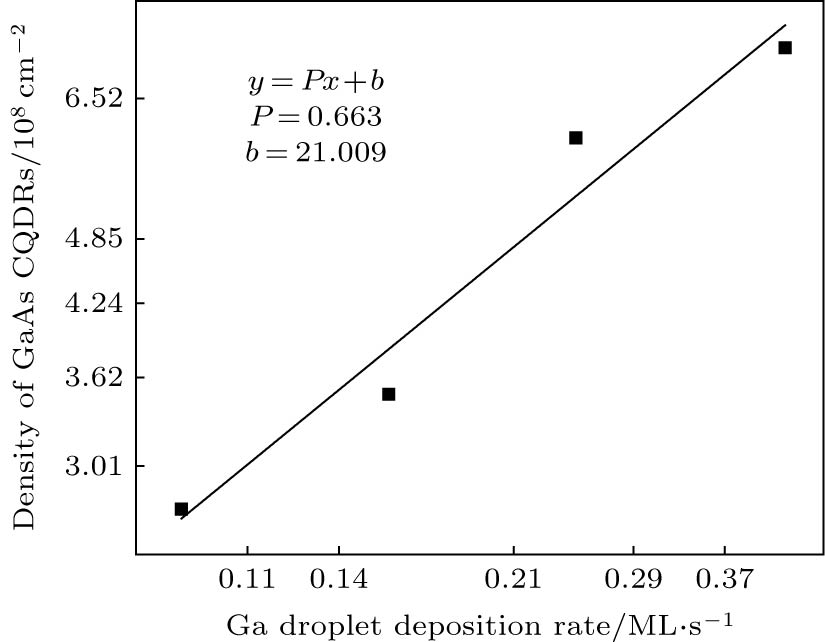

采用液滴外延法在GaAs (001)衬底上制备同心量子双环(concentric quantum double rings, CQDRs), 利用原子力显微镜表征其表面形貌, 并研究Ga液滴沉积速率对CQDRs的影响. 研究结果发现, 随着Ga液滴沉积速率的增加, CQDRs的密度增加, 内外环半径均降低. 根据成核理论中最大团簇密度和Ga液滴沉积速率之间的关系拟合出临界成核原子数目为5, 表明在Ga液滴形成阶段时稳定的Ga原子晶核至少包含5个Ga原子; 根据成核理论和拟合结果绘制成核过程状态转化图以深入理解Ga液滴形成过程. 相关研究结果对液滴外延法制备密度可控的GaAs同心量子双环具有一定的指导意义.For the fabrication of particular nanostructures, Stranski-Krastanov (SK) growth mode driven by strain is most widely used. Meanwhile, another technique that is used to form the complex nanostructures is the droplet epitaxy technique, which is based on the deposition of group III element nanoscale droplets onto substrate and followed by the reaction with group V element for crystallization into III-V compound nanostructures. Droplet epitaxy technique is simple and flexible, and it does not require additional complicated processing and has potential to develop various quantum nanostructures. It, unlike standard MBE growth, exploits the sequential supply of group-III and group-V elements to form quantum nanostructures. Quantum rings are a special class of quantum-confinement structure that can be fabricated by the droplet epitaxy technique and have attracted wide attention due to the Aharonov-Bohm effect, which is specific to the topology of a ring. In this paper, GaAs/GaAs (001) concentric quantum double rings (CQDRs) are prepared by droplet epitaxy technique at different Ga droplet deposition rates in monolayer per second (ML/S). The 2 μm × 2 μm atomic force microscope images are obtained to show the morphologies of CQDRs. We study the effects of Ga droplet deposition rates (0.09 ML/s, 0.154 ML/s, 0.25 ML/s, 0.43 ML/s) on CQDRs. The results show that with the increase of Ga droplet deposition rate, the density of CQDRs increases and the radius of inner ring and the radius of outer ring decrease. According to the nucleation theory, through the relationship between the maximum cluster density and the Ga droplet deposition rate, the critical number of atom nucleations is found to be 5, which suggests that the stable Ga atom crystal nucleus should contain at least 5 Ga atoms in the process of forming Ga droplet, and a nucleation state transformation diagram is drawn in order to obtain an insight into the process of forming Ga droplet according to the nucleation theory and fitting results. The research results could be instructive for preparing the GaAs concentric quantum double rings that the density can be controlled by droplet epitaxy.

[1] Lorke A, Luyken R J, Govorov A O, Kotthaus J P 2000 Phys. Rev. Lett. 84 2223

Google Scholar

Google Scholar

[2] 吴洪 2009 58 8549

Google Scholar

Google Scholar

Wu H 2009 Acta Phys. Sin. 58 8549

Google Scholar

Google Scholar

[3] Zarenia M, Pereira J M, Peeters F M, Farias G A 2009 Nano Lett. 9 4088

Google Scholar

Google Scholar

[4] Bayer M, Korkusinski M, Hawrylak P, Gutbrod T, Michel M, Forchel A 2003 Phys. Rev. Lett. 90 186801

Google Scholar

Google Scholar

[5] Ribeiro E, Govorov A O, Carvalho Jr W, Medeiros-Ribeiro G 2004 Phys. Rev. Lett. 92 126402

Google Scholar

Google Scholar

[6] 刘高福, 郭光杰, 周筑文 2015 四川大学学报(自然科学版) 52 6

Google Scholar

Google Scholar

Liu G F, Guo G J, Zhou Z W 2015 J. Sichuan. Univ: Nat. Sci. Ed. 52 6

Google Scholar

Google Scholar

[7] Chakraborty T, PietilInen P 1994 Phys. Rev. B 50 8460

Google Scholar

Google Scholar

[8] Teodoro M D, Campo V L, Lopez-Richard V, Marega Jr E, Marques G E, Galvao Gobato Y, Iikawa F, Brasil M J S P, AbuWaar Z Y, Dorogan V G, Mazur Yu I, Benamara M, Salamo G J 2010 Phys. Rev. Lett. 104 086401

Google Scholar

Google Scholar

[9] Sellers I R, Whiteside V R, Kuskovsky I L, Govorov A O, McCombe B D 2008 Phys. Rev. Lett. 100 136405

Google Scholar

Google Scholar

[10] Kobayashi S, Jiang C, Kawazu T, Sakaki H 2004 Jpn. J. Appl. Phys. 43 L662

Google Scholar

Google Scholar

[11] 王一, 杨晨, 郭祥, 王继红, 刘雪飞, 魏节敏, 郎啟智, 罗子江, 丁召 2018 67 080503

Google Scholar

Google Scholar

Wang Y, Yang C, Guo X, Wang J H, Liu X F, Wei J M, Lang Q Z, Luo Z J, Ding Z 2018 Acta Phys. Sin. 67 080503

Google Scholar

Google Scholar

[12] Chikyow T, Koguchi N 1990 Jpn. J. Appl. Phys. 29 L2093

Google Scholar

Google Scholar

[13] Kim J S, Song J D, Byeon C C, Kang H, Jeong M S, Cho N K, Park S J,Chol W J, Lee J, Kim J S, Leem J Y, Yim S Y 2009 Phys. Status Solidi C 6 802

Google Scholar

Google Scholar

[14] Kim H D, Okuyama R, Kyhm K, Eto M, Taylor R A, Nicolet A L, Potemski M, Nogues G, Dang L S, Je K C, Kim J, Kyhm J H, Yoen K H, Lee E H, Kim J Y, Han II K, Choi W, Song J D 2016 Nano. Lett. 16 27

[15] Kunrugsa M, Tung K H P, Danner A J, Panyakeow S, Ratanathammaphan S 2015 J. Cryst. Growth 425 287

Google Scholar

Google Scholar

[16] Mano T, Kuroda T, Sanguinetti S, Ochiai T, Tateno T, Kim J, Noda T, Kawabe M, Sakoda K, Kido G, Koguchi N 2005 Nano Lett. 5 425

Google Scholar

Google Scholar

[17] Boonpeng P, Jevasuwan W, Nuntawong N, Thainoi S, Panyakeow S, Ratanathammaphan S 2011 J. Cryst. Growth 323 271

Google Scholar

Google Scholar

[18] Li X L 2013 J. Cryst. Growth 377 59

Google Scholar

Google Scholar

[19] Kunrugsa M, Kiravittaya S, Panyakeow S, Ratanathammaphan S 2014 J. Cryst. Growth 402 285

Google Scholar

Google Scholar

[20] Venables J A, Persaud R, Metcalfe F L, Milne R H, Azim M 1994 J. Phys. Chem. Solids 55 955

Google Scholar

Google Scholar

[21] Venables J A, Spiller G D T, Hanbucken M 1984 Rep. Prog. Phys. 47 399

Google Scholar

Google Scholar

-

图 4 CQDRs 内、外环半径拟合曲线图及测量示意图 (a) 内外环测量示意图; (b) 内环平均半径拟合曲线图; (c) 外环平均半径拟合曲线图

Fig. 4. Fitting curves and the measurement schematic diagram of the radii of inner and outer ring for CQDRs: (a) Schematic diagram of inner and outer ring measurement; (b) fitting curve of the inner ring average radii; (c) fitting curve of the outer ring average radii.

-

[1] Lorke A, Luyken R J, Govorov A O, Kotthaus J P 2000 Phys. Rev. Lett. 84 2223

Google Scholar

Google Scholar

[2] 吴洪 2009 58 8549

Google Scholar

Google Scholar

Wu H 2009 Acta Phys. Sin. 58 8549

Google Scholar

Google Scholar

[3] Zarenia M, Pereira J M, Peeters F M, Farias G A 2009 Nano Lett. 9 4088

Google Scholar

Google Scholar

[4] Bayer M, Korkusinski M, Hawrylak P, Gutbrod T, Michel M, Forchel A 2003 Phys. Rev. Lett. 90 186801

Google Scholar

Google Scholar

[5] Ribeiro E, Govorov A O, Carvalho Jr W, Medeiros-Ribeiro G 2004 Phys. Rev. Lett. 92 126402

Google Scholar

Google Scholar

[6] 刘高福, 郭光杰, 周筑文 2015 四川大学学报(自然科学版) 52 6

Google Scholar

Google Scholar

Liu G F, Guo G J, Zhou Z W 2015 J. Sichuan. Univ: Nat. Sci. Ed. 52 6

Google Scholar

Google Scholar

[7] Chakraborty T, PietilInen P 1994 Phys. Rev. B 50 8460

Google Scholar

Google Scholar

[8] Teodoro M D, Campo V L, Lopez-Richard V, Marega Jr E, Marques G E, Galvao Gobato Y, Iikawa F, Brasil M J S P, AbuWaar Z Y, Dorogan V G, Mazur Yu I, Benamara M, Salamo G J 2010 Phys. Rev. Lett. 104 086401

Google Scholar

Google Scholar

[9] Sellers I R, Whiteside V R, Kuskovsky I L, Govorov A O, McCombe B D 2008 Phys. Rev. Lett. 100 136405

Google Scholar

Google Scholar

[10] Kobayashi S, Jiang C, Kawazu T, Sakaki H 2004 Jpn. J. Appl. Phys. 43 L662

Google Scholar

Google Scholar

[11] 王一, 杨晨, 郭祥, 王继红, 刘雪飞, 魏节敏, 郎啟智, 罗子江, 丁召 2018 67 080503

Google Scholar

Google Scholar

Wang Y, Yang C, Guo X, Wang J H, Liu X F, Wei J M, Lang Q Z, Luo Z J, Ding Z 2018 Acta Phys. Sin. 67 080503

Google Scholar

Google Scholar

[12] Chikyow T, Koguchi N 1990 Jpn. J. Appl. Phys. 29 L2093

Google Scholar

Google Scholar

[13] Kim J S, Song J D, Byeon C C, Kang H, Jeong M S, Cho N K, Park S J,Chol W J, Lee J, Kim J S, Leem J Y, Yim S Y 2009 Phys. Status Solidi C 6 802

Google Scholar

Google Scholar

[14] Kim H D, Okuyama R, Kyhm K, Eto M, Taylor R A, Nicolet A L, Potemski M, Nogues G, Dang L S, Je K C, Kim J, Kyhm J H, Yoen K H, Lee E H, Kim J Y, Han II K, Choi W, Song J D 2016 Nano. Lett. 16 27

[15] Kunrugsa M, Tung K H P, Danner A J, Panyakeow S, Ratanathammaphan S 2015 J. Cryst. Growth 425 287

Google Scholar

Google Scholar

[16] Mano T, Kuroda T, Sanguinetti S, Ochiai T, Tateno T, Kim J, Noda T, Kawabe M, Sakoda K, Kido G, Koguchi N 2005 Nano Lett. 5 425

Google Scholar

Google Scholar

[17] Boonpeng P, Jevasuwan W, Nuntawong N, Thainoi S, Panyakeow S, Ratanathammaphan S 2011 J. Cryst. Growth 323 271

Google Scholar

Google Scholar

[18] Li X L 2013 J. Cryst. Growth 377 59

Google Scholar

Google Scholar

[19] Kunrugsa M, Kiravittaya S, Panyakeow S, Ratanathammaphan S 2014 J. Cryst. Growth 402 285

Google Scholar

Google Scholar

[20] Venables J A, Persaud R, Metcalfe F L, Milne R H, Azim M 1994 J. Phys. Chem. Solids 55 955

Google Scholar

Google Scholar

[21] Venables J A, Spiller G D T, Hanbucken M 1984 Rep. Prog. Phys. 47 399

Google Scholar

Google Scholar

计量

- 文章访问数: 9043

- PDF下载量: 49

- 被引次数: 0

下载:

下载: