-

Fe基合金性能优异, 是首选的“双绿色”节能材料, 在电力电子信息领域具有重要的应用价值. 本文对单辊快淬制备的Fe64.8Co7.2Nb4Si4.8B19.2非晶薄带实施多场耦合热处理(电流张应力退火), 采用阻抗仪和磁力显微镜观测薄带纵向驱动巨磁阻抗效应及磁畴结构, 结合X射线衍射、随机各向异性模型和数值拟合分析薄带的磁晶各向异性和应力各向异性, 提出磁各向异性竞争因子k, 从磁各向异性角度研究合金带巨磁阻抗效应调控机制. 结果表明,

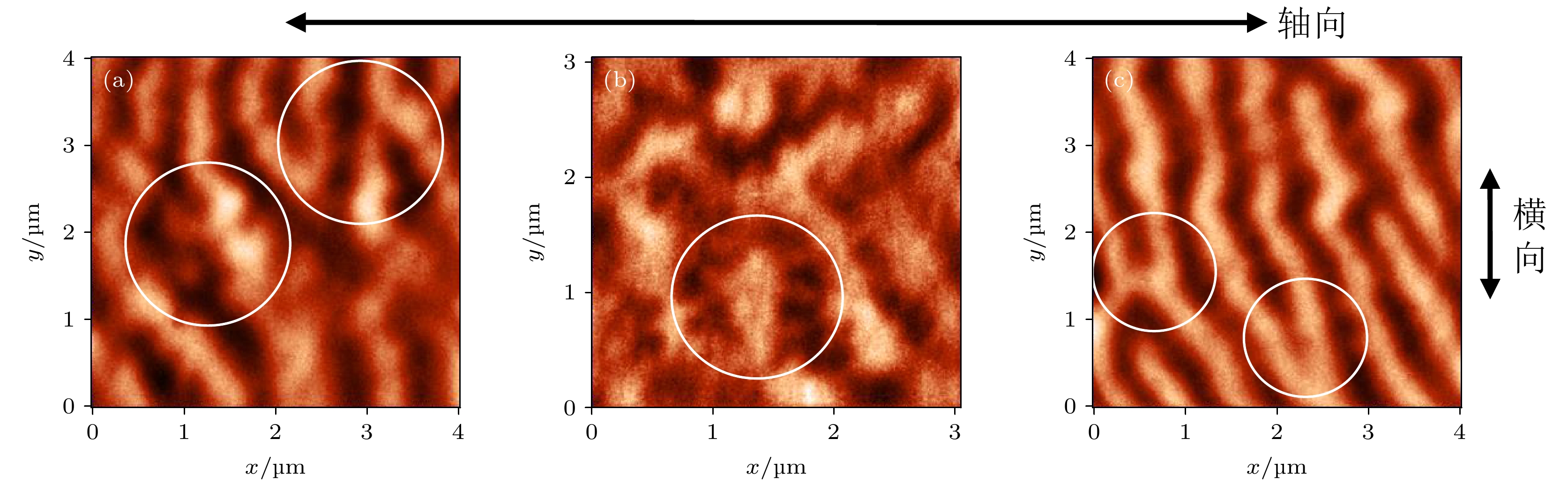

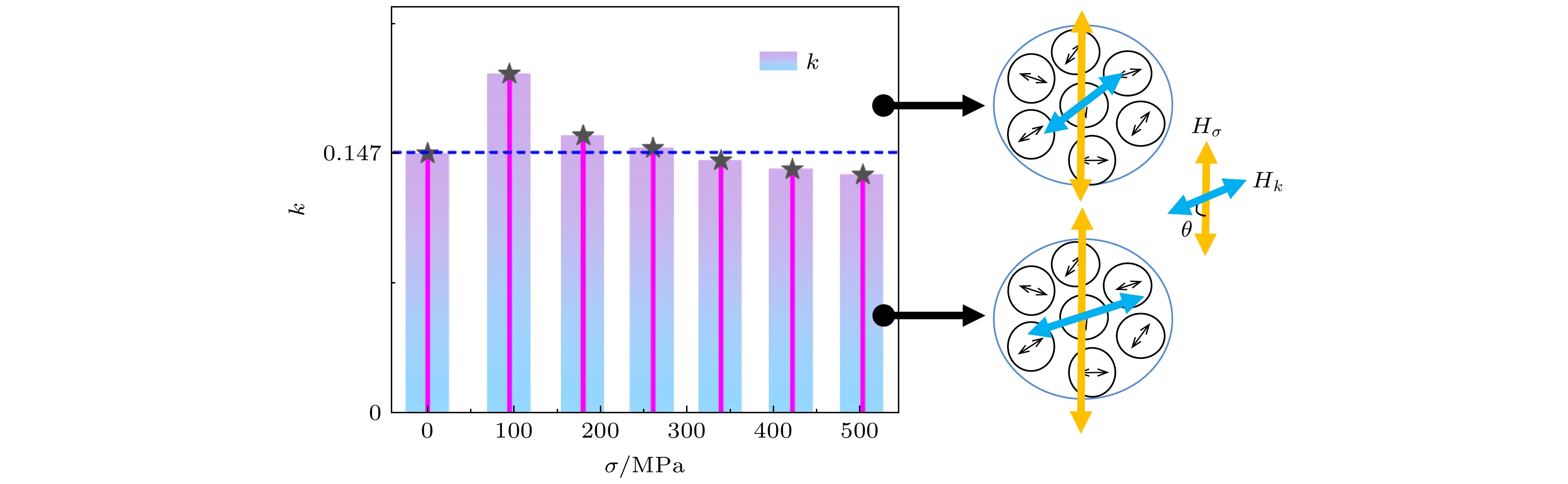

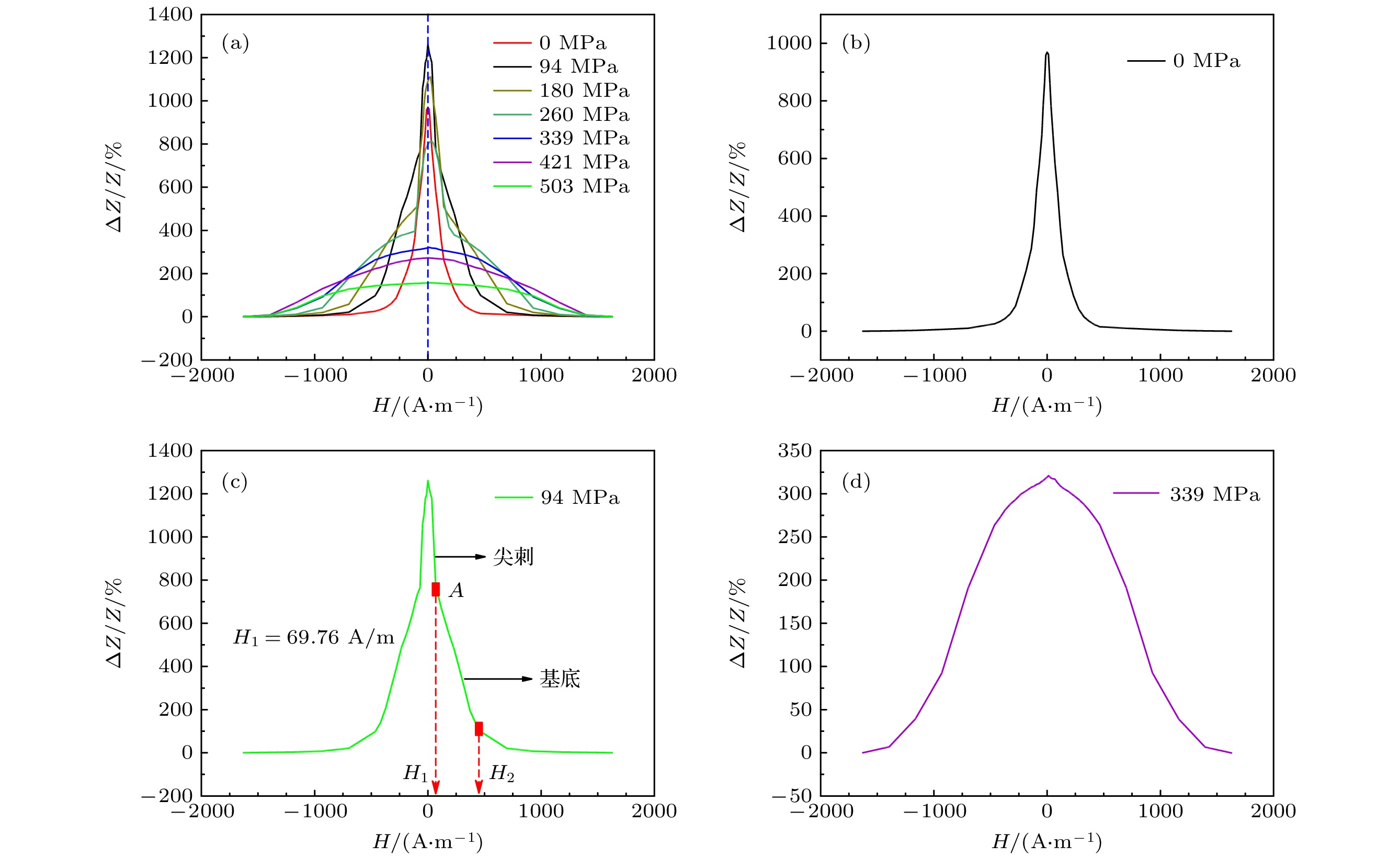

$ k \leqslant 0.147 $ 的薄带展现出“单峰”和“穹顶”状的巨磁阻抗效应, 且具有较规则的横向磁畴结构; 而$ k \gt 0.147 $ 的薄带展现出“尖刺+穹顶”状巨磁阻抗效应, 同时在较不规则的横向畴畴壁处观测到新畴的形核和分裂, 这为磁各向异性的竞争抑制作用提供了佐证. 因此, 本研究认为多场耦合热处理Fe64.8Co7.2Nb4Si4.8B19.2合金薄带展现出良好的应力敏感特性可由磁各向异性的竞争抑制作用解释, 它是材料巨磁阻抗效应实现调控的主要原因, 在调制优化材料磁性能方面具有良好的应用前景.Fe-based amorphous and nanocrystalline alloys are considered as the preferred dual-green energy-saving materials due to their unique magnetic properties, such as high permeability, low coercivity, and near-zero saturation magnetostriction. As such, they have received extensive attention in applications like magnetic core material for high-frequency transformers, common model chokes, ground fault interrupters, and rotors in motors, over the past decades. In this work, Fe64.8Co7.2Nb4Si4.8B19.2 (in atom percent) amorphous alloy ribbons are prepared by using the single roller quenching method, then subsequently subjected to multi-field coupling heating treatment in the air which includes heating by Joule heating effect and tensile stress field. Furthermore, the longitudinally driven giant magneto-impedance effect and magnetic domain structures of ribbons are observed by using 4294A impedance analyzer and magnetic force microscopy, respectively. The magneto-crystalline anisotropy field and stress anisotropy field of ribbons are analyzed by using X-ray diffraction, random anisotropy model, and numerical fitting. Meanwhile, the concept of magnetic anisotropy competing factor (k) is proposed, from the viewpoint of magnetic anisotropy, a mechanism for regulating giant magneto-impedance effect of ribbons prepared with multi-field coupling is studied. It is found that the longitudinally driven giant magneto-impedance effect gradually transforms from the single peak to dome-like with tensile stress increasing. However, a spike and dome-like giant magneto-impedance effect appears during such transformation, which is composed of two parts: spike-like top and dome-like base. Based on the magnetic domain structure of ribbons, it is found that the typical stress-annealed transversal magnetic domain structure is observed in ribbons of$k \leqslant 0.147$ , while nucleation and splitting phenomenon of new domains are observed at the transversal magnetic domain wall in ribbons of k > 0.147. Both longitudinally driven giant magneto-impedance effect and domain structures provide evidence to support the competing inhibition effect of magnetic anisotropy which exists in Fe-based alloy ribbon. Therefore, it is suggested that Fe-based alloys exhibit excellent stress-sensitive properties that can be understood by the competing inhibition effects of magnetic anisotropy. It is further shown that the competing inhibition effect of magnetic anisotropy is the main reason for regulating the giant magneto-impedance effect of soft magnetic materials. This multi-field coupling Fe-based alloy has good application prospects in regulating magnetic properties of magnetic materials.-

Keywords:

- multi-field coupling /

- giant magneto-impedance effect /

- magnetic domain structure /

- magnetic anisotropy competing factor

[1] Duwez P, Willens R H, Klement W 1960 J. Appl. Phys. 31 1136

[2] 汪卫华, 张哲峰 2021 金属学报 57 1

Google Scholar

Google Scholar

Wang W H, Zhang Z F 2021 Acta Metall. Sin. 57 1

Google Scholar

Google Scholar

[3] 姚可夫, 施凌翔, 陈双琴, 邵洋, 陈娜, 贾蓟丽 2018 67 016101

Google Scholar

Google Scholar

Yao K F, Shi L X, Chen S Q, Shao Y, Chen N, Jia J L 2018 Acta Phys. Sin. 67 016101

Google Scholar

Google Scholar

[4] Panina L V, Mohri K 1994 Appl. Phys. Lett. 65 1189

[5] Mohri K, Kawashiwa K, Yoshida H, Panina L V 1992 IEEE. Trans. Magn. 28 3150

Google Scholar

Google Scholar

[6] Indaa K, Mohri K, Inuzuka K 1994 IEEE. Trans. Magn. 30 4623

Google Scholar

Google Scholar

[7] Panina L V, Mohri K, Uchiyama T, Noda M, Bushida 1995 IEEE. Trans. Magn. 31 1249

Google Scholar

Google Scholar

[8] Kawashima K, Kohzawa K, Yoshida H, Mohri M 1993 IEEE. Trans. Magn. 29 3168

Google Scholar

Google Scholar

[9] 杨介信, 杨夑龙, 陈国, 蒋可玉, 沈国土, 胡炳元, 金若鹏 1998 中国科学 43 1051

Google Scholar

Google Scholar

Yang J X, Yang X L, Chen G, Jiang K Y, Shen G T, Hu B Y, Jin R P 1998 Chin. Sci. Bull. 43 1051

Google Scholar

Google Scholar

[10] Gong W Y, Wu Z M, Lin H, Yang J X, Zhao Z J 2008 J. Magn. Magn. Mater. 320 1553

Google Scholar

Google Scholar

[11] 方允樟, 许启明, 叶慧群, 郑金菊, 范晓珍, 潘日敏, 马云, 李文忠 2011 功能材料 42 1083

Fang Y Z, Xu Q M, Ye H Q, Zheng J J, Fan X Z, Pan R M, Ma Y, Li W Z 2011 Funct. Mater. 42 1083

[12] Zhukov A, Ipatov M, Churyukanova M, Talaat A, Blanco J M, Zhukova V 2017 J. Alloys Compd. 727 887

Google Scholar

Google Scholar

[13] Herzer G 2013 Acta. Mater. 61 718

Google Scholar

Google Scholar

[14] Zhukov A, Ipatov M, Corte-Leon P, Gonzalez-Legarreta L, Churyukanova M, Blanco J M, Gonzalez J, Taskaev S, Hernando B, Zhukova V 2020 J. Alloys Compd. 814 152225

Google Scholar

Google Scholar

[15] Corte-Leon P, Zhukova V, Ipatov M, Blanco J M, Gonzalez J, Zhukov A 2019 Intermetallics 105 92

Google Scholar

Google Scholar

[16] Zhukova V, Blanco J M, Ipatov M, Gonzalez J, Churyukanova M, Zhukov A 2018 Scr. Mater. 142 10

Google Scholar

Google Scholar

[17] Phan M H, Peng H X 2008 Prog. Mater. Sci. 53 323

Google Scholar

Google Scholar

[18] Ohnuma M, Yanai T, Hono K, Nakano M, Fukunaga H, Yoshizawa Y, Herzer G 2010 J. Appl. Phys. 108 093927

Google Scholar

Google Scholar

[19] Kernion S J, Ohodnicki P R, Grossmann J J, Leary A, Shen S, Keylin V, Huth J F, Horwath J, Lucas M S, McHenry M E 2012 Appl. Phys. Lett. 101 102408

Google Scholar

Google Scholar

[20] Iannotti V, Amoruso S, Ausanio G, Wang X, Lanotte L, Barone A C, Margaris G, Trohidou K N, Fiorani D 2011 Phys. Rev. B 83 214422

Google Scholar

Google Scholar

[21] Bolyachkin A S, Volegov A S, Kudrevatykh N V 2015 J. Magn. Magn. Mater. 378 362

Google Scholar

Google Scholar

[22] Muscas G, Concas G, Laureti S, Testa A M, Mathieu R, De Toro J A, Cannas C, Musinu A, Novak M A, Sangregorio C, Lee S S, Peddis D 2018 Phys. Chem. Chem. Phys. 20 28634

Google Scholar

Google Scholar

[23] 纪松, 杨国斌, 王润 1996 45 2061

Google Scholar

Google Scholar

Ji S, Yang G B, Wang R 1996 Acta Phys. Sin. 45 2061

Google Scholar

Google Scholar

[24] Hinokihara T, Miyashita S 2021 Phys. Rev. B 103 054421

Google Scholar

Google Scholar

[25] Hofmann B, Kronmüller H 1996 J. Magn. Magn. Mater. 152 91

Google Scholar

Google Scholar

[26] Herzer G 1995 Scr. Metall. Mater. 33 1741

Google Scholar

Google Scholar

[27] Hernando A, Kulik T 1994 Phys. Rev. B 49 7064

Google Scholar

Google Scholar

[28] 张建强, 路飞平, 赵小龙, 何林芳 2019 磁性材料及器件 50 9

Zhang J Q, Lu F P, Zhao X L, He L F 2019 J. Magn. Mater. Device 50 9

[29] Jaafar M, Pablo-Navarro A, Berganza E, Ares P, Magén C, Masseboeuf A, Gatel C, Snoeck E, Gómez-Herrero J, Teresa J M, Asenjo A 2020 Nanoscale 12 10090

Google Scholar

Google Scholar

-

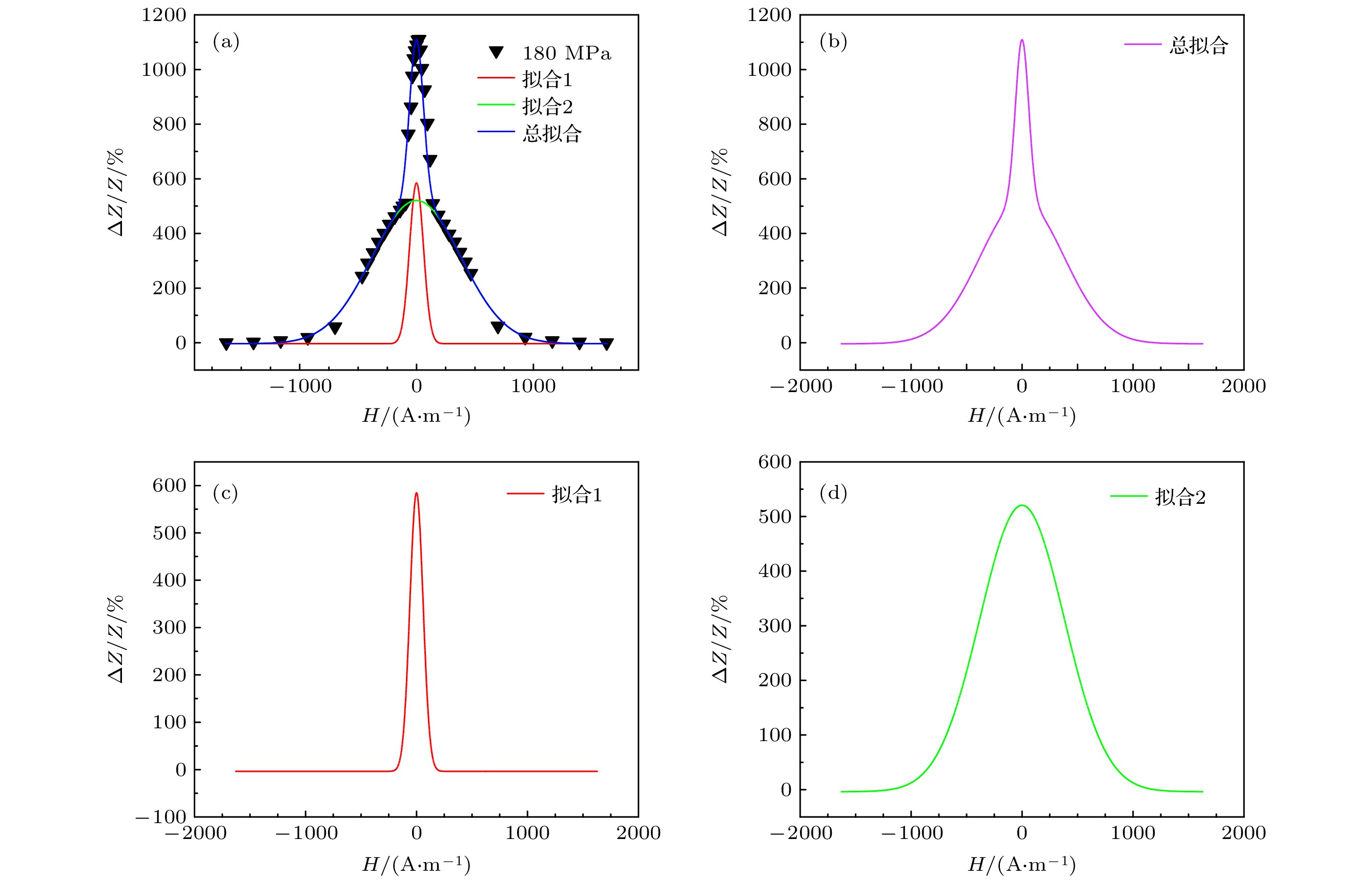

图 4 “尖刺+穹顶”状LDGMI曲线高斯拟合 (a) 180 MPa退火合金带LDGMI效应拟合; (b) 总拟合曲线; (c) “尖刺”状; (d) “穹顶”状

Fig. 4. Gaussian fitting of “spike and dome” like LDGMI effect curve: (a) Fitting curve of LDGMI effect for Fe-based alloy ribbon annealed with tensile stress of 180 MPa; (b) the whole fitting curve; (c) spike shape; (d) dome shape.

表 1 未加张应力退火Fe基合金带的结构参数和磁学量参数

Table 1. Structural and magnetic parameters of Fe-based alloy annealed without tensile stress.

表 2 MFC热处理Fe基合金带LDGMI效应曲线拟合DPGF参数和磁学参数

Table 2. DPGF parameters of LDGMI effect curves and magnetic parameters of Fe-based alloy heated by MFC method.

应力

σ/MPaDPGF参数 磁各向异性场 实验值 W1 W2 R Hk/(A·m–1) Hσ/(A·m–1) Heff/(A·m–1) k Heff/(A·m–1) 94 105.64 549.94 0.997 52.82 274.97 280.00 0.195 — 180 139.97 893.04 0.986 69.98 446.52 451.97 0.157 — 260 177.79 1183.86 0.975 88.90 591.93 598.57 0.150 — 339 — — — 106.5 745.23 752.80 0.143 772.52 421 — — — 124.32 899.94 908.49 0.138 903.81 503 — — — 142.36 1056.56 1066.11 0.135 1012.43 -

[1] Duwez P, Willens R H, Klement W 1960 J. Appl. Phys. 31 1136

[2] 汪卫华, 张哲峰 2021 金属学报 57 1

Google Scholar

Google Scholar

Wang W H, Zhang Z F 2021 Acta Metall. Sin. 57 1

Google Scholar

Google Scholar

[3] 姚可夫, 施凌翔, 陈双琴, 邵洋, 陈娜, 贾蓟丽 2018 67 016101

Google Scholar

Google Scholar

Yao K F, Shi L X, Chen S Q, Shao Y, Chen N, Jia J L 2018 Acta Phys. Sin. 67 016101

Google Scholar

Google Scholar

[4] Panina L V, Mohri K 1994 Appl. Phys. Lett. 65 1189

[5] Mohri K, Kawashiwa K, Yoshida H, Panina L V 1992 IEEE. Trans. Magn. 28 3150

Google Scholar

Google Scholar

[6] Indaa K, Mohri K, Inuzuka K 1994 IEEE. Trans. Magn. 30 4623

Google Scholar

Google Scholar

[7] Panina L V, Mohri K, Uchiyama T, Noda M, Bushida 1995 IEEE. Trans. Magn. 31 1249

Google Scholar

Google Scholar

[8] Kawashima K, Kohzawa K, Yoshida H, Mohri M 1993 IEEE. Trans. Magn. 29 3168

Google Scholar

Google Scholar

[9] 杨介信, 杨夑龙, 陈国, 蒋可玉, 沈国土, 胡炳元, 金若鹏 1998 中国科学 43 1051

Google Scholar

Google Scholar

Yang J X, Yang X L, Chen G, Jiang K Y, Shen G T, Hu B Y, Jin R P 1998 Chin. Sci. Bull. 43 1051

Google Scholar

Google Scholar

[10] Gong W Y, Wu Z M, Lin H, Yang J X, Zhao Z J 2008 J. Magn. Magn. Mater. 320 1553

Google Scholar

Google Scholar

[11] 方允樟, 许启明, 叶慧群, 郑金菊, 范晓珍, 潘日敏, 马云, 李文忠 2011 功能材料 42 1083

Fang Y Z, Xu Q M, Ye H Q, Zheng J J, Fan X Z, Pan R M, Ma Y, Li W Z 2011 Funct. Mater. 42 1083

[12] Zhukov A, Ipatov M, Churyukanova M, Talaat A, Blanco J M, Zhukova V 2017 J. Alloys Compd. 727 887

Google Scholar

Google Scholar

[13] Herzer G 2013 Acta. Mater. 61 718

Google Scholar

Google Scholar

[14] Zhukov A, Ipatov M, Corte-Leon P, Gonzalez-Legarreta L, Churyukanova M, Blanco J M, Gonzalez J, Taskaev S, Hernando B, Zhukova V 2020 J. Alloys Compd. 814 152225

Google Scholar

Google Scholar

[15] Corte-Leon P, Zhukova V, Ipatov M, Blanco J M, Gonzalez J, Zhukov A 2019 Intermetallics 105 92

Google Scholar

Google Scholar

[16] Zhukova V, Blanco J M, Ipatov M, Gonzalez J, Churyukanova M, Zhukov A 2018 Scr. Mater. 142 10

Google Scholar

Google Scholar

[17] Phan M H, Peng H X 2008 Prog. Mater. Sci. 53 323

Google Scholar

Google Scholar

[18] Ohnuma M, Yanai T, Hono K, Nakano M, Fukunaga H, Yoshizawa Y, Herzer G 2010 J. Appl. Phys. 108 093927

Google Scholar

Google Scholar

[19] Kernion S J, Ohodnicki P R, Grossmann J J, Leary A, Shen S, Keylin V, Huth J F, Horwath J, Lucas M S, McHenry M E 2012 Appl. Phys. Lett. 101 102408

Google Scholar

Google Scholar

[20] Iannotti V, Amoruso S, Ausanio G, Wang X, Lanotte L, Barone A C, Margaris G, Trohidou K N, Fiorani D 2011 Phys. Rev. B 83 214422

Google Scholar

Google Scholar

[21] Bolyachkin A S, Volegov A S, Kudrevatykh N V 2015 J. Magn. Magn. Mater. 378 362

Google Scholar

Google Scholar

[22] Muscas G, Concas G, Laureti S, Testa A M, Mathieu R, De Toro J A, Cannas C, Musinu A, Novak M A, Sangregorio C, Lee S S, Peddis D 2018 Phys. Chem. Chem. Phys. 20 28634

Google Scholar

Google Scholar

[23] 纪松, 杨国斌, 王润 1996 45 2061

Google Scholar

Google Scholar

Ji S, Yang G B, Wang R 1996 Acta Phys. Sin. 45 2061

Google Scholar

Google Scholar

[24] Hinokihara T, Miyashita S 2021 Phys. Rev. B 103 054421

Google Scholar

Google Scholar

[25] Hofmann B, Kronmüller H 1996 J. Magn. Magn. Mater. 152 91

Google Scholar

Google Scholar

[26] Herzer G 1995 Scr. Metall. Mater. 33 1741

Google Scholar

Google Scholar

[27] Hernando A, Kulik T 1994 Phys. Rev. B 49 7064

Google Scholar

Google Scholar

[28] 张建强, 路飞平, 赵小龙, 何林芳 2019 磁性材料及器件 50 9

Zhang J Q, Lu F P, Zhao X L, He L F 2019 J. Magn. Mater. Device 50 9

[29] Jaafar M, Pablo-Navarro A, Berganza E, Ares P, Magén C, Masseboeuf A, Gatel C, Snoeck E, Gómez-Herrero J, Teresa J M, Asenjo A 2020 Nanoscale 12 10090

Google Scholar

Google Scholar

计量

- 文章访问数: 6270

- PDF下载量: 61

- 被引次数: 0

下载:

下载: