-

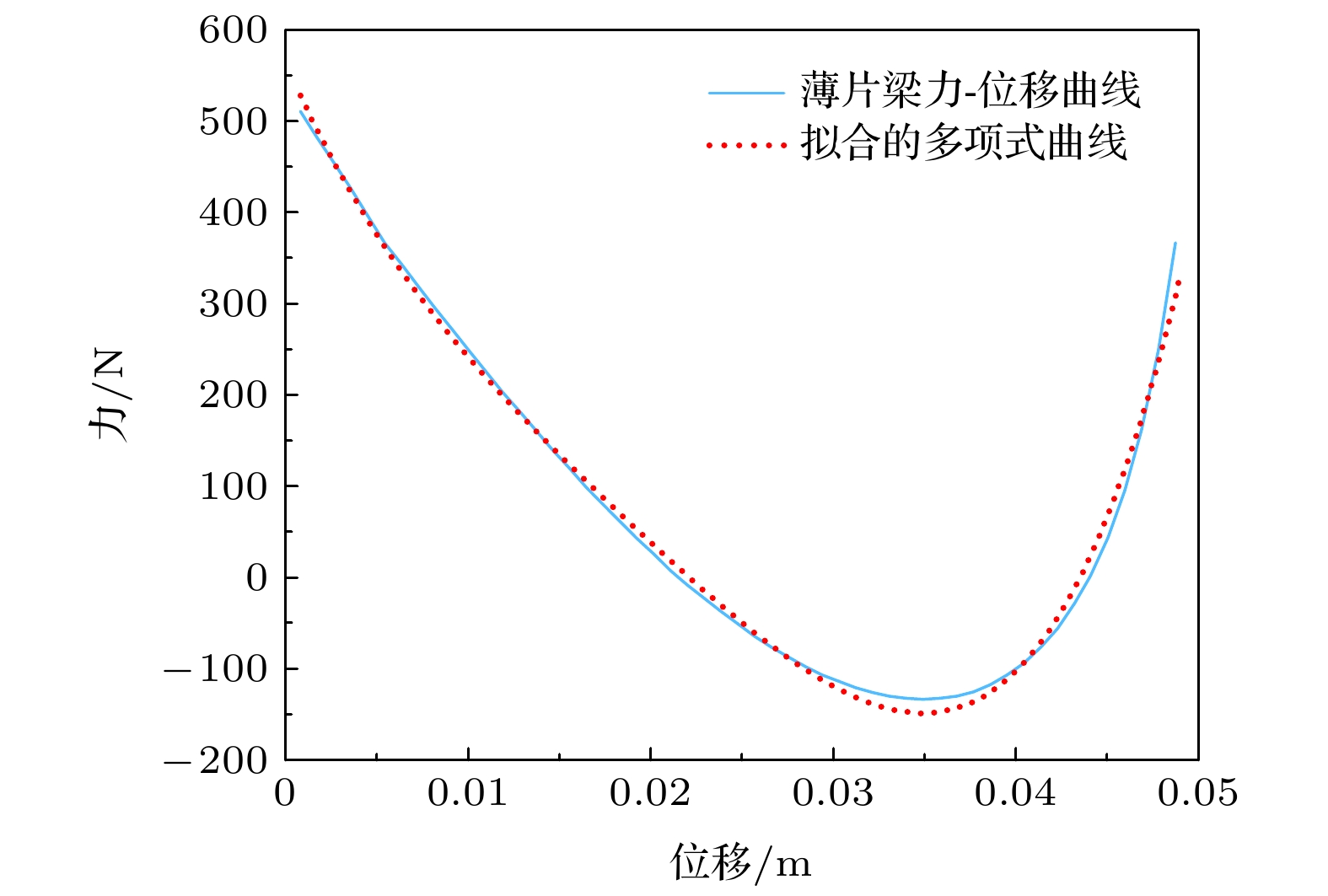

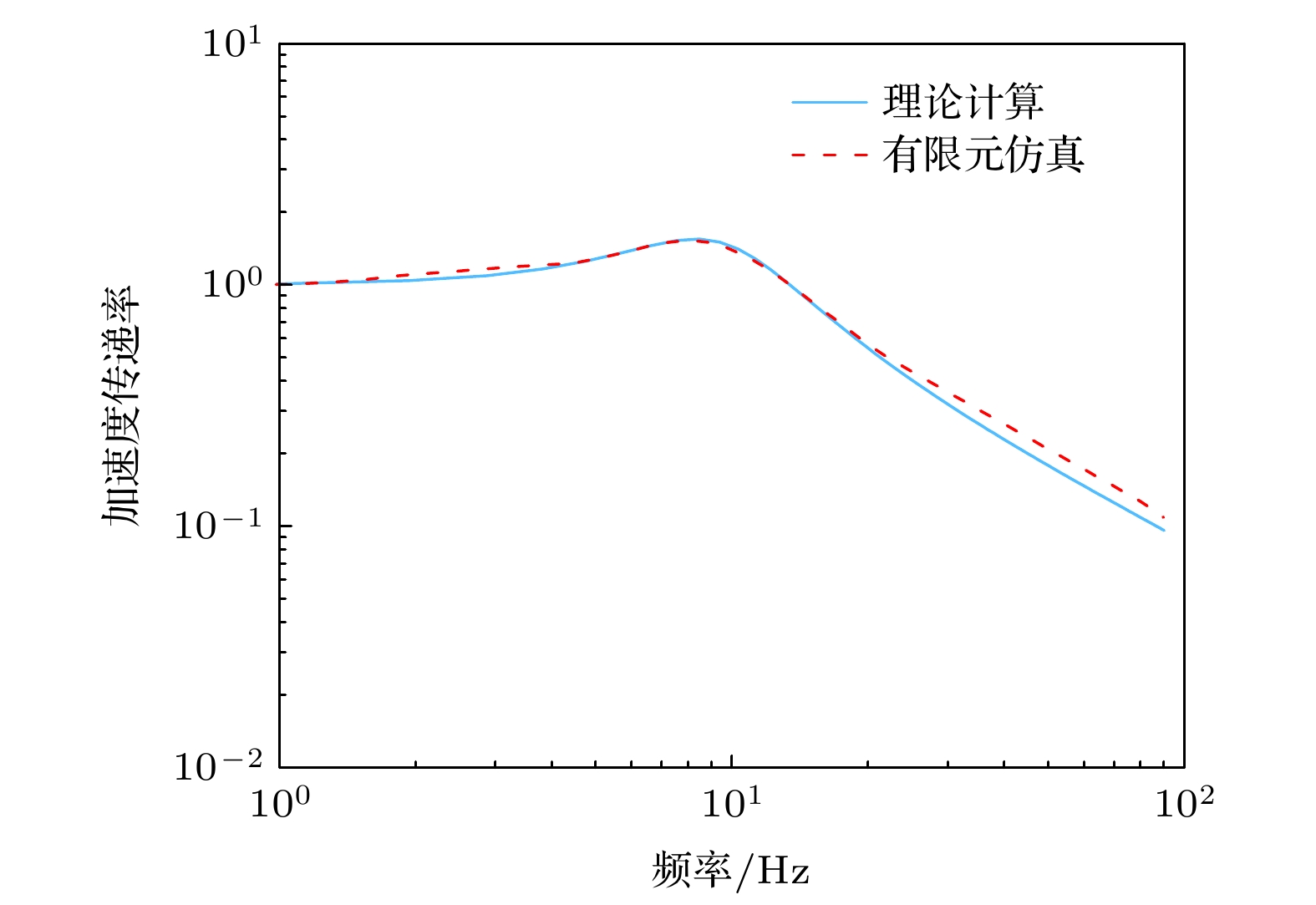

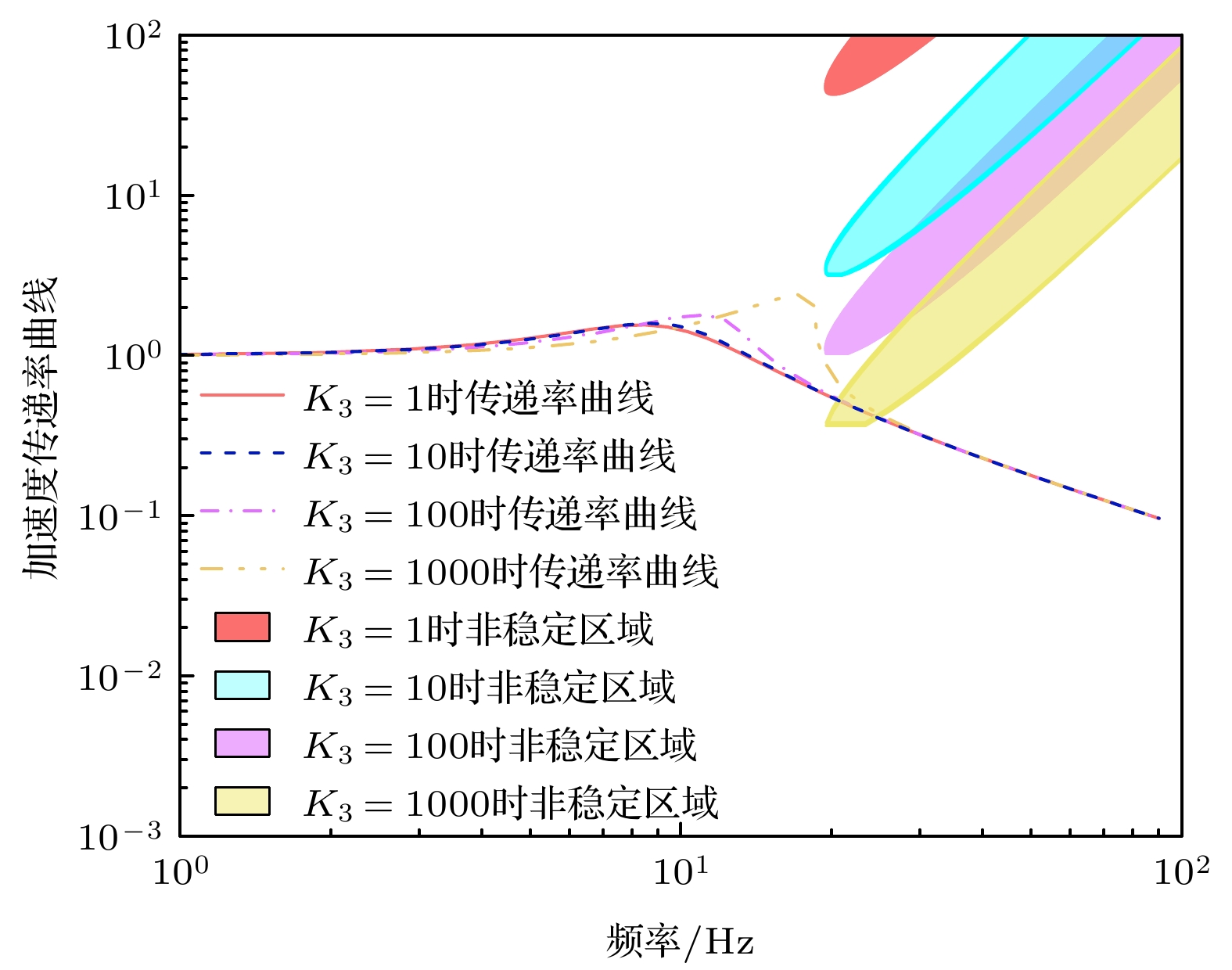

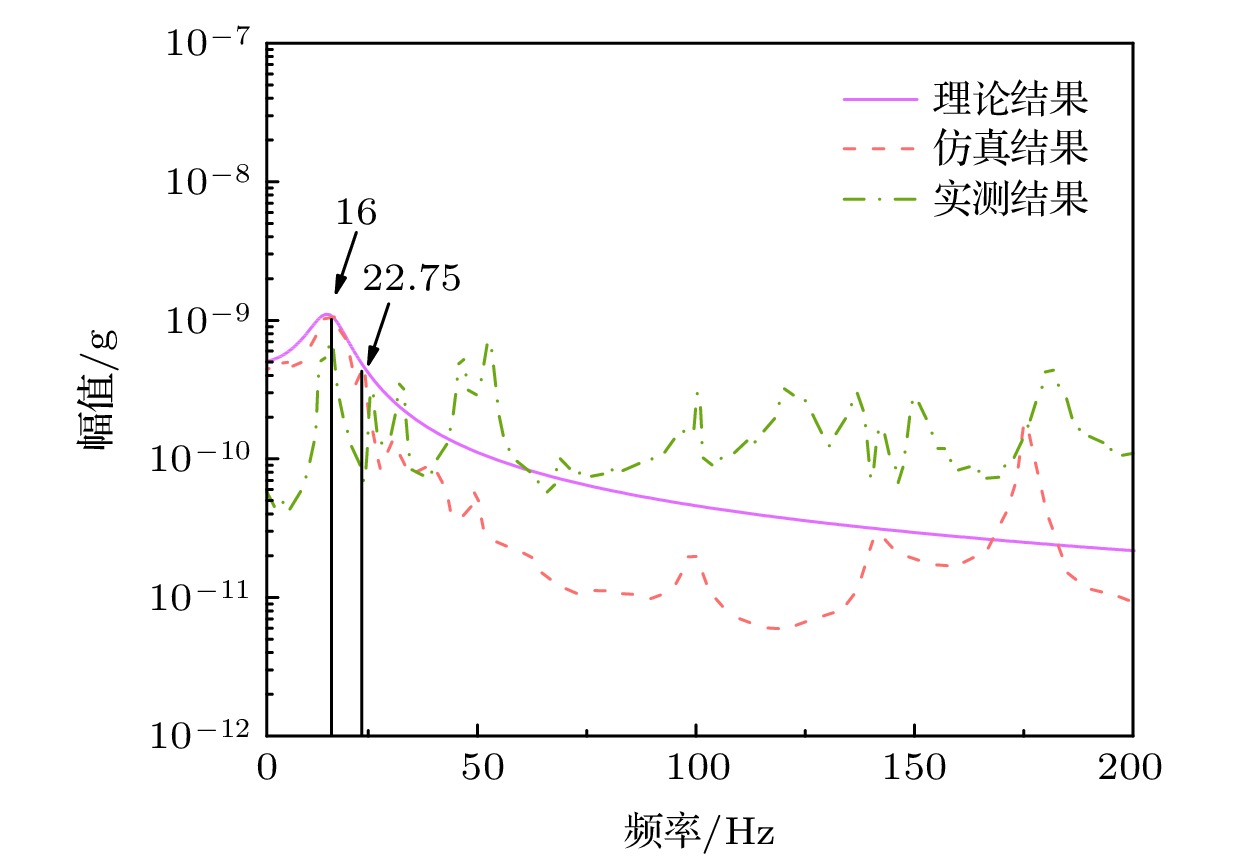

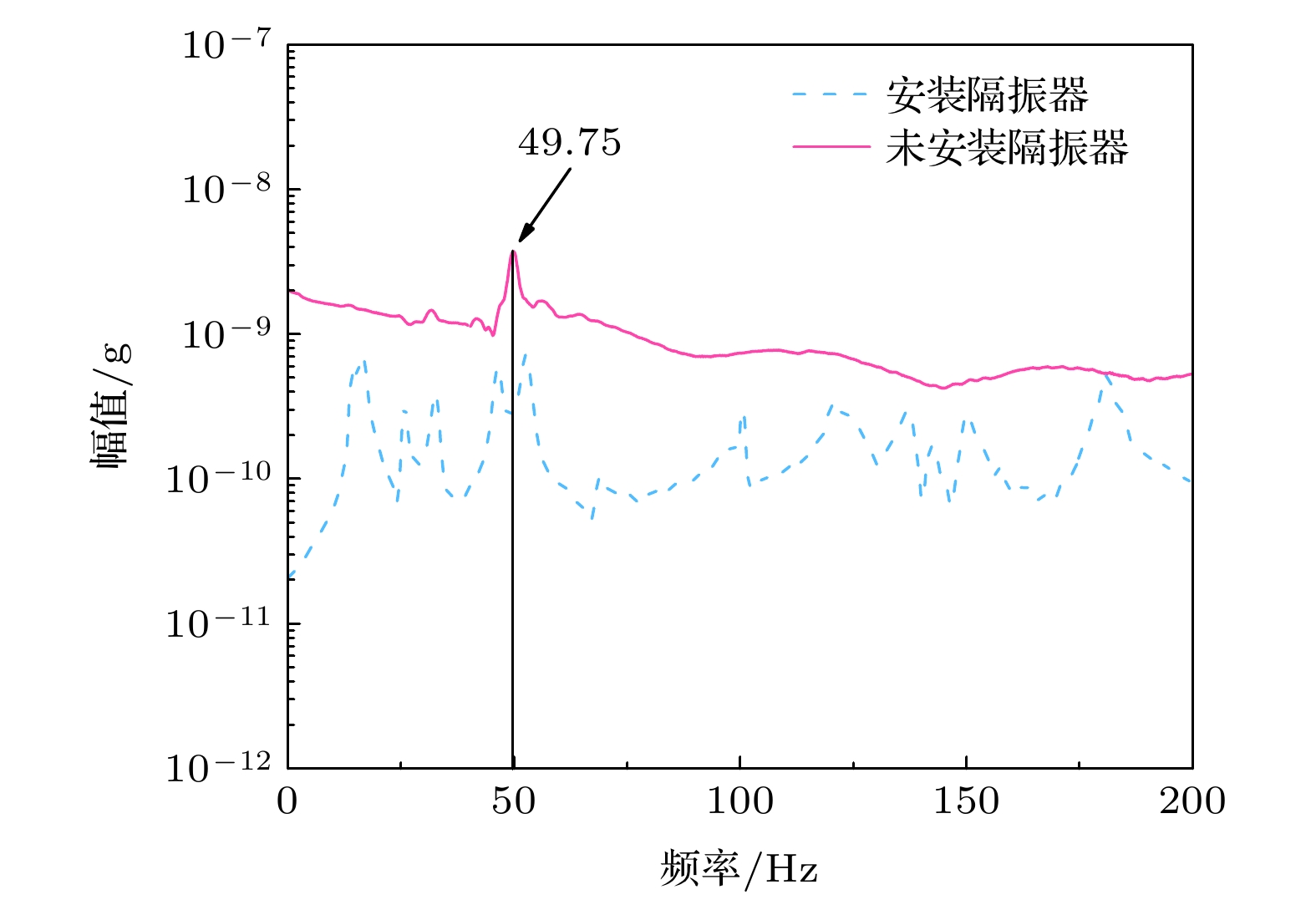

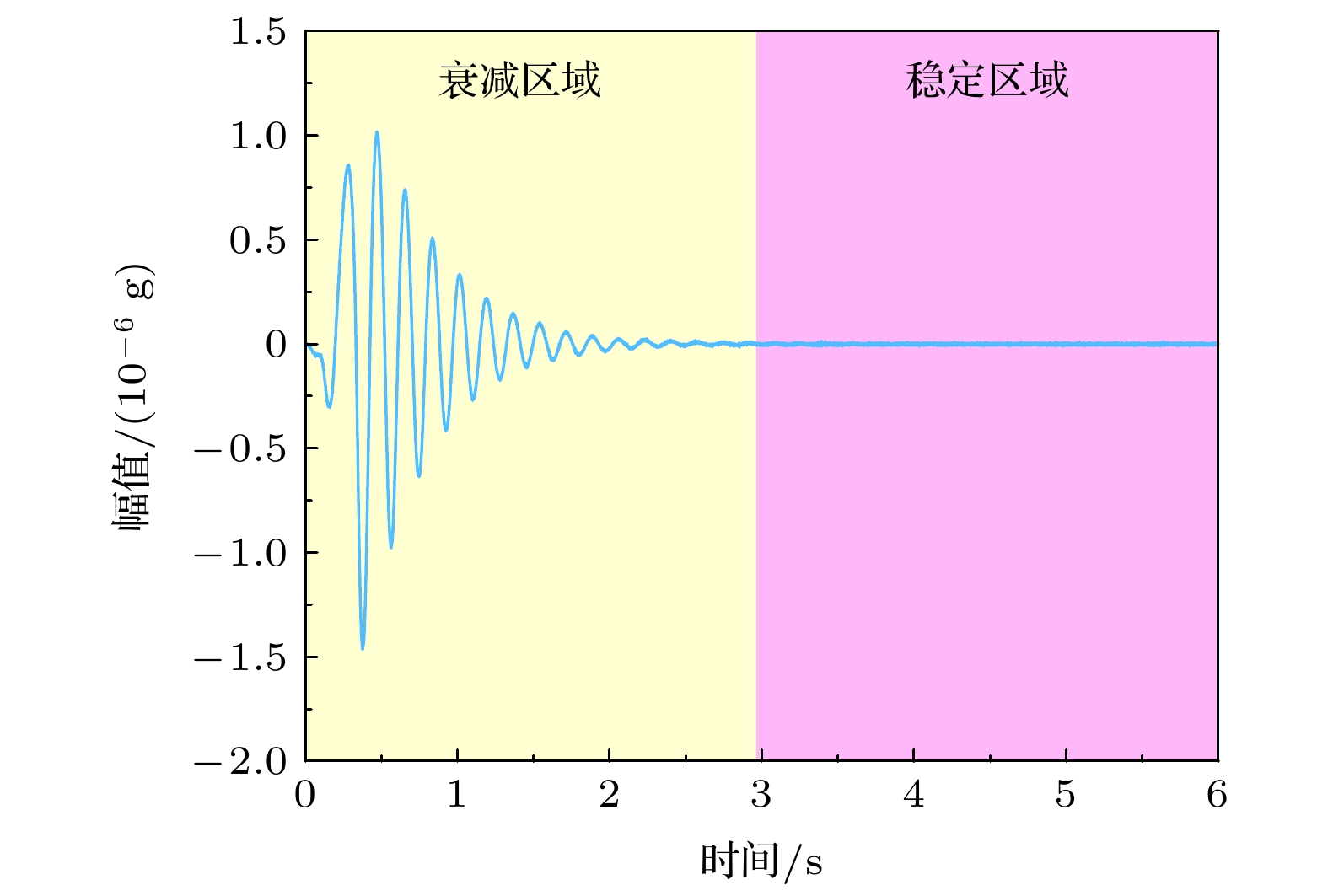

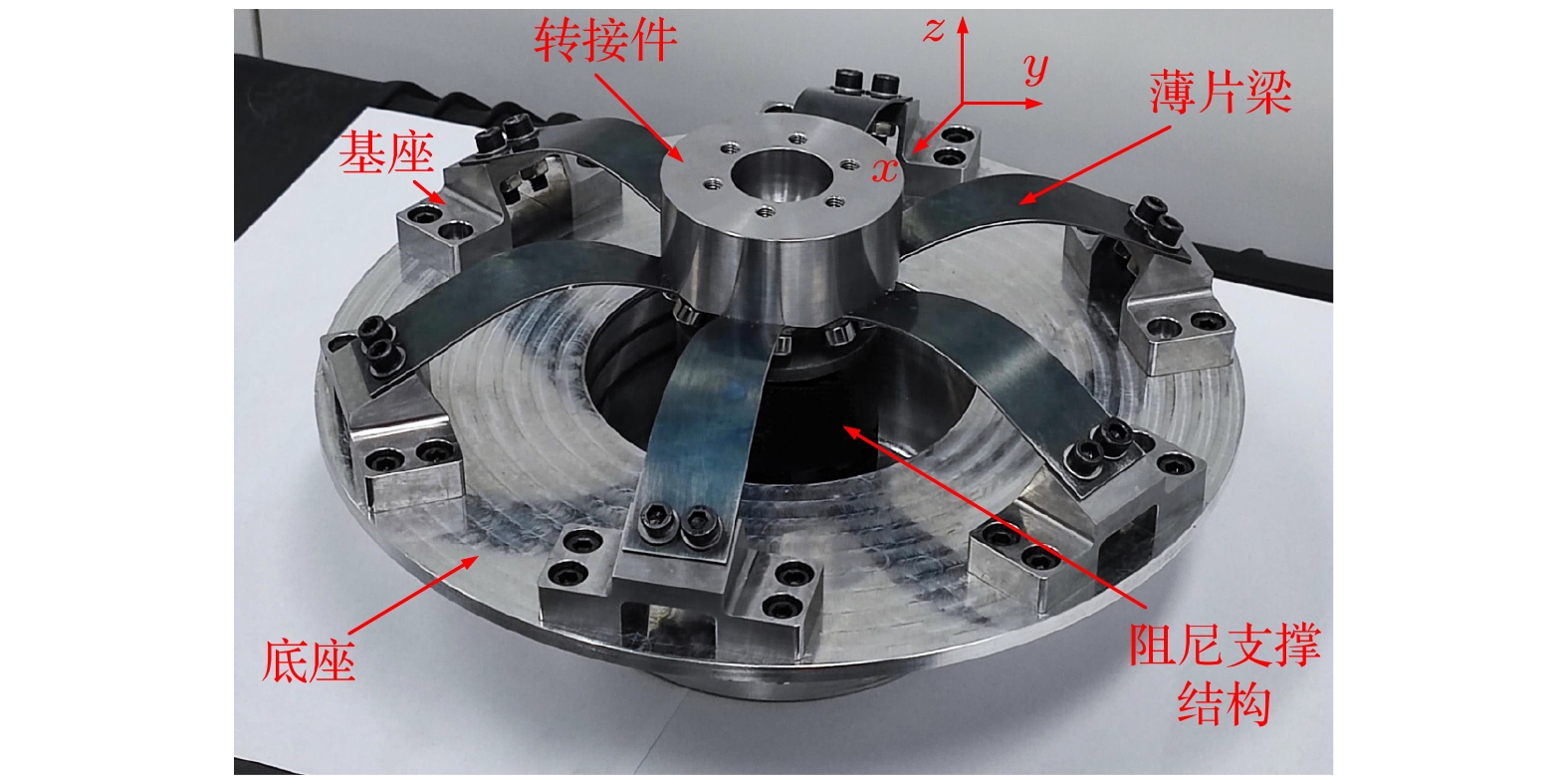

高能同步辐射光源施工现场, 采用激光跟踪仪对高能光源磁铁设备标定、预准直和隧道测量时, 激光跟踪仪受周边环境振动影响较大, 并严重危害其测量精度. 为了有效地控制环境振动的影响, 提出一种面向激光跟踪仪的宽频隔振器, 并安装在激光跟踪仪三角支架的支腿位置, 在保证隔振性能的同时兼具较好的承载能力. 针对上述系统, 建立等效单自由度非线性动力学微分方程, 采用复变量-平均法获得宽频隔振器的稳态响应解, 并应用数值有限元方法验证理论模型及计算结果的正确性. 在此基础上, 采用谐波平衡法分析非线性系统的稳定性, 并考虑关键设计参数K3对其隔振性能的影响. 结合实际工作环境, 选择部分典型工况(包括: 长时间静压, 垂向冲击激励和横向位移激励)进行实测, 评估宽频隔振器的静态稳定性和振动控制效果. 结果表明, 长时间静压后, 激光跟踪仪最大沉降位移约2×10–5 m; 不同动态载荷作用下, 宽频隔振器对激光跟踪仪振动响应幅值的衰减率最高可达97%, 且有效隔振频带较宽; 满足所有技术指标要求.High-energy synchrotron radiation source, as a large scientific device, is under construction in Beijing, China. This device is one of the fourth-generation synchrotron radiation sources with the highest brightness in the world. It will provide an important support platform for basic science and engineering science. As a kind of high-precision large-scale measurement equipment, laser tracker is used mainly in high-energy particle accelerator equipment installation, precision poses dynamic measurement and antenna feed dynamic motion precision engineering measurement field. At the construction site of high energy synchrotron radiation source, the laser tracker is often used to calibrate and pre-collimate the high energy source magnet equipment and carry on the tunnel measurement . However, the laser tracker is easily affected by the vibration of the surrounding environment, and the adverse vibration seriously affects its measurement accuracy and even causes the equipment to damage. In order to effectively control the influence of environmental vibration and ensure good static bearing capacity, a broadband vibration isolator for laser tracker is proposed. It is installed in the leg position of the triangular bracket of the laser tracker, which ensures the vibration isolation performance and good bearing capacity. For the above system, the equivalent single freedom nonlinear dynamic differential equation is established, and the steady-state response solution of the broadband isolator is obtained by using the complex variable-average method. The numerical finite element method is used to verify the correctness of the theoretical model and corresponding calculation results. On this basis, the stability of a nonlinear system is analyzed by harmonic balance method, and the influence of key designing parameter K3 on vibration isolation performance is considered. Combined with the complexity of the actual working environment of laser tracker, a variety of typical working conditions are set up for test, including long time static pressure test, vertical impact excitation and lateral displacement excitation tests, to evaluate the static stability and vibration control effect of broadband isolator. The experimental results show that the maximum static displacement of the laser tracker is about 2×10–5 m under static pressure in a long time, and the maximum static load is within the allowable error range. When the occasional impacting is triggered, the installation of broadband isolator can make the combination quickly restore stability in about 2.95 s, exhibiting better vibration isolation performance. Under different dynamic loads, by comparing the acceleration frequency response curves of the laser tracker with and without the isolator, in the frequency band below the fundamental frequency of the laser tracker, the attenuation rate of the combined system can be up to about 97% with and without the vibration isolator. In the frequency band above the fundamental frequency, the attenuation rate of the combined system with and without the vibration isolation system can reach up to about 88%, and the effective vibration isolation frequency band is extended. The broadband vibration isolator meets all technical requirements.

-

Keywords:

- laser tracker /

- vibration isolation system with broadband characteristic /

- high energy photon source /

- vibration control

[1] 罗涛, 何晓业, 汪昭义, 王巍, 李笑, 黄晴晴, 何振强, 柯志勇, 马娜, 王铜, 梁静, 李波, 门铃鸰, 王小龙, 董岚 2021 武汉大学学报(信息科学版) DOI: 10.13203/j.whugis20200718

Luo T, He X Y, Wang S Y, Wang W, Li X, Huang Q Q, He Z Q, Ke Z Y, Ma N, Wang T, Liang J, Li B, Men L L, Wang X L, Dong L 2021 Geomatics Inf. Sci. Wuhan Univ. DOI: 10.13203/j. whugis20200718 (in Chinese)

[2] Jiao Y, Duan Z, Guo Y, Ji D, Li X, Peng Y, Qin Q, Qiu J, Tian S, Wang J 2016 Phys. Procedia 84 40

Google Scholar

Google Scholar

[3] 李广云, 范百兴 2017 测绘学报 46 10

Google Scholar

Google Scholar

Li G Y, Fan B X 2017 Acta Geod. Cartogr. Sin. 46 10

Google Scholar

Google Scholar

[4] Kristiansen P, Horbach J, Döhrmann R, Heuer J 2015 J. Synchrotron Radiat. 22 4

Google Scholar

Google Scholar

[5] Omidalizarandi M, Kargoll B, Paffenholz J A, Paffenholz J A, Neumann I 2018 Adv. Mech. Eng. 10 119

Google Scholar

Google Scholar

[6] 徐亚明, 郑琪, 管啸 2020 测绘地理信息 45 812

Google Scholar

Google Scholar

Xu Y M, Zheng Q, Guan X 2020 J. Geomat. 45 812

Google Scholar

Google Scholar

[7] Bronowicki A J, Abhyankar N S, Griffin S F 1999 Smart Mater. Struct. 8 740

Google Scholar

Google Scholar

[8] Davis L, Hyland D, Yen G, Dask A 1999 Smart Mater. Struct. 8 753

Google Scholar

Google Scholar

[9] Vaillon L, Petitjean B, Frapard B, Lebihan D 1999 Smart Mater. Struct. 8 781

Google Scholar

Google Scholar

[10] Vaillon L, Sanctorum B, Sperandei J, Defendini A, Griseri G, Alberti M V 2002 Proc. 5th ESA Int. Conf. Spacecr. Guid Italy, Frascati, October

[11] Onoda J, Minesugi K 1996 AIAA J. 34 207

Google Scholar

Google Scholar

[12] Onoda J, Minesugi K 1994 J. Spacecraft Rockets 31 67

Google Scholar

Google Scholar

[13] Onoda J, Minesugi K 1996 AIAA J. 34 355

Google Scholar

Google Scholar

[14] Chen S B, Xuan M, Xin J, Liu Y, Gu S, Li J, Zhang L 2020 Int. J. Mech. Sci. 179 105592

Google Scholar

Google Scholar

[15] 姜伟伟, 徐治洲, 任戈 2014 噪声与振动控制 34 186

Google Scholar

Google Scholar

Jiang W W, Xu Z Z, Ren G 2014 Noise Vibr. Control 34 186

Google Scholar

Google Scholar

[16] 杜言鲁, 丁亚林, 许永森, 聂品 2015 中国机械工程 26 2880

Google Scholar

Google Scholar

Du Y L, Ding Y L, Xu Y S, Nie P 2015 Chin. Mech. Eng. 26 2880

Google Scholar

Google Scholar

[17] 郑凤翥, 宁飞, 王培群, 霍丽烨, 赵志草 2018 应用光学 39 453

Google Scholar

Google Scholar

Zheng F Z, Ning F, Wang P Q, Huo L Y, Zhao Z C 2018 J. Appl. Opt. 39 453

Google Scholar

Google Scholar

[18] Qi Y, Wang H L, Xu Q Q, Du Y L, Shao X Z, Yang H 2021 Optik 242 167016

Google Scholar

Google Scholar

[19] Dong G, Ma C, Y Luo 2020 Int. J. Appl. Electromagnet. Mech. 64 315

Google Scholar

Google Scholar

[20] 杜宁, 胡明勇, 毕勇, 朱庆生 2017 振动与冲击 36 184

Du N, Hu M Y, Bi Y, Zhu Q S 2017 J. Vibr. Shock 36 184

[21] Carrella A, Brennan M J, Waters T P 2007 J. Sound Vibr. 301 678

Google Scholar

Google Scholar

[22] Takamori A 2002 Ph. D. Dissertation (Tokyo: University of Tokyo)

[23] Stochino A, Abbot B, Aso Y, Barton M, Bertolini A, Boschi V, Coyne D, DeSalvo R, Galli C, Huang Y M 2007 Nucl. Instrum. Methods Phys. Res. , Sect. A 598 737

Google Scholar

Google Scholar

[24] Yao J, Wu K, Guo M, Wang G, Wang L 2019 IEEE Trans. Instrum. Meas. 99 1

Google Scholar

Google Scholar

[25] Xu D L, Yu Q P, Zhou J X, Bishop S R 2013 J. Sound Vibr. 332 3377

Google Scholar

Google Scholar

[26] Xu D L, Zhang Y Y, Zhou J X, Lou J J 2013 J. Vibr. Control 20 2314

Google Scholar

Google Scholar

[27] 李强, 徐登峰, 李林, 魏绍炎 2019 振动与冲击 38 100

Google Scholar

Google Scholar

Li Q, Xu D F, Li L, Wei S Y 2019 J. Vibr. Shock 38 100

Google Scholar

Google Scholar

[28] 严博, 马洪业, 韩瑞祥, 王珂, 武传宇 2019 机械工程学报 55 169

Google Scholar

Google Scholar

Yan B, Ma H X, Han R X, Wang K, Wu C Y 2019 J. Mech. Eng. 55 169

Google Scholar

Google Scholar

[29] Sun M, Chen J 2018 Math Probl Eng. 2018 5693618

Google Scholar

Google Scholar

[30] 刘海平, 申大山, 赵鹏鹏 2021 振动工程学报 34 490

Google Scholar

Google Scholar

Liu H P, Shen D S, Zhao P P 2021 J. Vibr. Eng. 34 490

Google Scholar

Google Scholar

-

表 1 薄片梁的设计参数

Table 1. Designing parameters of thin sheet beam.

名称 符号 数值 总长度 L 70 mm 初始角度 θ1 26° 端点角度 θ2 –25° 弹性模量 E 208 GPa 厚度 d 1 mm 初始宽度 w 24 mm 表 2 宽频隔振器材料参数表

Table 2. Material parameters of isolator with broadband characteristic.

名称 薄片梁 转接件 材料 60 Si2CrVA 10 F 密度/(kg·m3) 7850 7990 泊松比 0.3 0.24 弹性模量/Pa 2.1×1011 1.96×1011 表 3 长时间静压试验实测变形量

Table 3. Deformation measured under long time compression condition.

实测变形量/m 测试工况 5 h 15 h 方向 X –1.2×10–5 1.6×10–5 Y 6×10-6 –2.1×10–5 Z 1.2×10–5 5×10–5 表 4 试验工况表

Table 4. Test conditions table.

序号 工况 测点编号及位置 1 未安装隔振器, 钢块敲击地面 #1, #2, #3; 支架支腿位置 2 安装隔振器, 钢块敲击地面前后, 支架处响应 #1, #2, #3; 支架支腿位置 3 安装隔振器, 钢块敲击地面, 地面、支架及激光跟踪仪处响应 #2, #4, #5; 支架支腿、激光跟踪仪及地面垂向 4 安装隔振器, 钢块敲击地面, 激光跟踪仪处响应 #4; 激光跟踪仪安装面垂向 5 安装隔振器, 钢块敲击地面, 激光跟踪仪处响应 #4; 激光跟踪仪安装面水平向 6 安装隔振器, 水平推动激光跟踪仪处响应 #4; 激光跟踪仪安装面水平向 表 5 模态固有频率对比及振型图

Table 5. Natural frequencies and mode shapes.

模态阶数 固有频率/Hz 模态振型 仿真结果 实测结果 误差 1 14.31 14.75 3.0%

2 41.91 42.75 2.0%

3 60.50 47.25 3.3%

4 86.99 50.25 21.9%

5 88.66 57.75 34.9%

-

[1] 罗涛, 何晓业, 汪昭义, 王巍, 李笑, 黄晴晴, 何振强, 柯志勇, 马娜, 王铜, 梁静, 李波, 门铃鸰, 王小龙, 董岚 2021 武汉大学学报(信息科学版) DOI: 10.13203/j.whugis20200718

Luo T, He X Y, Wang S Y, Wang W, Li X, Huang Q Q, He Z Q, Ke Z Y, Ma N, Wang T, Liang J, Li B, Men L L, Wang X L, Dong L 2021 Geomatics Inf. Sci. Wuhan Univ. DOI: 10.13203/j. whugis20200718 (in Chinese)

[2] Jiao Y, Duan Z, Guo Y, Ji D, Li X, Peng Y, Qin Q, Qiu J, Tian S, Wang J 2016 Phys. Procedia 84 40

Google Scholar

Google Scholar

[3] 李广云, 范百兴 2017 测绘学报 46 10

Google Scholar

Google Scholar

Li G Y, Fan B X 2017 Acta Geod. Cartogr. Sin. 46 10

Google Scholar

Google Scholar

[4] Kristiansen P, Horbach J, Döhrmann R, Heuer J 2015 J. Synchrotron Radiat. 22 4

Google Scholar

Google Scholar

[5] Omidalizarandi M, Kargoll B, Paffenholz J A, Paffenholz J A, Neumann I 2018 Adv. Mech. Eng. 10 119

Google Scholar

Google Scholar

[6] 徐亚明, 郑琪, 管啸 2020 测绘地理信息 45 812

Google Scholar

Google Scholar

Xu Y M, Zheng Q, Guan X 2020 J. Geomat. 45 812

Google Scholar

Google Scholar

[7] Bronowicki A J, Abhyankar N S, Griffin S F 1999 Smart Mater. Struct. 8 740

Google Scholar

Google Scholar

[8] Davis L, Hyland D, Yen G, Dask A 1999 Smart Mater. Struct. 8 753

Google Scholar

Google Scholar

[9] Vaillon L, Petitjean B, Frapard B, Lebihan D 1999 Smart Mater. Struct. 8 781

Google Scholar

Google Scholar

[10] Vaillon L, Sanctorum B, Sperandei J, Defendini A, Griseri G, Alberti M V 2002 Proc. 5th ESA Int. Conf. Spacecr. Guid Italy, Frascati, October

[11] Onoda J, Minesugi K 1996 AIAA J. 34 207

Google Scholar

Google Scholar

[12] Onoda J, Minesugi K 1994 J. Spacecraft Rockets 31 67

Google Scholar

Google Scholar

[13] Onoda J, Minesugi K 1996 AIAA J. 34 355

Google Scholar

Google Scholar

[14] Chen S B, Xuan M, Xin J, Liu Y, Gu S, Li J, Zhang L 2020 Int. J. Mech. Sci. 179 105592

Google Scholar

Google Scholar

[15] 姜伟伟, 徐治洲, 任戈 2014 噪声与振动控制 34 186

Google Scholar

Google Scholar

Jiang W W, Xu Z Z, Ren G 2014 Noise Vibr. Control 34 186

Google Scholar

Google Scholar

[16] 杜言鲁, 丁亚林, 许永森, 聂品 2015 中国机械工程 26 2880

Google Scholar

Google Scholar

Du Y L, Ding Y L, Xu Y S, Nie P 2015 Chin. Mech. Eng. 26 2880

Google Scholar

Google Scholar

[17] 郑凤翥, 宁飞, 王培群, 霍丽烨, 赵志草 2018 应用光学 39 453

Google Scholar

Google Scholar

Zheng F Z, Ning F, Wang P Q, Huo L Y, Zhao Z C 2018 J. Appl. Opt. 39 453

Google Scholar

Google Scholar

[18] Qi Y, Wang H L, Xu Q Q, Du Y L, Shao X Z, Yang H 2021 Optik 242 167016

Google Scholar

Google Scholar

[19] Dong G, Ma C, Y Luo 2020 Int. J. Appl. Electromagnet. Mech. 64 315

Google Scholar

Google Scholar

[20] 杜宁, 胡明勇, 毕勇, 朱庆生 2017 振动与冲击 36 184

Du N, Hu M Y, Bi Y, Zhu Q S 2017 J. Vibr. Shock 36 184

[21] Carrella A, Brennan M J, Waters T P 2007 J. Sound Vibr. 301 678

Google Scholar

Google Scholar

[22] Takamori A 2002 Ph. D. Dissertation (Tokyo: University of Tokyo)

[23] Stochino A, Abbot B, Aso Y, Barton M, Bertolini A, Boschi V, Coyne D, DeSalvo R, Galli C, Huang Y M 2007 Nucl. Instrum. Methods Phys. Res. , Sect. A 598 737

Google Scholar

Google Scholar

[24] Yao J, Wu K, Guo M, Wang G, Wang L 2019 IEEE Trans. Instrum. Meas. 99 1

Google Scholar

Google Scholar

[25] Xu D L, Yu Q P, Zhou J X, Bishop S R 2013 J. Sound Vibr. 332 3377

Google Scholar

Google Scholar

[26] Xu D L, Zhang Y Y, Zhou J X, Lou J J 2013 J. Vibr. Control 20 2314

Google Scholar

Google Scholar

[27] 李强, 徐登峰, 李林, 魏绍炎 2019 振动与冲击 38 100

Google Scholar

Google Scholar

Li Q, Xu D F, Li L, Wei S Y 2019 J. Vibr. Shock 38 100

Google Scholar

Google Scholar

[28] 严博, 马洪业, 韩瑞祥, 王珂, 武传宇 2019 机械工程学报 55 169

Google Scholar

Google Scholar

Yan B, Ma H X, Han R X, Wang K, Wu C Y 2019 J. Mech. Eng. 55 169

Google Scholar

Google Scholar

[29] Sun M, Chen J 2018 Math Probl Eng. 2018 5693618

Google Scholar

Google Scholar

[30] 刘海平, 申大山, 赵鹏鹏 2021 振动工程学报 34 490

Google Scholar

Google Scholar

Liu H P, Shen D S, Zhao P P 2021 J. Vibr. Eng. 34 490

Google Scholar

Google Scholar

计量

- 文章访问数: 5429

- PDF下载量: 71

- 被引次数: 0

下载:

下载: