-

半金属铋(Bi)的表面合金具有的Rashba效应, 和其具体结构性质有重要关联. 本文结合扫描隧道显微镜(STM)和密度泛函理论(DFT), 系统地研究了Bi原子在Ag(111)和Au(111)上的不同初始生长行为. 在室温Ag(111)上, 连续的Ag2Bi合金薄膜会优先在Ag台阶边缘形成; 在570 K Ag(111)上, 随着覆盖度增加到0.33 分子层(ML), Bi优先取代配位数低的台阶边原子并从单原子随机分布转变为长程有序的Ag2Bi合金相; 随着覆盖度增加, Ag2Bi通过退合金过程转变成

$ p\times \sqrt{3} $ 结构的Bi膜. Bi在室温和570 K的Au(111)上的生长行为一致: 在覆盖度低于0.40 ML时, Bi会优先吸附在配位为5的Au原子上, 并以单原子和团簇的形式分别分散在Au(111)的密堆积区域和鱼骨纹重构的拐角处; 随着覆盖度增加到0.60 ML, 无序的Bi会逐渐转变成长程有序的($ \sqrt{37}\times \sqrt{37} $ )相; Bi的吸附会导致Au(111)表面应力逐步释放. Bi在Ag(111)和Au(111)上的不同生长行为表明, Bi原子与衬底之间的相互作用起着关键作用.The Rashba effect of surface alloys of semimetallic bismuth (Bi) is strongly related to its specific structural properties. The initial growth behaviors of Bi atoms on Ag(111) substrate and Au(111) substrate are systematically investigated by combining scanning tunneling microscopy (STM) and density flooding theory (DFT) in this paper. Continuous Ag2Bi alloy films are formed preferentially at the step edge on Ag(111) held at room temperature; Bi atoms replace step edge atoms with low coordination number and are randomly distributed from single atoms to the forming of long-range ordered Ag2Bi alloy phase as the coverage increases to 0.33 ML on Ag(111) held at 570 K. With the coverage increasing, Ag2Bi is converted into Bi films with a$ p\times \sqrt{3} $ structure by the dealloying process. In contrary to Ag(111), Bi growth behavior on Au(111) held at room temperature and at 570 K are consistent: Bi atoms are adsorbed preferentially on Au atom pairs with coordination 5 and are dispersed as single atoms and clusters in the densely packed region and the corners of the herringbone reconstruction when coverage level is below 0.40 ML; as the coverage level increases to 0.60 ML, the disordered Bi atoms gradually transform into the long-range ordered ($ \sqrt{37}\times \sqrt{37} $ ) phase. Moreover, the adsorption of Bi atoms leads the Au(111) surface strain to gradually release. The different growth behaviors of Bi atoms on Ag(111) substrate and Au(111) substrate suggest that the interaction between Bi atoms and the substrate plays a key role. Bi atoms are adsorbed preferentially around atoms with low surface coordination number under low coverage.-

Keywords:

- semimetal bismuth /

- Ag(111) /

- Au(111) /

- scanning tunneling microscopy

[1] Hofmann P 2006 Prog. Surf. Sci. 81 191

Google Scholar

Google Scholar

[2] Yang F Y, Liu K, Hong K M, Reich D H, Searson P C, Chien C L 1999 Science 284 1335

Google Scholar

Google Scholar

[3] Ast C R, Hochst H 2004 Phys. Rev. B 70 245122

Google Scholar

Google Scholar

[4] Pascual J I, Bihlmayer G, Koroteev Y M, Rust H P, Ceballos G, Hansmann M, Horn K, Chulkov E V, Blugel S, Echenique P M, Hofmann P 2004 Phys. Rev. Lett. 93 196802

Google Scholar

Google Scholar

[5] Hofmann P, Gayone J E, Bihlmayer G, Koroteev Y M, Chulkov E V 2005 Phys. Rev. B 71 195413

Google Scholar

Google Scholar

[6] 赵林, 刘国东, 周兴江 2021 70 017406

Google Scholar

Google Scholar

Zhao L, Liu G D, Zhou X J 2021 Acta Phys. Sin. 70 017406

Google Scholar

Google Scholar

[7] Wang Z F, Liu B, Zhu W 2019 Phys. Rev. Lett. 123 126403

Google Scholar

Google Scholar

[8] Chen G Y, Huang A, Lin Y H, Chen C J, Lin D S, Chang P Y, Jeng H T, Bihlmayer G, Hsu P J 2020 npj Quantum Mater. 5 89

Google Scholar

Google Scholar

[9] Chen R, Lee J, Lee W, Li D 2019 Chem. Rev. 119 9260

Google Scholar

Google Scholar

[10] Weitzel B, Micklitz H 1991 Phys. Rev. Lett. 66 385

Google Scholar

Google Scholar

[11] Dong P, Cheng J, Li Y K 2019 Mater. Res. Bull. 111 154

Google Scholar

Google Scholar

[12] Xiao S H, Wei D H, Jin X F 2012 Phys. Rev. Lett. 109 166805

Google Scholar

Google Scholar

[13] Kowalczyk P J, Mahapatra O, Brown S A, Bian G, Wang X, Chiang T C 2013 Nano Lett. 13 43

Google Scholar

Google Scholar

[14] Heremans J P, Thrush C M, Morelli D T, Wu M C 2002 Phys. Rev. Lett. 88 216801

Google Scholar

Google Scholar

[15] Roushan P, Seo J, Parker C V, Hor Y S, Hsieh D, Qian D, Richardella A, Hasan M Z, Cava R J, Yazdani A 2009 Nature 460 1106

Google Scholar

Google Scholar

[16] Yamada K, Souma S, Yamauchi K, Shimamura N, Sugawara K, Trang C X, Oguchi T, Ueno K, Takahashi T, Sato T 2018 Nano Lett. 18 3235

Google Scholar

Google Scholar

[17] Fang A, Adamo C, Jia S, Cava R J, Wu S C, Felser C, Kapitulnik A 2018 Sci. Adv. 4 eaaq0330

Google Scholar

Google Scholar

[18] 孟雨欣, 赵漪凡, 李绍春 2021 70 148101

Google Scholar

Google Scholar

Meng Y X, Zhao Y F, Li S C 2021 Acta Phys. Sin. 70 148101

Google Scholar

Google Scholar

[19] Reis F, Li G, Dudy L, Bauernfeind M, Glass S, Hanke W, Thomale R, Schafer J, Claessen R 2017 Science 357 287

Google Scholar

Google Scholar

[20] Kawakami N, Lin C L, Kawai M, Arafune R, Takagi N 2015 Appl. Phys. Lett. 107 031602

Google Scholar

Google Scholar

[21] Song F, Wells J W, Jiang Z, Saxegaard M, Wahlstrom E 2015 ACS Appl. Mater. Interfaces 7 8525

Google Scholar

Google Scholar

[22] Gou J, Kong L J, He X Y, Huang Y L, Sun J T, Meng S, Wu K H, Chen L, Wee A T S 2020 Sci. Adv. 6 eaba2773

Google Scholar

Google Scholar

[23] Sun J T, Huang H, Wong S L, Gao H J, Feng Y P, Wee A T S 2012 Phys. Rev. Lett. 109 246804

Google Scholar

Google Scholar

[24] Zhang K H L, McLeod I M, Lu Y H, Dhanak V R, Matilainen A, Lahti M, Pussi K, Egdell R G, Wang X S, Wee A T S, Chen W 2011 Phys. Rev. B 83 235418

Google Scholar

Google Scholar

[25] Hu J B, Hu J P, Zhang Z D, Shen K C, Liang Z F, Zhang H, Tian Q W, Wang P, Jiang Z, Huang H, Well J W, Song F 2020 Appl. Surf. Sci. 513 145797

Google Scholar

Google Scholar

[26] Hu J P, Liang Z F, Shen K C, Xie L, Zhang H, Huang C Q, Huang Y B, Huang H, Tang J X, Jiang Z, Yu M, Song F 2021 Nano Res. 14 4704

Google Scholar

Google Scholar

[27] Horcas I, Fernández R, Gómez-Rodríguez J M, Colchero J, Gómez-Herrero J, Baró A M 2007 Rev. Sci. Instrum. 78 013705

Google Scholar

Google Scholar

[28] Perdew J P, Chevary J A, Vosko S H, Jackson K A, Pederson M R, Singh D J, Fiolhais C 1993 Phys. Rev. B 48 4978

[29] Liang Z F, Wang Y, Hua C Q, Xiao C C, Chen M G, Jiang Z, Tai R Z, Lu Y H, Song F 2019 Nanoscale 11 14134

Google Scholar

Google Scholar

[30] Blochl P E 1994 Phys. Rev. B 50 17953

Google Scholar

Google Scholar

[31] Kresse G, Joubert D 1999 Phys. Rev. B 59 1758

[32] 郭宇, 周思, 赵纪军 2021 70 027102

Google Scholar

Google Scholar

Guo Y, Zhou S, Zhao J J 2021 Acta Phys. Sin. 70 027102

Google Scholar

Google Scholar

[33] Dong L, Wang A, Li E, Wang Q, Li G, Huan Q, Gao H J 2019 Chin. Phys. Lett. 36 028102

Google Scholar

Google Scholar

[34] Huang H, Sun J-T, Feng Y P, Chen W, Wee A T S 2011 Phys. Chem. Chem. Phys. 13 20933

Google Scholar

Google Scholar

[35] Yang S, Hu Z P, Wang W H, Cheng P, Chen L, Wu K H 2020 Chin. Phys. Lett. 37 096803

Google Scholar

Google Scholar

[36] Campos L C, Manfrinato V R, Sanchez-Yamagishi J D, Kong J, Jarillo-Herrero P 2009 Nano Lett. 9 2600

Google Scholar

Google Scholar

[37] Zhang S, Song Y, Li H, Li J M, Qian K, Liu C, Wang J O, Qian T, Zhang Y Y, Lu J C 2020 Chin. Phys. Lett. 37 068103

Google Scholar

Google Scholar

[38] Narasimhan S, Vanderbilt D 1992 Phys. Rev. Lett. 69 1564

Google Scholar

Google Scholar

[39] Hanke F, Björk J 2013 Phys. Rev. B 87 235422

[40] Kawakami N, Lin C L, Kawahara K, Kawai M, Arafune R, Takagi N 2017 Phys. Rev. B 96 205402

Google Scholar

Google Scholar

[41] Chen H H, Su S H, Chang S L, Cheng B Y, Chen S W, Chen H Y, Lin M F, Huang J C A 2015 Sci. Rep. 5 11623

Google Scholar

Google Scholar

[42] Zhou D C, Si N, Jiang B H, Song X F, Huang H, Ji Q M, Niu T C 2019 Adv. Mater. Interfaces 6 1901050

Google Scholar

Google Scholar

[43] He B C, Tian G, Gou J, Liu B X, Shen K C, Tian Q W, Yu Z Q, Song F, Xie H P, Gao Y L 2019 Surf. Sci. 679 147

Google Scholar

Google Scholar

[44] Girard Y, Chacon C, de Abreu G, Lagoute J, Repain V, Rousset S 2013 Surf. Sci. 617 118

Google Scholar

Google Scholar

[45] Walen H, Liu D J, Oh J, Lim H, Evans J W, Kim Y, Thiel P A 2015 J. Chem. Phys. 143 014704

Google Scholar

Google Scholar

[46] Min B K, Deng X, Pinnaduwage D, Schalek R, Friend C M 2005 Phys. Rev. B 72 121410

Google Scholar

Google Scholar

[47] Jewell A D, Tierney H L, Sykes E C H 2010 Phys. Rev. B 82 205401

Google Scholar

Google Scholar

-

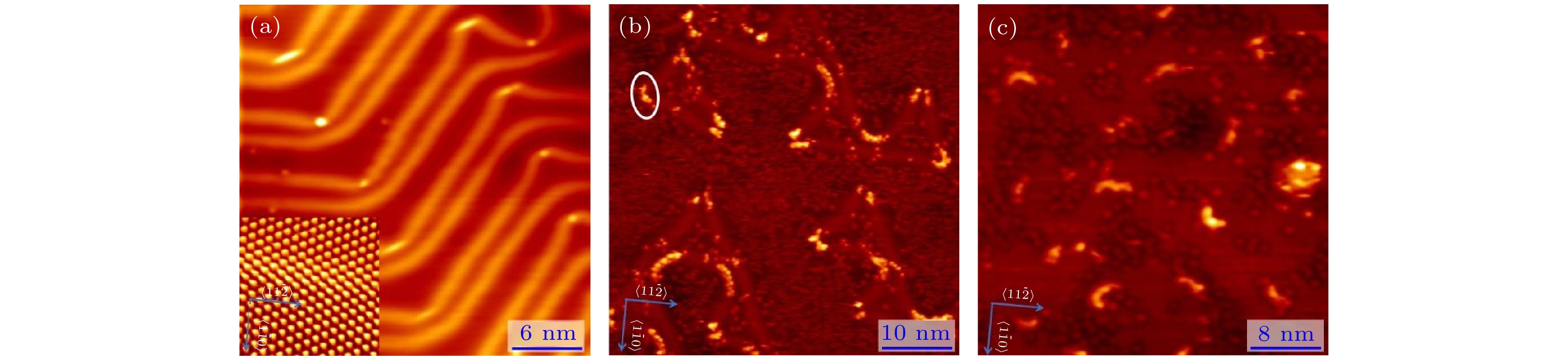

图 1 0.10 ML Bi原子沉淀到Ag(111)表面的STM图 (a) 大面积的STM图, 图中包含Ag(111)台阶, 在台阶处有大量的Bi原子聚集; (b) 图(a)中靠近台阶边的放大图; (c) 图(a)中台面上的放大图; (d) Bi原子嵌入到Ag(111)表面的模型图; Ag原子: 白色; Bi原子: 紫色. 图中标尺和整个图的比例为1∶5

Fig. 1. STM images of 0.10 ML Bi deposited on Ag(111) surface: (a) Large scale STM image contains Ag(111) step where an amount of Bi atoms are aggregated; (b) high-resolution STM image is obtained at step edge in Figure (a); (c) high-resolution STM image is obtained far away the step edge in Figure (a); (d) model structure of Bi atom embedded in Ag(111) surface. Ag atom: white; Bi atom: purple. The scale ruler of images in Figure (a)–(c) images is 1∶5.

图 2 (a) 干净的Au(111) STM图, 左下角插图是Au(111)原子分辨; (b), (c) 在常温Au(111)表面沉积0.04 ML, 0.15 ML Bi

Fig. 2. (a) Large-scale STM image of cleaning Au(111) surface. The bottom left inset shows the atomic resolution STM image of Au(111) surface; (b), (c) different amounts of Bi are deposited on Au(111) surface of Au(111) at room temperature. The coverage of (a), (b) is 0.04 ML, and 0.15 ML, respectively.

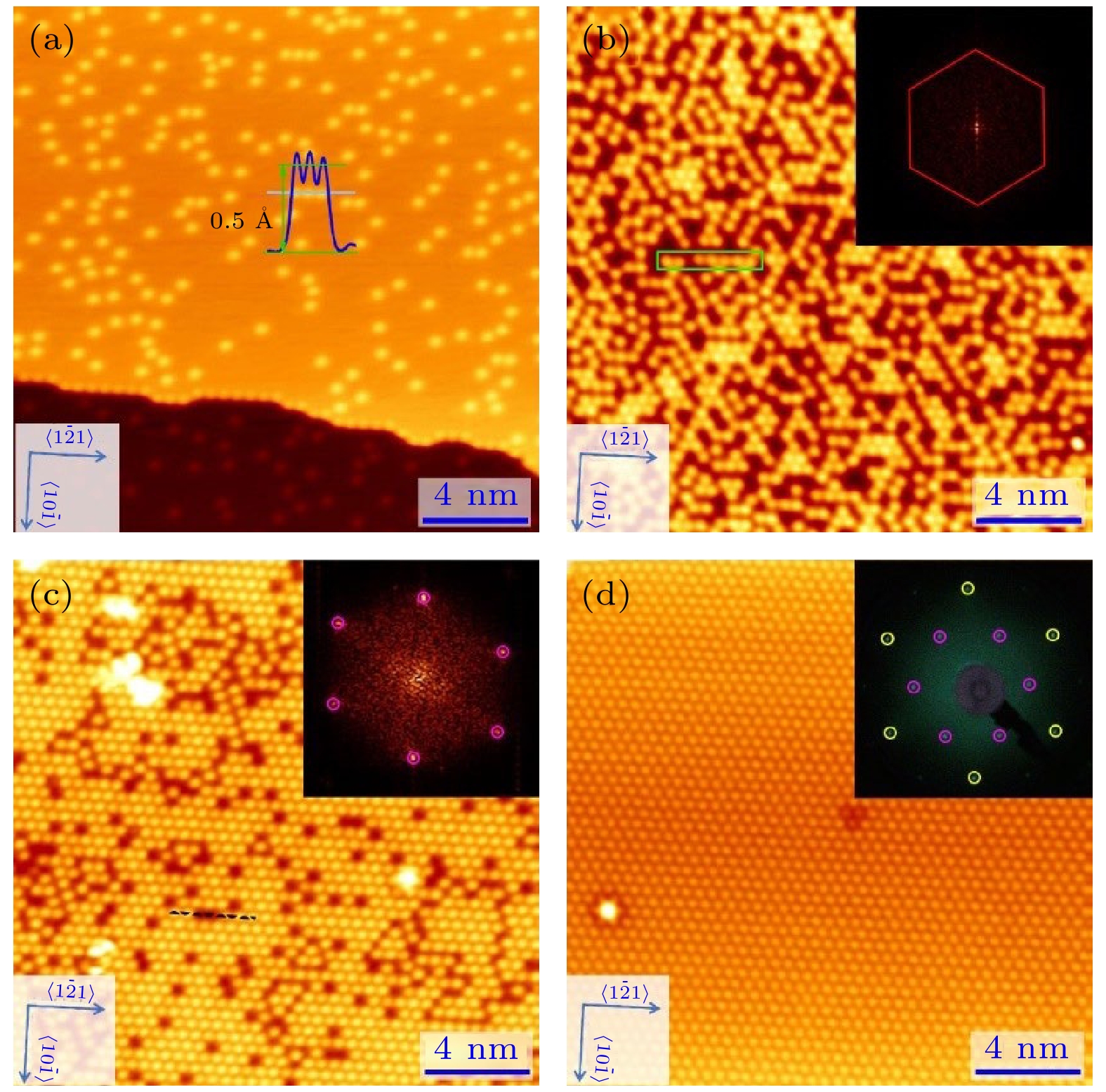

图 3 在570 K的Ag(111)衬底上沉淀不同覆盖度的Bi原子 (a) 0.10 ML; (b) 0.25 ML; (c) 0.31 ML; (d) 0.33 ML. (b), (c)中的插图是FFT变换; (d)中的插图是LEED图, 黄色圆圈中的点是Ag(111)的第一级衍射斑点, 品红色圆圈中的点是

$ \sqrt{3}\times \sqrt{3} $ 结构的第一级衍射斑点; (c)中的黑色虚线标明了三个原子长度的线缺陷. 图中标尺和整个图的比例为1∶5Fig. 3. Bi atoms were deposited on Ag(111) surface with 570 K: (a) 0.10 ML; (b) 0.25 ML; (c) 0.31 ML; (d) 0.33 ML. The insets are FFT transform in Figure (b) and (c). The inset is a LEED image where the dots in the yellow circle are the first order diffraction spots of Ag(111) and the dots in the magenta circle are the first order diffraction spots of the

$ \sqrt{3}\times \sqrt{3} $ structure in (d). The black dotted line in c indicates a line defect of three atomic lengths. The scale ruler of images in Figure (a)–(d) images is 1∶5.图 4 在常温和加热570 K的情况, Bi膜退合金过程 (a) 在保持常温的

$ \sqrt{3}\times \sqrt{3} $ 结构上再沉淀0.07 ML Bi得到的STM图, 左下角插图是单层$ p\times \sqrt{3} $ 结构的原子分辨图; (b) 在图(a)的基础上, 将样品加热至570 K并保温10 min得到的STM图; (c)$\sqrt{3}\times $ $ \sqrt{3}$ 结构和$ p\times \sqrt{3} $ 结构交界处的侧视图. Ag原子: 蓝绿色; Bi原子: 紫色. 图中标尺和整个图的比例为1∶5Fig. 4. Observation of Bi film alloying-to-dealloying transition at room temperature and 570 K: (a) 0.07 ML Bi was deposited on

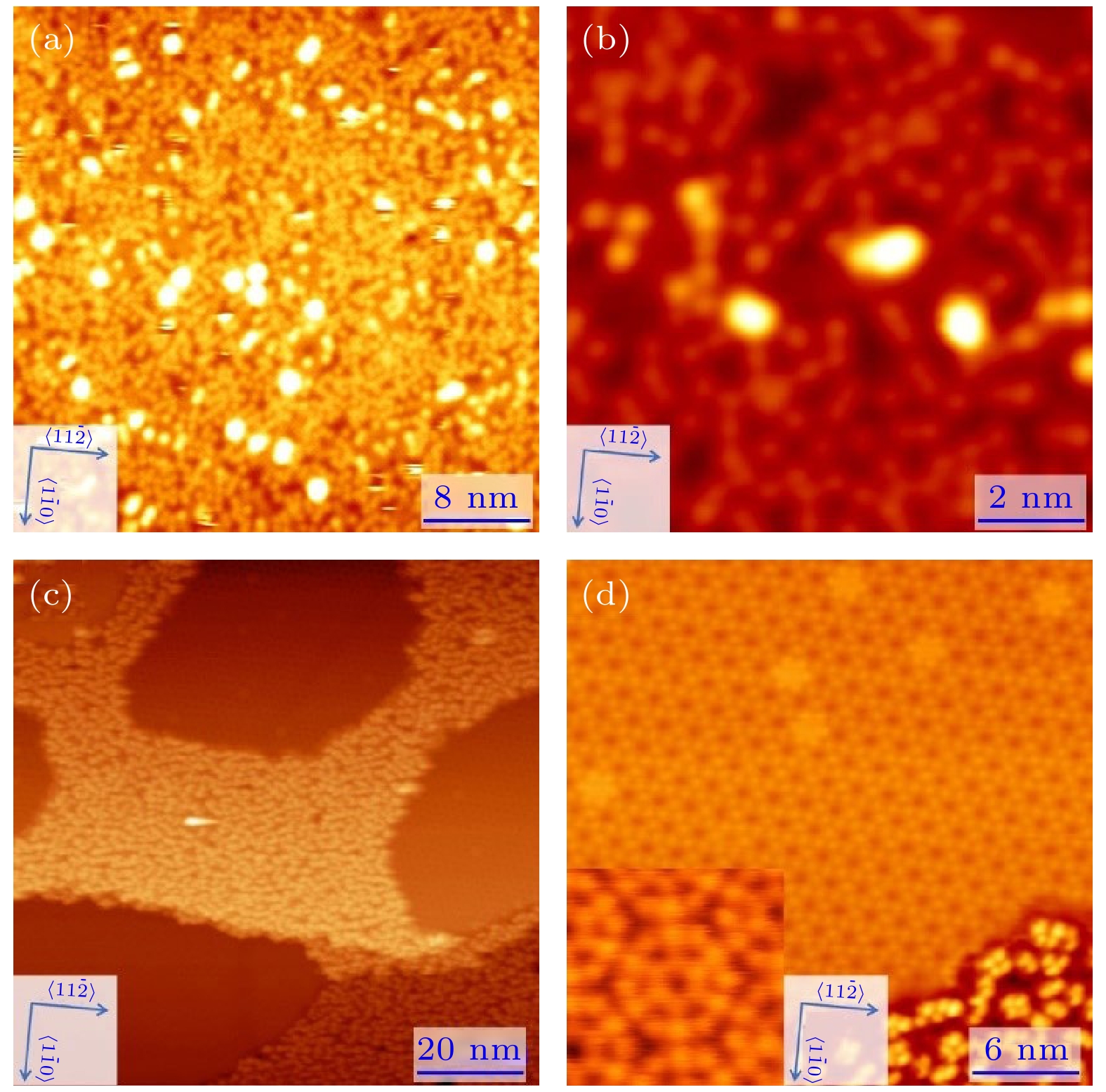

$ \sqrt{3}\times \sqrt{3} $ structure kept at room temperature. The bottom left inset shows the atomic resolution STM image of$ p\times \sqrt{3} $ structure; (b) heating the sample to 570 K and holding for 10 min; (c) side view of$ \sqrt{3}\times \sqrt{3} $ structure and$ p\times \sqrt{3} $ structure. Ag atom: blue-green; Bi atom: purple. The scale ruler of images in Figure (a)–(b) is 1∶5.图 5 低覆盖度下, Bi原子调控鱼骨纹形状 (a), (c) 570 K的Au(111)衬底上蒸镀0.02 ML, 0.18 ML Bi原子; (b), (d) 分别是图(a)和图(c)的放大图

Fig. 5. Bi atoms regulate the shape of herringbone below 0.18 ML: (a), (c) 0.02 ML and 0.18 ML Bi is deposited on Au(111) surface with 570 K; (b), (d) high-resolution STM images of Figure(a) and Figure (c), respectively.

图 6 (a), (c) 在保温570 K的Au(111)衬底上蒸镀0.40 ML, 0.60 ML Bi原子; (b), (d) 分别是图(a)和图(c)的放大图. 图中标尺和整个图的比例为1:5

Fig. 6. (a), (c) 0.40 ML, 0.60 ML Bi is deposited on Au(111) surface with 570 K; (b), (d) high-resolution STM images of Figure (a) and Figure (c), respectively. The scale ruler of images in Figure (a) and Figure (c) is 1∶5.

-

[1] Hofmann P 2006 Prog. Surf. Sci. 81 191

Google Scholar

Google Scholar

[2] Yang F Y, Liu K, Hong K M, Reich D H, Searson P C, Chien C L 1999 Science 284 1335

Google Scholar

Google Scholar

[3] Ast C R, Hochst H 2004 Phys. Rev. B 70 245122

Google Scholar

Google Scholar

[4] Pascual J I, Bihlmayer G, Koroteev Y M, Rust H P, Ceballos G, Hansmann M, Horn K, Chulkov E V, Blugel S, Echenique P M, Hofmann P 2004 Phys. Rev. Lett. 93 196802

Google Scholar

Google Scholar

[5] Hofmann P, Gayone J E, Bihlmayer G, Koroteev Y M, Chulkov E V 2005 Phys. Rev. B 71 195413

Google Scholar

Google Scholar

[6] 赵林, 刘国东, 周兴江 2021 70 017406

Google Scholar

Google Scholar

Zhao L, Liu G D, Zhou X J 2021 Acta Phys. Sin. 70 017406

Google Scholar

Google Scholar

[7] Wang Z F, Liu B, Zhu W 2019 Phys. Rev. Lett. 123 126403

Google Scholar

Google Scholar

[8] Chen G Y, Huang A, Lin Y H, Chen C J, Lin D S, Chang P Y, Jeng H T, Bihlmayer G, Hsu P J 2020 npj Quantum Mater. 5 89

Google Scholar

Google Scholar

[9] Chen R, Lee J, Lee W, Li D 2019 Chem. Rev. 119 9260

Google Scholar

Google Scholar

[10] Weitzel B, Micklitz H 1991 Phys. Rev. Lett. 66 385

Google Scholar

Google Scholar

[11] Dong P, Cheng J, Li Y K 2019 Mater. Res. Bull. 111 154

Google Scholar

Google Scholar

[12] Xiao S H, Wei D H, Jin X F 2012 Phys. Rev. Lett. 109 166805

Google Scholar

Google Scholar

[13] Kowalczyk P J, Mahapatra O, Brown S A, Bian G, Wang X, Chiang T C 2013 Nano Lett. 13 43

Google Scholar

Google Scholar

[14] Heremans J P, Thrush C M, Morelli D T, Wu M C 2002 Phys. Rev. Lett. 88 216801

Google Scholar

Google Scholar

[15] Roushan P, Seo J, Parker C V, Hor Y S, Hsieh D, Qian D, Richardella A, Hasan M Z, Cava R J, Yazdani A 2009 Nature 460 1106

Google Scholar

Google Scholar

[16] Yamada K, Souma S, Yamauchi K, Shimamura N, Sugawara K, Trang C X, Oguchi T, Ueno K, Takahashi T, Sato T 2018 Nano Lett. 18 3235

Google Scholar

Google Scholar

[17] Fang A, Adamo C, Jia S, Cava R J, Wu S C, Felser C, Kapitulnik A 2018 Sci. Adv. 4 eaaq0330

Google Scholar

Google Scholar

[18] 孟雨欣, 赵漪凡, 李绍春 2021 70 148101

Google Scholar

Google Scholar

Meng Y X, Zhao Y F, Li S C 2021 Acta Phys. Sin. 70 148101

Google Scholar

Google Scholar

[19] Reis F, Li G, Dudy L, Bauernfeind M, Glass S, Hanke W, Thomale R, Schafer J, Claessen R 2017 Science 357 287

Google Scholar

Google Scholar

[20] Kawakami N, Lin C L, Kawai M, Arafune R, Takagi N 2015 Appl. Phys. Lett. 107 031602

Google Scholar

Google Scholar

[21] Song F, Wells J W, Jiang Z, Saxegaard M, Wahlstrom E 2015 ACS Appl. Mater. Interfaces 7 8525

Google Scholar

Google Scholar

[22] Gou J, Kong L J, He X Y, Huang Y L, Sun J T, Meng S, Wu K H, Chen L, Wee A T S 2020 Sci. Adv. 6 eaba2773

Google Scholar

Google Scholar

[23] Sun J T, Huang H, Wong S L, Gao H J, Feng Y P, Wee A T S 2012 Phys. Rev. Lett. 109 246804

Google Scholar

Google Scholar

[24] Zhang K H L, McLeod I M, Lu Y H, Dhanak V R, Matilainen A, Lahti M, Pussi K, Egdell R G, Wang X S, Wee A T S, Chen W 2011 Phys. Rev. B 83 235418

Google Scholar

Google Scholar

[25] Hu J B, Hu J P, Zhang Z D, Shen K C, Liang Z F, Zhang H, Tian Q W, Wang P, Jiang Z, Huang H, Well J W, Song F 2020 Appl. Surf. Sci. 513 145797

Google Scholar

Google Scholar

[26] Hu J P, Liang Z F, Shen K C, Xie L, Zhang H, Huang C Q, Huang Y B, Huang H, Tang J X, Jiang Z, Yu M, Song F 2021 Nano Res. 14 4704

Google Scholar

Google Scholar

[27] Horcas I, Fernández R, Gómez-Rodríguez J M, Colchero J, Gómez-Herrero J, Baró A M 2007 Rev. Sci. Instrum. 78 013705

Google Scholar

Google Scholar

[28] Perdew J P, Chevary J A, Vosko S H, Jackson K A, Pederson M R, Singh D J, Fiolhais C 1993 Phys. Rev. B 48 4978

[29] Liang Z F, Wang Y, Hua C Q, Xiao C C, Chen M G, Jiang Z, Tai R Z, Lu Y H, Song F 2019 Nanoscale 11 14134

Google Scholar

Google Scholar

[30] Blochl P E 1994 Phys. Rev. B 50 17953

Google Scholar

Google Scholar

[31] Kresse G, Joubert D 1999 Phys. Rev. B 59 1758

[32] 郭宇, 周思, 赵纪军 2021 70 027102

Google Scholar

Google Scholar

Guo Y, Zhou S, Zhao J J 2021 Acta Phys. Sin. 70 027102

Google Scholar

Google Scholar

[33] Dong L, Wang A, Li E, Wang Q, Li G, Huan Q, Gao H J 2019 Chin. Phys. Lett. 36 028102

Google Scholar

Google Scholar

[34] Huang H, Sun J-T, Feng Y P, Chen W, Wee A T S 2011 Phys. Chem. Chem. Phys. 13 20933

Google Scholar

Google Scholar

[35] Yang S, Hu Z P, Wang W H, Cheng P, Chen L, Wu K H 2020 Chin. Phys. Lett. 37 096803

Google Scholar

Google Scholar

[36] Campos L C, Manfrinato V R, Sanchez-Yamagishi J D, Kong J, Jarillo-Herrero P 2009 Nano Lett. 9 2600

Google Scholar

Google Scholar

[37] Zhang S, Song Y, Li H, Li J M, Qian K, Liu C, Wang J O, Qian T, Zhang Y Y, Lu J C 2020 Chin. Phys. Lett. 37 068103

Google Scholar

Google Scholar

[38] Narasimhan S, Vanderbilt D 1992 Phys. Rev. Lett. 69 1564

Google Scholar

Google Scholar

[39] Hanke F, Björk J 2013 Phys. Rev. B 87 235422

[40] Kawakami N, Lin C L, Kawahara K, Kawai M, Arafune R, Takagi N 2017 Phys. Rev. B 96 205402

Google Scholar

Google Scholar

[41] Chen H H, Su S H, Chang S L, Cheng B Y, Chen S W, Chen H Y, Lin M F, Huang J C A 2015 Sci. Rep. 5 11623

Google Scholar

Google Scholar

[42] Zhou D C, Si N, Jiang B H, Song X F, Huang H, Ji Q M, Niu T C 2019 Adv. Mater. Interfaces 6 1901050

Google Scholar

Google Scholar

[43] He B C, Tian G, Gou J, Liu B X, Shen K C, Tian Q W, Yu Z Q, Song F, Xie H P, Gao Y L 2019 Surf. Sci. 679 147

Google Scholar

Google Scholar

[44] Girard Y, Chacon C, de Abreu G, Lagoute J, Repain V, Rousset S 2013 Surf. Sci. 617 118

Google Scholar

Google Scholar

[45] Walen H, Liu D J, Oh J, Lim H, Evans J W, Kim Y, Thiel P A 2015 J. Chem. Phys. 143 014704

Google Scholar

Google Scholar

[46] Min B K, Deng X, Pinnaduwage D, Schalek R, Friend C M 2005 Phys. Rev. B 72 121410

Google Scholar

Google Scholar

[47] Jewell A D, Tierney H L, Sykes E C H 2010 Phys. Rev. B 82 205401

Google Scholar

Google Scholar

计量

- 文章访问数: 9285

- PDF下载量: 367

- 被引次数: 0

下载:

下载: