-

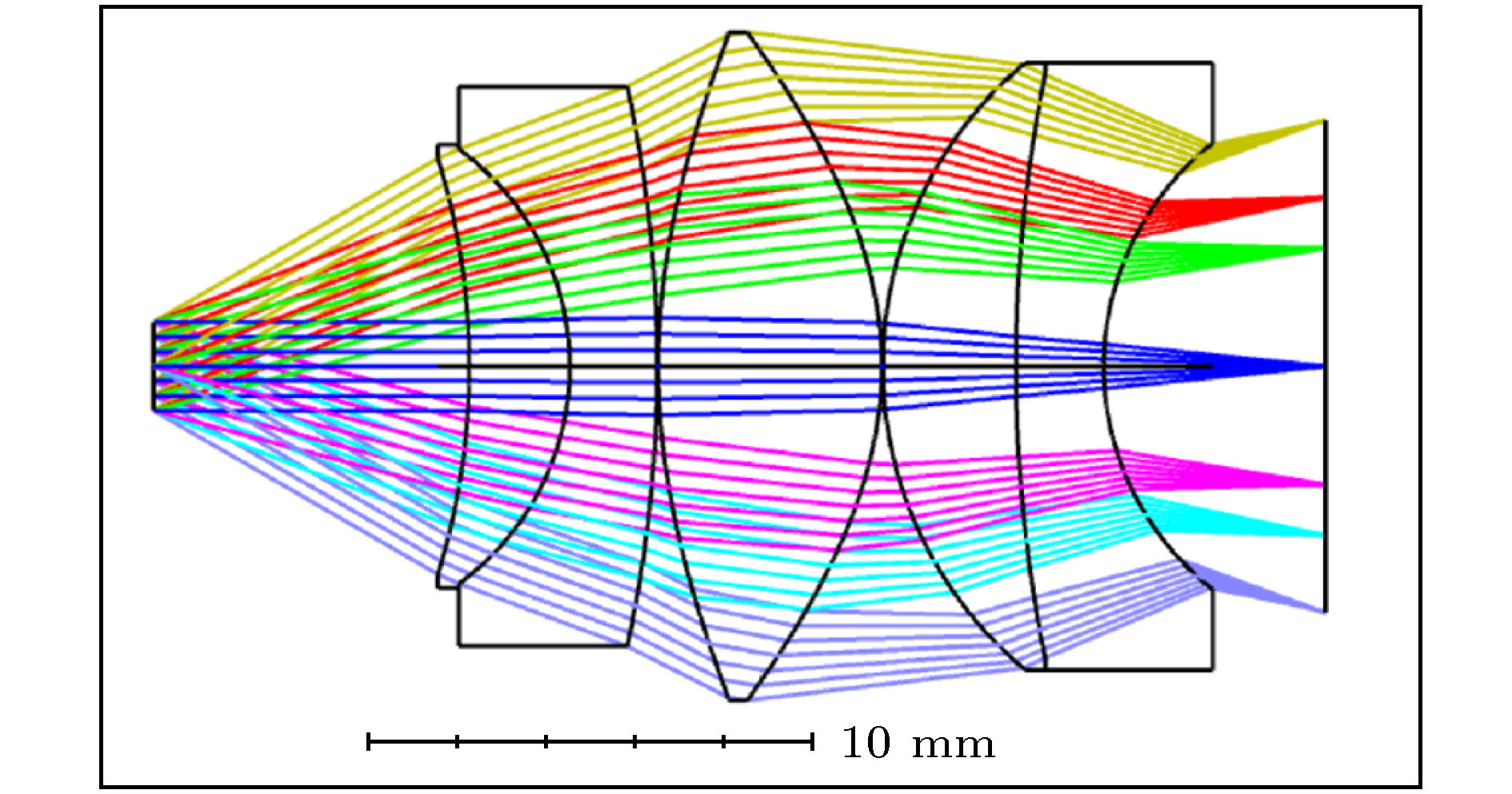

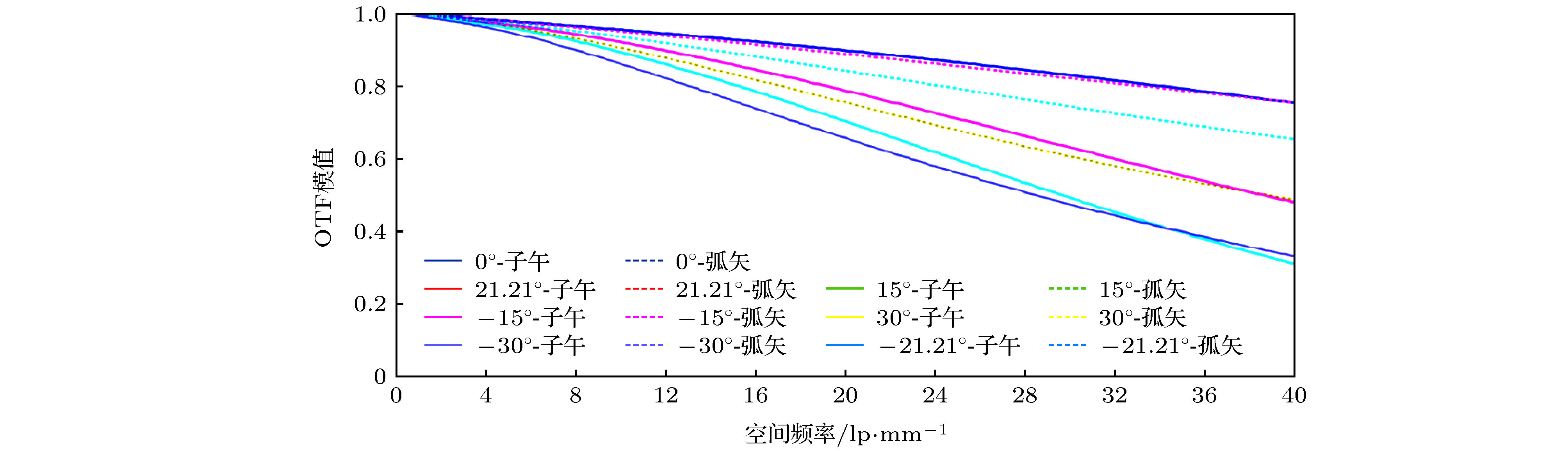

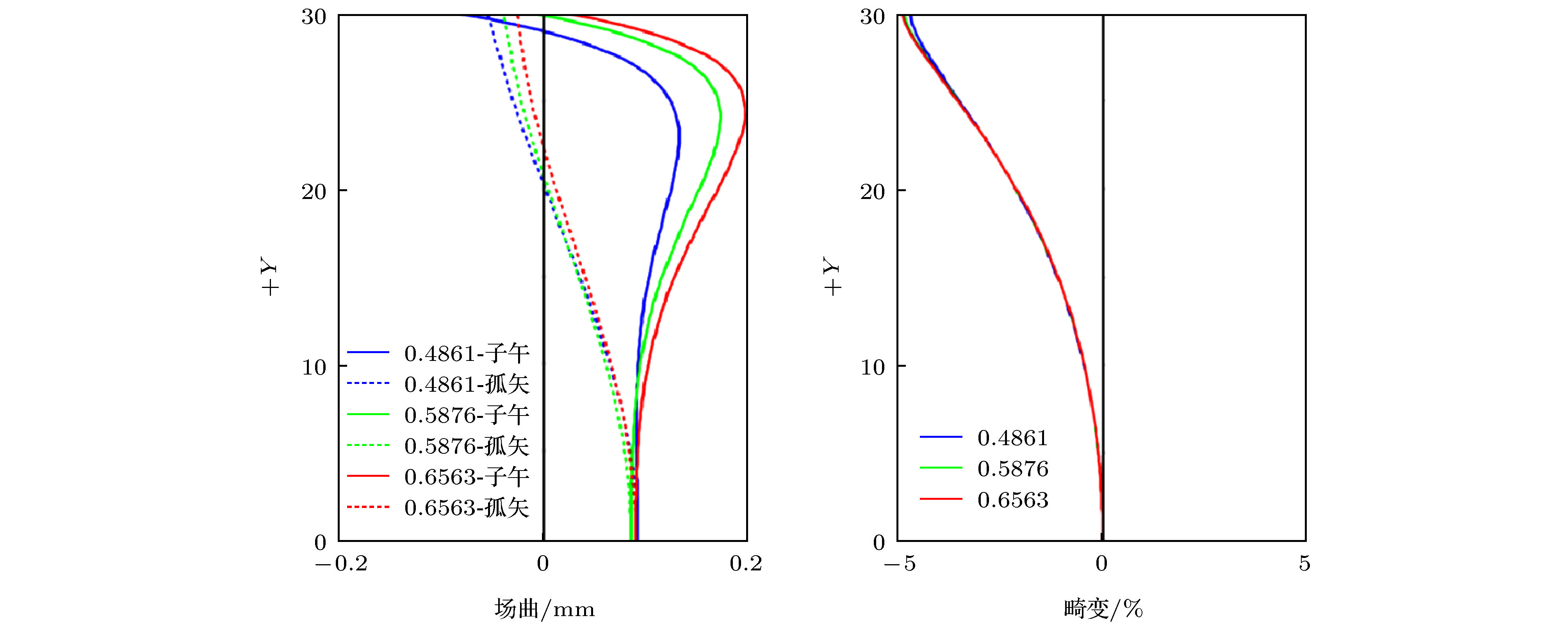

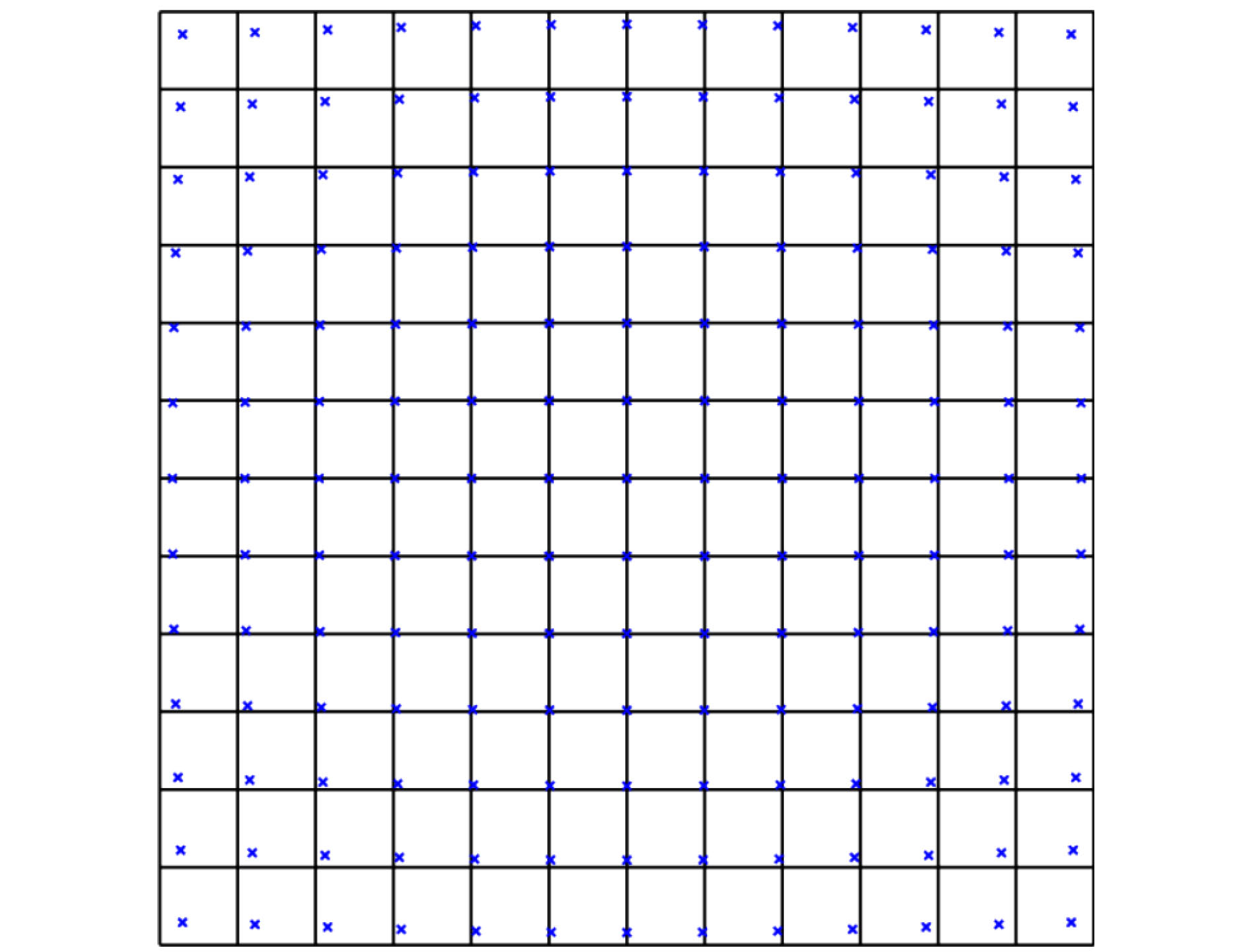

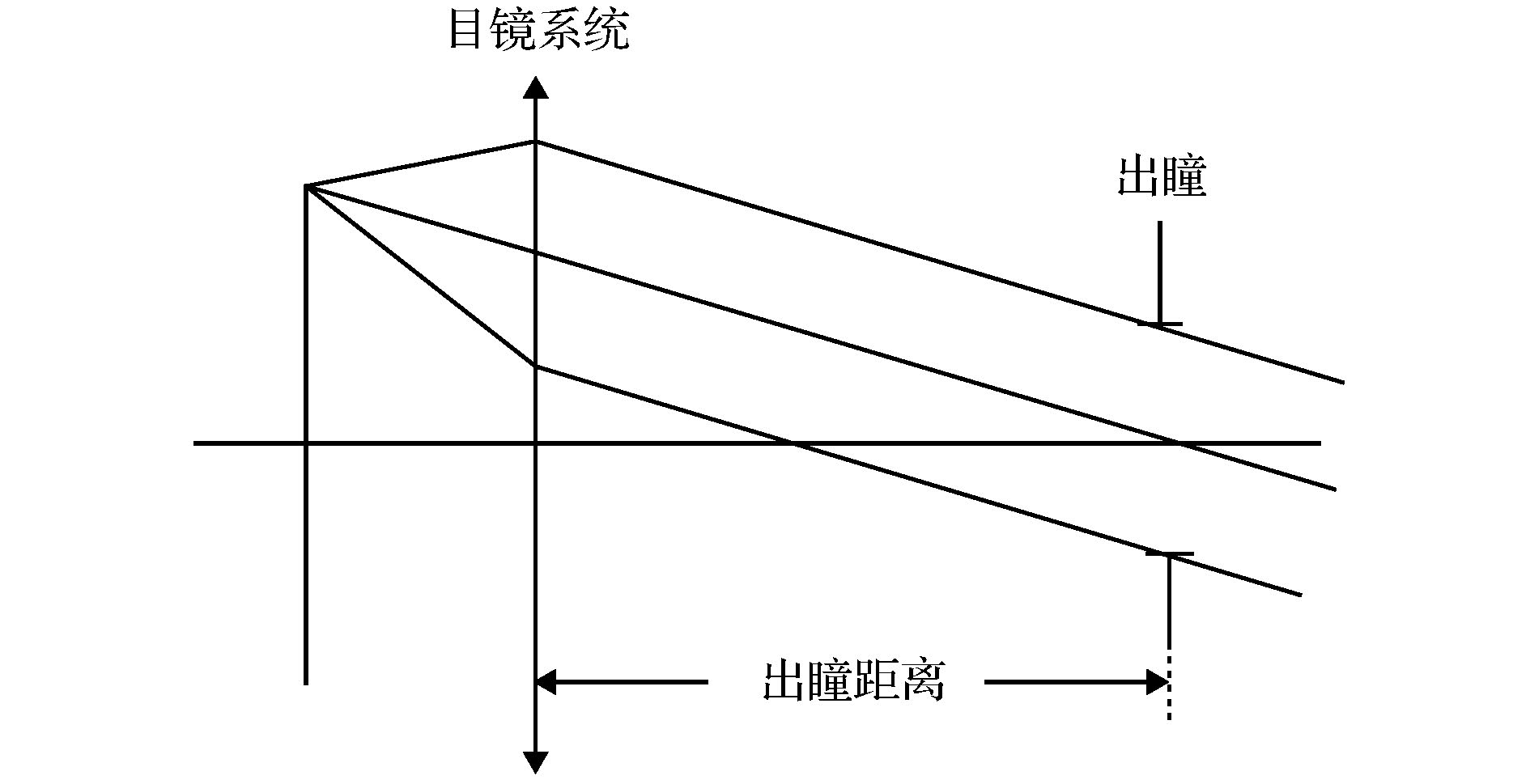

随着显微镜性能的不断提升, 要求显微目镜具有更大的视场、放大倍率以及更好的成像质量. 显微目镜由于孔径光阑外置, 且焦距较短, 其设计难点在于如何校正大视场带来的畸变与其他轴外像差, 并在此基础上获得符合人眼观察要求的出瞳距离. 本文分析了目镜光学系统存在的主要像差, 特别是带有畸变的光学系统对成像所产生的影响. 将自由曲面应用在显微目镜光学系统畸变校正中, 设计出一款视场角达到60° (即 ± 30°), 放大倍率达到25× 且全视场畸变小于5%的高倍率广角显微目镜. 采用五片三组元式结构, 其中自由曲面镜片采用塑料材料且关于XOZ与YOZ平面对称, 实现了结构简单、易于加工且成本较低的高性能显微目镜设计.With the great improvement of microscope property, the eyepiece of microscope is required to have a larger field of view, high magnification, and better imaging quality. Because of the external aperture stop and short focal length, the design difficulty of microscope eyepiece lies in how to correct the distortion and other off-axis aberrations caused by the large field of view, and how to obtain an eye relief that meets the requirements for human observation is also important. The main aberrations of the eyepiece optical system, especially the effect of the optical system with distortion on imaging is analyzed in this paper. The freeform surface is applied to the distortion correction of the optical system of the microscope eyepiece. A wide-angle microscope eyepiece with field of vision of 60° and a magnification of 25× is described in this paper. The full-field distortion is less than 5%. The microscope eyepiece adopts a five-piece three-element structure, in which the freeform surface lens is made of plastic material and is symmetrical about the XOZ plane and YOZ plane. A high-performance microscope eyepiece design with simple structure, easy processing, and low cost is realized.

-

Keywords:

- microscope eyepiece /

- freeform surface /

- large field of view /

- high magnification

[1] Missig M D, Morris G M 1995 Appl. Opt. 34 2452

Google Scholar

Google Scholar

[2] 孟祥翔 2015 博士学位论文 (长春: 中国科学院光学精密机械与物理研究所)

Meng X X 2015 Ph. D. Dissertation (Changchun: Changchun Institute of Optics, Fine Mechanics and Physics, Chinese Academy of Sciences) (in Chinese)

[3] 侯佳 2013 博士学位论文 (杭州: 浙江大学)

Hou J 2013 Ph. D. Dissertation (Hangzhou: Zhejiang University) (in Chinese)

[4] Yang T, Jin G F, Zhu J 2017 Chin. Opt. Lett. 06 81

Google Scholar

Google Scholar

[5] 张以谟 2008 应用光学 (北京: 电子工业出版社) 第 494 页

Zhang Y M 2008 Applied Optics (Beijing: Publishing House of Electronics Industry) p494 (in Chinese)

[6] Fang F Z, Zhang X D, Weckenmann A, Zhang G, Evans C 2013 CIRP Ann. 62 823

Google Scholar

Google Scholar

[7] Gissibl T, Thiele S, Herkommer A, Giessen H 2016 Nat. Commun. 7 11763

Google Scholar

Google Scholar

[8] Li H, Naples N J, Zhao X, Yi A Y 2016 Adv. Opt. Technol. 5 335

Google Scholar

Google Scholar

[9] Zhou T, Liu X, Liang Z, Liu Y, Xie J, Wang X 2017 Front. Mech. Eng. 12 46

Google Scholar

Google Scholar

[10] 李荣彬, 杜雪, 张志辉 2015 超精密自由曲面光学设计、加工及测量技术 (北京: 机械工业出版社) 第 9 页

Li R B, Du X, Zhang Z H 2015 Design, Machining and Measurement Technologies of Ultra-precision Freeform Optics (Beijing: China Machine Press) p9 (in Chinese)

[11] Beier M, Hartung J, Peschel T, Damm C, Gebhardt A, Scheiding S, Stumpf D, Zeitner U, Risse S, Eberhardt R, Tünnermann A 2015 Appl. Opt. 54 3530

Google Scholar

Google Scholar

[12] Stock J, Broemel A, Hartung J, Ochse D, Gross H 2017 Appl. Opt. 56 391

Google Scholar

Google Scholar

[13] Feng Z, Huang L, Gong M, Jin G 2013 Opt. Express 21 14728

Google Scholar

Google Scholar

[14] Zhang Y, Wu R, Liu P, Zheng Z, Li H, Liu X 2014 Opt. Commun. 331 297

Google Scholar

Google Scholar

[15] 姚红兵, 丁勇, 辛忠华 2018 应用光学 39 423

Google Scholar

Google Scholar

Yao H B, Ding Y, Xin Z H 2018 J. Appl. Opt. 39 423

Google Scholar

Google Scholar

[16] 梁文跃, 李远兴, 龙拥兵 2017 激光与光电子学进展 1 217

Google Scholar

Google Scholar

Liang W Y, Li X Y, Long Y B 2017 Las. Optoelect. Prog. 1 217

Google Scholar

Google Scholar

[17] Zhen R Z, Xiang H, Xu L 2009 Appl.Opt. 48 6627

Google Scholar

Google Scholar

[18] Chang L, Herbert G 2018 Appl.Opt. 57 5758

Google Scholar

Google Scholar

[19] Yang T, Zhu J, Wu X 2015 Opt. Express 23 10233

Google Scholar

Google Scholar

[20] Cheng D, Wang Y, Hua H 2011 Opt. Lett. 36 2098

Google Scholar

Google Scholar

[21] 任瑞敏, 尹亚玲, 王志章, 郭超修, 印建平 2016 65 114101

Google Scholar

Google Scholar

Ren R M, Yi Y L, Wang Z Z, Guo C X, Yin J P 2016 Acta Phys. Sin. 65 114101

Google Scholar

Google Scholar

[22] 姚远 2014 硕士学位论文 (杭州: 浙江大学)

Yao Y 2014 M.S. Dissertation (Hangzhou: Zhejiang University) (in Chinese)

[23] Ries H, Muschaweck J 2002 J. Opt. Soc. Am. A 19 590

Google Scholar

Google Scholar

[24] 李林, 黄一帆, 王涌天 2015 现代光学设计方法 (北京: 北京理工大学出版社) 第355页

Li L, Hang Y F, Wang Y T 2015 Modern Optical Design (Beijing: Beijing Institute of Technology Press) p355 (in Chinese)

-

表 1 广角显微目镜参数指标

Table 1. Design requirements for the wide-angle microscope eyepiece.

设计指标 数值 焦距/mm 10 放大倍率 25× 出瞳直径/mm 2 出瞳距离/mm 7 视场角/(°) 60 后截距/mm 5 畸变/% < 5% 表 2 广角目镜光学系统参数

Table 2. Optical prescription data for wide-angle eyepiece optical system.

表面 半径/mm 厚度/mm 材料 物面 Infinity Infinity 光阑 Infinity 7.11 2 –16.00 2.26 H-ZLAF78 B 3 –6.00 1.96 ZF4 4 –30.08 0.03 5* 15.27 5.03 PMMA 6* –8.31 0.02 7 8.92 3.00 H-ZK7 8 33.30 1.98 ZF52 9 6.40 5 像面 Infinity — *表面5和6为非球面. 表 3 XY多项式系数

Table 3. XY polynomial coefficients.

表面5 表面6 Conic –4.00 –1.71 E3 4.18 × 10–3 0.017 E5 5.64 × 10–3 0.019 E10 2.33 × 10–3 3.00 × 10–3 E12 –8.73 × 10–5 2.58 × 10–4 E14 –4.19 × 10–5 1.10 × 10–4 E21 –4.19 × 10–4 –5.56 × 10–4 E23 4.59 × 10–6 6.61 × 10–6 E25 6.85 × 10–8 4.95 × 10–7 E27 1.38 × 10–7 2.77 × 10–7 E36 –7.25 × 10–6 6.64 × 10–9 E38 6.09 × 10–6 7.13 × 10–6 E40 3.81 × 10–8 3.39 × 10–7 E42 5.18 × 10–10 2.58 × 10–8 E44 –3.43 × 10–10 7.32 × 10–9 表 4 成像质量评价指标

Table 4. Evaluation index of imaging quality

评价指标 数值 40 lp/mm处MTF > 0.3 畸变/% < 5 场曲/mm < 0.2 表 5 一般目视系统允许的相对畸变[5]

Table 5. Distortion allowed by general visual systems.

视场角2ω' 相对畸变 δyz' 40° 5% 60°—70° 10% > 70° > 10% 表 6 公差系数

Table 6. Tolerance Parameter.

公差项 公差值 半径/mm 0.02 厚度/mm 0.03 元件倾斜/(°) 0.02 元件偏心/mm 0.02 不规则度/fringes 3 阿贝数/% 2 折射率 0.002 表 7 蒙特卡罗分析结果

Table 7. Results of Monte Carlo analysis.

概率 40 lp/mm处平均MTF 90% 0.508 80% 0.510 50% 0.523 20% 0.540 10% 0.549 -

[1] Missig M D, Morris G M 1995 Appl. Opt. 34 2452

Google Scholar

Google Scholar

[2] 孟祥翔 2015 博士学位论文 (长春: 中国科学院光学精密机械与物理研究所)

Meng X X 2015 Ph. D. Dissertation (Changchun: Changchun Institute of Optics, Fine Mechanics and Physics, Chinese Academy of Sciences) (in Chinese)

[3] 侯佳 2013 博士学位论文 (杭州: 浙江大学)

Hou J 2013 Ph. D. Dissertation (Hangzhou: Zhejiang University) (in Chinese)

[4] Yang T, Jin G F, Zhu J 2017 Chin. Opt. Lett. 06 81

Google Scholar

Google Scholar

[5] 张以谟 2008 应用光学 (北京: 电子工业出版社) 第 494 页

Zhang Y M 2008 Applied Optics (Beijing: Publishing House of Electronics Industry) p494 (in Chinese)

[6] Fang F Z, Zhang X D, Weckenmann A, Zhang G, Evans C 2013 CIRP Ann. 62 823

Google Scholar

Google Scholar

[7] Gissibl T, Thiele S, Herkommer A, Giessen H 2016 Nat. Commun. 7 11763

Google Scholar

Google Scholar

[8] Li H, Naples N J, Zhao X, Yi A Y 2016 Adv. Opt. Technol. 5 335

Google Scholar

Google Scholar

[9] Zhou T, Liu X, Liang Z, Liu Y, Xie J, Wang X 2017 Front. Mech. Eng. 12 46

Google Scholar

Google Scholar

[10] 李荣彬, 杜雪, 张志辉 2015 超精密自由曲面光学设计、加工及测量技术 (北京: 机械工业出版社) 第 9 页

Li R B, Du X, Zhang Z H 2015 Design, Machining and Measurement Technologies of Ultra-precision Freeform Optics (Beijing: China Machine Press) p9 (in Chinese)

[11] Beier M, Hartung J, Peschel T, Damm C, Gebhardt A, Scheiding S, Stumpf D, Zeitner U, Risse S, Eberhardt R, Tünnermann A 2015 Appl. Opt. 54 3530

Google Scholar

Google Scholar

[12] Stock J, Broemel A, Hartung J, Ochse D, Gross H 2017 Appl. Opt. 56 391

Google Scholar

Google Scholar

[13] Feng Z, Huang L, Gong M, Jin G 2013 Opt. Express 21 14728

Google Scholar

Google Scholar

[14] Zhang Y, Wu R, Liu P, Zheng Z, Li H, Liu X 2014 Opt. Commun. 331 297

Google Scholar

Google Scholar

[15] 姚红兵, 丁勇, 辛忠华 2018 应用光学 39 423

Google Scholar

Google Scholar

Yao H B, Ding Y, Xin Z H 2018 J. Appl. Opt. 39 423

Google Scholar

Google Scholar

[16] 梁文跃, 李远兴, 龙拥兵 2017 激光与光电子学进展 1 217

Google Scholar

Google Scholar

Liang W Y, Li X Y, Long Y B 2017 Las. Optoelect. Prog. 1 217

Google Scholar

Google Scholar

[17] Zhen R Z, Xiang H, Xu L 2009 Appl.Opt. 48 6627

Google Scholar

Google Scholar

[18] Chang L, Herbert G 2018 Appl.Opt. 57 5758

Google Scholar

Google Scholar

[19] Yang T, Zhu J, Wu X 2015 Opt. Express 23 10233

Google Scholar

Google Scholar

[20] Cheng D, Wang Y, Hua H 2011 Opt. Lett. 36 2098

Google Scholar

Google Scholar

[21] 任瑞敏, 尹亚玲, 王志章, 郭超修, 印建平 2016 65 114101

Google Scholar

Google Scholar

Ren R M, Yi Y L, Wang Z Z, Guo C X, Yin J P 2016 Acta Phys. Sin. 65 114101

Google Scholar

Google Scholar

[22] 姚远 2014 硕士学位论文 (杭州: 浙江大学)

Yao Y 2014 M.S. Dissertation (Hangzhou: Zhejiang University) (in Chinese)

[23] Ries H, Muschaweck J 2002 J. Opt. Soc. Am. A 19 590

Google Scholar

Google Scholar

[24] 李林, 黄一帆, 王涌天 2015 现代光学设计方法 (北京: 北京理工大学出版社) 第355页

Li L, Hang Y F, Wang Y T 2015 Modern Optical Design (Beijing: Beijing Institute of Technology Press) p355 (in Chinese)

计量

- 文章访问数: 15280

- PDF下载量: 163

- 被引次数: 0

下载:

下载: