-

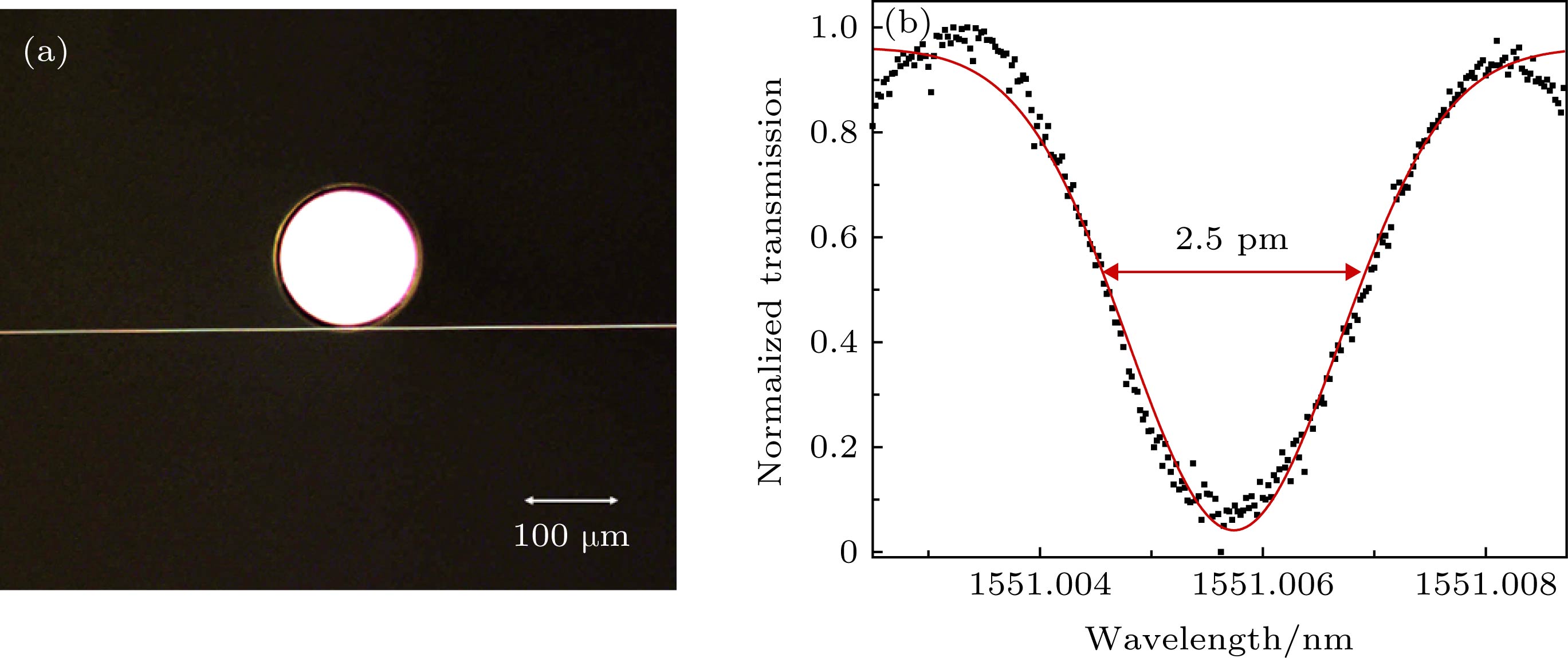

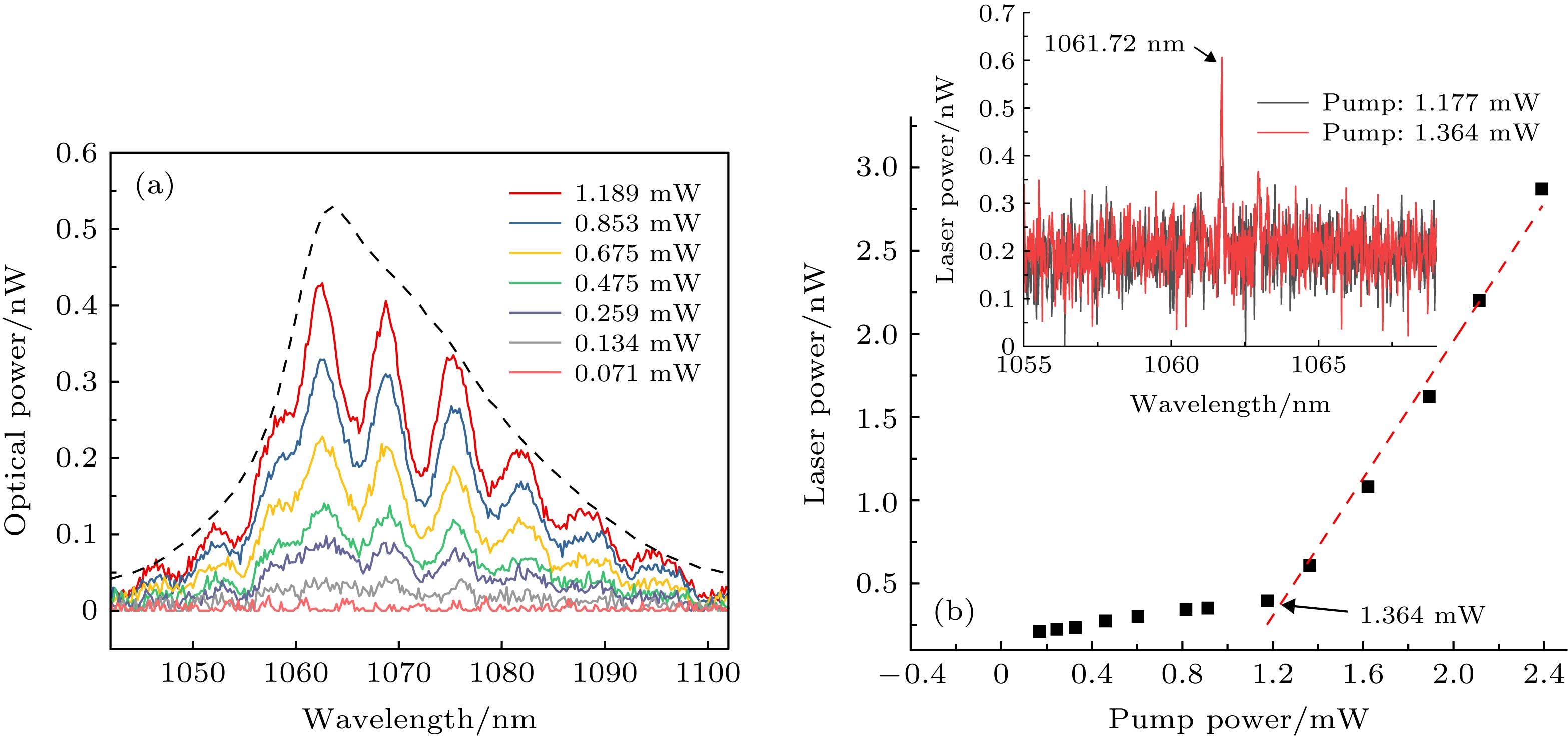

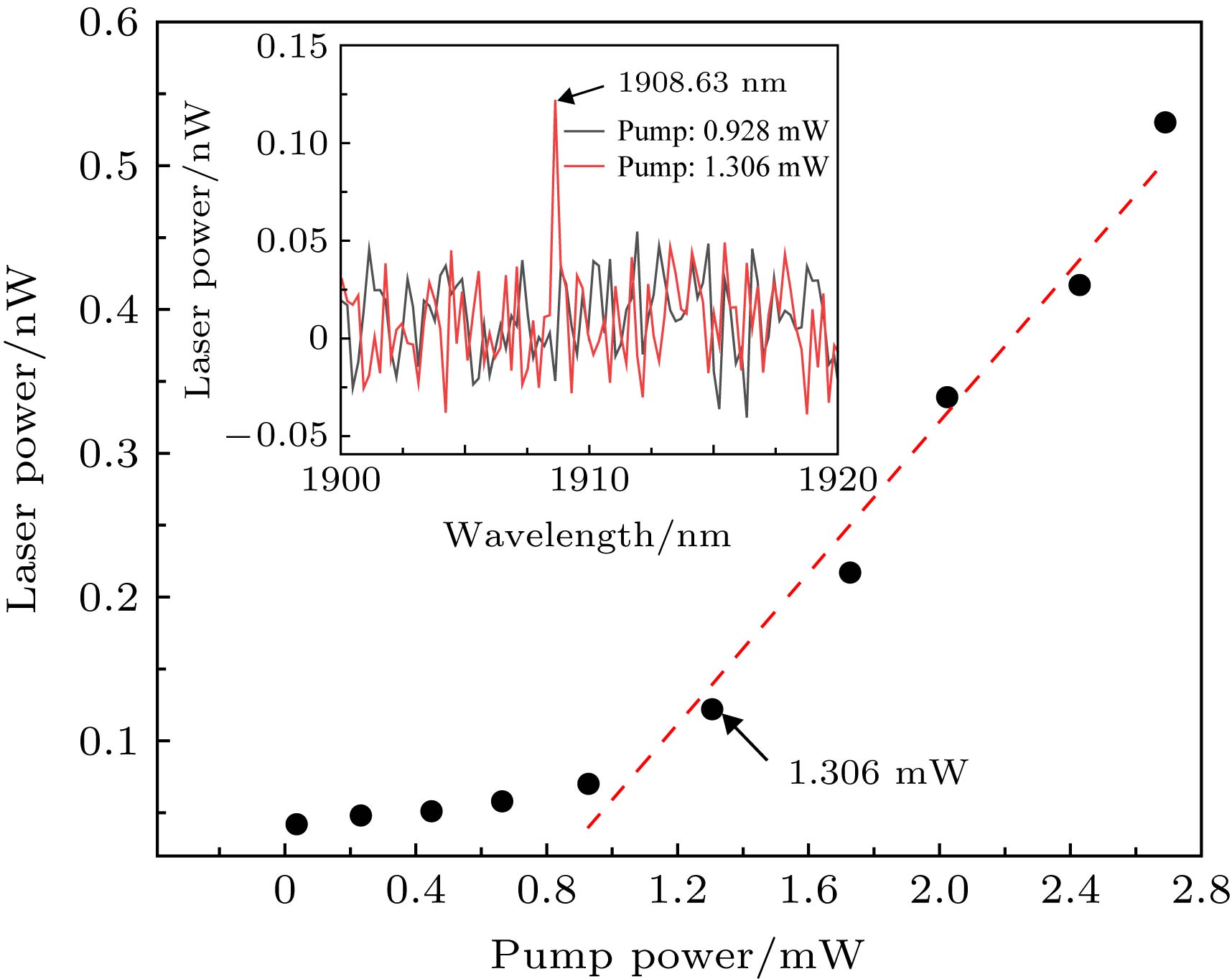

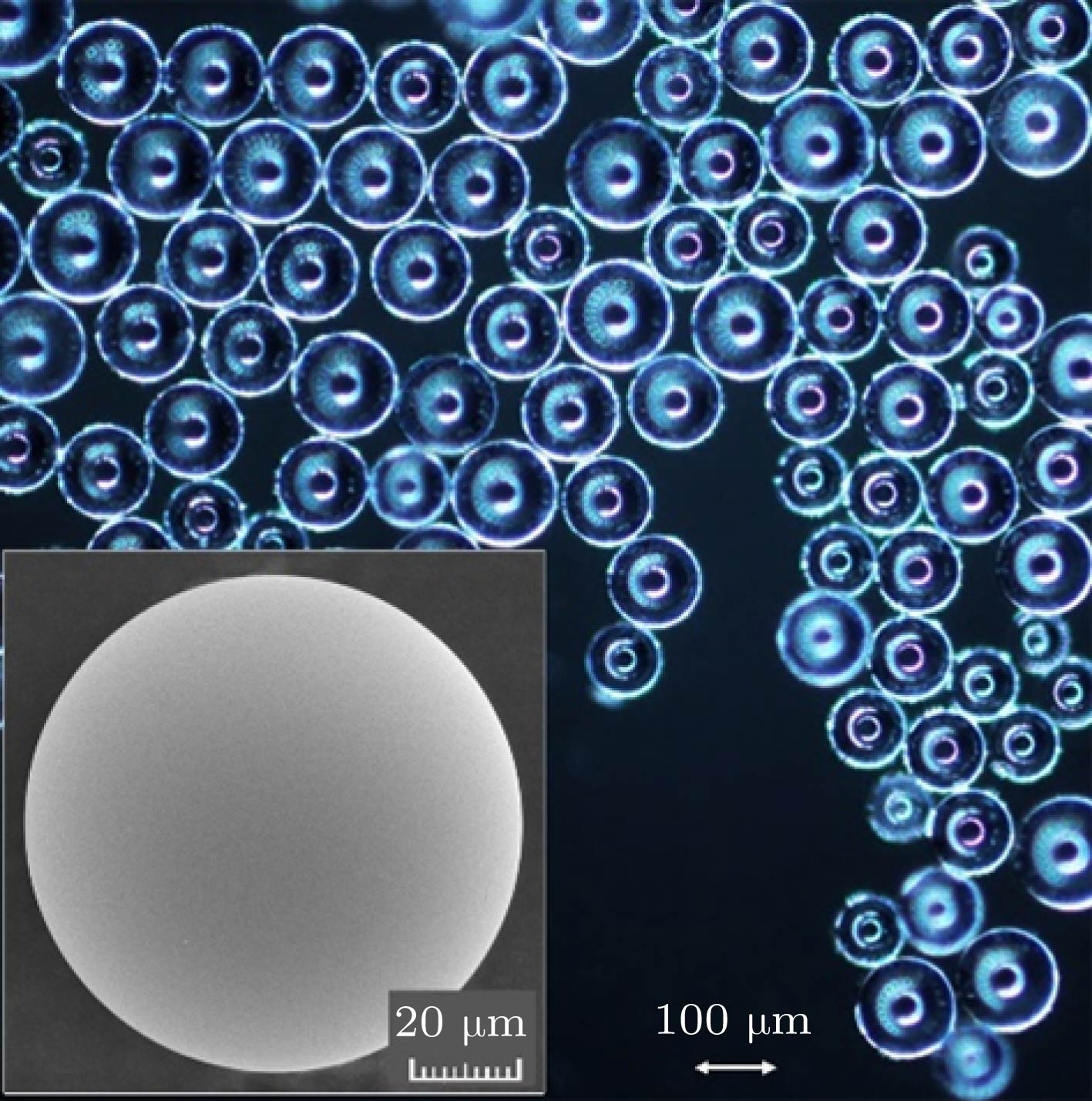

提出一种热压法制备微盘激光器的工艺, 仅使用实验室常用电阻加热炉具即可制备出不同直径/厚度的微盘激光器. 选用TeO2-ZnO-Na2O碲酸盐玻璃为基质材料, 制备出直径分布在100—400 μm范围内、最小厚度可达8 μm、典型品质因数(Q值)约为105的微盘激光器. 对碲酸盐玻璃基质材料掺入稀土离子Nd3+和Tm3+, 通过光纤锥耦合法开展微盘的抽运耦合实验, 即可在耦合系统的输出光谱中获得明显的荧光回廊模式和激光模式. 以一颗直径为105.74 μm、厚度为10.4 μm的Nd3+掺杂微盘为例, 当抽运光功率提升至1.364 mW以上时, 即可在1.06 μm附近获得激光峰. 同样实验表明, 对Tm3+掺杂的微盘进行抽运耦合实验可获得1.9 μm附近的激光峰.In this work, we report a two-step thermal pressing method of fabricating microdisk lasers that are suitable for processing thermally stable glass materials, and we utilize a tellurite glass (TeO2-ZnO-Na2O) to demonstrate the feasibility of this method. Compared with the conventional microdisk fabricating methods that rely on a series of complicated procedures, such as lithography, etching, thermal reflow, and ion implantation, this thermal pressing method involves only two heating procedures and can be accomplished with simple laboratory resistive heating furnaces. In the first heating procedure, we crush bulk tellurite glass into powders and drop those powders through a vertical heating furnace. Glass powders are transformed into microspheres by surface tension in the furnace. In the second heating procedure, microspheres are placed between two flat/smooth surfaces and are thermally treated when being pressed with suitable weights. With this procedure, the “flattened” microspheres turn into the microdisks. In this work, we demonstrate that our fabricated tellurite glass microdisks possess diameters of 100-400 μm, thinnest thickness of ~ 8 μm, and typical quality-factor (Q-factor) of ~ 105. We also dope tellurite glass with active dopants such as Nd3+ and Tm3+ to fabricate the active microdisk resonators. We couple those active microdisk resonators with fiber tapers and demonstrate that with appropriate pump power, apparent fluorescence whispering gallery mode and laser mode can be obtained. Taking a 105.74-μm-diameter, 10.4-μm-thickness, and Nd3+-doped tellurite glass microdisk for example, we show that as the pump power increases above a threshold of 1.364 mW, a lasing peak near 1.06 μm can be obtained. We also show that lasing peaks near 1.9 μm can be obtained by coupling/pumping Tm3+ doped microdisks.

-

Keywords:

- thermal pressing /

- microdisk laser /

- whispering gallery mode /

- tellurite glass

[1] Sandoghdar V, Treussart F, Hare J, Lefevre-Seguin V, Raimond J, Haroche S 1996 Phys. Rev. A 54 R1777

Google Scholar

Google Scholar

[2] Murugan G S, Zervas M N, Panitchob Y, Wilkinson J S 2011 Opt. Lett. 36 73

Google Scholar

Google Scholar

[3] 黄衍堂, 彭隆祥, 庄世坚, 李强龙, 廖廷俤, 许灿华, 段亚凡 2017 66 244208

Google Scholar

Google Scholar

Huang Y T, Peng L X, Zhuang S J, Li Q L, Liao Y D, Xu C H, Duan Y F 2017 Acta Phys. Sin. 66 244208

Google Scholar

Google Scholar

[4] Gorajoobi S B, Murugan G S, Zervas M N 2019 Opt. Express 27 25493

Google Scholar

Google Scholar

[5] Qian K, Tang J, Guo H, Zhang W, Liu J H, Liu J, Xue C Y, Zhang W D 2016 Chin. Phys. B 25 114209

Google Scholar

Google Scholar

[6] Vernooy D W, Ilchenko V S, Mabuchi H, Streed E W, Kimble H J 1998 Opt. Lett. 23 247

Google Scholar

Google Scholar

[7] Sasagawa K, Yonezawa Z, Iwai R, Ohta J, Nunoshita M 2004 Appl. Phys. Lett. 85 4325

Google Scholar

Google Scholar

[8] Peng X, Song F, Jiang S, Peyghambarian N, Kuwata-Gonokami M, Xu L 2003 Appl. Phys. Lett. 82 1497

Google Scholar

Google Scholar

[9] Elliott G R, Hewak D W, Murugan G S, Wilkinson J S 2007 Opt. Express 15 17542

Google Scholar

Google Scholar

[10] Li C, Dai S, Zhang Q, Shen X, Wang X, Zhang P, Lu L, Wu Y, Lv S 2015 Chin. Phys. B 24 044208

Google Scholar

Google Scholar

[11] 胡博, 吴越豪, 郑雨璐, 戴世勋 2019 68 064209

Google Scholar

Google Scholar

Hu B, Wu Y H, Zheng Y L, Dai S X 2019 Acta Phys. Sin. 68 064209

Google Scholar

Google Scholar

[12] Yang K, Dai S X, Wu Y H, Nie Q H 2018 Chin. Phys. B 27 117701

Google Scholar

Google Scholar

[13] Spillane S M, Kippenberg T J, Vahala K J, Goh K W, Wilcut E, Kimble H J 2005 Phys. Rev. A 71 013817

Google Scholar

Google Scholar

[14] Kippenberg T J, Spillane S M, Vahala K J 2004 Appl. Phys. Lett. 85 6113

Google Scholar

Google Scholar

[15] Wang T J, He J Y, Lee C A, Niu H 2012 Opt. Express 20 028119

Google Scholar

Google Scholar

[16] Tulek A, Akbulut D, Bayindir M 2009 Appl. Phys. Lett. 94 203302

Google Scholar

Google Scholar

[17] Polman A, Min B, Kalkman J, Kippenberg T J, Vahala K J 2004 Appl. Phys. Lett. 84 1037

Google Scholar

Google Scholar

[18] Zou L X, Liu B W, Lv X M, Yang Y D, Xiao J L, Huang Y Z 2015 Appl. Phys. Lett. 106 191107

Google Scholar

Google Scholar

[19] Yang Z, Wu Y, Yang K, Xu P, Zhang W, Dai S, Xu T 2017 Opt. Mat. 72 524

Google Scholar

Google Scholar

[20] Li A Z, Zhang J Q, Zhang M, Li W H, Wang S B, Lewis E, Brambilla G, Wang P F 2018 Opt. Lett. 43 4325

Google Scholar

Google Scholar

[21] Jiang S S, Guo C L, Che K J, Luo Z Q, Du T J, Fu H Y, Xu H Y, Cai Z P 2019 Photon. Res. 7 566

Google Scholar

Google Scholar

-

图 6 (a)从一颗掺Nd3+的有源微盘谐振腔中获取的不同抽运功率下的回廊模; (b)微盘谐振腔的激光阈值现象(内插图为微盘谐振腔在抽运阈值附近(1.177 mW和1.364 mW)出现的激光峰)

Fig. 6. (a) Whispering gallery mode patterns obtained with a Nd3+-doped tellurite glass microdisk at different pump powers; (b) threshold behavior of the microdisk laser. Inset in panel (b) shows the transmission spectra of the coupling system at pump powers of 1.177 mW and 1.364 mW.

图 7 从一颗掺Tm3+微盘(直径为104.34 μm, 厚度为15.86 μm)中测得的激光阈值现象(内插图为微盘谐振腔在抽运阈值(0.928 mW和1.306 mW)附近出现的位于1908.63 nm处的激光峰)

Fig. 7. Threshold behavior of a Tm3+-doped microdisk laser (diameter: 104.34 μm, thickness: 15.86 μm). Inset: transmission spectra of the coupling system at pump powers of 0.928 mW and 1.306 mW.

-

[1] Sandoghdar V, Treussart F, Hare J, Lefevre-Seguin V, Raimond J, Haroche S 1996 Phys. Rev. A 54 R1777

Google Scholar

Google Scholar

[2] Murugan G S, Zervas M N, Panitchob Y, Wilkinson J S 2011 Opt. Lett. 36 73

Google Scholar

Google Scholar

[3] 黄衍堂, 彭隆祥, 庄世坚, 李强龙, 廖廷俤, 许灿华, 段亚凡 2017 66 244208

Google Scholar

Google Scholar

Huang Y T, Peng L X, Zhuang S J, Li Q L, Liao Y D, Xu C H, Duan Y F 2017 Acta Phys. Sin. 66 244208

Google Scholar

Google Scholar

[4] Gorajoobi S B, Murugan G S, Zervas M N 2019 Opt. Express 27 25493

Google Scholar

Google Scholar

[5] Qian K, Tang J, Guo H, Zhang W, Liu J H, Liu J, Xue C Y, Zhang W D 2016 Chin. Phys. B 25 114209

Google Scholar

Google Scholar

[6] Vernooy D W, Ilchenko V S, Mabuchi H, Streed E W, Kimble H J 1998 Opt. Lett. 23 247

Google Scholar

Google Scholar

[7] Sasagawa K, Yonezawa Z, Iwai R, Ohta J, Nunoshita M 2004 Appl. Phys. Lett. 85 4325

Google Scholar

Google Scholar

[8] Peng X, Song F, Jiang S, Peyghambarian N, Kuwata-Gonokami M, Xu L 2003 Appl. Phys. Lett. 82 1497

Google Scholar

Google Scholar

[9] Elliott G R, Hewak D W, Murugan G S, Wilkinson J S 2007 Opt. Express 15 17542

Google Scholar

Google Scholar

[10] Li C, Dai S, Zhang Q, Shen X, Wang X, Zhang P, Lu L, Wu Y, Lv S 2015 Chin. Phys. B 24 044208

Google Scholar

Google Scholar

[11] 胡博, 吴越豪, 郑雨璐, 戴世勋 2019 68 064209

Google Scholar

Google Scholar

Hu B, Wu Y H, Zheng Y L, Dai S X 2019 Acta Phys. Sin. 68 064209

Google Scholar

Google Scholar

[12] Yang K, Dai S X, Wu Y H, Nie Q H 2018 Chin. Phys. B 27 117701

Google Scholar

Google Scholar

[13] Spillane S M, Kippenberg T J, Vahala K J, Goh K W, Wilcut E, Kimble H J 2005 Phys. Rev. A 71 013817

Google Scholar

Google Scholar

[14] Kippenberg T J, Spillane S M, Vahala K J 2004 Appl. Phys. Lett. 85 6113

Google Scholar

Google Scholar

[15] Wang T J, He J Y, Lee C A, Niu H 2012 Opt. Express 20 028119

Google Scholar

Google Scholar

[16] Tulek A, Akbulut D, Bayindir M 2009 Appl. Phys. Lett. 94 203302

Google Scholar

Google Scholar

[17] Polman A, Min B, Kalkman J, Kippenberg T J, Vahala K J 2004 Appl. Phys. Lett. 84 1037

Google Scholar

Google Scholar

[18] Zou L X, Liu B W, Lv X M, Yang Y D, Xiao J L, Huang Y Z 2015 Appl. Phys. Lett. 106 191107

Google Scholar

Google Scholar

[19] Yang Z, Wu Y, Yang K, Xu P, Zhang W, Dai S, Xu T 2017 Opt. Mat. 72 524

Google Scholar

Google Scholar

[20] Li A Z, Zhang J Q, Zhang M, Li W H, Wang S B, Lewis E, Brambilla G, Wang P F 2018 Opt. Lett. 43 4325

Google Scholar

Google Scholar

[21] Jiang S S, Guo C L, Che K J, Luo Z Q, Du T J, Fu H Y, Xu H Y, Cai Z P 2019 Photon. Res. 7 566

Google Scholar

Google Scholar

计量

- 文章访问数: 10149

- PDF下载量: 69

- 被引次数: 0

下载:

下载: