-

Positron annihilation technique is an atomic-scale characterization method used to analyze the defects and microstructure of materials, which is extremely sensitive to open volume defects. By examining the annihilation behaviour of positrons and electrons in open volume defects, local electron density and atomic structure information around the annihilation site can be obtained, such as the size and concentration of vacancies, and vacancy clusters. In recent years, positron annihilation spectroscopy has evolved into a superior tool for characterizing features of material compared with conventional methods. The coincident Doppler broadening technique provides unique advantages for examining the local electronic structure and chemical environment (elemental composition) information about defects due to its effectiveness describing high momentum electronic information. The low momentum portion of the quotient spectrum indicates the Doppler shift generated by the annihilation of valence electrons near the vacancy defect. Changes in the peak amplitudes and positions of the characteristic peaks in the high momentum region can reveal elemental information about the positron annihilation point. The physical mechanism of element segregation, the structural features of open volume defects and the interaction between interstitial atoms and vacancy defects are well investigated by using the coincidence Doppler broadening technology. In recent years, based on the development of Doppler broadening technology, the sensitivity of slow positron beam coincidence Doppler broadening technology with adjustable energy has been significantly enhanced at a certain depth. It is notable that slow positron beam techniques can offer surface, defect, and interface microstructural information as a function of material depth. It compensates for the fact that the traditional coincidence Doppler broadening technique can only determine the overall defect information. Positron annihilation technology has been applied to the fields of second phase evolution in irradiated materials, hydrogen/helium effect, and free volume in thin films, as a result of the continuous development of slow positron beam and the improvement of various experimental test methods based on slow positron beam. In this paper, the basic principles of the coincidence Doppler broadening technique are briefly discussed, and the application research progress of the coincidence Doppler broadening technique in various materials is reviewed by combining the reported developments: 1) the evolution behaviour of nanoscale precipitation in alloys; 2) the interaction between lattice vacancies and impurity atoms in semiconductors; 3) the changes of oxygen vacancy and metal cation concentration in oxide material. In addition, coincident Doppler broadening technology has been steadily used to estimate and quantify the sizes, quantities, and distributions of free volume holes in polymers.

-

Keywords:

- coincidence Doppler /

- electron momentum /

- element distribution /

- microscopic defects

[1] Lynn K G, MacDonald J R, Boie R A, Feldman L C, Gabbe J D, Robbins M F, Bonderup E, Golovchenko J 1977 Phys. Rev. Lett. 38 241

Google Scholar

Google Scholar

[2] Lynn K G, Goland A N 1976 Solid. State. Commun. 18 1549

Google Scholar

Google Scholar

[3] Zhang X, Lu G 2010 Phys. Rev. B. 82 012101

Google Scholar

Google Scholar

[4] Elsayed M, Krause-Rehberg R, Christian E, Nadine E, Bernd K 2018 Phys. Status Solidi A 215 1800036

Google Scholar

Google Scholar

[5] Abhaya S, Rajaraman R, Sarguna R M, Pradyumna K P, David C, Amarendra G 2019 J. Alloys Compd. 806 780

Google Scholar

Google Scholar

[6] 曹兴忠, 宋力刚, 靳硕学, 张仁刚, 王宝义, 魏龙 2017 66 027801

Google Scholar

Google Scholar

Cao X Z, Song L G, Jin S X, Zhang R G, Wang B Y, Wei L 2017 Acta Phys. Sin. 66 027801

Google Scholar

Google Scholar

[7] 胡远超, 曹兴忠, 李玉晓, 张鹏, 靳硕学, 卢二阳, 于润升, 魏龙, 王宝义 2015 64 247804

Google Scholar

Google Scholar

Hu Y C, Cao X Z, Li Y X, Zhang P, Jin S X, Lu E Y, Yu R S, Wei L, Wang B Y 2015 Acta Phys. Sin. 64 247804

Google Scholar

Google Scholar

[8] Grafutin V I, Prokop’ev E P 2002 Phys. Usp. 45 59

Google Scholar

Google Scholar

[9] 郗传英 2005 博士学位论文 (合肥: 中国科学技术大学)

Xi C Y 2005 Ph. D. Dissertation (Hefei: University of Science and Technology of China

[10] Ishizaki T, Yoshiie T, Sato K, Yanagita S, Xu Q, Komatsu M, Kiritani M 2003 Mater. Sci. Eng. A 350 102

Google Scholar

Google Scholar

[11] Elsayed M, Bondarenko V, Petters K, Gebauer J, Krause-Rehberg R 2008 J. Appl. Phy. 104 103526

Google Scholar

Google Scholar

[12] Xia R, Cao X Z, Gao M Z, Zhang P, Zeng M F, Wang B Y, Wei L 2017 Phys. Chem. Chem. Phys. 19 3616

Google Scholar

Google Scholar

[13] Karwasz G P, Zecca A, Brusa R S, Pliszkab D 2004 J. Alloys Compd. 382 244

Google Scholar

Google Scholar

[14] Utpalla P, Sharma S K, Sudarshan K, Kumar V, Pujari P K 2019 Eur. Polym. J. 117 10

Google Scholar

Google Scholar

[15] Suzuki T, He C Q, Kondo K, Shantarovich V, Ito Y 2003 Radiat. Phys. Chem. 68 489

Google Scholar

Google Scholar

[16] Sharma S K, Prakash J, Bahadur J, Sudarshan K, Maheshwari P, Mazumderc S, Pujari P K 2014 Phys. Chem. Chem. Phys. 16 1399

Google Scholar

Google Scholar

[17] Seeger A 1973 J. Phys. F: Met. Phys. 3 284

Google Scholar

Google Scholar

[18] 朱特, 曹兴忠 2020 69 177801

Google Scholar

Google Scholar

Zhu T, Cao X Z 2020 Acta Phys. Sin. 69 177801

Google Scholar

Google Scholar

[19] Wang B Y, Cao X Z, Yu R S, Wei C F, Zhang Z M, Ma C X, Chang T B, Pei G X, Li J C, Zheng L S, Wei L, Wang T M, He Y J, Yu W Z, Zhu S Y 2004 Positron Annihilation, ICPA-13 Proceedings Kyoto, Japan Sep 7–12, 2003 pp513–515

[20] Zhang R G, Wang B Y, Zhang H, Wei L 2005 Appl. Surf. Sci. 245 340

Google Scholar

Google Scholar

[21] Wan D Y, Wang Y T, Wang B Y, Ma C X, Sun H, Wei L 2003 J. Cryst. Growth 253 230

Google Scholar

Google Scholar

[22] 王丹妮, 王宝义, 张兰芝, 钟玉荣, 章志明, 李道武, 魏龙, 张天保 2008 核技术 31 577

Google Scholar

Google Scholar

Wang D N, Wang B Y, Zhang L Z, Zhong Y R, Zheng Z M, Li D W, Wei L, Zhang T B 2008 Nucl. Tech. 31 577

Google Scholar

Google Scholar

[23] Asoka-Kumar P, Alatalo M, Ghosh V J, Kruseman A C, Nielsen B, Lynn K G 1996 Phys. Rev. B 77 2097

Google Scholar

Google Scholar

[24] Brusa R S, Deng W, Karwasz G P, Zecca A 2002 Nucl. Instrum. Methods Phys. Res. , Sect. B 194 519

Google Scholar

Google Scholar

[25] Xi C Y, Ye B J, Kong W, Weng H M, Zhou X Y, Han R D 2006 Chin. J. Chem. Phys. 19 203

Google Scholar

Google Scholar

[26] Lee S U, Lee Y J, Kim J R, Jeong K E, Jeong S Y 2019 J. Ind. Eng. Chem. 79 443

Google Scholar

Google Scholar

[27] Sugita K, Ogawa R, Mizuno M, Araki Hm, Yabuuchi A 2022 Scr. Mater. 208 114339

Google Scholar

Google Scholar

[28] Jin K, Guo W, Lu C Y, Ullah M W, Zhang Y W, Weber W J, Wang L M, Poplawsky J D, Bei H B 2016 Acta Mater. 121 365

Google Scholar

Google Scholar

[29] Jin S X, Zhang P, Lu E Y, Guo L P, Wang B Y, Cao X Z 2016 Acta Mater. 103 658

Google Scholar

Google Scholar

[30] Zhong Z H, Xu Q, Mori K, Tokitani M 2019 Philos. Mag. 99 1515

Google Scholar

Google Scholar

[31] 王少阶 2008 应用正电子谱学(上卷) (武汉: 湖北科学技术出版社) 第85页

Wang S J 2008 Applied Positron Spectroscopy (Vol. 1) (Wuhan: Hubei Science and Technology Press) p85

[32] Onitsuka T, Takenaka M, Kuramoto, Nagai Y, Hasegawa M 2001 Phys. Rev. B 65 012204

Google Scholar

Google Scholar

[33] Bartha K, Zháňal P, Stráský J, Čížek J, Dopita M, Lukáč F, Harcuba P, Hájek M, Polyakova V, Semenova I, Janečeka M 2019 J. Alloys Compd. 788 771

Google Scholar

Google Scholar

[34] Nagai Y, Hasegawa M, Tang Z, Hempel A, Yubuta K, Shimamura T, Kawazoe Y, Kawai A, Kano F 2000 Phys. Rev. B 61 6574

Google Scholar

Google Scholar

[35] Liu X S, Zhang P, Wang B Y, Cao X Z, Jin S X, Yu R S 2021 Materials 14 1451

Google Scholar

Google Scholar

[36] Abhaya S, Rajaraman S. Kalavathi R, Amarendra G 2015 J. Alloys Compd. 620 277

Google Scholar

Google Scholar

[37] Ye F J, Zhu T, Wang Q Q, Song Y M, Zhang H Q, Kuang P, Zhang P, Yu R S, Cao X Z, Wang B Y 2022 Intermetallics 149 107670

Google Scholar

Google Scholar

[38] Nagai Y, Tang Z, Hassegawa M, Kanai T, Saneyasu M 2001 Phys. Rev. B 63 134110

Google Scholar

Google Scholar

[39] Xu Q, Yoshiie T, Sato K 2007 Phys. Status Solidi C 4 3573

Google Scholar

Google Scholar

[40] Wang X W, ZhongY R, Wang B Y, Zhang H Y 2009 J. Mater. Res. 24 1794

Google Scholar

Google Scholar

[41] 王茜茜 2022 硕士学位论文 (贵阳: 贵州大学)

Wang Q Q 2022 M. S. Thesis (Guiyang: Guizhou University

[42] Sabelová V, Kršjak V, Kuriplach Jm, Dai Y, Slugeň V 2015 J. Nucl. Mater. 458 350

Google Scholar

Google Scholar

[43] Fujii K, Fukuya K, Nakata N, Hono K, Nagai Y, Hasegawa M 2005 J. Nucl. Mater. 340 247

Google Scholar

Google Scholar

[44] Ge W N, Rahman A, Cheng H, Zhang M, Liu J D, Zhang Z M, Ye B J 2018 J. Magn. Magn. Mater. 449 401

Google Scholar

Google Scholar

[45] Kundu R, Bhattacharya S, Roy D, Nambissan P M G 2017 RSC Adv. 7 8131

Google Scholar

Google Scholar

[46] Qin M J, Gao F, Cizek J, Yang S J, Fan X L, Zhao L L, Xu J, Dong G G, Reece M, Yan H X 2019 Acta Mater. 164 76

Google Scholar

Google Scholar

[47] Ahmed M, Mukherjee S, Singha T, Nambissan P M G 2023 J. Phys. Chem. Solids 181 111513

Google Scholar

Google Scholar

[48] Thorat A V, Ghoshal T, Morris M A, Nambissan P M G 2014 Acta Phys. Pol. A 125 756

Google Scholar

Google Scholar

[49] Das A, Mandal A C, Roy S, Prashanth P, Ahamed S I, Kar S, Prasad M S, Nambissan P M G 2016 Physica E 83 389

Google Scholar

Google Scholar

[50] Ghosh S, Khan G K, Mandal K, Samanta A, Nambissan P M G 2013 J. Phys. Chem. C 117 8458

Google Scholar

Google Scholar

[51] Das A 2019 Curr. Sci. 117 1990

Google Scholar

Google Scholar

[52] Yu R S, Maekawa M, Kawasuso A, Wang B Y, Wei L 2012 Nucl. Instrum. Methods Phys. Res. , Sect. B 270 47

Google Scholar

Google Scholar

[53] Elsayed M, Krause-Rehberg R, Korff B, Ratschinski I, Leipner H S 2013 Eur. Phys. J. B 86 358

Google Scholar

Google Scholar

[54] Xu J, Moxom J, Somieski B, White C W 2001 Phys. Rev. B 64 112404

Google Scholar

Google Scholar

[55] Slotte J, Makkonen I, Tuomisto F 2016 ECS J. Solid State Sci. Technol. 5 3166

Google Scholar

Google Scholar

[56] Simpson P J, Jenei Z, Asoka-Kumar P, Robison R R, Law M E 2012 Appl. Phys. Lett. 85 1538

Google Scholar

Google Scholar

[57] Das A, Mandal A C, Roy S, Nambissan P M G 2018 AIP Adv. 8 095013

Google Scholar

Google Scholar

[58] Pasang T, Namratha K, Guagliardo P, Byrappa K, Ranganathaiah C, Samarin S, FWilliams J 2015 Mater. Res. Express 2 045502

Google Scholar

Google Scholar

[59] Sharma S K, Bahadur J, Bahadur J, Sudarshan K, Maheshwari P, Mazumder S, Pujari P K 2014 Phys. Chem. Phys. Chem. 16 1399

Google Scholar

Google Scholar

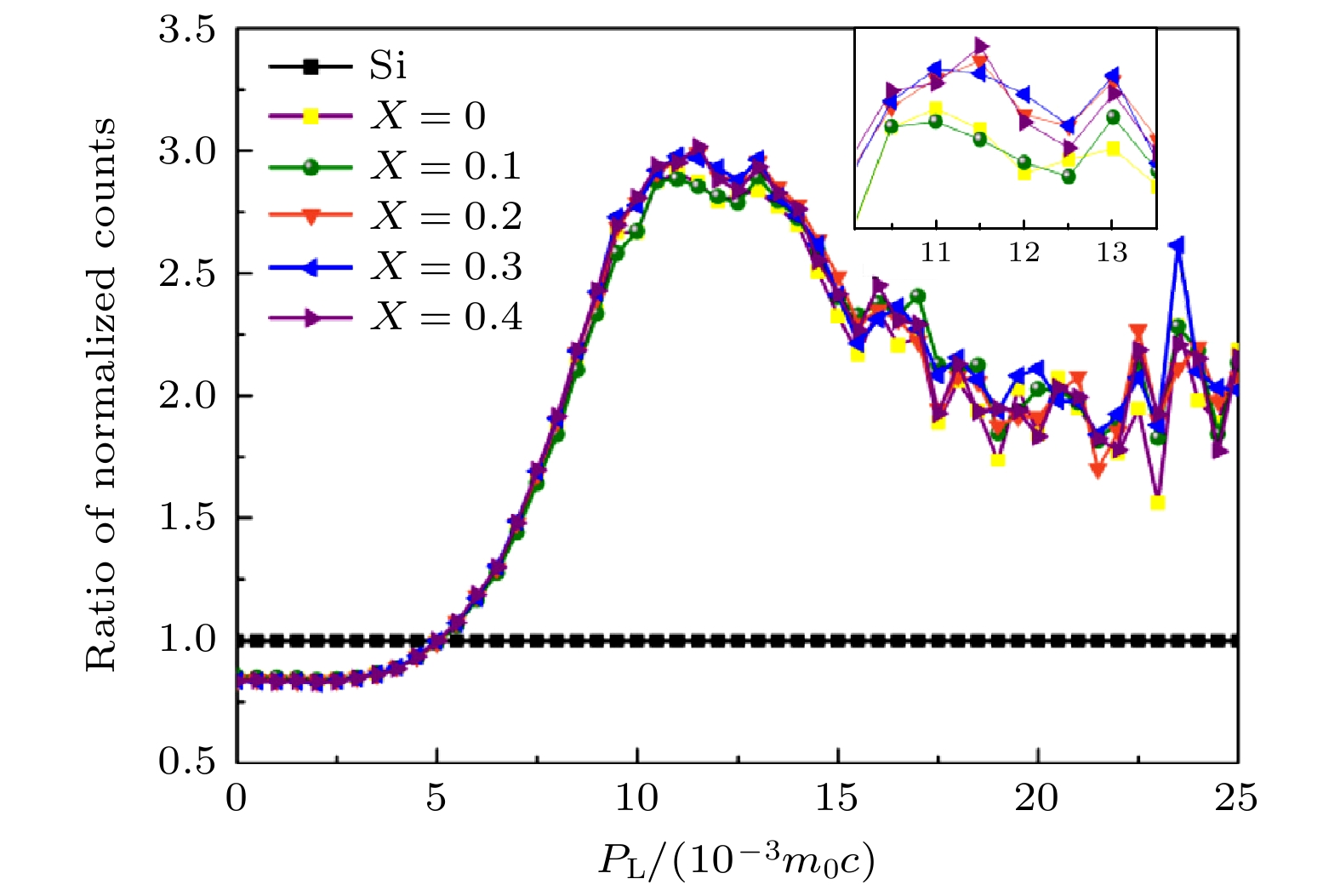

[60] Cao X Z, Xia R, Yang J, Zeng M, Wang B Y, Yu R S, Wei L 2017 Acta Phys. Pol A 132 1535

Google Scholar

Google Scholar

[61] Ghasemifard M, Ghamari M 2023 J. Appl. Polym. Sci. 141 1

Google Scholar

Google Scholar

[62] Rana U, Nambissan P M G, Malika S, Chakrabarti K 2014 Phys. Chem. Chem. Phys. 7 3292

Google Scholar

Google Scholar

[63] Cao X Z, Zhu T, Jin S X, Kuang P, Zhang P, Lu E Y, Gong Y H, Guo L P, Wang B Y 2017 Appl. Phys. A 123 176

Google Scholar

Google Scholar

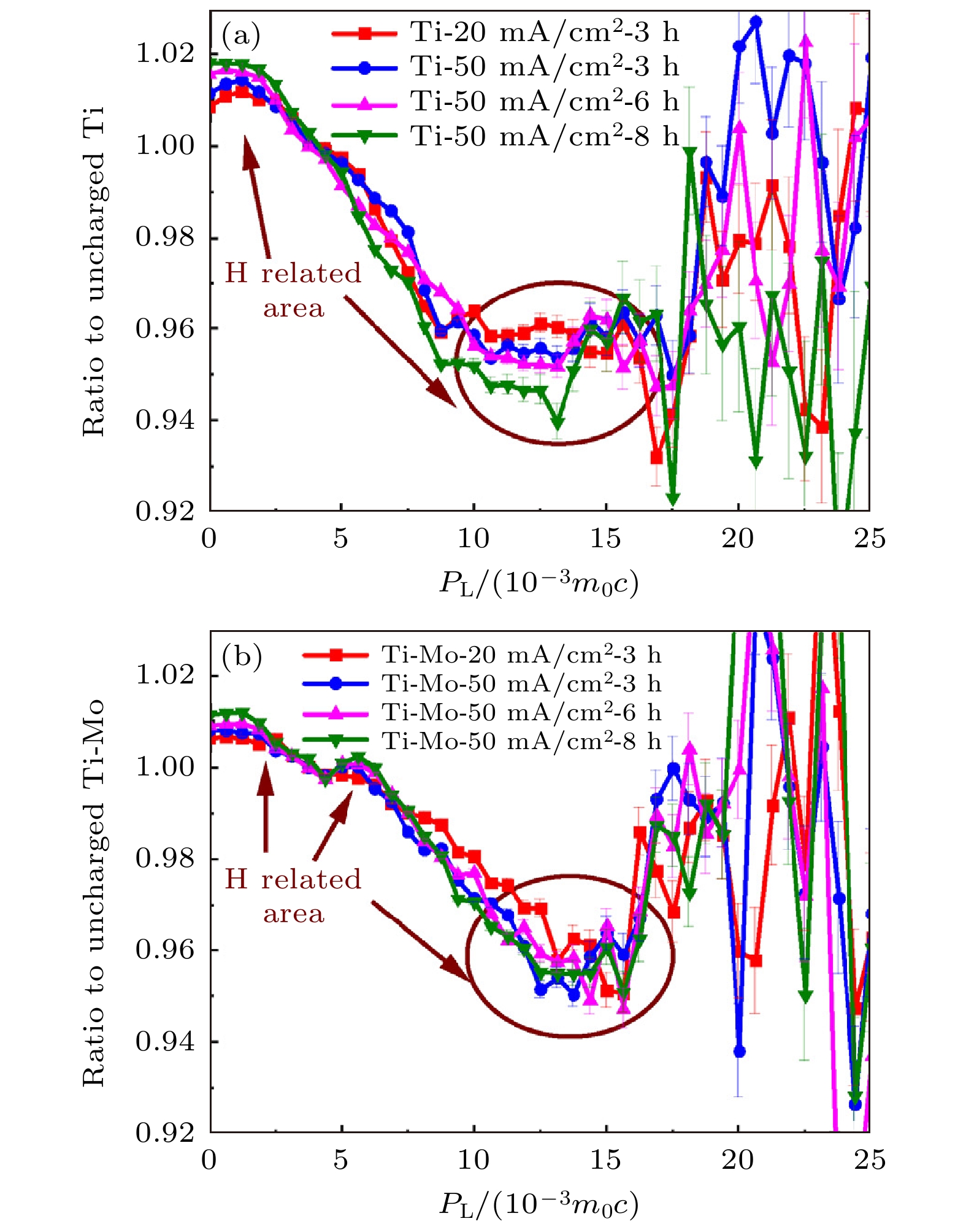

[64] An X D, Zhu T, Wan M P, Li Y H, Wang Q Q, Zhang P, Liu J Y, Song Y M, Zhang Z K, Wang B Y, Cao X Z 2021 Int. J. Hydrogen Energy 46 13163

Google Scholar

Google Scholar

[65] Wang Q Q, An X D, Zhu T, Wan M P, Zhang P, Ye F J, Song Y M, Huang C W, Ma R, Wang B Y, Cao X Z 2021 J. Alloys Compd. 885 160909

Google Scholar

Google Scholar

[66] Fujinami M, Sawada T, Akahane T 2003 Radiat. Phys. Chem. 68 631

Google Scholar

Google Scholar

[67] Beyerlein I J, Demkowicz M J, Misraa A, Uberuaga B P 2015 Prog. Mater. Sci. 74 125

Google Scholar

Google Scholar

[68] Liu Y L, Song L G, Chen Y, Bai R Y, Wang Z, Zhu T, Zhang P, Jin S X, Wang H H, Lu E Y, Cao X Z, Wang B Y 2021 Fusion Eng. Des. 162 112118

Google Scholar

Google Scholar

[69] Ren X L, Yao B D, Zhu T, Zhong Z H, Wang Y X, Cao X Z, Jinno S, Xu Q 2020 Intermetallics 126 106942

Google Scholar

Google Scholar

[70] Zhang L Z, Wang D N, Wang B Y, Yu R S, Wei L 2007 Appl. Surf. Sci. 253 7309

Google Scholar

Google Scholar

[71] Reiner M, Pikart P, Hugenschmidt C 2014 J. Alloys Compd. 587 515

Google Scholar

Google Scholar

[72] Khanam A, Slotte J, Tuomisto F, Subhechha S, Popovici M, Kar G S 2022 J. Appl. Phys. 131 245301

Google Scholar

Google Scholar

[73] 杨静 2015 博士学位论文 (北京: 中国科学院高能物理研究所)

Yang J 2015 Ph. D. Dissertation (Beijing: Institute of High Energy Physics, Chinese Academy of Sciences

[74] Wiktor J, Jomard G, Torrent M 2015 Phys. Rev. B 93 125113

Google Scholar

Google Scholar

[75] Yang Q G, Cao X Z, Wang B Y, Wang P, Olsson P 2023 Phys. Rev. B 108 104113

Google Scholar

Google Scholar

[76] Simula K A, Haerkönen J, Zhelezova I, Drummond N D, Tuomisto F, Makkonen I 2023 Phys. Rev. B 108 045201

Google Scholar

Google Scholar

[77] Makkonen I, Hakala M, Puska M J 2006 Phys. Rev. B 73 035103

Google Scholar

Google Scholar

[78] Puska M J, Seitsonen A P, Nieminen R M 1995 Phys. Rev. B 52 10947

Google Scholar

Google Scholar

[79] Yang Q G, Hu Z, Makkonen L, Desgardin P, Egger W, Barthe M F, Olsson P 2022 J. Nucl. Mater. 571 154019

Google Scholar

Google Scholar

[80] 刘永利 2022 博士学位论文 (北京: 中国科学院高能物理研究所)

Liu Y L 2022 Ph. D. Dissertation (Beijing: Institute of High Energy Physics, Chinese Academy of Sciences

[81] Yang Q G, Olsson P 2023 Acta Mater. 242 118429

Google Scholar

Google Scholar

[82] Elsayed M, Staab T E M, Čížek J, Krause-Rehberg R 2021 Acta Mater. 219 117228

Google Scholar

Google Scholar

[83] Elsayed M, Krause-Rehberg R, Korff B, Richter S, Leipner H S 2013 J. Appl. Phys. 113 094902

Google Scholar

Google Scholar

[84] Rauch C, Makkonen I, Tuomisto F 2011 Phys Status Solidi A 208 1548

Google Scholar

Google Scholar

[85] Makkonena I, Hakalab M, Puska M J 2006 Physica B 376-377 972

Google Scholar

Google Scholar

[86] Slotte J, Tuomisto F 2012 Mater. Sci. Semicond. Process. 15 669

Google Scholar

Google Scholar

[87] Linez F, Makkonen I, Tuomisto F 2016 Phys. Rev. B 94 014103

Google Scholar

Google Scholar

-

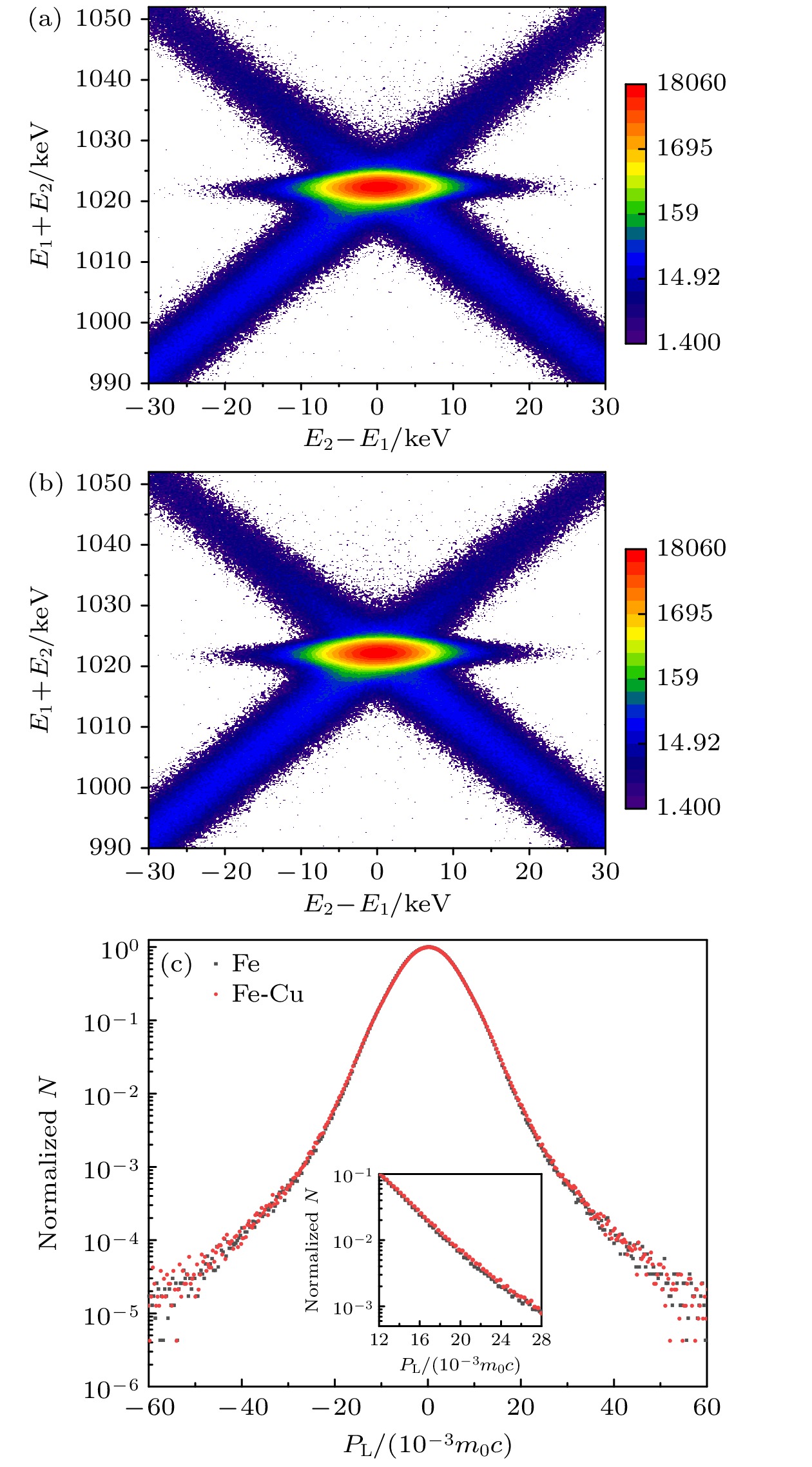

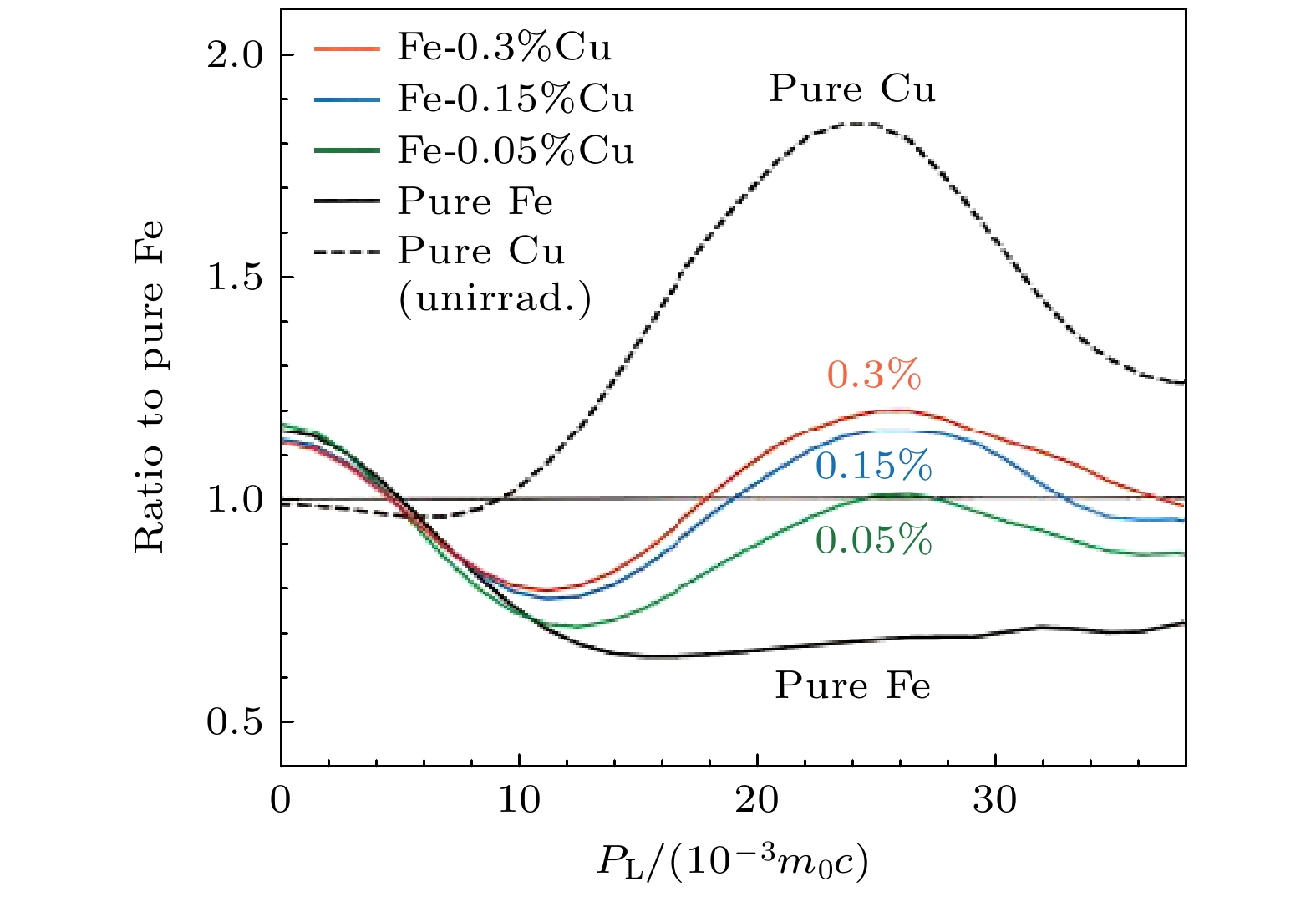

图 3 不同样品的CDB谱图 (a) 纯Fe样品; (b) Fe-Cu样品; (c)对角化后的纯Fe和Fe-Cu样品. 插图为Cu特征峰(PL = 12×10–3m0c—28×10–3m0c)附近的扩展图

Figure 3. CDB spectra of different samples: (a) Pure Fe; (b) Fe-Cu samples; (c) pure Fe and Fe-Cu samples after diagonalization. Inset is an extended view near the Cu characteristic peak (PL = 12×10–3m0c—28×10–3m0c)

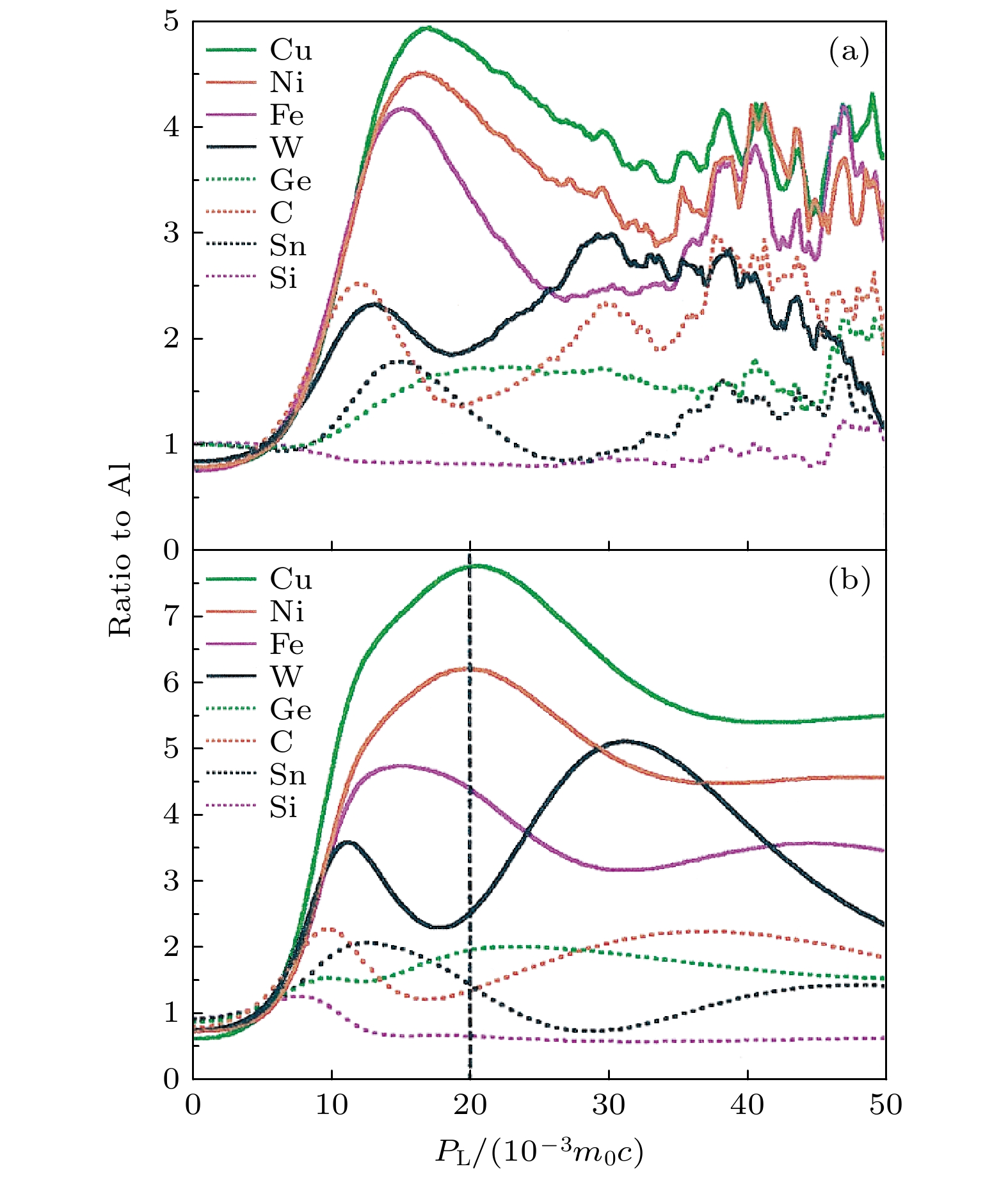

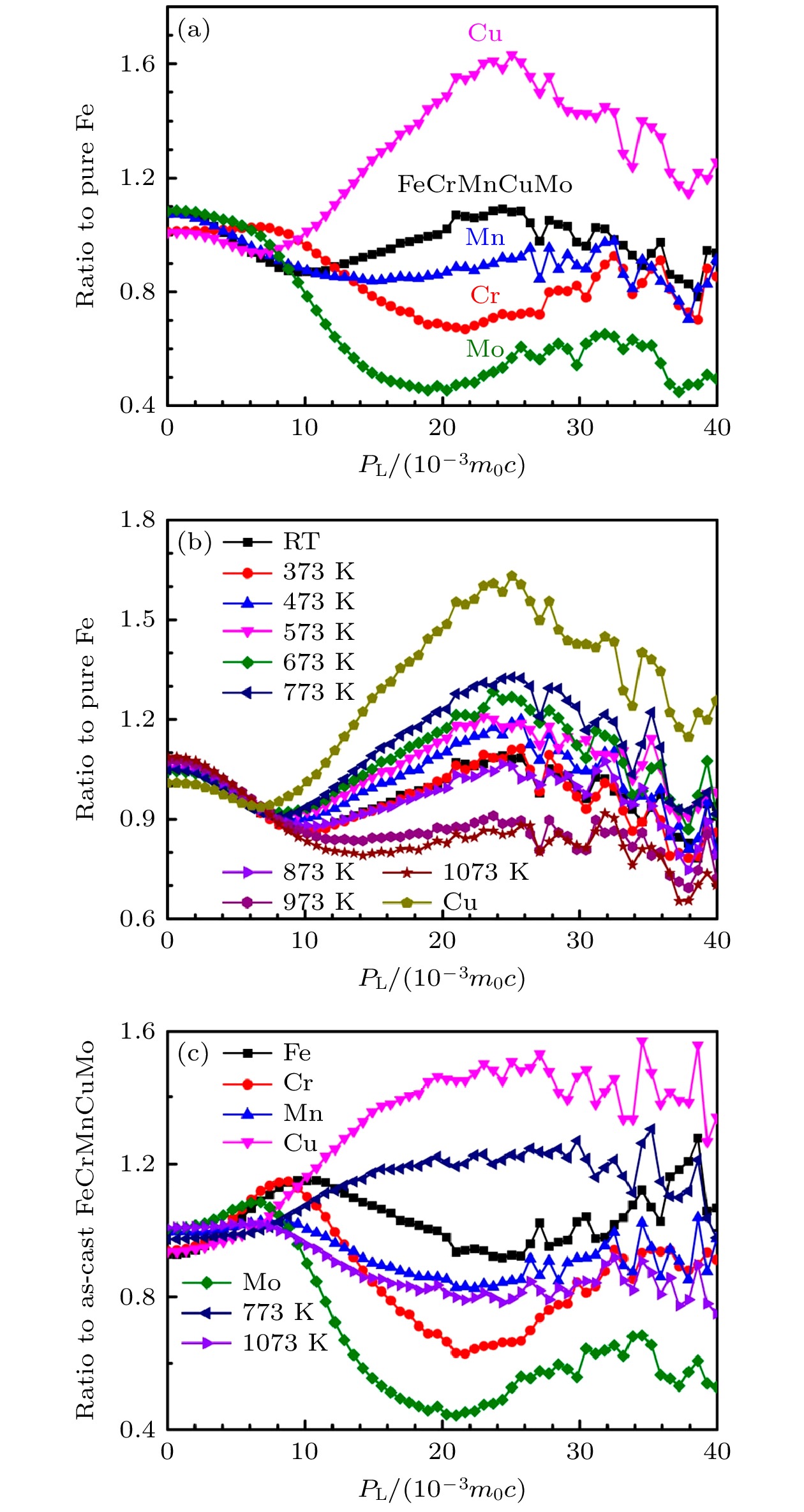

图 10 (a) FeCrMnCuMo合金、纯Cr, Mn, Cu和Mo相对于纯Fe的CDB谱图[30]; (b) 铸态、退火态FeCrMnCuMo合金和纯Cu相对于纯Fe的CDB谱图[30]; (c)纯Fe, Cr, Mn, Cu与FeCrMnCuMo在773 K和1073 K下退火相比于铸态FeCrMnCuMo合金的CDB谱图[30]

Figure 10. (a) CDB ratio curves of the FeCrMnCuMo alloy, pure Cr, Mn, Cu and Mo with respect to pure Fe; (b) as-cast, annealed FeCrMnCuMo alloy and pure Cu with respect to pure Fe; (c) pure Fe, Cr, Mn, Cu and Mo and annealed FeCrMnCuMo alloy at 773 K and 1073 K with respect to the as-cast FeCrMnCuMo[30].

图 32 (a) Al-In合金在淬火后以及纯In的多普勒谱图[82]; (b) 模拟计算的单空位和双空位以及空位-In复合物的多普勒谱图[82]

Figure 32. (a) Doppler spectra of Al-In alloys after quenching as well as the spectrum of the pure indium reference[82]; (b) calculated ratio curves with respect to Al for mono- and di-vacancies as well as for vacancy-In complexes[82].

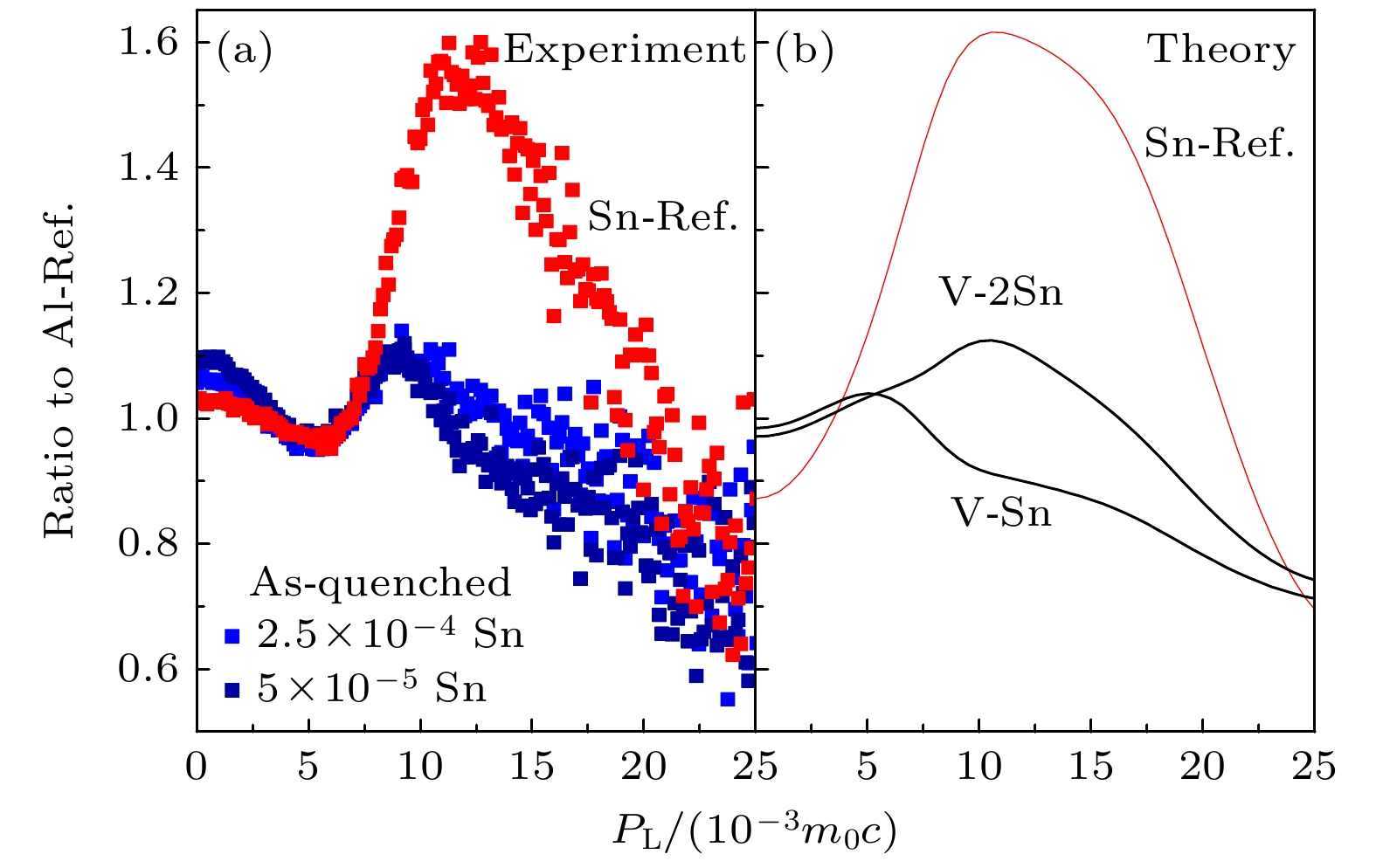

图 33 (a) Al-Sn合金在淬火后以及纯Sn的多普勒谱图[82]; (b) 模拟计算的单位和双空位以及空位-Sn复合物的多普勒谱图[82]

Figure 33. (a) Doppler spectra of Al-In alloys after quenching as well as the spectrum of the pure indium reference[82]; (b) calculated ratio curves with respect to Al for mono- and di-vacancies as well as for vacancy-In complexes[82].

图 34 (a) Zn-扩散GaAs(淬火态)和纯Zn样品的多普勒谱图[83]; (b) 理论上计算了GaAs中不同空位和空位配合物的动量密度[83]

Figure 34. (a) Results of Doppler broadening spectroscopy of Zn-diffused SI GaAs (as-quenched) and pure Zn samples[83]; (b) ratio of the momentum density to bulk GaAs for different vacancies and vacancy complexes in GaAs are theoretically calculated[83].

-

[1] Lynn K G, MacDonald J R, Boie R A, Feldman L C, Gabbe J D, Robbins M F, Bonderup E, Golovchenko J 1977 Phys. Rev. Lett. 38 241

Google Scholar

Google Scholar

[2] Lynn K G, Goland A N 1976 Solid. State. Commun. 18 1549

Google Scholar

Google Scholar

[3] Zhang X, Lu G 2010 Phys. Rev. B. 82 012101

Google Scholar

Google Scholar

[4] Elsayed M, Krause-Rehberg R, Christian E, Nadine E, Bernd K 2018 Phys. Status Solidi A 215 1800036

Google Scholar

Google Scholar

[5] Abhaya S, Rajaraman R, Sarguna R M, Pradyumna K P, David C, Amarendra G 2019 J. Alloys Compd. 806 780

Google Scholar

Google Scholar

[6] 曹兴忠, 宋力刚, 靳硕学, 张仁刚, 王宝义, 魏龙 2017 66 027801

Google Scholar

Google Scholar

Cao X Z, Song L G, Jin S X, Zhang R G, Wang B Y, Wei L 2017 Acta Phys. Sin. 66 027801

Google Scholar

Google Scholar

[7] 胡远超, 曹兴忠, 李玉晓, 张鹏, 靳硕学, 卢二阳, 于润升, 魏龙, 王宝义 2015 64 247804

Google Scholar

Google Scholar

Hu Y C, Cao X Z, Li Y X, Zhang P, Jin S X, Lu E Y, Yu R S, Wei L, Wang B Y 2015 Acta Phys. Sin. 64 247804

Google Scholar

Google Scholar

[8] Grafutin V I, Prokop’ev E P 2002 Phys. Usp. 45 59

Google Scholar

Google Scholar

[9] 郗传英 2005 博士学位论文 (合肥: 中国科学技术大学)

Xi C Y 2005 Ph. D. Dissertation (Hefei: University of Science and Technology of China

[10] Ishizaki T, Yoshiie T, Sato K, Yanagita S, Xu Q, Komatsu M, Kiritani M 2003 Mater. Sci. Eng. A 350 102

Google Scholar

Google Scholar

[11] Elsayed M, Bondarenko V, Petters K, Gebauer J, Krause-Rehberg R 2008 J. Appl. Phy. 104 103526

Google Scholar

Google Scholar

[12] Xia R, Cao X Z, Gao M Z, Zhang P, Zeng M F, Wang B Y, Wei L 2017 Phys. Chem. Chem. Phys. 19 3616

Google Scholar

Google Scholar

[13] Karwasz G P, Zecca A, Brusa R S, Pliszkab D 2004 J. Alloys Compd. 382 244

Google Scholar

Google Scholar

[14] Utpalla P, Sharma S K, Sudarshan K, Kumar V, Pujari P K 2019 Eur. Polym. J. 117 10

Google Scholar

Google Scholar

[15] Suzuki T, He C Q, Kondo K, Shantarovich V, Ito Y 2003 Radiat. Phys. Chem. 68 489

Google Scholar

Google Scholar

[16] Sharma S K, Prakash J, Bahadur J, Sudarshan K, Maheshwari P, Mazumderc S, Pujari P K 2014 Phys. Chem. Chem. Phys. 16 1399

Google Scholar

Google Scholar

[17] Seeger A 1973 J. Phys. F: Met. Phys. 3 284

Google Scholar

Google Scholar

[18] 朱特, 曹兴忠 2020 69 177801

Google Scholar

Google Scholar

Zhu T, Cao X Z 2020 Acta Phys. Sin. 69 177801

Google Scholar

Google Scholar

[19] Wang B Y, Cao X Z, Yu R S, Wei C F, Zhang Z M, Ma C X, Chang T B, Pei G X, Li J C, Zheng L S, Wei L, Wang T M, He Y J, Yu W Z, Zhu S Y 2004 Positron Annihilation, ICPA-13 Proceedings Kyoto, Japan Sep 7–12, 2003 pp513–515

[20] Zhang R G, Wang B Y, Zhang H, Wei L 2005 Appl. Surf. Sci. 245 340

Google Scholar

Google Scholar

[21] Wan D Y, Wang Y T, Wang B Y, Ma C X, Sun H, Wei L 2003 J. Cryst. Growth 253 230

Google Scholar

Google Scholar

[22] 王丹妮, 王宝义, 张兰芝, 钟玉荣, 章志明, 李道武, 魏龙, 张天保 2008 核技术 31 577

Google Scholar

Google Scholar

Wang D N, Wang B Y, Zhang L Z, Zhong Y R, Zheng Z M, Li D W, Wei L, Zhang T B 2008 Nucl. Tech. 31 577

Google Scholar

Google Scholar

[23] Asoka-Kumar P, Alatalo M, Ghosh V J, Kruseman A C, Nielsen B, Lynn K G 1996 Phys. Rev. B 77 2097

Google Scholar

Google Scholar

[24] Brusa R S, Deng W, Karwasz G P, Zecca A 2002 Nucl. Instrum. Methods Phys. Res. , Sect. B 194 519

Google Scholar

Google Scholar

[25] Xi C Y, Ye B J, Kong W, Weng H M, Zhou X Y, Han R D 2006 Chin. J. Chem. Phys. 19 203

Google Scholar

Google Scholar

[26] Lee S U, Lee Y J, Kim J R, Jeong K E, Jeong S Y 2019 J. Ind. Eng. Chem. 79 443

Google Scholar

Google Scholar

[27] Sugita K, Ogawa R, Mizuno M, Araki Hm, Yabuuchi A 2022 Scr. Mater. 208 114339

Google Scholar

Google Scholar

[28] Jin K, Guo W, Lu C Y, Ullah M W, Zhang Y W, Weber W J, Wang L M, Poplawsky J D, Bei H B 2016 Acta Mater. 121 365

Google Scholar

Google Scholar

[29] Jin S X, Zhang P, Lu E Y, Guo L P, Wang B Y, Cao X Z 2016 Acta Mater. 103 658

Google Scholar

Google Scholar

[30] Zhong Z H, Xu Q, Mori K, Tokitani M 2019 Philos. Mag. 99 1515

Google Scholar

Google Scholar

[31] 王少阶 2008 应用正电子谱学(上卷) (武汉: 湖北科学技术出版社) 第85页

Wang S J 2008 Applied Positron Spectroscopy (Vol. 1) (Wuhan: Hubei Science and Technology Press) p85

[32] Onitsuka T, Takenaka M, Kuramoto, Nagai Y, Hasegawa M 2001 Phys. Rev. B 65 012204

Google Scholar

Google Scholar

[33] Bartha K, Zháňal P, Stráský J, Čížek J, Dopita M, Lukáč F, Harcuba P, Hájek M, Polyakova V, Semenova I, Janečeka M 2019 J. Alloys Compd. 788 771

Google Scholar

Google Scholar

[34] Nagai Y, Hasegawa M, Tang Z, Hempel A, Yubuta K, Shimamura T, Kawazoe Y, Kawai A, Kano F 2000 Phys. Rev. B 61 6574

Google Scholar

Google Scholar

[35] Liu X S, Zhang P, Wang B Y, Cao X Z, Jin S X, Yu R S 2021 Materials 14 1451

Google Scholar

Google Scholar

[36] Abhaya S, Rajaraman S. Kalavathi R, Amarendra G 2015 J. Alloys Compd. 620 277

Google Scholar

Google Scholar

[37] Ye F J, Zhu T, Wang Q Q, Song Y M, Zhang H Q, Kuang P, Zhang P, Yu R S, Cao X Z, Wang B Y 2022 Intermetallics 149 107670

Google Scholar

Google Scholar

[38] Nagai Y, Tang Z, Hassegawa M, Kanai T, Saneyasu M 2001 Phys. Rev. B 63 134110

Google Scholar

Google Scholar

[39] Xu Q, Yoshiie T, Sato K 2007 Phys. Status Solidi C 4 3573

Google Scholar

Google Scholar

[40] Wang X W, ZhongY R, Wang B Y, Zhang H Y 2009 J. Mater. Res. 24 1794

Google Scholar

Google Scholar

[41] 王茜茜 2022 硕士学位论文 (贵阳: 贵州大学)

Wang Q Q 2022 M. S. Thesis (Guiyang: Guizhou University

[42] Sabelová V, Kršjak V, Kuriplach Jm, Dai Y, Slugeň V 2015 J. Nucl. Mater. 458 350

Google Scholar

Google Scholar

[43] Fujii K, Fukuya K, Nakata N, Hono K, Nagai Y, Hasegawa M 2005 J. Nucl. Mater. 340 247

Google Scholar

Google Scholar

[44] Ge W N, Rahman A, Cheng H, Zhang M, Liu J D, Zhang Z M, Ye B J 2018 J. Magn. Magn. Mater. 449 401

Google Scholar

Google Scholar

[45] Kundu R, Bhattacharya S, Roy D, Nambissan P M G 2017 RSC Adv. 7 8131

Google Scholar

Google Scholar

[46] Qin M J, Gao F, Cizek J, Yang S J, Fan X L, Zhao L L, Xu J, Dong G G, Reece M, Yan H X 2019 Acta Mater. 164 76

Google Scholar

Google Scholar

[47] Ahmed M, Mukherjee S, Singha T, Nambissan P M G 2023 J. Phys. Chem. Solids 181 111513

Google Scholar

Google Scholar

[48] Thorat A V, Ghoshal T, Morris M A, Nambissan P M G 2014 Acta Phys. Pol. A 125 756

Google Scholar

Google Scholar

[49] Das A, Mandal A C, Roy S, Prashanth P, Ahamed S I, Kar S, Prasad M S, Nambissan P M G 2016 Physica E 83 389

Google Scholar

Google Scholar

[50] Ghosh S, Khan G K, Mandal K, Samanta A, Nambissan P M G 2013 J. Phys. Chem. C 117 8458

Google Scholar

Google Scholar

[51] Das A 2019 Curr. Sci. 117 1990

Google Scholar

Google Scholar

[52] Yu R S, Maekawa M, Kawasuso A, Wang B Y, Wei L 2012 Nucl. Instrum. Methods Phys. Res. , Sect. B 270 47

Google Scholar

Google Scholar

[53] Elsayed M, Krause-Rehberg R, Korff B, Ratschinski I, Leipner H S 2013 Eur. Phys. J. B 86 358

Google Scholar

Google Scholar

[54] Xu J, Moxom J, Somieski B, White C W 2001 Phys. Rev. B 64 112404

Google Scholar

Google Scholar

[55] Slotte J, Makkonen I, Tuomisto F 2016 ECS J. Solid State Sci. Technol. 5 3166

Google Scholar

Google Scholar

[56] Simpson P J, Jenei Z, Asoka-Kumar P, Robison R R, Law M E 2012 Appl. Phys. Lett. 85 1538

Google Scholar

Google Scholar

[57] Das A, Mandal A C, Roy S, Nambissan P M G 2018 AIP Adv. 8 095013

Google Scholar

Google Scholar

[58] Pasang T, Namratha K, Guagliardo P, Byrappa K, Ranganathaiah C, Samarin S, FWilliams J 2015 Mater. Res. Express 2 045502

Google Scholar

Google Scholar

[59] Sharma S K, Bahadur J, Bahadur J, Sudarshan K, Maheshwari P, Mazumder S, Pujari P K 2014 Phys. Chem. Phys. Chem. 16 1399

Google Scholar

Google Scholar

[60] Cao X Z, Xia R, Yang J, Zeng M, Wang B Y, Yu R S, Wei L 2017 Acta Phys. Pol A 132 1535

Google Scholar

Google Scholar

[61] Ghasemifard M, Ghamari M 2023 J. Appl. Polym. Sci. 141 1

Google Scholar

Google Scholar

[62] Rana U, Nambissan P M G, Malika S, Chakrabarti K 2014 Phys. Chem. Chem. Phys. 7 3292

Google Scholar

Google Scholar

[63] Cao X Z, Zhu T, Jin S X, Kuang P, Zhang P, Lu E Y, Gong Y H, Guo L P, Wang B Y 2017 Appl. Phys. A 123 176

Google Scholar

Google Scholar

[64] An X D, Zhu T, Wan M P, Li Y H, Wang Q Q, Zhang P, Liu J Y, Song Y M, Zhang Z K, Wang B Y, Cao X Z 2021 Int. J. Hydrogen Energy 46 13163

Google Scholar

Google Scholar

[65] Wang Q Q, An X D, Zhu T, Wan M P, Zhang P, Ye F J, Song Y M, Huang C W, Ma R, Wang B Y, Cao X Z 2021 J. Alloys Compd. 885 160909

Google Scholar

Google Scholar

[66] Fujinami M, Sawada T, Akahane T 2003 Radiat. Phys. Chem. 68 631

Google Scholar

Google Scholar

[67] Beyerlein I J, Demkowicz M J, Misraa A, Uberuaga B P 2015 Prog. Mater. Sci. 74 125

Google Scholar

Google Scholar

[68] Liu Y L, Song L G, Chen Y, Bai R Y, Wang Z, Zhu T, Zhang P, Jin S X, Wang H H, Lu E Y, Cao X Z, Wang B Y 2021 Fusion Eng. Des. 162 112118

Google Scholar

Google Scholar

[69] Ren X L, Yao B D, Zhu T, Zhong Z H, Wang Y X, Cao X Z, Jinno S, Xu Q 2020 Intermetallics 126 106942

Google Scholar

Google Scholar

[70] Zhang L Z, Wang D N, Wang B Y, Yu R S, Wei L 2007 Appl. Surf. Sci. 253 7309

Google Scholar

Google Scholar

[71] Reiner M, Pikart P, Hugenschmidt C 2014 J. Alloys Compd. 587 515

Google Scholar

Google Scholar

[72] Khanam A, Slotte J, Tuomisto F, Subhechha S, Popovici M, Kar G S 2022 J. Appl. Phys. 131 245301

Google Scholar

Google Scholar

[73] 杨静 2015 博士学位论文 (北京: 中国科学院高能物理研究所)

Yang J 2015 Ph. D. Dissertation (Beijing: Institute of High Energy Physics, Chinese Academy of Sciences

[74] Wiktor J, Jomard G, Torrent M 2015 Phys. Rev. B 93 125113

Google Scholar

Google Scholar

[75] Yang Q G, Cao X Z, Wang B Y, Wang P, Olsson P 2023 Phys. Rev. B 108 104113

Google Scholar

Google Scholar

[76] Simula K A, Haerkönen J, Zhelezova I, Drummond N D, Tuomisto F, Makkonen I 2023 Phys. Rev. B 108 045201

Google Scholar

Google Scholar

[77] Makkonen I, Hakala M, Puska M J 2006 Phys. Rev. B 73 035103

Google Scholar

Google Scholar

[78] Puska M J, Seitsonen A P, Nieminen R M 1995 Phys. Rev. B 52 10947

Google Scholar

Google Scholar

[79] Yang Q G, Hu Z, Makkonen L, Desgardin P, Egger W, Barthe M F, Olsson P 2022 J. Nucl. Mater. 571 154019

Google Scholar

Google Scholar

[80] 刘永利 2022 博士学位论文 (北京: 中国科学院高能物理研究所)

Liu Y L 2022 Ph. D. Dissertation (Beijing: Institute of High Energy Physics, Chinese Academy of Sciences

[81] Yang Q G, Olsson P 2023 Acta Mater. 242 118429

Google Scholar

Google Scholar

[82] Elsayed M, Staab T E M, Čížek J, Krause-Rehberg R 2021 Acta Mater. 219 117228

Google Scholar

Google Scholar

[83] Elsayed M, Krause-Rehberg R, Korff B, Richter S, Leipner H S 2013 J. Appl. Phys. 113 094902

Google Scholar

Google Scholar

[84] Rauch C, Makkonen I, Tuomisto F 2011 Phys Status Solidi A 208 1548

Google Scholar

Google Scholar

[85] Makkonena I, Hakalab M, Puska M J 2006 Physica B 376-377 972

Google Scholar

Google Scholar

[86] Slotte J, Tuomisto F 2012 Mater. Sci. Semicond. Process. 15 669

Google Scholar

Google Scholar

[87] Linez F, Makkonen I, Tuomisto F 2016 Phys. Rev. B 94 014103

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 8060

- PDF Downloads: 198

- Cited By: 0

DownLoad:

DownLoad: