-

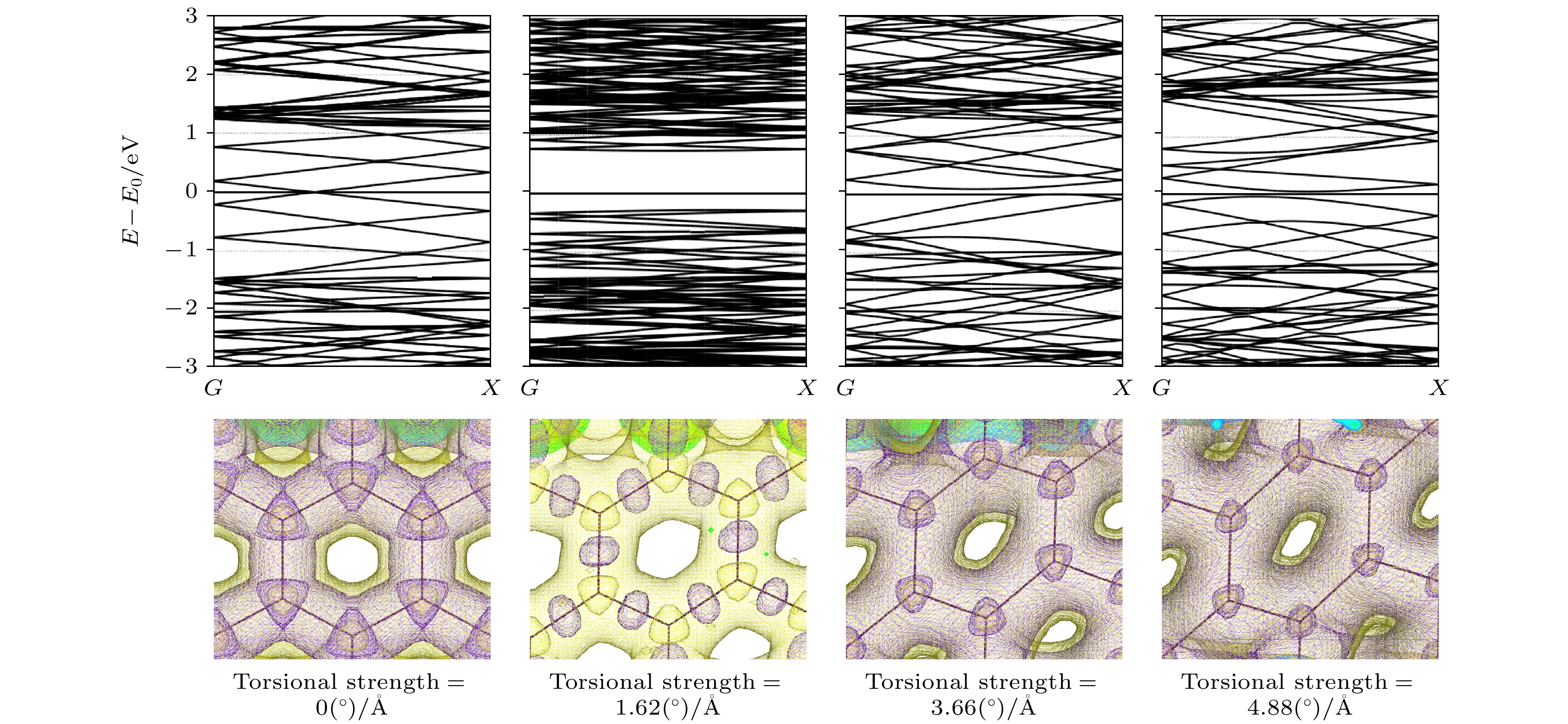

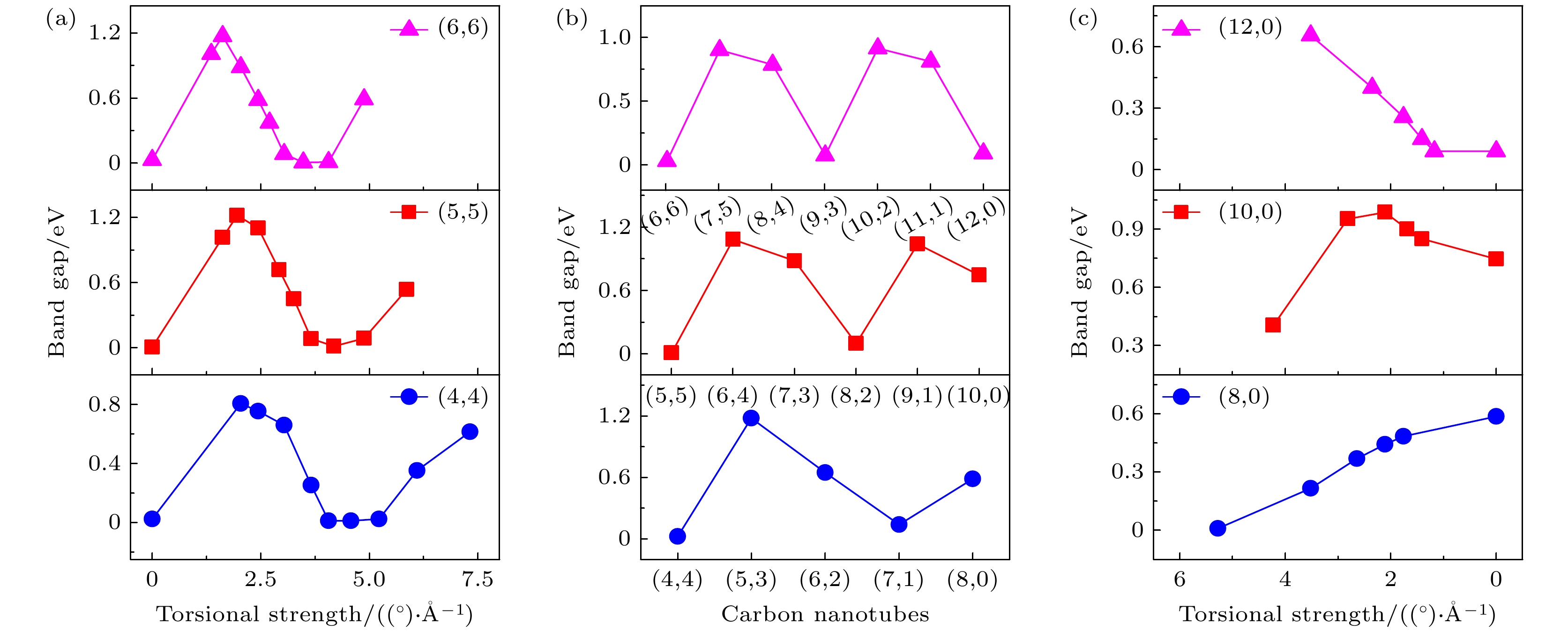

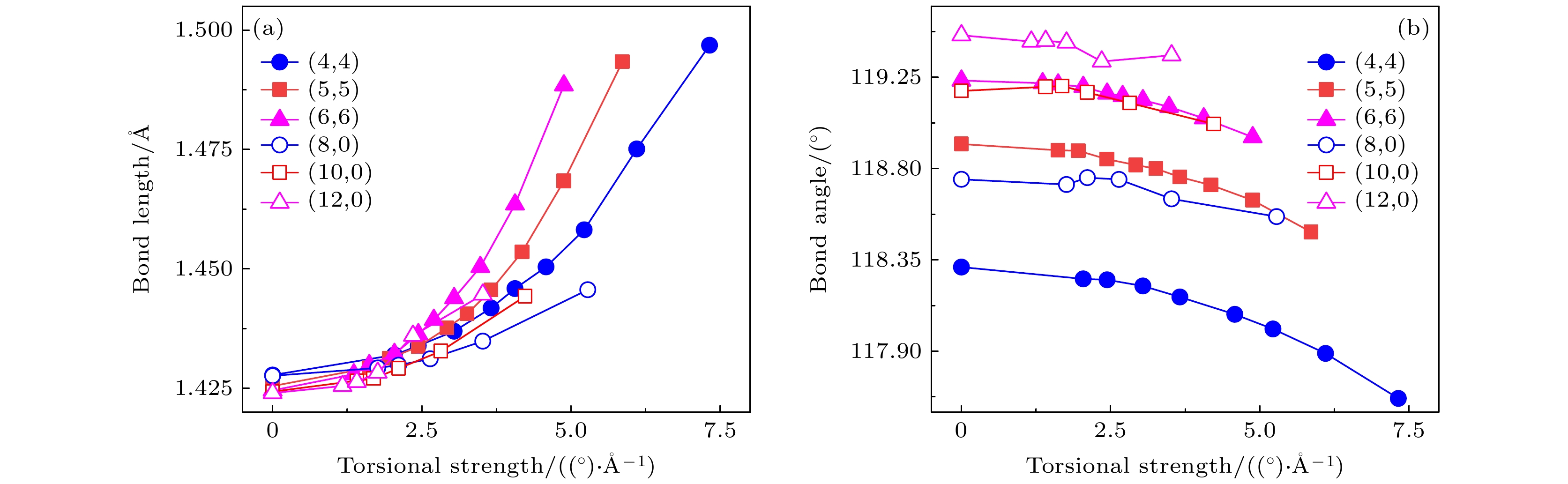

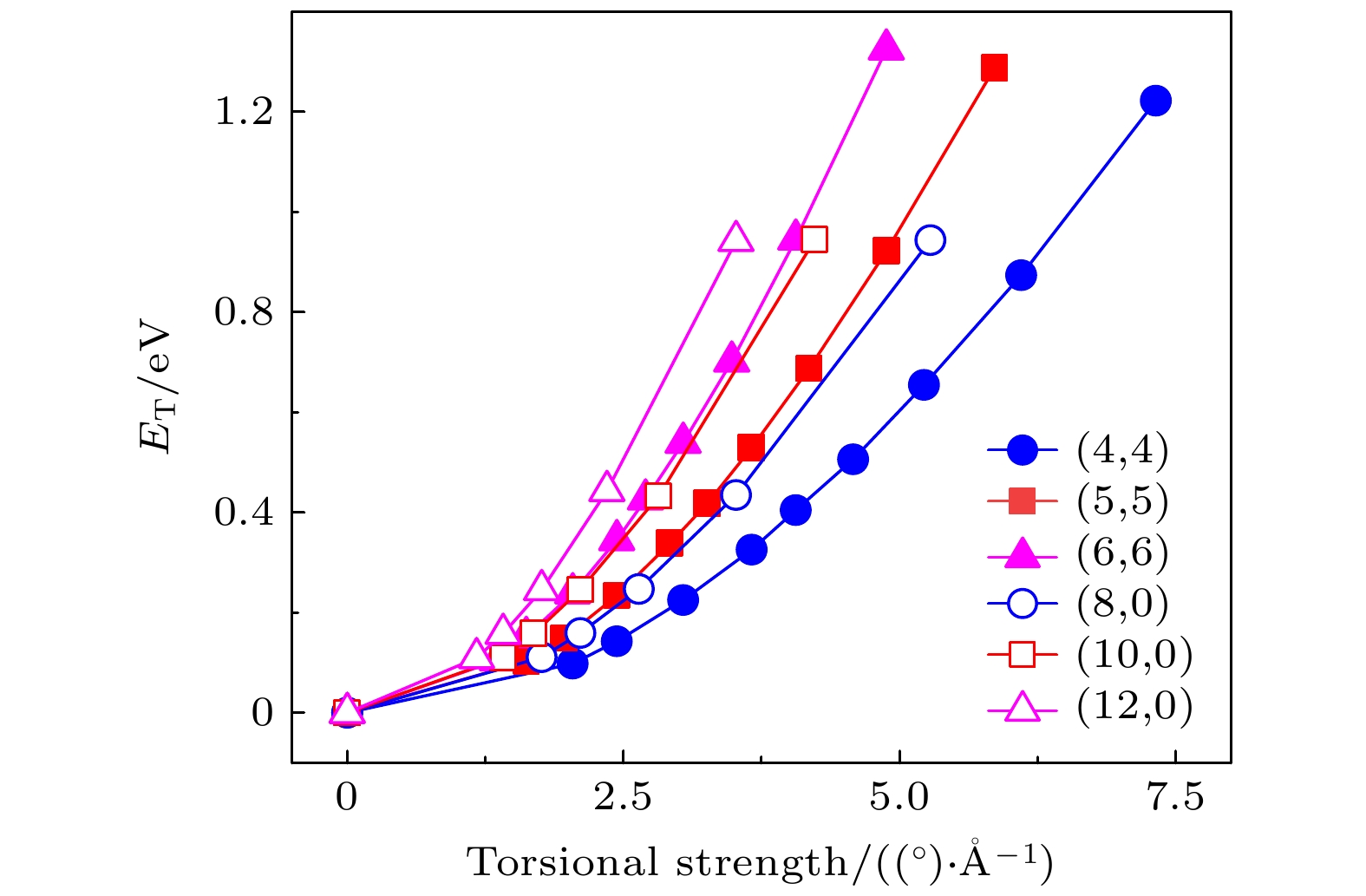

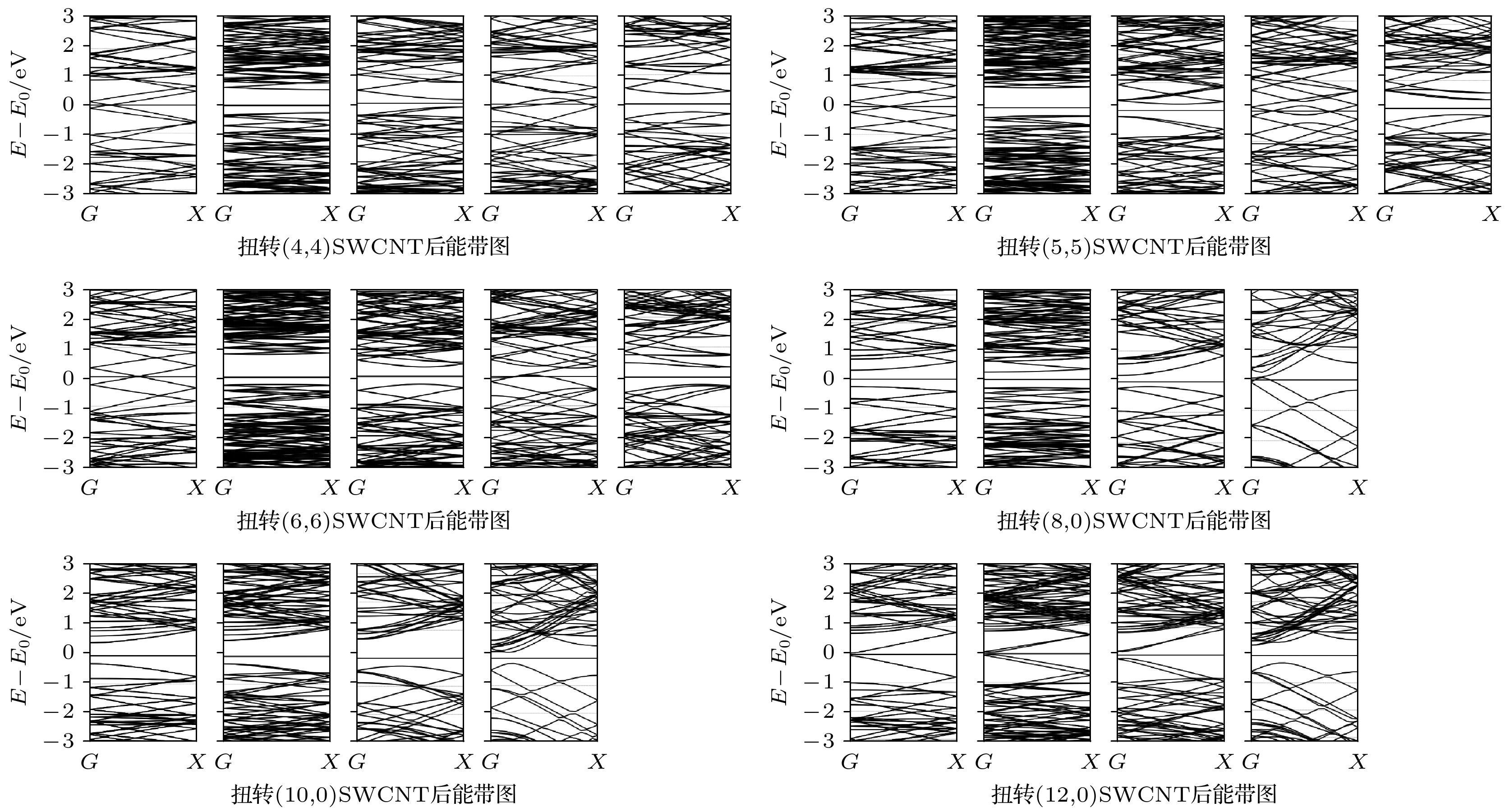

The controllable band gap of single-walled carbon nanotube (SWCNT) has become a research hotspot. This study introduces a torsional model that involves each rotating carbon atom along the axial direction of SWCNT, and a detailed description of the model creation process. Two guidelines for constructing the model are proposed, and the self-consistency of the torsion model is established through first-principles density functional theory. Initially, the band gap map of SWCNTs under torsion is present. As the twist strength increases, the band gap of SWCNT undergoes several phase transitions, including semiconductor-metal transition and metal-semiconductor transition. Moreover, we investigate the variations in the average bond length, average bond angle, and diameter of SWCNT under torsion. Furthermore, this work turns to the analysis of carbon atomic energy statistics, revealing distinct energy changes for different types of single-walled carbon nanotubes under identical torsion intensity. The findings shed light on the controllable band gap of SWCNTs, offering a theoretical foundation for the development of nanoelectronic devices and microintegrated circuits utilizing single-walled carbon nanotubes. In conclusion, this research presents a novel approach for exploring the controllable band gap of single-walled carbon nanotube through torsional manipulation. Theoretical insights into the behavior of SWCNTs under torsion provide valuable contributions to the field and pave the way for potential applications in nanoelectronics and microintegrated circuits.

-

Keywords:

- single-walled carbon nanotubes /

- first principles /

- torsional deformation /

- band gap

[1] Iijima S 1991 Nature 354 56

Google Scholar

Google Scholar

[2] Iijima S, Ichihashi T 1993 Nature 364 737

Google Scholar

Google Scholar

[3] Treacy M, Ebbesen T W, Gibson J M 1996 Nature 381 680

Google Scholar

Google Scholar

[4] Krishnan A, Dujardin E, Ebbesen T W, Yianilos P N, Treacy M M J 1998 Phys. Rev. B 58 14013

Google Scholar

Google Scholar

[5] Hernandez E, Goze C, Bernier P, Rubio A 1999 Appl. Phys. A Mater. 68 287

Google Scholar

Google Scholar

[6] Takakura A, Beppu K, Nishihara T, Fukui A, Kozeki T, Namazu T, Miyauchi Y, Itami K 2019 Nat. Commun. 10 3040

Google Scholar

Google Scholar

[7] Fischer J E, Johnson A T 1999 Curr. Opin. Solid St. M. 4 28

Google Scholar

Google Scholar

[8] Jia J, Shi D, Feng X, Chen G 2014 Carbon 76 54

Google Scholar

Google Scholar

[9] Ezawa M 2006 Phys. Rev. B 73 045432

Google Scholar

Google Scholar

[10] Karimkhani H, Vahed H 2022 Optik 254 168633

Google Scholar

Google Scholar

[11] Tombler T W, Zhou C W, Alexseyev L, Kong J, Dai H J, Lei L, Jayanthi C S, Tang M J, Wu S Y 2000 Nature 405 769

Google Scholar

Google Scholar

[12] Jia J M, Ju S P, Shi D N, Lin K F 2012 J. Appl. Phys. 111 013704

Google Scholar

Google Scholar

[13] Yang L, Han J 2000 Phys. Rev. Lett. 85 154

Google Scholar

Google Scholar

[14] Moon S, Song W, Kim N, Lee J S, Na P S, Lee S G, Park J, Jung M H, Lee H W, Kang K H, Lee C J, Kim J 2007 Nanotechnology 18 235201

Google Scholar

Google Scholar

[15] Mazzoni M, Chacham H 2000 Appl. Phys. Lett. 76 1561

Google Scholar

Google Scholar

[16] Peng S, Cho K 2002 J. Appl. Mech T. ASME 69 451

Google Scholar

Google Scholar

[17] Shtogun Y V, Woods L M 2009 Carbon 47 3252

Google Scholar

Google Scholar

[18] Shtogun Y V, Woods L M 2009 J. Phys. Chem. C 113 4792

Google Scholar

Google Scholar

[19] Kang Y J, Kim Y H, Chang K J 2009 Curr. Appl. Phys. 9 S7

Google Scholar

Google Scholar

[20] Berd M, Moussi K, Aouabdia Y, Benchallal L, Chahi G, Kahouadji B 2021 Chem. Phys. Lett. 781 138988

Google Scholar

Google Scholar

[21] Kato K, Koretsune T, Saito S 2012 Phys. Rev. B 85 115448

Google Scholar

Google Scholar

[22] Wang Q 2008 Carbon 46 1172

Google Scholar

Google Scholar

[23] Wang Y, Wang X X, Ni X G 2004 Model. Simul. Mater. Sc. 12 1099

Google Scholar

Google Scholar

[24] Kang J W, Kim K S, Park S Y, Kim H, Hwang H J, Choi Y G 2010 J. Comput. Theor. Nanos. 7 2317

Google Scholar

Google Scholar

[25] Melker A I, Zhaldybin A I 2007 Nanomeeting (Minsk Byelarus: May 22–25) p233

[26] Dian R H, Lei Z, Ya F D, Cheng L L 2017 Mater. Res. Express 4 105004

Google Scholar

Google Scholar

[27] Ansari R, Mirnezhad M, Rouhi H 2015 Acta. Mech. 226 2955

Google Scholar

Google Scholar

[28] Hohenberg P, Kohn W 1964 Phys. Rev. 136 B864

Google Scholar

Google Scholar

[29] Kohn W, Sham L 1965 Phys. Rev. 140 A1133

Google Scholar

Google Scholar

[30] Langreth D C, Mehl M J 1983 Phys. Rev. B 28 1809

Google Scholar

Google Scholar

[31] Blochl P E 1994 Phys. Rev. B 50 17953

Google Scholar

Google Scholar

[32] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[33] Kinoshita Y, Ohno N 2010 Phys. Rev. B 82 085433

Google Scholar

Google Scholar

-

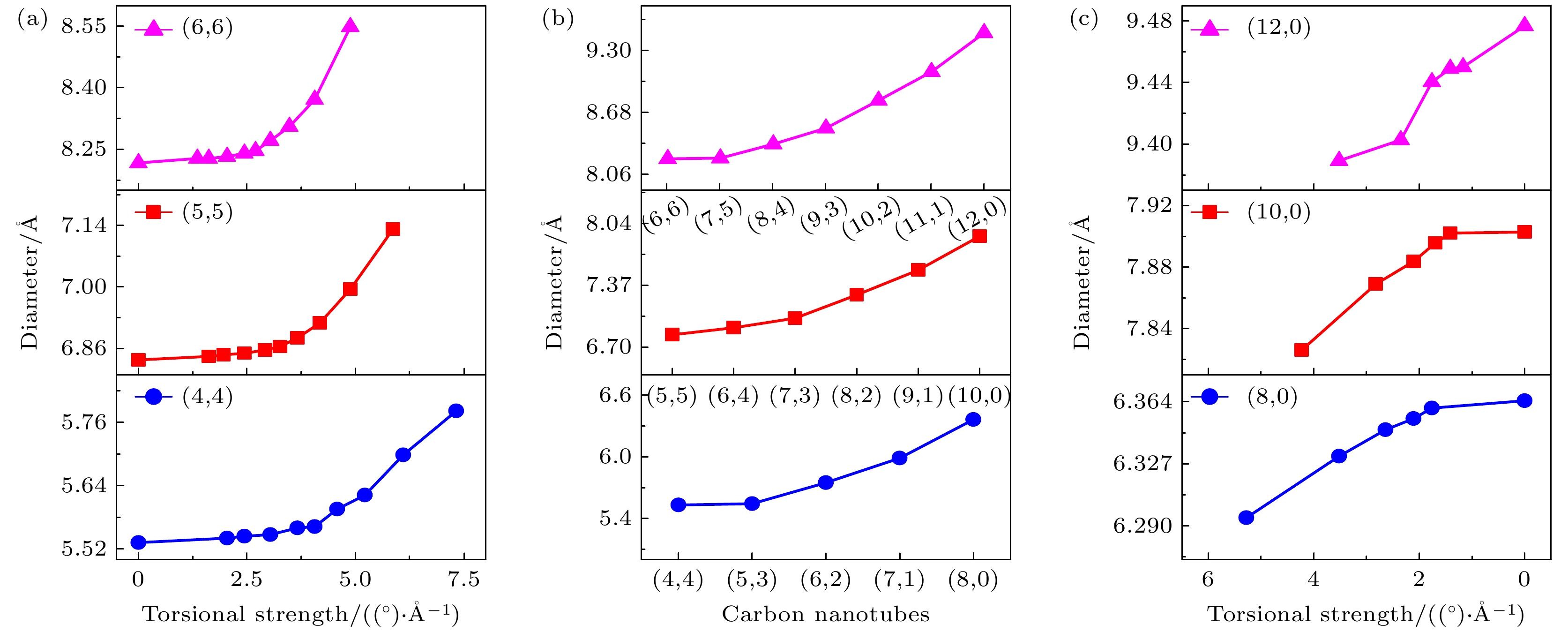

图 7 单壁碳纳米管直径变化图 (a) 扶手椅型单壁碳纳米管直径随扭转强度的变化; (b) 3类碳纳米带中本征单壁碳纳米管直径变化; (c)锯齿型单壁碳纳米管直径随扭转强度的变化

Figure 7. Diameter variation chart of SWCNTs: (a) Relationship between diameter and torsional strength for armchair SWCNTs; (b) diameter of SWCNTs in three types of carbon nanoribbons; (c) relationship between diameter and torsional strength for zigzag SWCNTs.

-

[1] Iijima S 1991 Nature 354 56

Google Scholar

Google Scholar

[2] Iijima S, Ichihashi T 1993 Nature 364 737

Google Scholar

Google Scholar

[3] Treacy M, Ebbesen T W, Gibson J M 1996 Nature 381 680

Google Scholar

Google Scholar

[4] Krishnan A, Dujardin E, Ebbesen T W, Yianilos P N, Treacy M M J 1998 Phys. Rev. B 58 14013

Google Scholar

Google Scholar

[5] Hernandez E, Goze C, Bernier P, Rubio A 1999 Appl. Phys. A Mater. 68 287

Google Scholar

Google Scholar

[6] Takakura A, Beppu K, Nishihara T, Fukui A, Kozeki T, Namazu T, Miyauchi Y, Itami K 2019 Nat. Commun. 10 3040

Google Scholar

Google Scholar

[7] Fischer J E, Johnson A T 1999 Curr. Opin. Solid St. M. 4 28

Google Scholar

Google Scholar

[8] Jia J, Shi D, Feng X, Chen G 2014 Carbon 76 54

Google Scholar

Google Scholar

[9] Ezawa M 2006 Phys. Rev. B 73 045432

Google Scholar

Google Scholar

[10] Karimkhani H, Vahed H 2022 Optik 254 168633

Google Scholar

Google Scholar

[11] Tombler T W, Zhou C W, Alexseyev L, Kong J, Dai H J, Lei L, Jayanthi C S, Tang M J, Wu S Y 2000 Nature 405 769

Google Scholar

Google Scholar

[12] Jia J M, Ju S P, Shi D N, Lin K F 2012 J. Appl. Phys. 111 013704

Google Scholar

Google Scholar

[13] Yang L, Han J 2000 Phys. Rev. Lett. 85 154

Google Scholar

Google Scholar

[14] Moon S, Song W, Kim N, Lee J S, Na P S, Lee S G, Park J, Jung M H, Lee H W, Kang K H, Lee C J, Kim J 2007 Nanotechnology 18 235201

Google Scholar

Google Scholar

[15] Mazzoni M, Chacham H 2000 Appl. Phys. Lett. 76 1561

Google Scholar

Google Scholar

[16] Peng S, Cho K 2002 J. Appl. Mech T. ASME 69 451

Google Scholar

Google Scholar

[17] Shtogun Y V, Woods L M 2009 Carbon 47 3252

Google Scholar

Google Scholar

[18] Shtogun Y V, Woods L M 2009 J. Phys. Chem. C 113 4792

Google Scholar

Google Scholar

[19] Kang Y J, Kim Y H, Chang K J 2009 Curr. Appl. Phys. 9 S7

Google Scholar

Google Scholar

[20] Berd M, Moussi K, Aouabdia Y, Benchallal L, Chahi G, Kahouadji B 2021 Chem. Phys. Lett. 781 138988

Google Scholar

Google Scholar

[21] Kato K, Koretsune T, Saito S 2012 Phys. Rev. B 85 115448

Google Scholar

Google Scholar

[22] Wang Q 2008 Carbon 46 1172

Google Scholar

Google Scholar

[23] Wang Y, Wang X X, Ni X G 2004 Model. Simul. Mater. Sc. 12 1099

Google Scholar

Google Scholar

[24] Kang J W, Kim K S, Park S Y, Kim H, Hwang H J, Choi Y G 2010 J. Comput. Theor. Nanos. 7 2317

Google Scholar

Google Scholar

[25] Melker A I, Zhaldybin A I 2007 Nanomeeting (Minsk Byelarus: May 22–25) p233

[26] Dian R H, Lei Z, Ya F D, Cheng L L 2017 Mater. Res. Express 4 105004

Google Scholar

Google Scholar

[27] Ansari R, Mirnezhad M, Rouhi H 2015 Acta. Mech. 226 2955

Google Scholar

Google Scholar

[28] Hohenberg P, Kohn W 1964 Phys. Rev. 136 B864

Google Scholar

Google Scholar

[29] Kohn W, Sham L 1965 Phys. Rev. 140 A1133

Google Scholar

Google Scholar

[30] Langreth D C, Mehl M J 1983 Phys. Rev. B 28 1809

Google Scholar

Google Scholar

[31] Blochl P E 1994 Phys. Rev. B 50 17953

Google Scholar

Google Scholar

[32] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[33] Kinoshita Y, Ohno N 2010 Phys. Rev. B 82 085433

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 5736

- PDF Downloads: 114

- Cited By: 0

DownLoad:

DownLoad: