-

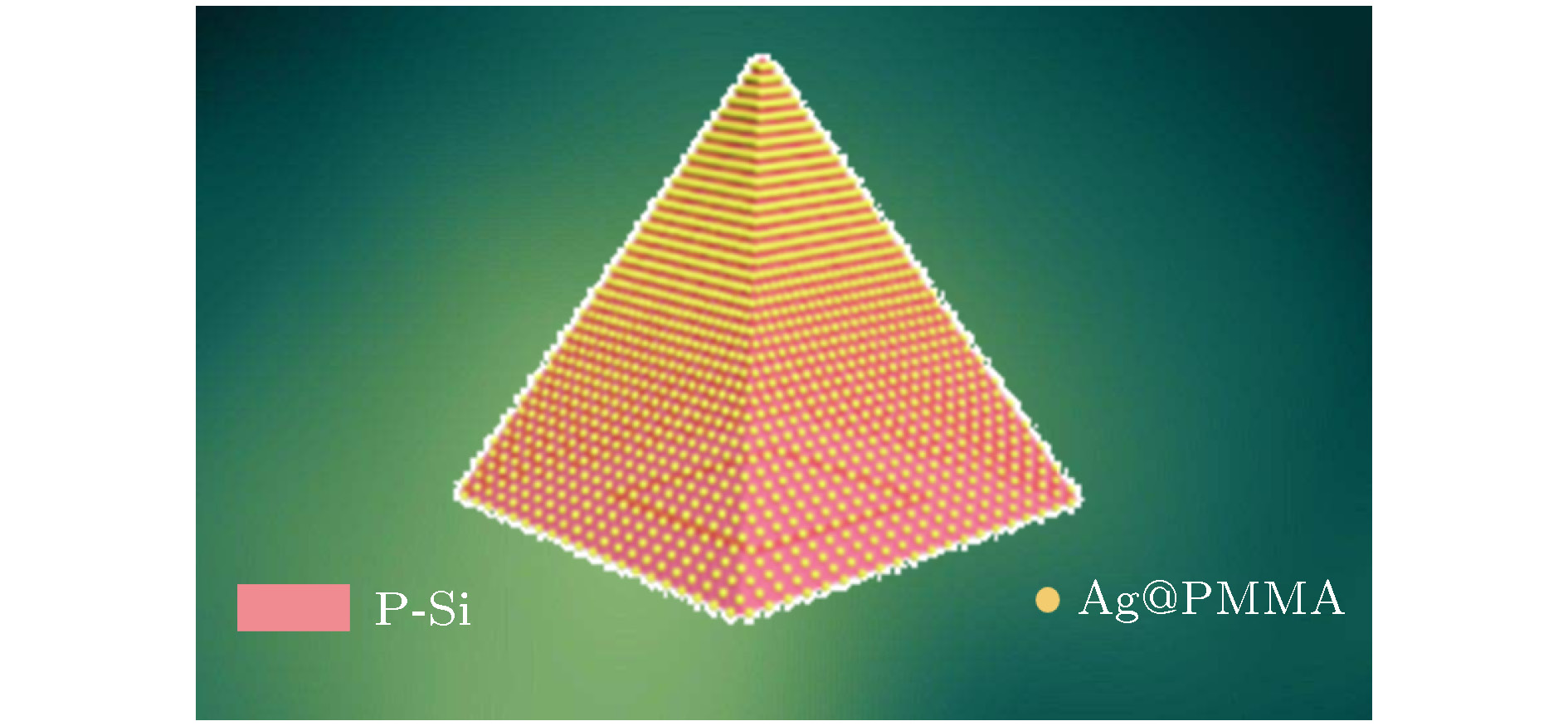

Surface enhanced Raman scattering (SERS) is a highly sensitive spectroscopy technique, which is widely used in chemical reaction detecting, medical diagnostics, and food analysis. The construction of the substrate structure has a very important influence on enhancing the SERS signal of the probe molecule. In this paper, a three-dimensional (3D) pyramid stereo composite SERS substrate is prepared by using polymethyl methacrylate (PMMA) to encapsulate silver nanoparticles, which achieves high sensitivity detection of Rhodamine 6G (R6G) molecules. By adjusting the dispersion density of silver nanoparticles in the PMMA acetone solution, the effective oscillation of light in the pyramid valley is realized, which not only ensures the high-density "hot spot" effect of the 3D structure, but also avoids deforming the adsorption probe molecules caused by the metal-molecule interaction. It also effectively prevents the silver nanoparticles from being oxidized and provides a larger range of electromagnetic enhancement for probe molecules, resulting in a stable output of the enhanced Raman signal. This research result provides an effective strategy for designing a high performance and reusable SERS substrate, meanwhile, it has important guiding significance for further designing an SERS substrate with improved 3D structure in the future study.

-

Keywords:

- surface-enhanced Raman scattering /

- sliver nanoparticles /

- polymethyl methacrylate /

- three-dimensional pyramid stereo composite structure

[1] Fleischmann M, Hendra P J, Mcquillan A J 1974 Chem. Phys. Lett. 26 163

Google Scholar

Google Scholar

[2] Guerrini L, Krpetić Ž, van Lierop D, Alvarez Puebla A R, Graham D 2015 Angew. Chem. Int. Edit. 54 1144

Google Scholar

Google Scholar

[3] Kubackova J, Fabriciova G, Miskovsky P, Jancura D, Sanchez-Cortes S 2015 Anal. Chem. 87 663

Google Scholar

Google Scholar

[4] Zhang C, Li C, Yu J, Jiang S, Xu S, Yang C, Liu Y J, Gao X, Liu A, Man B 2018 Sensor. Actuat. B Chem. 258 163

Google Scholar

Google Scholar

[5] Sotiriou G A, Blattmann C O, Deligiannakis Y 2015 Nanoscale 8 796

[6] Fortuni B, Inose T, Uezono S, Toyouchi S, Umemoto K, Sekine S, Fujita Y, Ricci M, Lu G, Masuhara A, Hutchison JA, Latterini L, Uji I H 2017 Chem. Commun. 53 11298

Google Scholar

Google Scholar

[7] 冯仕靓, 王靖宇, 陈舒, 孟令雁, 沈少鑫, 杨志林 2019 68 147801

Google Scholar

Google Scholar

Feng S L, Wang J Y, Chen S, Meng L Y, Shen S X, Yang Z L 2019 Acta Phys. Sin. 68 147801

Google Scholar

Google Scholar

[8] Fan C, Zhu S, Xin H, Tian Y, Liang E 2017 J. Optics-UK 19 015401

Google Scholar

Google Scholar

[9] 张娜 2015 硕士学位论文 (苏州: 苏州大学)

Zhang N 2015 M. S. Thesis (Suzhou: Soochow University) (in Chinese)

[10] 张星, 郝艳玲, 方炎 2013 光散射学报 2 5

Google Scholar

Google Scholar

Zhang X, Hao Y L, Fang Y 2013 The Journal of Light Scattering 2 5

Google Scholar

Google Scholar

[11] Xu S, Jiang S, Wang J, Wei J, Yue W, Ma Y 2016 Sens. Actuators, B 222 1175

[12] 程自强, 石海泉, 余萍, 刘志敏 2018 67 197302

Google Scholar

Google Scholar

Cheng Z Q, Shi H Q, Yu P, Liu Z M 2018 Acta Phys. Sin. 67 197302

Google Scholar

Google Scholar

[13] Xu S, Tang W, Chase D B, Sparkset D L, Raboit J 2018 ACS Appl. Nano Mater. 1 1257

[14] Xu W, Xiao J, Chen Y, Chen Y, Ling X, Zhang J 2013 Adv. Mater. 25 928

Google Scholar

Google Scholar

[15] Sivashanmugan K, Liao J D, Liu B H, Yao C K 2013 Anal. Chim. Acta 800 56

Google Scholar

Google Scholar

[16] Park S, Lee J, Ko H 2017 ACS Appl. Mater. Interfaces 9 44088

Google Scholar

Google Scholar

[17] Yang C, Chen Y, Liu D, Chen C, Wang J, Fan Y, Huang S, Lei W 2018 ACS Appl. Mater. Interfaces 10 8317

[18] Tang H, Meng G, Huang Q, Zhang Z, Huang Z, Zhu C 2012 Adv. Funct. Mater. 22 218

Google Scholar

Google Scholar

[19] Li X, Chen G, Yang L, Zhen J, Liu J 2010 Adv. Funct. Mater. 20 2815

Google Scholar

Google Scholar

[20] Lee S, Hahm M G, Vajtai R, Hashim D P, Thurakitseree T, Chipara A C, Ajayan P M, Hafneret J H 2012 Adv. Mater. 24 5261

Google Scholar

Google Scholar

[21] 黄晨玥 2016 硕士学位论文 (南京: 东南大学)

Huang C Y 2016 M.S. Thesis (Nanjin: Southeast University) (in Chinese)

[22] Yuan Z, Zhao S, Zhang L, Yu L, Li X, Lu Y 2017 RSC Adv. 7 11904

Google Scholar

Google Scholar

[23] Smyth C A, Mirza I, Lunney J G, McCabe E M 2013 Appl. Surf. Sci. 264 31

Google Scholar

Google Scholar

[24] Wang K, Sun D W, Pu H, Wei Q, Huang L 2019 ACS Appl. Mater. Interfaces 11 29177

Google Scholar

Google Scholar

[25] Wang X, Bai X, Pang Z, Zhu J, Wu Y, Yang H, Qi Y, Wen X 2019 Opt. Mater. Express 9 1872

Google Scholar

Google Scholar

[26] Gaballah S T, El-Nazer H A, Abdel-Monem R A, El-Liethy M A, Hemdan B A, Rabie S 2019 Int. J. Biol. Macromol. 121 707

Google Scholar

Google Scholar

[27] Zhong L B, Yin J, Zheng Y M, Liu Q, Cheng X X, Luo F H 2014 Anal. Chem. 86 6262

Google Scholar

Google Scholar

[28] Shiohara A, Langer J, Polavarapu L, Lizmarzán L M 2014 Nanoscale 6 9817

Google Scholar

Google Scholar

[29] 卢思辰, 高宇坤, 杨楠, 张晨萌, 尤汀汀, 殷鹏刚 2018 光谱学与光谱分析 38 176

Lu S C, Gao Y K, Yang N, Zhang C M, You T T, Yin P G 2018 Spectroscopy and Spectral Analysis 38 176

[30] Li C, Yu J, Xu S, Jiang S, Xiu X, Chen C, Liu A, Wu T, Man B, Zhang C 2018 Adv. Mater. Technol. 3 1800174

Google Scholar

Google Scholar

[31] Yao G, Zhang H, Zhang S, Liao F, Huang Z, Bie B, Lin Y 2017 RSC Adv. 7 27281

Google Scholar

Google Scholar

[32] Zhang X Y, Hu A, Zhang T, Xue X J, Wen J Z, Duley W W 2010 Appl. Phys. Lett. 96 043109

Google Scholar

Google Scholar

[33] Peng B, Li Z, Mutlugun E, Hernández Martínez P L, Li D, Zhang Q, Gao Y, Demir H V, Xiong Q 2014 Nanoscale 6 5592

Google Scholar

Google Scholar

[34] Jin L, She G, Wang X, Mu L, Shi W 2014 Appl. Surf. Sci. 320 591

Google Scholar

Google Scholar

[35] Natan M J 2006 Faraday Discuss 132 321

Google Scholar

Google Scholar

-

图 2 (a) 金字塔硅基底的SEM图; (b)和(c)为银纳米颗粒浓度为0.75 g/mL 的AgNPs@PMMA/P-Si基底在不同倍数下的SEM图; (d) 银纳米颗粒的粒径分布图; (e)银纳米颗粒、银纳米颗粒与PMMA混合溶液的紫外吸收光谱

Figure 2. (a) SEM image of P-Si substrate; (b) SEM image of AgNPs@PMMA/P-Si substrates with AgNPs concentration of 0.75 g/mL in different magnification; (c) size distribution of AgNPs; (d) UV-vis spectra of AgNPs and AgNPs@PMMA solution.

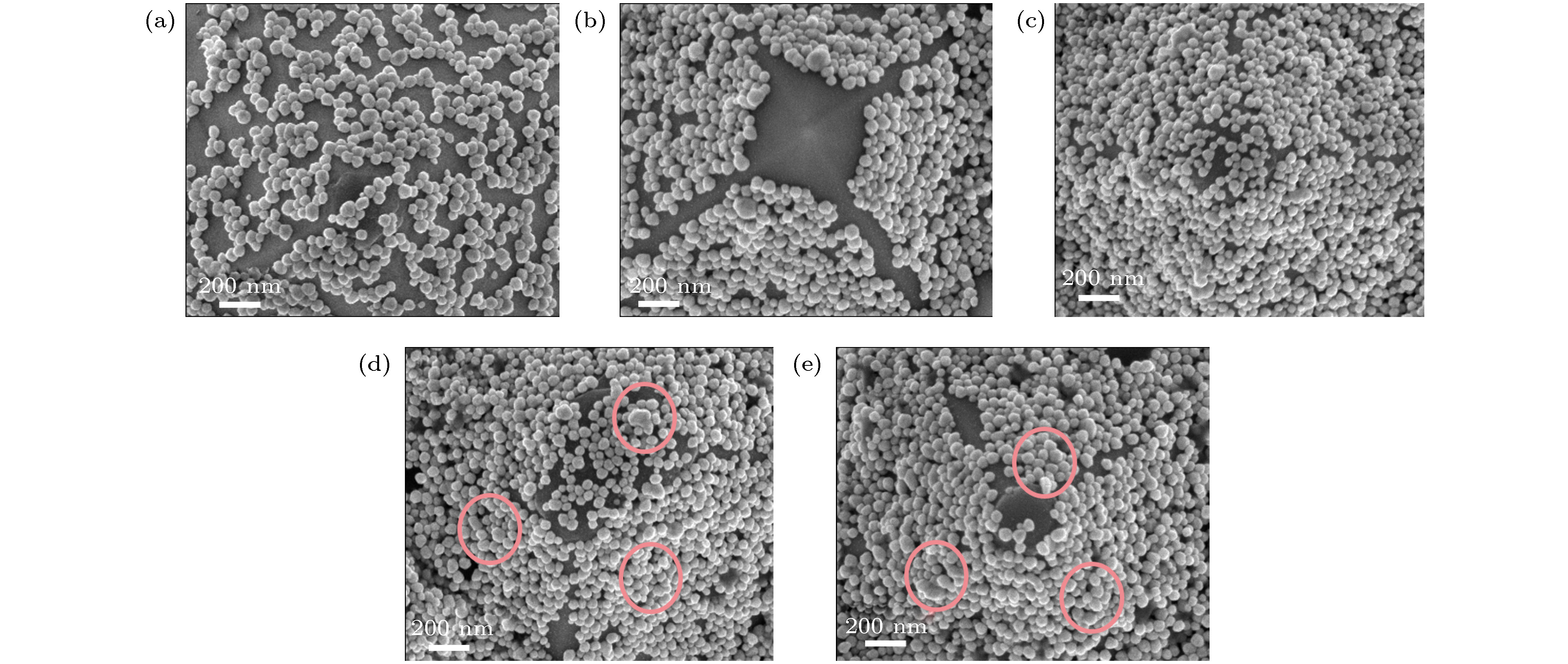

图 3 (a)−(e)不同浓度的银纳米颗粒PMMA丙酮溶液制备的AgNPs@PMMA/P-Si基底的SEM图 (a) 0.55 g/mL; (b) 0.65 g/mL; (c) 0.75 g/mL; (d) 0.85 g/mL; (e) 0.95 g/mL

Figure 3. (a)−(e) SEM images of AgNPs@PMMA/ P-Si substrates with different concentrations of AgNPs in PMMA acetone solution: (a) 0.55 g/mL; (b) 0.65 g/mL; (c) 0.75 g/mL; (d) 0.85 g/mL; (e) 0.95 g/mL

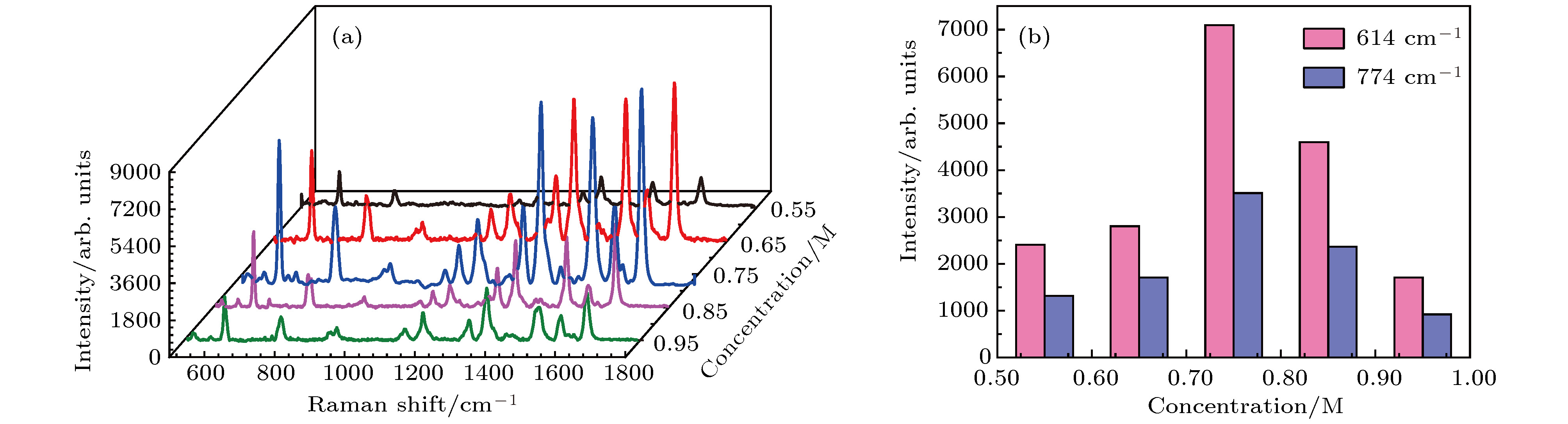

图 4 (a) 10–7 mol/L浓度的R6G分子在不同浓度AgNPs@PMMA/P-Si基底上的SERS光谱; (b) 对应(a)图中的R6G分子在614 cm–1和774 cm–1处的拉曼峰强

Figure 4. (a) SERS spectra of R6G (10–7 mol/L) on the AgNPs@PMMA/P-Si substrates fabricated with different concentrations; (b) corresponding to the Raman peak at 614 and 774 cm–1 for the R6G molecule in Fig. (a).

图 5 (a) 10–10−10–14 mol/L的R6G分子吸附在银颗粒浓度为0.75 g/mL的AgNPs@PMMA/P-Si基底上的SERS光谱; (b) 吸附在AgNPs@PMMA/P-Si基底上的R6G分子在614和1365 cm–1处的拉曼峰强度与浓度的关系; (c) SERS基底的拉曼检测示意图; (d) R6G分子在三维复合SERS基底上的探测极限(10–13 mol/L)和的平面Si基底上的探测极限(10–4 mol/L)光谱的对比

Figure 5. (a) SERS spectra of R6G with concentrations from 10–10 to 10–14 mol/L on the AgNPs@PMMA/P-Si with AgNPs concentration of 0.75 g/mL substrate; (b) the intensity of R6G peak at 614 cm–1 and 1365 cm–1 changes as a function of R6G molecule concentration on the AgNPs@PMMA/P-Si substrates; (c) schematic illustration showing the Raman detection of SERS substrates; (d) comparison of the detection limit of the R6 G molecule on the 3D composite SERS substrate (10–13 mol/L) and the detection limit (10–4 mol/L) on the planar Si substrate.

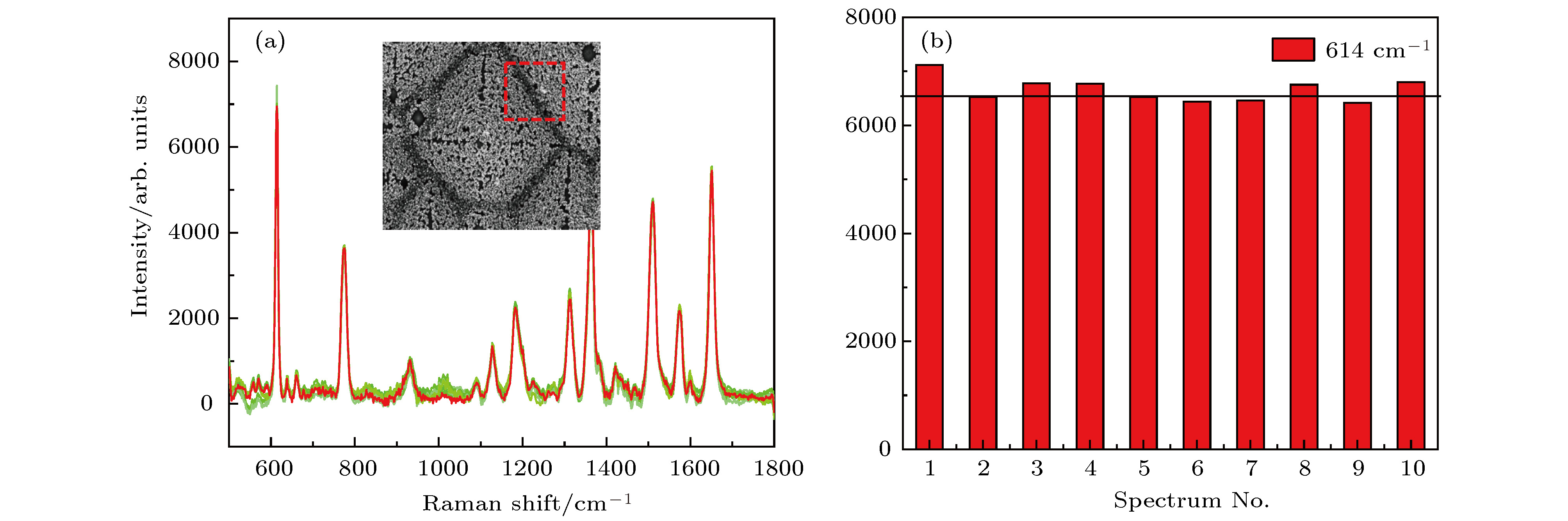

图 6 (a) 0.75 g/mL浓度的AgNPs@ PMMA/P-Si基底塔基位置处10个随机位置R6G分子(10–7 mol/L)的平均SERS谱(红线为10条SERS谱线的平均值); (b) 相应(a)图中614 cm–1处拉曼峰强度变化统计图

Figure 6. (a) Average SERS spectrum of the 10–7 mol/L R6G molecules from 10 random positions in the base tower of AgNPs@ PMMA/P-Si with concentration of 0.75 g/mL substrate (red line is the average of 10 SERS spectrum lines); (b) statistical diagram of variation of Raman peak intensity at 614 cm–1 is in the corresponding Fig. (a).

图 7 (a) 10–7 mol/L的R6G分子分别吸附在AgNPs@PMMA/P-Si, AgNPs@PMMA/F-Si和AgNPs/P-Si基底上的拉曼光谱; (b)在18 d时间内每隔3 d分别在AgNPs@PMMA/P-Si和AgNPs/PMMA/F-Si基底上所采集到的10–7 mol/L的R6G分子614 cm–1峰处的拉曼强度

Figure 7. (a) The Raman spectra of R6G molecule with 10–7 mol/L on the AgNPs@PMMA/P-Si, AgNPs@PMMA/F-Si, and AgNPs/P-Si substrates; (b) the intensity of the signal at 614 cm–1 of R6G (10–7 mol/L) collected with 18 days every three days respectively on the AgNPs@PMMA/P-Si and AgNPs/PMMA/F-Si substrate.

-

[1] Fleischmann M, Hendra P J, Mcquillan A J 1974 Chem. Phys. Lett. 26 163

Google Scholar

Google Scholar

[2] Guerrini L, Krpetić Ž, van Lierop D, Alvarez Puebla A R, Graham D 2015 Angew. Chem. Int. Edit. 54 1144

Google Scholar

Google Scholar

[3] Kubackova J, Fabriciova G, Miskovsky P, Jancura D, Sanchez-Cortes S 2015 Anal. Chem. 87 663

Google Scholar

Google Scholar

[4] Zhang C, Li C, Yu J, Jiang S, Xu S, Yang C, Liu Y J, Gao X, Liu A, Man B 2018 Sensor. Actuat. B Chem. 258 163

Google Scholar

Google Scholar

[5] Sotiriou G A, Blattmann C O, Deligiannakis Y 2015 Nanoscale 8 796

[6] Fortuni B, Inose T, Uezono S, Toyouchi S, Umemoto K, Sekine S, Fujita Y, Ricci M, Lu G, Masuhara A, Hutchison JA, Latterini L, Uji I H 2017 Chem. Commun. 53 11298

Google Scholar

Google Scholar

[7] 冯仕靓, 王靖宇, 陈舒, 孟令雁, 沈少鑫, 杨志林 2019 68 147801

Google Scholar

Google Scholar

Feng S L, Wang J Y, Chen S, Meng L Y, Shen S X, Yang Z L 2019 Acta Phys. Sin. 68 147801

Google Scholar

Google Scholar

[8] Fan C, Zhu S, Xin H, Tian Y, Liang E 2017 J. Optics-UK 19 015401

Google Scholar

Google Scholar

[9] 张娜 2015 硕士学位论文 (苏州: 苏州大学)

Zhang N 2015 M. S. Thesis (Suzhou: Soochow University) (in Chinese)

[10] 张星, 郝艳玲, 方炎 2013 光散射学报 2 5

Google Scholar

Google Scholar

Zhang X, Hao Y L, Fang Y 2013 The Journal of Light Scattering 2 5

Google Scholar

Google Scholar

[11] Xu S, Jiang S, Wang J, Wei J, Yue W, Ma Y 2016 Sens. Actuators, B 222 1175

[12] 程自强, 石海泉, 余萍, 刘志敏 2018 67 197302

Google Scholar

Google Scholar

Cheng Z Q, Shi H Q, Yu P, Liu Z M 2018 Acta Phys. Sin. 67 197302

Google Scholar

Google Scholar

[13] Xu S, Tang W, Chase D B, Sparkset D L, Raboit J 2018 ACS Appl. Nano Mater. 1 1257

[14] Xu W, Xiao J, Chen Y, Chen Y, Ling X, Zhang J 2013 Adv. Mater. 25 928

Google Scholar

Google Scholar

[15] Sivashanmugan K, Liao J D, Liu B H, Yao C K 2013 Anal. Chim. Acta 800 56

Google Scholar

Google Scholar

[16] Park S, Lee J, Ko H 2017 ACS Appl. Mater. Interfaces 9 44088

Google Scholar

Google Scholar

[17] Yang C, Chen Y, Liu D, Chen C, Wang J, Fan Y, Huang S, Lei W 2018 ACS Appl. Mater. Interfaces 10 8317

[18] Tang H, Meng G, Huang Q, Zhang Z, Huang Z, Zhu C 2012 Adv. Funct. Mater. 22 218

Google Scholar

Google Scholar

[19] Li X, Chen G, Yang L, Zhen J, Liu J 2010 Adv. Funct. Mater. 20 2815

Google Scholar

Google Scholar

[20] Lee S, Hahm M G, Vajtai R, Hashim D P, Thurakitseree T, Chipara A C, Ajayan P M, Hafneret J H 2012 Adv. Mater. 24 5261

Google Scholar

Google Scholar

[21] 黄晨玥 2016 硕士学位论文 (南京: 东南大学)

Huang C Y 2016 M.S. Thesis (Nanjin: Southeast University) (in Chinese)

[22] Yuan Z, Zhao S, Zhang L, Yu L, Li X, Lu Y 2017 RSC Adv. 7 11904

Google Scholar

Google Scholar

[23] Smyth C A, Mirza I, Lunney J G, McCabe E M 2013 Appl. Surf. Sci. 264 31

Google Scholar

Google Scholar

[24] Wang K, Sun D W, Pu H, Wei Q, Huang L 2019 ACS Appl. Mater. Interfaces 11 29177

Google Scholar

Google Scholar

[25] Wang X, Bai X, Pang Z, Zhu J, Wu Y, Yang H, Qi Y, Wen X 2019 Opt. Mater. Express 9 1872

Google Scholar

Google Scholar

[26] Gaballah S T, El-Nazer H A, Abdel-Monem R A, El-Liethy M A, Hemdan B A, Rabie S 2019 Int. J. Biol. Macromol. 121 707

Google Scholar

Google Scholar

[27] Zhong L B, Yin J, Zheng Y M, Liu Q, Cheng X X, Luo F H 2014 Anal. Chem. 86 6262

Google Scholar

Google Scholar

[28] Shiohara A, Langer J, Polavarapu L, Lizmarzán L M 2014 Nanoscale 6 9817

Google Scholar

Google Scholar

[29] 卢思辰, 高宇坤, 杨楠, 张晨萌, 尤汀汀, 殷鹏刚 2018 光谱学与光谱分析 38 176

Lu S C, Gao Y K, Yang N, Zhang C M, You T T, Yin P G 2018 Spectroscopy and Spectral Analysis 38 176

[30] Li C, Yu J, Xu S, Jiang S, Xiu X, Chen C, Liu A, Wu T, Man B, Zhang C 2018 Adv. Mater. Technol. 3 1800174

Google Scholar

Google Scholar

[31] Yao G, Zhang H, Zhang S, Liao F, Huang Z, Bie B, Lin Y 2017 RSC Adv. 7 27281

Google Scholar

Google Scholar

[32] Zhang X Y, Hu A, Zhang T, Xue X J, Wen J Z, Duley W W 2010 Appl. Phys. Lett. 96 043109

Google Scholar

Google Scholar

[33] Peng B, Li Z, Mutlugun E, Hernández Martínez P L, Li D, Zhang Q, Gao Y, Demir H V, Xiong Q 2014 Nanoscale 6 5592

Google Scholar

Google Scholar

[34] Jin L, She G, Wang X, Mu L, Shi W 2014 Appl. Surf. Sci. 320 591

Google Scholar

Google Scholar

[35] Natan M J 2006 Faraday Discuss 132 321

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 14846

- PDF Downloads: 181

- Cited By: 0

DownLoad:

DownLoad: