-

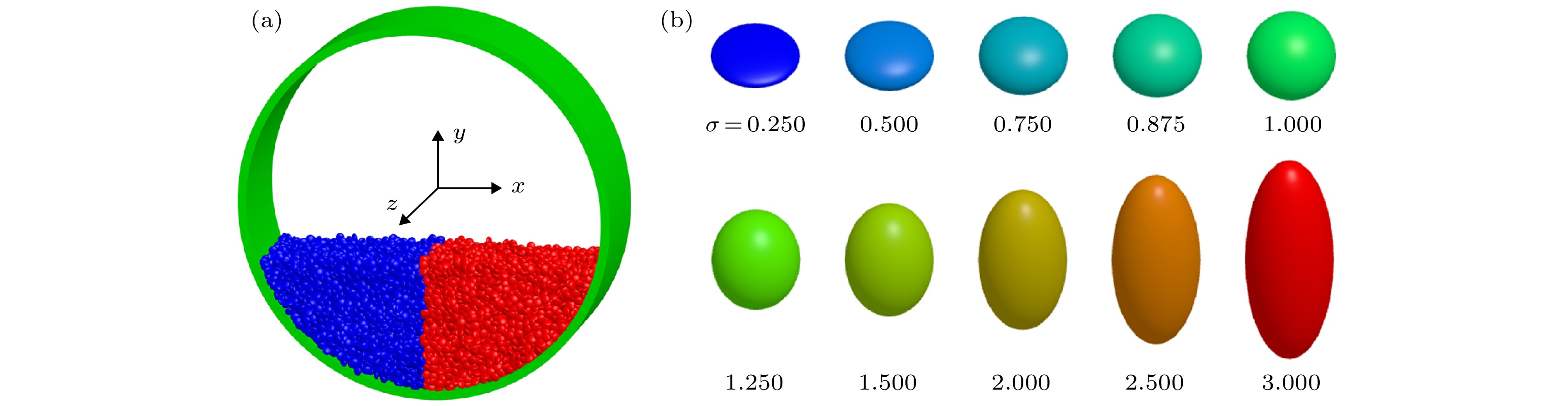

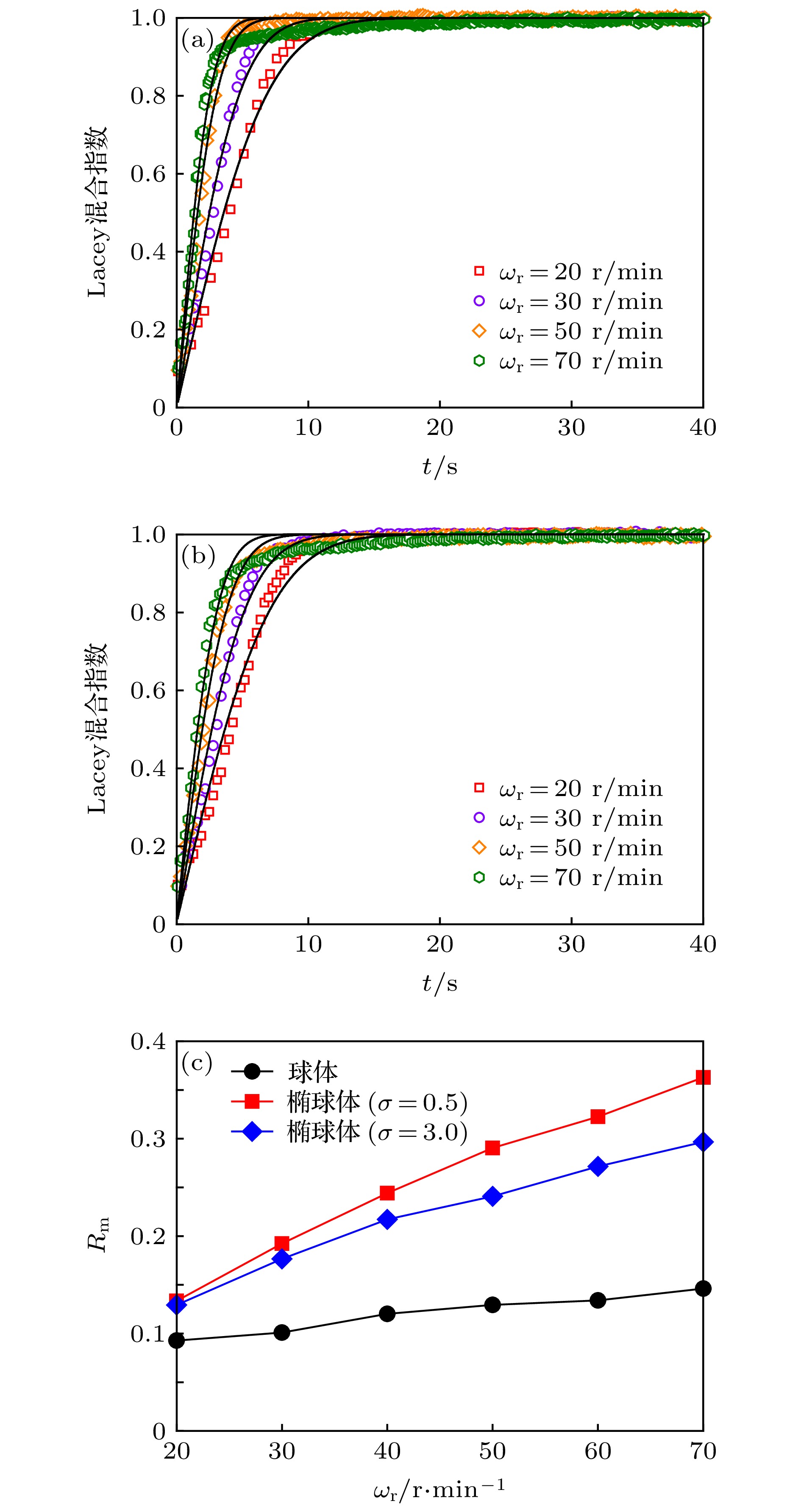

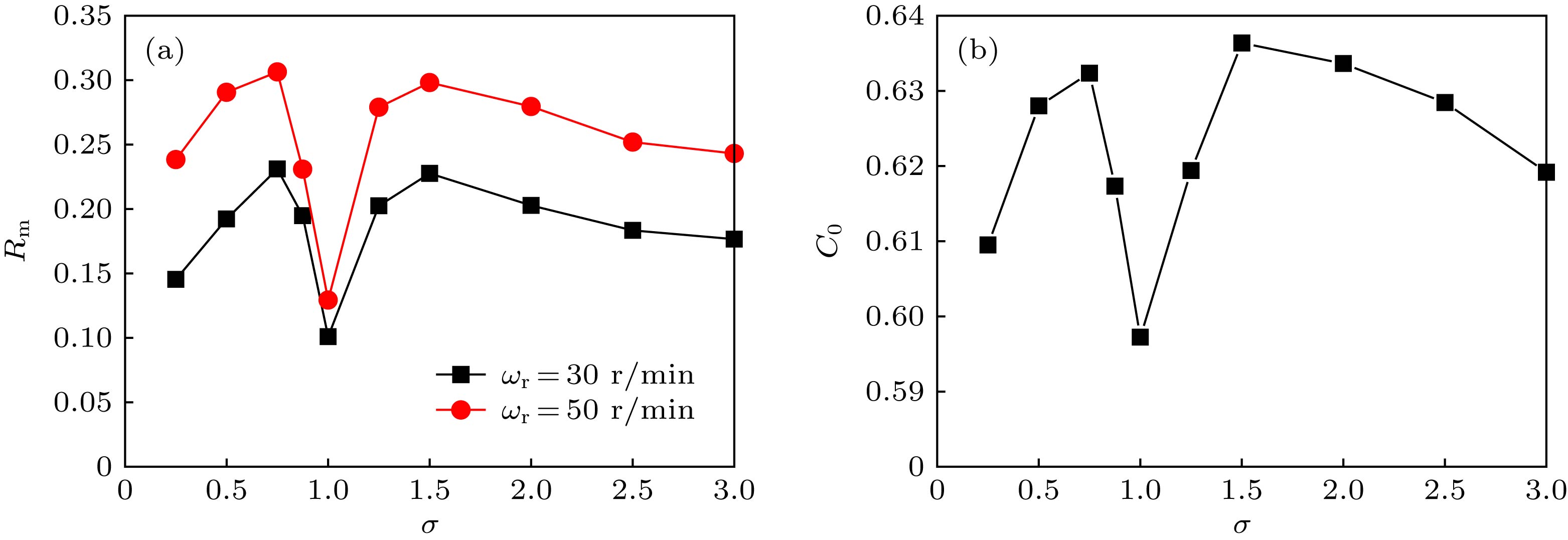

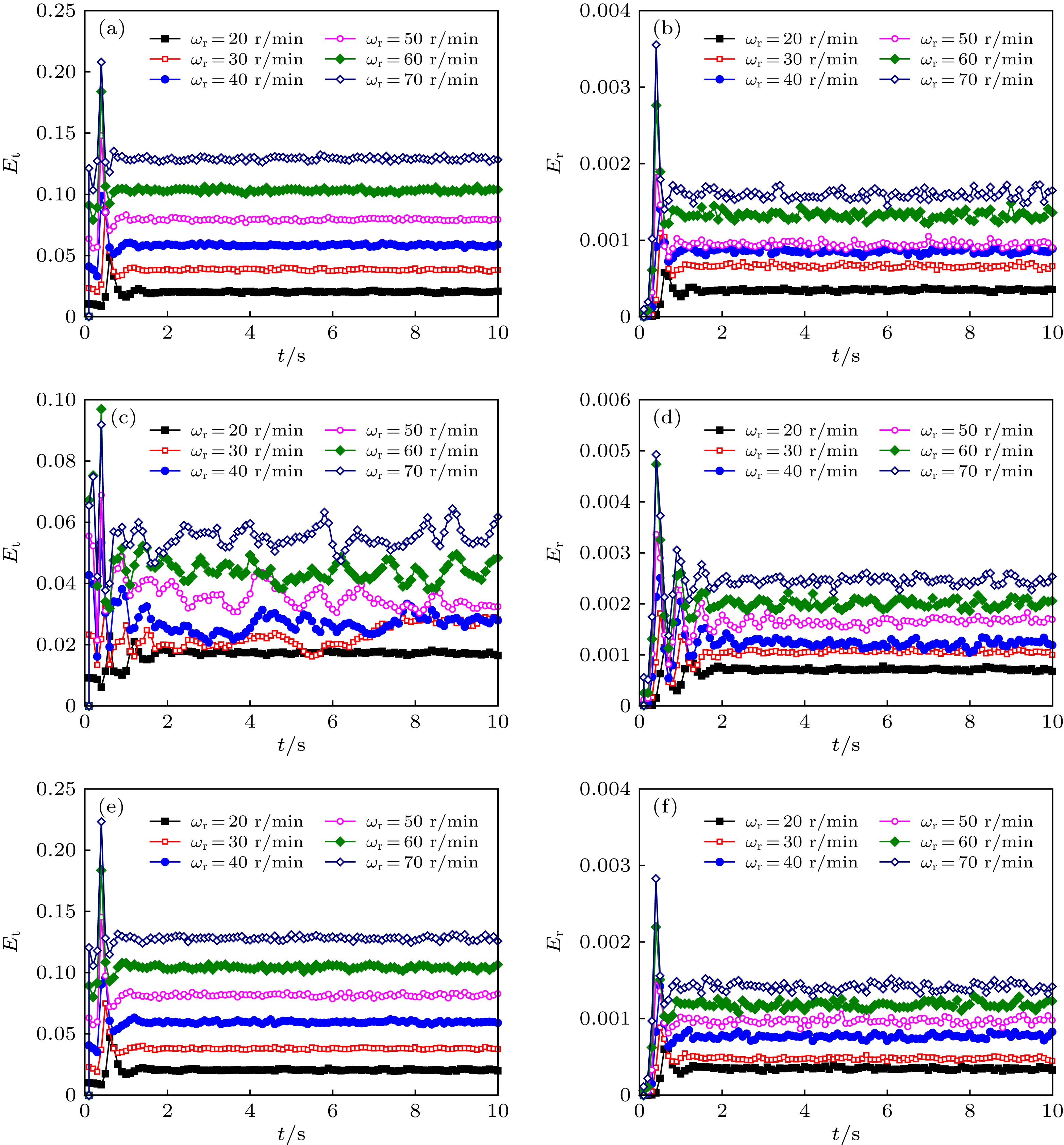

Granular flow in the drum widely appears in the fields of industrial production, and discrete element method (DEM) proves to be a critical tool for studying the flow characteristics of granular materials. Considering simple contact and efficient calculations, the three-dimensional spheres are originally adopted by the DEM. Therefore, the DEM simulations mainly focus on spherical particles, while the dynamics of non-spherical particles in rotating drums is relatively rarely studied. It is reported that particle shape significantly affects the macroscopic and microscopic properties of the granular flow. Compared with spherical particles, non-spherical particles have low fluidity and great interlock. Meanwhile, it is questionable whether conclusions drawn from spherical particle systems can be transplanted to non-spherical particle systems. In this work, super-quadric equations based on continuous function representation are used to describe the spherical and ellipsoidal particles. Considering the complex contact detection between particles, the Newton iteration algorithm is used to solve the non-linear equations. Meanwhile, a non-linear contact model considering the equivalent radius of curvature at the local contact point is used to calculate the contact force between the super-quadric elements. To examine the validity of DEM model, we compare our simulated results with the previous experimental results for mixing process of ellipsoids, and this method is verified by good agreement between the simulated results and the experimental results. According to the aforementioned method, the influences of rotating speed, fill level, and aspect ratio on the mixing rate are discussed. The results show that the granular system reaches the cascading regime and the S-shaped surface of the granular bed is observed. In addition, Lacey mixing index is used to quantify the mixing of granular systems, and the mixing rate is obtained by fitting the Lacey mixing index. The mixing rate increases as the rotating speed increases. At the same rotating speed, the mixing rate of ellipsoids is faster than that of spheres. Meanwhile, the ellipsoidal particles have the fastest mixing rate when the aspect ratio is 0.75 or 1.50. When the aspect ratio is less than 0.75, the mixing ratio increases as the aspect ratio increases; when the aspect ratio is greater than 1.50, the mixing ratio decreases as the aspect ratio increases. Moreover, more pronounced velocity stratification is observed for ellipsoids. The translational kinetic energy of ellipsoidal particles is higher than that of spherical particles, and their rotational kinetic energy is lower than that of spheres. The aspect ratio of particles can adjust the contact mode between particles and cause the interlock. It means that the relative rotation between particles is limited and the efficiency of the external energy transferring to the non-spherical system may be improved. -

Keywords:

- discrete element method /

- super-quadric element /

- ellipsoidal particle /

- mixing characteristics

[1] Gioia G, Ott-Monsivais S E, Hill K M 2006 Phys. Rev. Lett. 96 138001

Google Scholar

Google Scholar

[2] Emilien A, Farhang R 2014 Phys. Rev. Lett. 112 078001

Google Scholar

Google Scholar

[3] Jaeger H M, Nagel S R 1992 Science 255 1523

Google Scholar

Google Scholar

[4] 季顺迎, 孙其诚, 严颖 2011 中国科学: 物理学 力学 天文学 41 1112

Ji S Y, Sun Q C, Yan Y 2011 Sci. Sin-Phys. Mech. Astron. 41 1112

[5] 黄德财, 孙刚, 厚美瑛, 陆坤权 2006 55 4754

Google Scholar

Google Scholar

Huang D C, Sun G, Hou M Y, Lu K Q 2006 Acta Phys. Sin. 55 4754

Google Scholar

Google Scholar

[6] 彭政, 蒋亦民, 刘锐, 厚美瑛 2013 62 024502

Google Scholar

Google Scholar

Peng Z, Jiang Y M, Liu R, Hou M Y 2013 Acta Phys. Sin. 62 024502

Google Scholar

Google Scholar

[7] 孙其诚, 王光谦 2008 57 4667

Google Scholar

Google Scholar

Sun Q C, Wang G Q 2008 Acta Phys. Sin. 57 4667

Google Scholar

Google Scholar

[8] 夏建新, 吉祖稳, 毛旭锋, 曹华德 2013 科学通报 58 1200

Xia J X, Ji Z W, Mao X F, Cao H D 2013 Chin. Sci. Bull. 58 1200

[9] 刘扬, 韩燕龙, 贾富国, 姚丽娜, 王会, 史宇菲 2015 64 114501

Google Scholar

Google Scholar

Liu Y, Han Y L, Jia F G, Yao L N, Wang H, Shi Y F 2015 Acta Phys. Sin. 64 114501

Google Scholar

Google Scholar

[10] 陈泉, 杨晖, 李然, 韩韧, 孙其诚 2019 中国科学: 物理学 力学 天文学 49 067001

Chen Q, Yang H, Li R, Han R, Sun Q C 2019 Sci. Sin.: Phys. Mech. Astron. 49 067001

[11] Cundall P A, Strack O D L 1979 Géotechnique 29 47

Google Scholar

Google Scholar

[12] 赵子渊, 李昱君, 王富帅, 张祺, 厚美瑛, 李文辉, 马钢 2018 67 104502

Google Scholar

Google Scholar

Zhao Z Y, Li Y J, Wang F S, Zhang Q, Hou M Y, Li W H, Ma G 2018 Acta Phys. Sin. 67 104502

Google Scholar

Google Scholar

[13] Chand R, Khaskheli M A, Qadir A, Ge B, Shi Q 2012 Physica A 391 4590

Google Scholar

Google Scholar

[14] 黄德财, 冯耀东, 解为梅, 陆明, 吴海平, 胡凤兰, 邓开明 2012 61 124501

Google Scholar

Google Scholar

Huang D C, Feng Y D, Xie W M, Lu M, Wu H P, Hu F L, Deng K M 2012 Acta Phys. Sin. 61 124501

Google Scholar

Google Scholar

[15] Gui N, Fan J 2015 Int. J. Heat Mass Tran. 84 740

Google Scholar

Google Scholar

[16] Xiao X, Tan Y, Zhang H, Deng R, Jiang S 2017 Powder Technol. 314 182

Google Scholar

Google Scholar

[17] Chou S H, Hu H J, Hsiau S S 2016 Adv. Powder Technol. 27 1912

Google Scholar

Google Scholar

[18] Halidan M, Chandratilleke G R, Dong K J, Yu A B 2018 Powder Technol. 325 92

Google Scholar

Google Scholar

[19] 高红利, 赵永志, 刘格思, 陈友川, 郑津洋 2011 60 074501

Google Scholar

Google Scholar

Gao H L, Zhao Y Z, Liu G S, Chen Y C, Zheng J Y 2011 Acta Phys. Sin. 60 074501

Google Scholar

Google Scholar

[20] Zhong W, Yu A, Liu X, Tong Z, Zhang H 2016 Powder Technol. 302 108

Google Scholar

Google Scholar

[21] Lu G, Third J R, Müller C R 2015 Chem. Eng. Sci. 127 425

Google Scholar

Google Scholar

[22] Obermayr M, Dressler K, Vrettos C, Eberhard P 2013 Comput. Geotech. 49 299

Google Scholar

Google Scholar

[23] Govender N, Wilke D N, Kok S 2015 Appl. Math. Comput. 267 810

[24] 刘璐, 季顺迎 2019 中国科学: 物理学 力学 天文学 49 064601

Liu L, Ji S Y 2019 Sci. Sin.: Phys. Mech. Astron. 49 064601

[25] 王嗣强, 季顺迎 2018 67 094501

Google Scholar

Google Scholar

Wang S Q, Ji S Y 2018 Acta Phys. Sin. 67 094501

Google Scholar

Google Scholar

[26] Garboczi E J, Bullard J W 2017 Adv. Powder Technol. 28 325

Google Scholar

Google Scholar

[27] Gui N, Yang X, Tu J, Jiang S 2017 Powder Technol. 318 248

Google Scholar

Google Scholar

[28] Ma H, Zhao Y 2017 Chem. Eng. Sci. 172 636

Google Scholar

Google Scholar

[29] Ma H, Zhao Y 2018 Granul. Matter 20 41

Google Scholar

Google Scholar

[30] Kodam M, Bharadwaj R, Curtis J, Hancock B, Wassgren C 2010 Chem. Eng. Sci. 65 5863

Google Scholar

Google Scholar

[31] You Y, Zhao Y 2018 Powder Technol. 331 179

Google Scholar

Google Scholar

[32] Barr 1981 IEEE Comput. Graph. Appl. 1 11

Google Scholar

Google Scholar

[33] Soltanbeigi B, Podlozhnyuk A, Papanicolopulos S A, Kloss C, Pirker S, Ooi J Y 2018 Powder Technol. 329 288

Google Scholar

Google Scholar

[34] Houlsby G T 2009 Powder Technol. 36 953

[35] Podlozhnyuk A, Pirker S, Kloss C 2016 Comput. Part. Mech. 4 101

[36] Zhou Z Y, Zou R P, Pinson D, Yu A B 2011 Ind. Eng. Chem. Res. 50 9787

Google Scholar

Google Scholar

[37] He S Y, Gan J Q, Pinson D, Zhou Z Y 2019 Powder Technol. 341 157

Google Scholar

Google Scholar

[38] Goldman R 2005 Comput. Aided Geom. D 22 632

Google Scholar

Google Scholar

[39] Lacey P M C 1954 J. Chem. Technol. Biot. 4 257

[40] Jiang M, Zhao Y, Liu G, Zheng J 2011 Particuology 9 270

Google Scholar

Google Scholar

[41] He S, Gan J, Pinson D, Zhou Z 2017 EPJ Web of Conferences 140 06018

Google Scholar

Google Scholar

[42] Donev A, Cisse I, Sachs D, Variano E A, Stillinger F H, Connelly R, Torquato S, Chaikin P M 2004 Science 303 990

Google Scholar

Google Scholar

[43] Delaney G W, Cleary P W 2010 Europhys. Lett. 89 34002

Google Scholar

Google Scholar

-

图 3 不同转动圈数下颗粒混合过程的实验结果[31]和离散元数值结果的对比 (a) ωr = 20 r/min的流动图案; (b) ωr = 20 r/min的Lacey混合指数; (c) ωr = 40 r/min的Lacey混合指数

Figure 3. Comparison of mixing process between experiment results[31] and DEM simulation results at different rotating speeds: (a) Mixing pattern at 20 r/min; (b) Lacey mixing index at 20 r/min; (c) Lacey mixing index at 40 r/min.

图 5 旋转速度和颗粒长宽比对混合过程的影响 (a) ωr = 20 r/min的椭球颗粒(σ = 3.0); (b) ωr = 40 r/min的椭球颗粒(σ = 3.0); (c) ωr = 20 r/min的球体颗粒(σ = 1.0); (d) ωr = 20 r/min的椭球颗粒(σ = 0.5)

Figure 5. The influence of rotating speed and aspect ratio on the mixing process: (a) Ellipsoids (σ = 3.0) at 20 r/min; (b) ellipsoids (σ = 3.0) at 40 r/min; (c) sphere (σ = 1.0) at 20 r/min; (d) ellipsoids (σ = 0.5) at 20 r/min

图 10 在不同转速下球体和椭球颗粒的平动动能和转动动能随时间的变化 (a), (b) 椭球(σ = 0.5); (c), (d) 球体(σ = 1.0); (e), (f) 椭球(σ = 3.0)

Figure 10. Translational and rotational kinetic energy at different rotating speeds for differently shaped particles: (a), (b) Ellipsoids (σ = 0.5); (c), (d) spheres (σ = 1.0); (e), (f) ellipsoids (σ = 3.0)

表 1 椭球颗粒离散元模拟的主要计算参数

Table 1. DEM simulation parameters of ellipsoids

参数 符号 单位 数值 参数 符号 单位 数值 弹性模量 E GPa 1.0 颗粒间摩擦系数 μs — 0.3 泊松比 ν — 0.3 法向阻尼系数 Cn — 0.05 颗粒密度 ρ kg/m3 1150.0 切向阻尼系数 Ct — 0.05 颗粒与圆筒的摩擦系数 μws — 0.9 时间步长 dt s 1 × 10–6 -

[1] Gioia G, Ott-Monsivais S E, Hill K M 2006 Phys. Rev. Lett. 96 138001

Google Scholar

Google Scholar

[2] Emilien A, Farhang R 2014 Phys. Rev. Lett. 112 078001

Google Scholar

Google Scholar

[3] Jaeger H M, Nagel S R 1992 Science 255 1523

Google Scholar

Google Scholar

[4] 季顺迎, 孙其诚, 严颖 2011 中国科学: 物理学 力学 天文学 41 1112

Ji S Y, Sun Q C, Yan Y 2011 Sci. Sin-Phys. Mech. Astron. 41 1112

[5] 黄德财, 孙刚, 厚美瑛, 陆坤权 2006 55 4754

Google Scholar

Google Scholar

Huang D C, Sun G, Hou M Y, Lu K Q 2006 Acta Phys. Sin. 55 4754

Google Scholar

Google Scholar

[6] 彭政, 蒋亦民, 刘锐, 厚美瑛 2013 62 024502

Google Scholar

Google Scholar

Peng Z, Jiang Y M, Liu R, Hou M Y 2013 Acta Phys. Sin. 62 024502

Google Scholar

Google Scholar

[7] 孙其诚, 王光谦 2008 57 4667

Google Scholar

Google Scholar

Sun Q C, Wang G Q 2008 Acta Phys. Sin. 57 4667

Google Scholar

Google Scholar

[8] 夏建新, 吉祖稳, 毛旭锋, 曹华德 2013 科学通报 58 1200

Xia J X, Ji Z W, Mao X F, Cao H D 2013 Chin. Sci. Bull. 58 1200

[9] 刘扬, 韩燕龙, 贾富国, 姚丽娜, 王会, 史宇菲 2015 64 114501

Google Scholar

Google Scholar

Liu Y, Han Y L, Jia F G, Yao L N, Wang H, Shi Y F 2015 Acta Phys. Sin. 64 114501

Google Scholar

Google Scholar

[10] 陈泉, 杨晖, 李然, 韩韧, 孙其诚 2019 中国科学: 物理学 力学 天文学 49 067001

Chen Q, Yang H, Li R, Han R, Sun Q C 2019 Sci. Sin.: Phys. Mech. Astron. 49 067001

[11] Cundall P A, Strack O D L 1979 Géotechnique 29 47

Google Scholar

Google Scholar

[12] 赵子渊, 李昱君, 王富帅, 张祺, 厚美瑛, 李文辉, 马钢 2018 67 104502

Google Scholar

Google Scholar

Zhao Z Y, Li Y J, Wang F S, Zhang Q, Hou M Y, Li W H, Ma G 2018 Acta Phys. Sin. 67 104502

Google Scholar

Google Scholar

[13] Chand R, Khaskheli M A, Qadir A, Ge B, Shi Q 2012 Physica A 391 4590

Google Scholar

Google Scholar

[14] 黄德财, 冯耀东, 解为梅, 陆明, 吴海平, 胡凤兰, 邓开明 2012 61 124501

Google Scholar

Google Scholar

Huang D C, Feng Y D, Xie W M, Lu M, Wu H P, Hu F L, Deng K M 2012 Acta Phys. Sin. 61 124501

Google Scholar

Google Scholar

[15] Gui N, Fan J 2015 Int. J. Heat Mass Tran. 84 740

Google Scholar

Google Scholar

[16] Xiao X, Tan Y, Zhang H, Deng R, Jiang S 2017 Powder Technol. 314 182

Google Scholar

Google Scholar

[17] Chou S H, Hu H J, Hsiau S S 2016 Adv. Powder Technol. 27 1912

Google Scholar

Google Scholar

[18] Halidan M, Chandratilleke G R, Dong K J, Yu A B 2018 Powder Technol. 325 92

Google Scholar

Google Scholar

[19] 高红利, 赵永志, 刘格思, 陈友川, 郑津洋 2011 60 074501

Google Scholar

Google Scholar

Gao H L, Zhao Y Z, Liu G S, Chen Y C, Zheng J Y 2011 Acta Phys. Sin. 60 074501

Google Scholar

Google Scholar

[20] Zhong W, Yu A, Liu X, Tong Z, Zhang H 2016 Powder Technol. 302 108

Google Scholar

Google Scholar

[21] Lu G, Third J R, Müller C R 2015 Chem. Eng. Sci. 127 425

Google Scholar

Google Scholar

[22] Obermayr M, Dressler K, Vrettos C, Eberhard P 2013 Comput. Geotech. 49 299

Google Scholar

Google Scholar

[23] Govender N, Wilke D N, Kok S 2015 Appl. Math. Comput. 267 810

[24] 刘璐, 季顺迎 2019 中国科学: 物理学 力学 天文学 49 064601

Liu L, Ji S Y 2019 Sci. Sin.: Phys. Mech. Astron. 49 064601

[25] 王嗣强, 季顺迎 2018 67 094501

Google Scholar

Google Scholar

Wang S Q, Ji S Y 2018 Acta Phys. Sin. 67 094501

Google Scholar

Google Scholar

[26] Garboczi E J, Bullard J W 2017 Adv. Powder Technol. 28 325

Google Scholar

Google Scholar

[27] Gui N, Yang X, Tu J, Jiang S 2017 Powder Technol. 318 248

Google Scholar

Google Scholar

[28] Ma H, Zhao Y 2017 Chem. Eng. Sci. 172 636

Google Scholar

Google Scholar

[29] Ma H, Zhao Y 2018 Granul. Matter 20 41

Google Scholar

Google Scholar

[30] Kodam M, Bharadwaj R, Curtis J, Hancock B, Wassgren C 2010 Chem. Eng. Sci. 65 5863

Google Scholar

Google Scholar

[31] You Y, Zhao Y 2018 Powder Technol. 331 179

Google Scholar

Google Scholar

[32] Barr 1981 IEEE Comput. Graph. Appl. 1 11

Google Scholar

Google Scholar

[33] Soltanbeigi B, Podlozhnyuk A, Papanicolopulos S A, Kloss C, Pirker S, Ooi J Y 2018 Powder Technol. 329 288

Google Scholar

Google Scholar

[34] Houlsby G T 2009 Powder Technol. 36 953

[35] Podlozhnyuk A, Pirker S, Kloss C 2016 Comput. Part. Mech. 4 101

[36] Zhou Z Y, Zou R P, Pinson D, Yu A B 2011 Ind. Eng. Chem. Res. 50 9787

Google Scholar

Google Scholar

[37] He S Y, Gan J Q, Pinson D, Zhou Z Y 2019 Powder Technol. 341 157

Google Scholar

Google Scholar

[38] Goldman R 2005 Comput. Aided Geom. D 22 632

Google Scholar

Google Scholar

[39] Lacey P M C 1954 J. Chem. Technol. Biot. 4 257

[40] Jiang M, Zhao Y, Liu G, Zheng J 2011 Particuology 9 270

Google Scholar

Google Scholar

[41] He S, Gan J, Pinson D, Zhou Z 2017 EPJ Web of Conferences 140 06018

Google Scholar

Google Scholar

[42] Donev A, Cisse I, Sachs D, Variano E A, Stillinger F H, Connelly R, Torquato S, Chaikin P M 2004 Science 303 990

Google Scholar

Google Scholar

[43] Delaney G W, Cleary P W 2010 Europhys. Lett. 89 34002

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 14095

- PDF Downloads: 146

- Cited By: 0

DownLoad:

DownLoad: