-

Granular medium is ubiquitous in nature, and is an important issue in many infrastructural construction projects. In particular, the gravity discharge of fine particles from a silo constitutes an important problem of research, because of its many industrial applications. However, the physical mechanism of this system remains unclear. In this work, we study the discharge of silo from the bottom or lateral orifice, by performing pseudo-three-dimensional (3D) continuum simulations based on the local constitutive theory. The simulation is two-dimensional (2D), in order to study the 3D silo, we add the lateral frictional force in the averaged momentum equation. For a rectangular silo with an orifice of height

$D$ and the silo thickness$W$ , we study the influence of the orifice size ($W$ and$D$ ) on the granular pressure and velocity. The force analysis and simulation results reveal that for the relation between the granular pressure and the orifice size, there exist two regimes: when$D/W$ is small enough, the pressure near the orifice varies only with$D$ ; when$D/W$ is large enough, the pressure varies only with$W$ . These scaling laws are the same for both bottom and lateral orifice. Somewhat surprisingly, the simulation results also show that when the orifice is at the bottom, the scaling law of the vertical velocity is different from that of the pressure; when it is on the lateral side, the scaling law of the horizontal velocity is consistent with that of the pressure. This observation contradicts a hypothesis that the flow rate of discharge is controlled by the granular pressure near the orifice, and validates the recent experimental results reported in the literature. Furthermore, the relationship between the vertical velocity and the orifice size reveals that when the orifice is at the bottom, the critical value of$D/W$ for the transition of regime is much larger than the lateral orifice case, the flow rate will depend only on$W$ when$D/W\gg50$ . This condition is hardly satisfied in practice, so the new scaling law has not yet been observed for the bottom orifice case in the literature. Furthermore, this work demonstrates that the stagnant zone has an important effect on the discharge of silo, especially for the lateral orifice case. Since a non-local constitutive law can well describe the quasi-static flow, it will be interesting to modify the local constitutive model into a non-local constitutive model, and to compare the results from the two models.-

Keywords:

- local constitutive law /

- continuum simulation /

- granular medium /

- discharge of silo

[1] Andreotti B, Forterre Y, Pouliquen O 2013 Granular Media: Between Fluid and Solid (Cambridge: Cambridge University Press) p1

[2] 陆坤权, 刘寄星 2004 物理 33 629

Google Scholar

Google Scholar

Lu K Q, Liu J X 2004 Physics 33 629

Google Scholar

Google Scholar

[3] Radjai F, Dubois F 2011 Discrete-element Modeling of Granular Materials (London: Wiley-Iste) p425

[4] Midi G D R 2004 Eur. Phys. J. E 14 341

Google Scholar

Google Scholar

[5] Jop P, Forterre Y, Pouliquen O 2006 Nature 441 727

Google Scholar

Google Scholar

[6] Lagree P Y, Staron L, Popinet S 2011 J. Fluid Mech. 686 378

Google Scholar

Google Scholar

[7] Staron L, Lagree P Y, Popinet S 2012 Phys. Fluids 24 103301

Google Scholar

Google Scholar

[8] Staron L, Lagree P Y, Popinet S 2014 Eur. Phys. J. E 37 1

Google Scholar

Google Scholar

[9] Andreotti B, Forterre Y, Pouliquen O 2013 Granular Media: Between Fluid and Solid (Cambridge: Cambridge University Press) pp239-246

[10] Andreotti B, Forterre Y, Pouliquen O 2013 Granular Media: Between Fluid and Solid (Cambridge: Cambridge University Press) pp87-91

[11] Sperl M 2006 Granular Matter 8 59

Google Scholar

Google Scholar

[12] Perge C, Aguirre M A, Gago P A, Pugnaloni L A, Le Tourneau D, Géminard J C 2012 Phys. Rev. E 85 021303

Google Scholar

Google Scholar

[13] Aguirre M A, Grande J G, Calvo A, Pugnaloni L A, Géminard J C 2011 Phys. Rev. E 83 061305

Google Scholar

Google Scholar

[14] Beverloo W A, Leniger H A, De Velde J V 1961 J. Chem. Eng. Sci. 15 260

Google Scholar

Google Scholar

[15] Sheldon H G, Durian D J 2010 Granular Matter 12 579

Google Scholar

Google Scholar

[16] Thomas C C, Durian D J 2015 Phys. Rev. Lett. 114 178001

Google Scholar

Google Scholar

[17] 张昱, 韦艳芳, 彭政, 蒋亦民, 段文山, 厚美瑛 2011 65 084502

Google Scholar

Google Scholar

Zhang Y, Wei Y F, Peng Z, Jiang Y M, Duan W S, Hou M Y 2011 Acta Phys. Sin. 65 084502

Google Scholar

Google Scholar

[18] Zhou Y, Lagree P Y, Popinet S, Aussillous P, Ruyer P 2017 J. Fluid Mech. 829 459

Google Scholar

Google Scholar

[19] Lagree P Y 2007 Math. Mech. 87 486

Google Scholar

Google Scholar

[20] Jop P, Forterre Y, Pouliquen O 2005 J. Fluid Mech. 541 167

Google Scholar

Google Scholar

[21] Popinet S 2009 J. Comput. Phys. 228 5838

Google Scholar

Google Scholar

[22] Janda A, Zuriguel I, Maza D 2012 Phys. Rev. Lett. 108 248001

Google Scholar

Google Scholar

[23] Benyamine M, Djermane M, Dalloz-Dubrujeaud B, Aussillous P 2014 Phys. Rev. E 90 032201

Google Scholar

Google Scholar

[24] Kamrin K, Koval G 2012 Phys. Rev. Lett. 108 178301

Google Scholar

Google Scholar

-

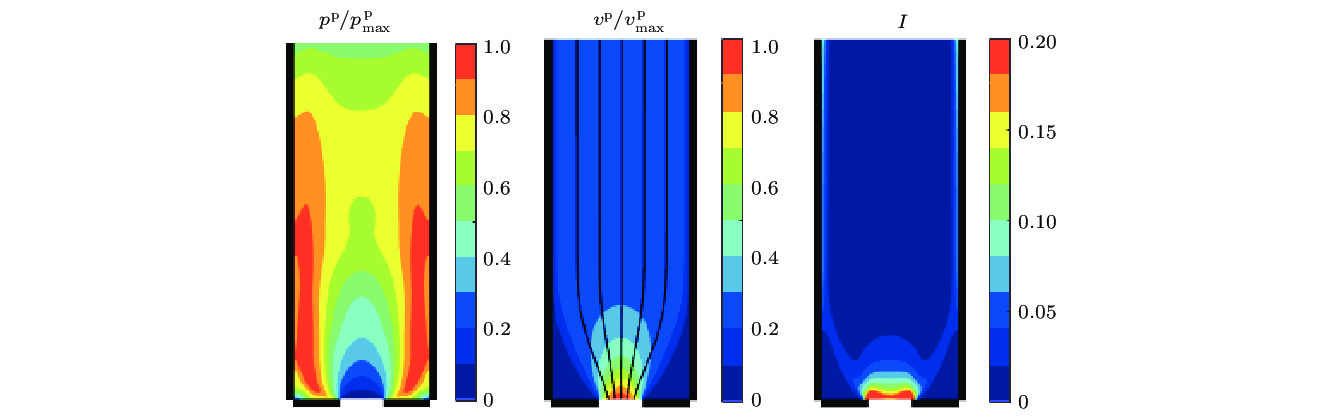

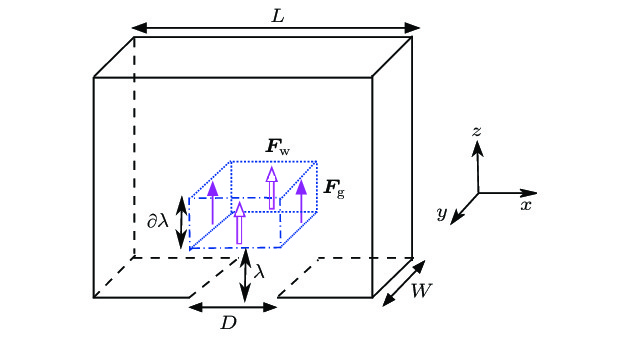

图 2

$ D = 0.3125L $ 以及$ W = 0.25L $ 情况下$ t/\sqrt{L/g} = 4 $ 时刻连续数值模拟结果, 从左至右: 容器内压强与其最大值之比; 竖直方向速度与其最大值之比, 其中黑色实线表示颗粒物流线; 无量纲常数$ I = d\sqrt{2}D_2/(\sqrt{p/\rho}) $ Figure 2. Continuum simulation results with

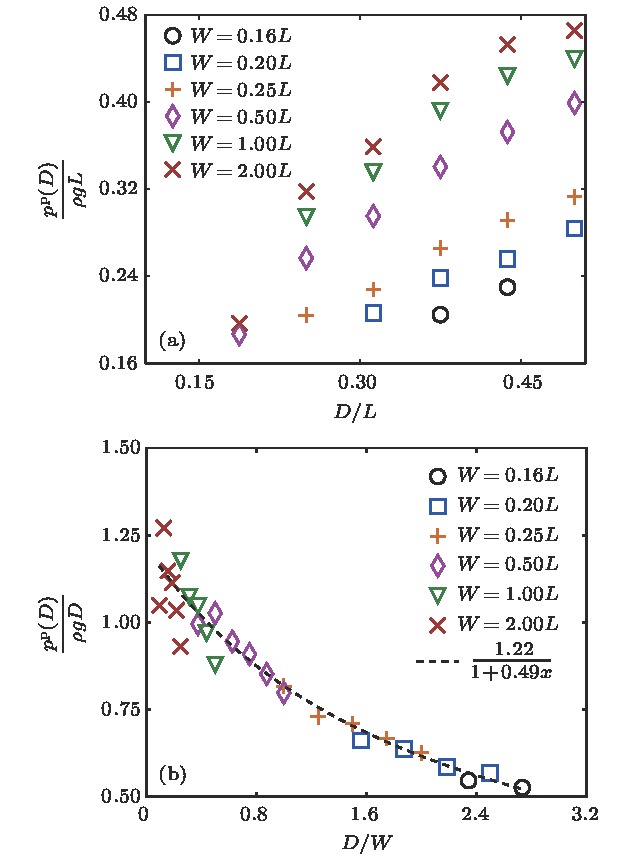

$ D = 0.3125L $ and$ W = 0.25L $ at time$ t/\sqrt{L/g} = 4 $ , from the left to the right: pressure$ p^{\rm p} $ normalized by it's maximum value within the silo; the vertical velocity$ v^{\rm p} $ normalized by it's maximum value within the silo, the black lines represent the streamlines; dimensionless number$ I = d\sqrt{2}D_2/(\sqrt{p/\rho}) $ .图 4 在

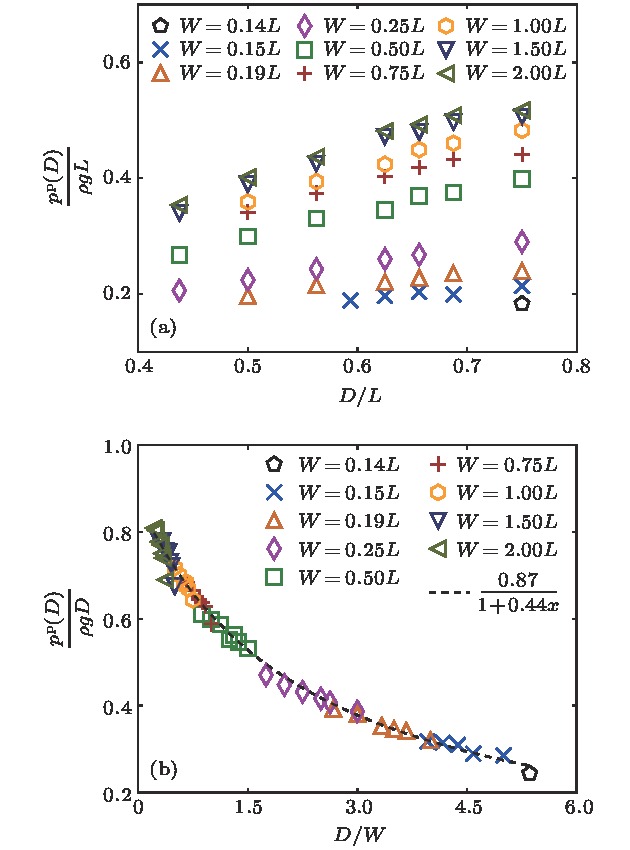

$ W $ 不同的情况下距离出口$ D $ 处的颗粒物压强$ p^{\rm p}(D) $ 结果 (a) 无量纲化压强$ p^{\rm p}(D)/(\rho g L) $ 随无量纲化出口尺寸$ D/L $ 的变化; (b) 无量纲化压强$ p^{\rm p}(D)/(\rho g D) $ 随无量纲化出口尺寸$ D/W $ 的变化Figure 4. Results of granular pressure at the distance

$ D $ from the orifice$ p^{\rm p}(D) $ for various$ W $ : (a) Dimensionless pressure$ p^{\rm p}(D)/(\rho g L) $ vs dimensionless orifice size$ D/L $ ; (b) dimensionless pressure$ p^{\rm p}(D)/(\rho g D) $ vs dimensionless orifice size$ D/W $ .图 5 在

$ W $ 不同的情况下位于出口处中心线的竖直方向速度$ v^{\rm p}_0 $ 结果 (a) 无量纲化速度$ {v^{\rm p}_0}^2/(2gL) $ 随无量纲化出口尺寸$ D/L $ 的变化; (b) 无量纲化速度$ {v^{\rm p}_0}^2/(2gW) $ 随无量纲化出口尺寸$ D/W $ 的变化Figure 5. Results of vertical velocity on the central streamline

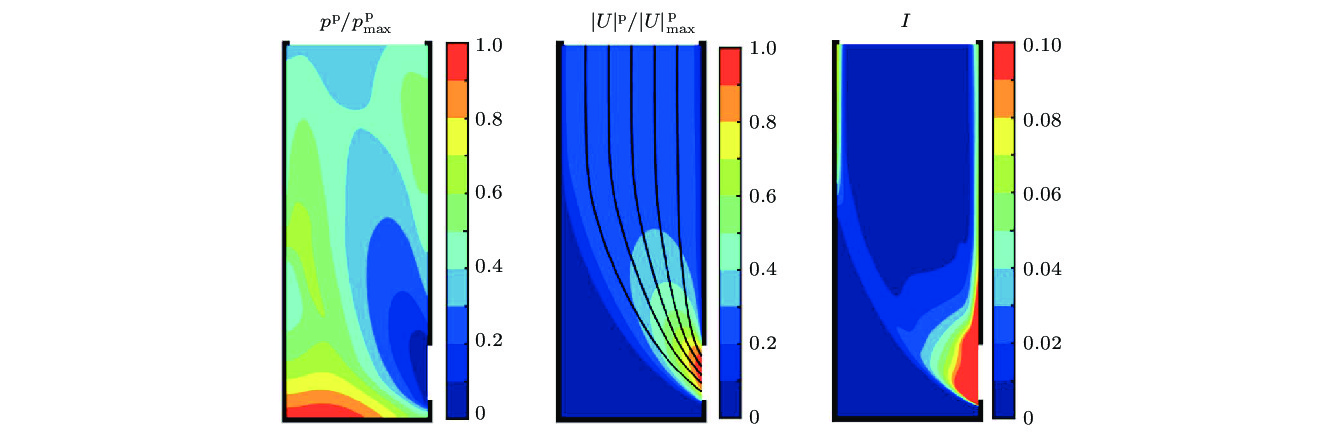

$ v^{\rm p}_0 $ for various$ W $ : (a) Dimensionless vertical velocity$ {v^{\rm p}_0}^2/(2gL) $ vs dimensionless orifice size$ D/L $ ; (b) dimensionless vertical velocity$ {v^{\rm p}_0}^2/(2gW) $ vs dimensionless orifice size$ D/W $ .图 6

$ D = 0.40125L $ 以及$ W = 0.25L $ 情况下$ t/\sqrt{L/g} = 4 $ 时刻连续数值模拟结果, 从左至右: 容器内压强与其最大值之比; 总速度与其最大值之比, 其中黑色实线表示颗粒物流线; 无量纲常数$ I = d\sqrt{2}D_2/(\sqrt{p/\rho}) $ Figure 6. Continuum simulation results with

$ D = 0.40125L $ and$ W = 0.25L $ at time$ t/\sqrt{L/g} = 4 $ , from the left to the right: pressure$ p^{\rm p} $ normalized by it's maximum value within the silo; the total velocity$ U^p $ normalized by it's maximum value within the silo, the black lines represent the streamlines; dimensionless number$ I = d\sqrt{2}D_2/(\sqrt{p/\rho}) $ .图 8 在

$ W $ 不同的情况下距离出口$ D $ 处的颗粒物压强$ p^{\rm p}(D) $ 结果 (a) 无量纲化压强$ p^{\rm p}(D)/(\rho g L) $ 随无量纲化出口尺寸$ D/L $ 的变化; (b) 无量纲化压强$ p^{\rm p}(D)/(\rho g D) $ 随无量纲化出口尺寸$ D/W $ 的变化Figure 8. Results of granular pressure at the distance

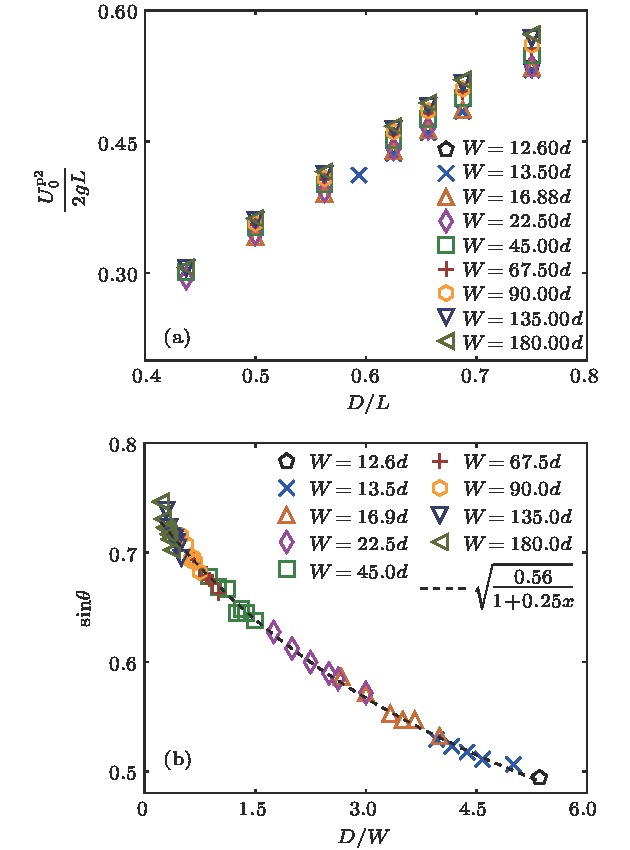

$ D $ from the orifice$ p^{\rm p}(D) $ for various$ W $ : (a) Dimensionless pressure$ p^{\rm p}(D)/(\rho g L) $ vs. dimensionless orifice size$ D/L $ ; (b) dimensionless pressure$ p^{\rm p}(D)/(\rho g D) $ vs. dimensionless orifice size$ D/W $ .图 9 在

$ W $ 不同的情况下位于出口处中心流线上速度结果 (a) 无量纲化总速度$ {U_0^{\rm p}}^2/(2gL) $ 随无量纲化出口尺寸$ D/L $ 的变化; (b) 速度倾斜角$ {\rm {sin}} \theta $ 随无量纲化出口尺寸$ D/W $ 的变化Figure 9. Results of velocity on the central streamline at the orifice for various

$ W $ : (a) Dimensionless total velocity$ {U_0^{\rm p}}^2/(2gL) $ vs dimensionless orifice size$ D/L $ ; (b) angle of inclination$ {\rm {sin}} \theta $ vs dimensionless orifice size$ D/W $ .表 1 容器及颗粒物的尺寸

Table 1. Size of silo and particle.

$h_p$ 4L $D$ [0.3125, 0.40125, 0.4375, 0.5, 0.5938,

0.625, 0.6562, 0.6875, 0.75]L$W$ [0.16, 0.2, 0.25, 0.5, 1, 2]L $d$ $L/90$ -

[1] Andreotti B, Forterre Y, Pouliquen O 2013 Granular Media: Between Fluid and Solid (Cambridge: Cambridge University Press) p1

[2] 陆坤权, 刘寄星 2004 物理 33 629

Google Scholar

Google Scholar

Lu K Q, Liu J X 2004 Physics 33 629

Google Scholar

Google Scholar

[3] Radjai F, Dubois F 2011 Discrete-element Modeling of Granular Materials (London: Wiley-Iste) p425

[4] Midi G D R 2004 Eur. Phys. J. E 14 341

Google Scholar

Google Scholar

[5] Jop P, Forterre Y, Pouliquen O 2006 Nature 441 727

Google Scholar

Google Scholar

[6] Lagree P Y, Staron L, Popinet S 2011 J. Fluid Mech. 686 378

Google Scholar

Google Scholar

[7] Staron L, Lagree P Y, Popinet S 2012 Phys. Fluids 24 103301

Google Scholar

Google Scholar

[8] Staron L, Lagree P Y, Popinet S 2014 Eur. Phys. J. E 37 1

Google Scholar

Google Scholar

[9] Andreotti B, Forterre Y, Pouliquen O 2013 Granular Media: Between Fluid and Solid (Cambridge: Cambridge University Press) pp239-246

[10] Andreotti B, Forterre Y, Pouliquen O 2013 Granular Media: Between Fluid and Solid (Cambridge: Cambridge University Press) pp87-91

[11] Sperl M 2006 Granular Matter 8 59

Google Scholar

Google Scholar

[12] Perge C, Aguirre M A, Gago P A, Pugnaloni L A, Le Tourneau D, Géminard J C 2012 Phys. Rev. E 85 021303

Google Scholar

Google Scholar

[13] Aguirre M A, Grande J G, Calvo A, Pugnaloni L A, Géminard J C 2011 Phys. Rev. E 83 061305

Google Scholar

Google Scholar

[14] Beverloo W A, Leniger H A, De Velde J V 1961 J. Chem. Eng. Sci. 15 260

Google Scholar

Google Scholar

[15] Sheldon H G, Durian D J 2010 Granular Matter 12 579

Google Scholar

Google Scholar

[16] Thomas C C, Durian D J 2015 Phys. Rev. Lett. 114 178001

Google Scholar

Google Scholar

[17] 张昱, 韦艳芳, 彭政, 蒋亦民, 段文山, 厚美瑛 2011 65 084502

Google Scholar

Google Scholar

Zhang Y, Wei Y F, Peng Z, Jiang Y M, Duan W S, Hou M Y 2011 Acta Phys. Sin. 65 084502

Google Scholar

Google Scholar

[18] Zhou Y, Lagree P Y, Popinet S, Aussillous P, Ruyer P 2017 J. Fluid Mech. 829 459

Google Scholar

Google Scholar

[19] Lagree P Y 2007 Math. Mech. 87 486

Google Scholar

Google Scholar

[20] Jop P, Forterre Y, Pouliquen O 2005 J. Fluid Mech. 541 167

Google Scholar

Google Scholar

[21] Popinet S 2009 J. Comput. Phys. 228 5838

Google Scholar

Google Scholar

[22] Janda A, Zuriguel I, Maza D 2012 Phys. Rev. Lett. 108 248001

Google Scholar

Google Scholar

[23] Benyamine M, Djermane M, Dalloz-Dubrujeaud B, Aussillous P 2014 Phys. Rev. E 90 032201

Google Scholar

Google Scholar

[24] Kamrin K, Koval G 2012 Phys. Rev. Lett. 108 178301

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 14130

- PDF Downloads: 66

- Cited By: 0

DownLoad:

DownLoad: