-

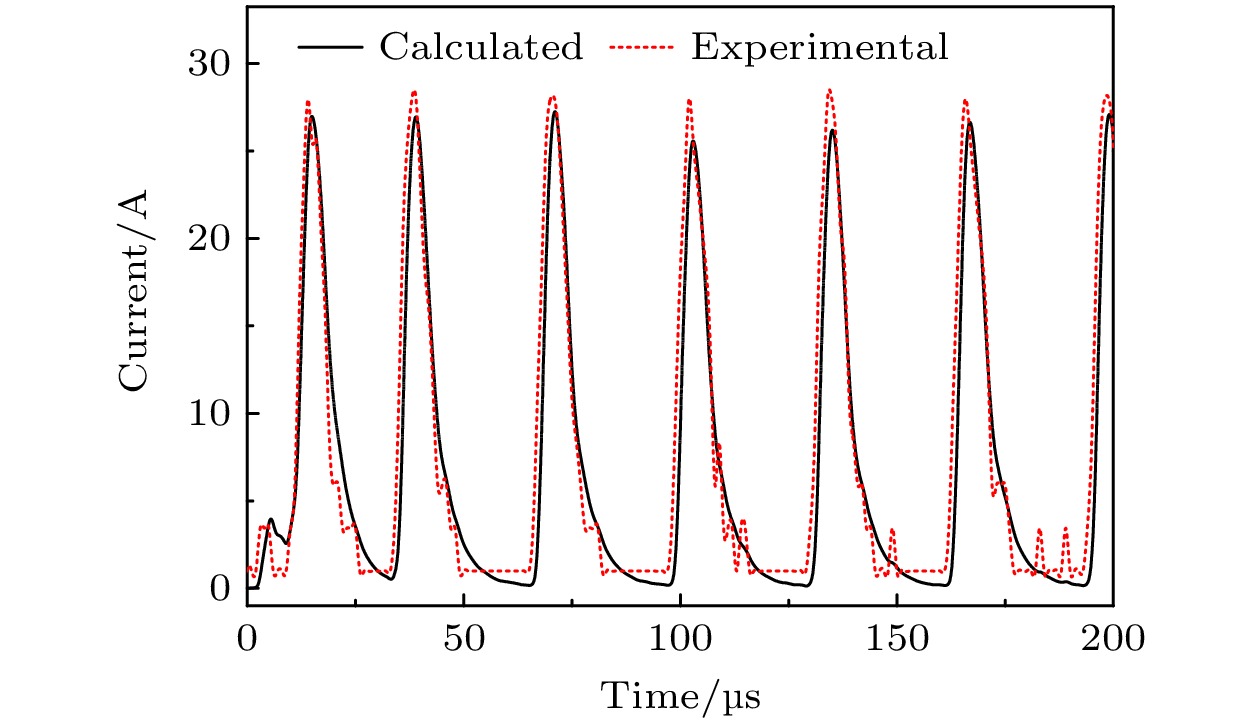

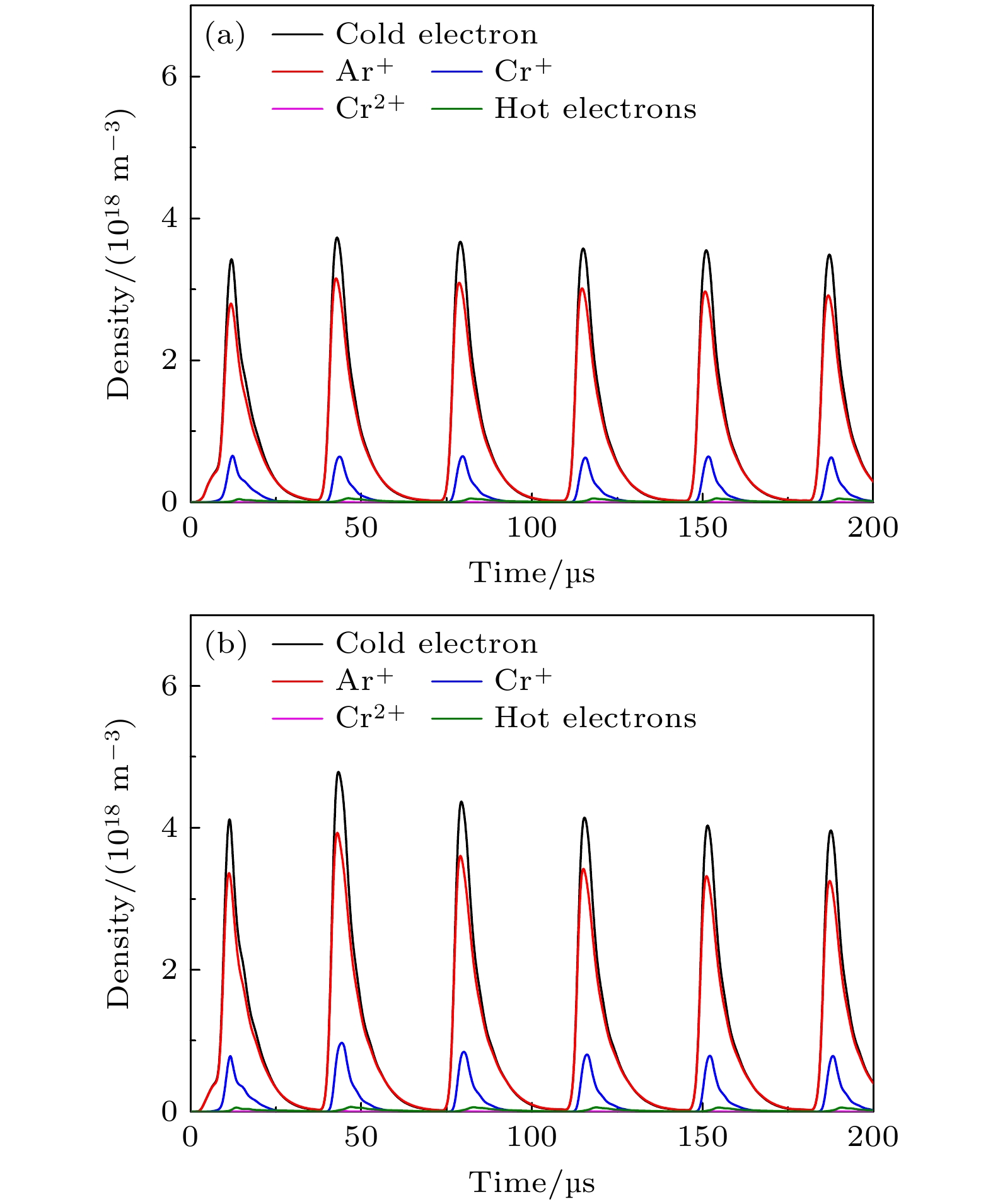

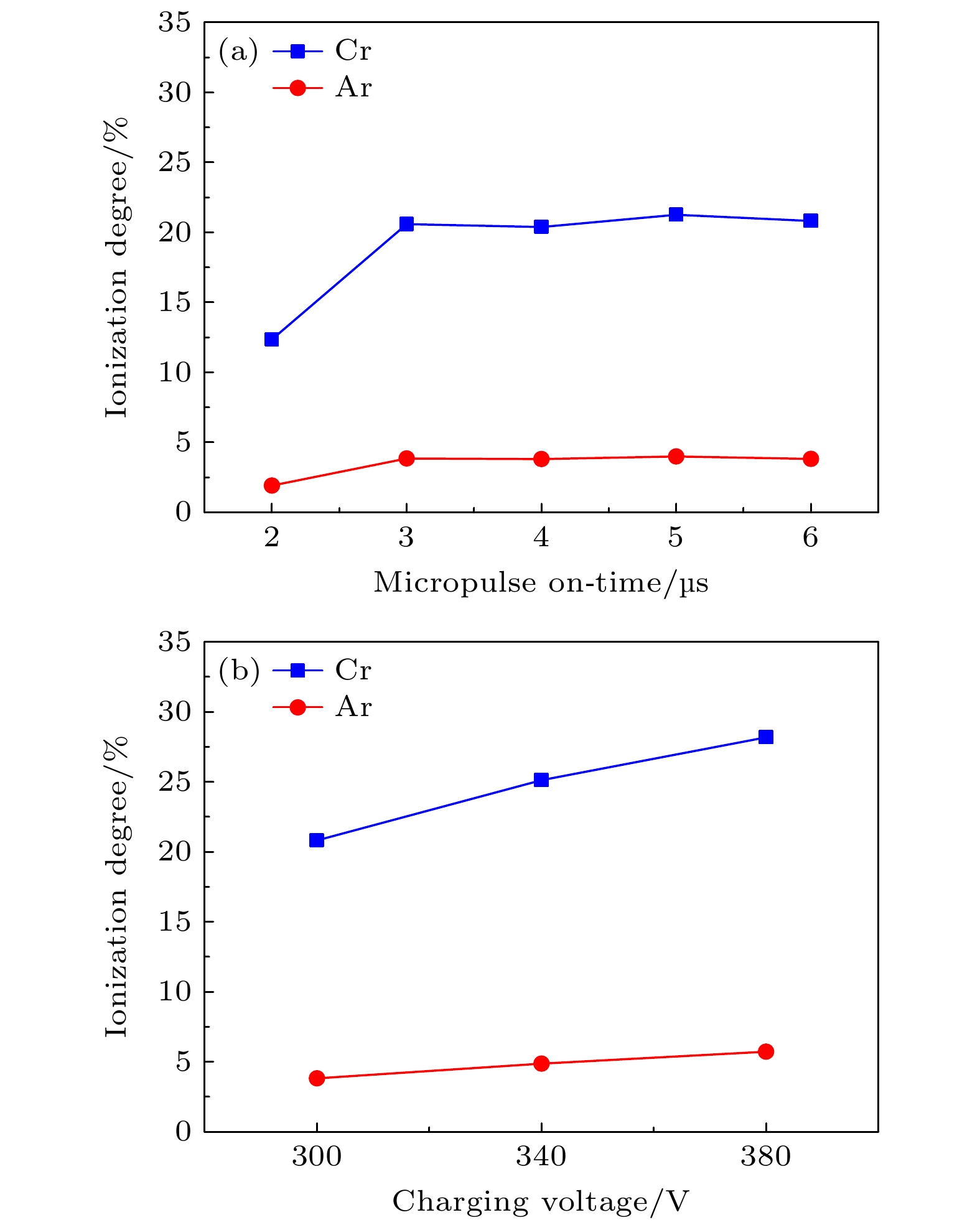

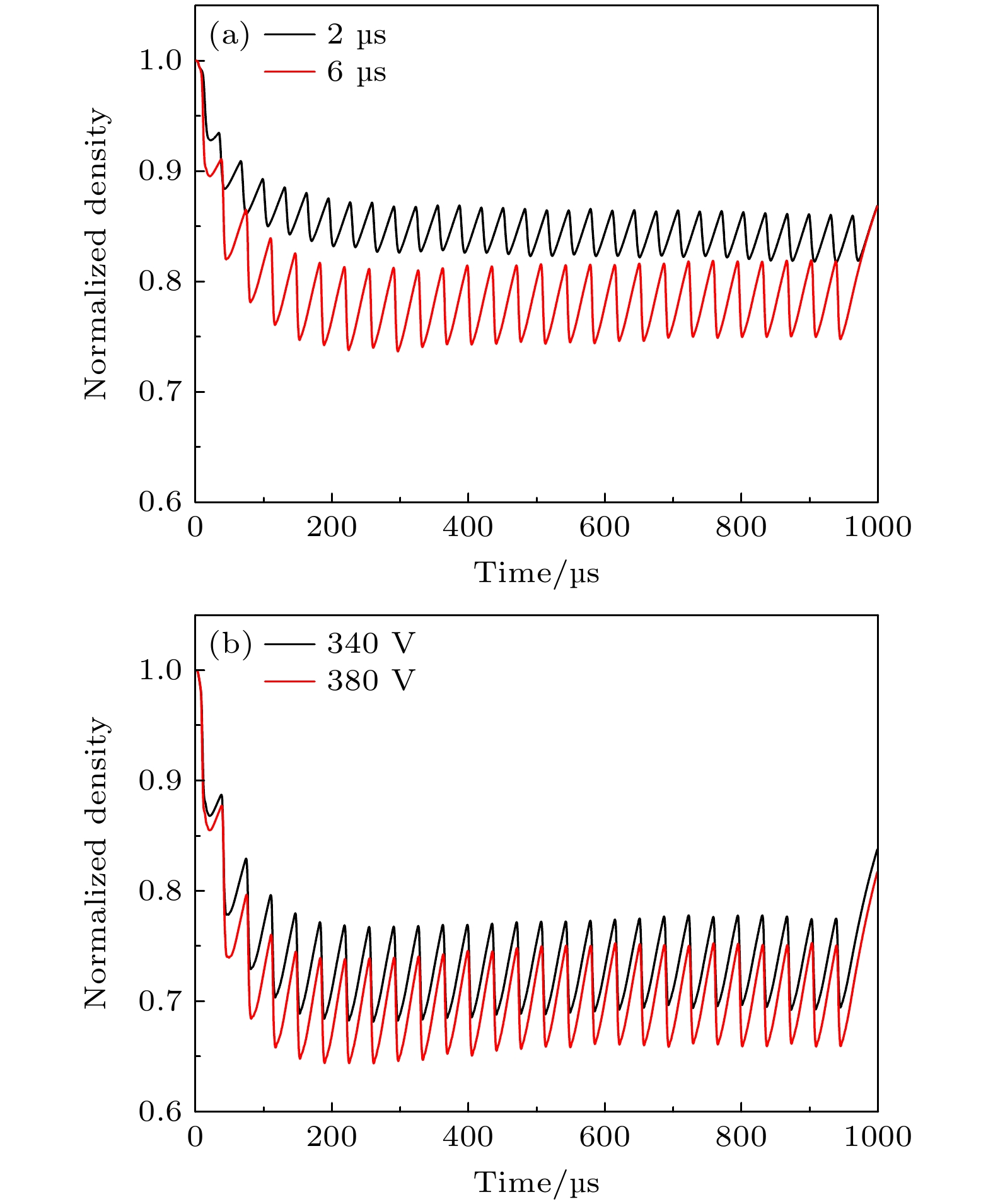

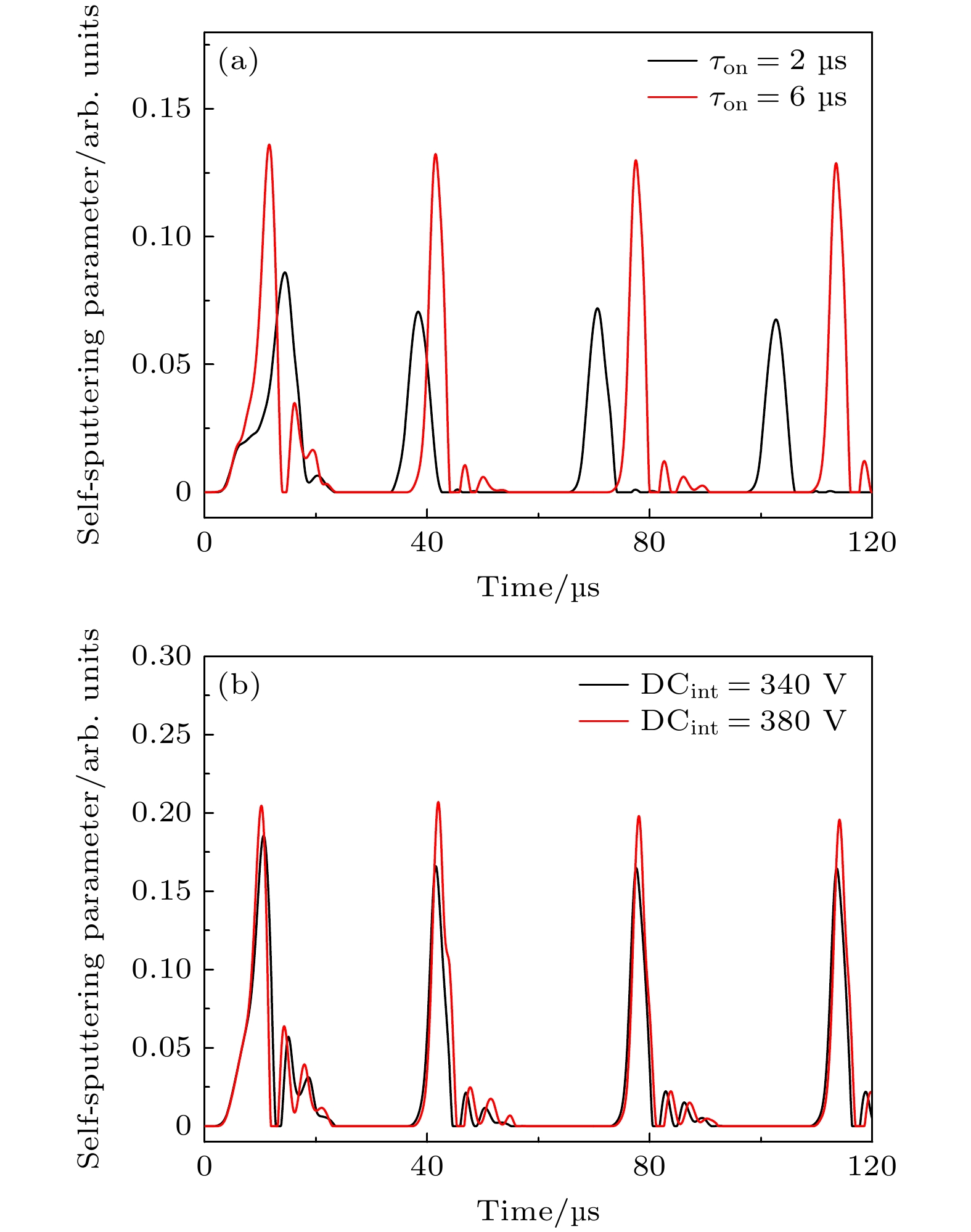

深振荡脉冲磁控溅射(deep oscillation magnetron sputtering, DOMS)以一系列微脉冲振荡波形的形式向靶提供能量, 提供高密度等离子体的同时能够实现完全消除电弧放电和提高靶材原子离化率, 实现高质量薄膜的沉积制备. 针对DOMS微脉冲放电形式拓宽放电参数空间, 提高工艺灵活性的特点, 建立脉冲等离子体整体模型, 测量充电电压DCint = 300—380 V和微脉冲开启时间τon = 2—6 μs的Cr靶放电电压电流, 将电压电流波形作为模型输入条件, 获得DOMS放电等离子体参数随时间变化规律. 充电电压300 V, 等离子体峰值密度由τon = 2 μs的1.34×1018 m–3增至τon = 3 μs的2.64×1018 m–3, τon由3 μs增至6 μs时, 等离子体峰值密度基本不变. 靶材离化率随τon变化趋呈现相近趋势, 由τon = 2 μs的12%增至τon = 3 μs的20%, τon进一步增至6 μs, 离化率基本保持不变. 固定τon = 6 μs, DCint由300 V升高至380 V, 等离子体峰值密度由2.67×1018 m–3增至3.90×1018 m–3, 金属离化率由21%增至28%. DOMS放电具有高功率脉冲磁控溅射典型的金属自溅射现象, 峰值自溅射参数Πpeak随功率密度线性增大, 表明峰值功率密度是调控DOMS放电中金属自溅射的主要参数. Πpeak最高达到0.20, 金属自溅射程度远高于常规脉冲直流磁控溅射, 等离子体密度和沉积通量中金属离化率提高, 原子沉积带来的阴影效应减轻, 是DOMS沉积薄膜质量提高的原因.A global model for deep oscillation magnetron sputtering (DOMS) discharge is established to investigate the plasma characteristics in the ionization region. Target voltage and current waveforms with micropulse on-time τon of 2–6 μs and charging voltage of 300–380 V are acquired and used as an input of the proposed model. The effects of micropulse on-time and charging voltage on the plasma are investigated. At τon = 2 μs, the DOMS plasma density oscillates with the discharge current waveform. The plasma is mainly composed of Ar+ ions though the ionization fraction of Ar is only 2%. The proportion of Cr+ ions is lower but has a relatively high ionization fraction of 12%, and Cr2+ ions are negligible. The peak plasma density increases from 1.34×1018 m–3 at τon = 2 μs to 2.64×1018 m–3 at τon = 3 μs and the metal ionization fraction increases to 20%. Further increasing the on-time leads the peak density and ionization fraction to slightly change. When the charging voltage increases from 300 V to 380 V at τon = 6 μs, the peak plasma density increases linearly from 2.67×1018 m–3 to 3.90×1018 m–3, and the metal ionization fraction increases from 21% to 28%. The gas rarefaction occurs in the ionization region for DOMS discharge. The gas density oscillates in the initial stage of macropulse, and 5–6 micropulses later it reaches dynamic equilibrium. The Ar density dynamics shows that the Ar consumption is mainly caused by electron impact ionization, followed by electron impact excitation, and the consumption rate caused by sputter wind is about 10% of the electron impact ionization. The typical metal self-sputtering phenomenon of high power impulse magnetron sputtering (HiPIMS) also appears in the DOMS discharge. The peak value of self-sputtering parameter increases linearly with the peak power density rising. This suggests that the peak power density is one of the important parameters to manipulate the metal self-sputtering process in the DOMS discharge. The peak value of self-sputtering parameter reaches up to 0.20, indicating that a certain degree of metal self-sputtering occurs. The plasma density and the ionization fraction of the depositing flux are improved, which relieves the shadowing effect during conventional magnetron sputtering as a result of low ionization degree of sputtered metal.

-

Keywords:

- deep oscillation magnetron sputtering /

- magnetron plasma /

- global model /

- Cr target /

- metal self-sputtering

[1] Kouznetsov V, Macák K, Schneider J M, Helmersson U, Petrov I 1999 Surf. Coat. Technol. 122 290

Google Scholar

Google Scholar

[2] Anders A 2011 Surf. Coat. Technol. 205 S1

Google Scholar

Google Scholar

[3] Sarakinos K, Alami J, Konstantinidis S 2010 Surf. Coat. Technol. 204 1661

Google Scholar

Google Scholar

[4] Greczynski G, Petrov I, Greene J E, Hultman L 2019 J. Vac. Sci. Technol. A 37 60801

Google Scholar

Google Scholar

[5] Christie D J, Tomasel F, Sproul W D, Carter D C 2004 J. Vac. Sci. Technol. A 22 1415

Google Scholar

Google Scholar

[6] Hajihoseini H, Čada M, Hubička Z, Ünaldi S, Raadu M A, Brenning N, Gudmundsson J T, Lundin D 2019 Plasma 2 201

Google Scholar

Google Scholar

[7] Lin J L, Wang B, Sproul W D, Ou Y X, Dahan I 2013 J. Phys. D: Appl. Phys. 46 84008

Google Scholar

Google Scholar

[8] 王浩琦, 欧伊翔, 华青松, 邱马顺, 帅麒麟, 付薇 2022 北京师范大学学报(自然科学版) 58 775

Google Scholar

Google Scholar

Wang H Q, Ou Y X, Hua Q S, Qiu M S, Shuai Q L, Fu W 2022 J. Beijing Normal Univ. (Nat. Sci.) 58 775

Google Scholar

Google Scholar

[9] Sanekata M, Nakagomi Y, Hirayama M, Nishida H, Nishimiya N, Tona M, Yamamoto H, Tsukamoto K, Fuke K, Ohshimo K, Koyasu K, Misaizu F 2022 J. Appl. Phys. 131 243301

Google Scholar

Google Scholar

[10] Yokoyama E, Sanekata M, Nishimiya N, Tona M, Yamamoto H, Tsukamoto K, Fuke K, Ohshimo K, Misaizu F 2023 Jpn. J. Appl. Phys. 62 L1008

Google Scholar

Google Scholar

[11] 欧伊翔, 王浩琦, 庞盼, 罗军, 陈琳, 廖斌, 雷明凯, 欧阳晓平 2020 稀有金属材料与工程 49 2476

Ou Y X, Wang H Q, Pang P, Luo J, Chen L, Liao B, Lei M K, Ouyang X P 2020 Rare Metal Mat. Eng. 49 2476

[12] Oliveira J C, Fe Rnandes F, Fe Rreira F, Cavaleiro A 2015 Surf. Coat. Technol. 264 140

Google Scholar

Google Scholar

[13] Ferreira F, Cavaleiro A, Oliveira J 2021 J. Mater. Eng. Perform. 30 3912

Google Scholar

Google Scholar

[14] Belosludtsev A, Vlček J, Houška J, Haviar S, Čerstvý R 2020 Surf. Coat. Technol. 392 125716

Google Scholar

Google Scholar

[15] Gao J Y, Ferreira F, Lei M K 2024 J. Appl. Phys. 135 33301

Google Scholar

Google Scholar

[16] Gudmundsson J T, Fischer J, Hinriksson B P, Rudolph M, Lundin D 2022 Surf. Coat. Technol. 442 128189

Google Scholar

Google Scholar

[17] Ziegler J F, Ziegler M D, Biersack J P 2010 Nucl. Instrum. Methods Phys. Res. B 268 1818

Google Scholar

Google Scholar

[18] Gudmundsson J T 2020 Plasma Sources Sci. Technol. 29 113001

Google Scholar

Google Scholar

[19] Vlček J, Kudláček P, Burcalová K, Musil J 2007 Europhys. Lett. 77 45002

Google Scholar

Google Scholar

[20] Huo C, Raadu M A, Lundin D, Gudmundsson J T, Anders A, Brenning N 2012 Plasma Sources Sci. Technol. 21 45004

Google Scholar

Google Scholar

[21] Anders A, Čapek J, Hála M, Martinu L 2012 J. Phys. D: Appl. Phys. 45 12003

Google Scholar

Google Scholar

[22] Oliveira J C, Ferreira F, Anders A, Cavaleiro A 2018 Appl. Surf. Sci. 433 934

Google Scholar

Google Scholar

-

表 1 不同微脉冲开启时间DOMS放电参数

Table 1. Discharge parameters of DOMS using different micropulse on-time.

充电

电压/V微脉冲开启

时间τon/μs峰值

电压/V峰值

电流/A峰值

功率/kW300 2 635.8 27.5 14.4 300 3 729.0 50.6 29.8 300 4 714.4 49.4 29.2 300 5 726.0 51.5 31.0 300 6 731.6 51.5 30.8 340 6 810.6 63.8 42.2 380 6 870.7 73.5 48.7 表 2 DOMS溅射Cr靶主要等离子体反应

Table 2. Reactions considered in DOMS plasma using a Cr target.

反应 阈值/eV 速率系数/(m3·s–1) e + Ar → Ar+ + 2e 15.76 $2.3\times 10^{-14}T_{\rm e}^{0.59} \exp(-17.44/T_{\rm e}) $ e + Ar → Arm + e 11.56 $2.5\times 10^{-15}T_{\rm e}^{0.74}\exp(- 11.56/T_{\rm e}) $ e + Arm → Ar+ + 2e 4.20 $6.8\times 10^{-15}T_{\rm e}^{0.67} \exp(-4.2/T_{\rm e}) $ e + Cr → Cr+ + 2e 6.76 $4.12\times 10^{-13}T_{\rm e}^{ -0.151}\exp(- 10.71/T_{\rm e})$ e + Cr+ → Cr2+ + 2e 16.49 $5.27\times 10^{-14}T_{\rm e}^{ 0.087}\exp(- 22.05/T_{\rm e})$ Ar+ + Cr → Ar + Cr+ — $1\times10^{-15} $ Arm + Cr → Ar + Cr+ + e — $3.3\times10^{-16} $ -

[1] Kouznetsov V, Macák K, Schneider J M, Helmersson U, Petrov I 1999 Surf. Coat. Technol. 122 290

Google Scholar

Google Scholar

[2] Anders A 2011 Surf. Coat. Technol. 205 S1

Google Scholar

Google Scholar

[3] Sarakinos K, Alami J, Konstantinidis S 2010 Surf. Coat. Technol. 204 1661

Google Scholar

Google Scholar

[4] Greczynski G, Petrov I, Greene J E, Hultman L 2019 J. Vac. Sci. Technol. A 37 60801

Google Scholar

Google Scholar

[5] Christie D J, Tomasel F, Sproul W D, Carter D C 2004 J. Vac. Sci. Technol. A 22 1415

Google Scholar

Google Scholar

[6] Hajihoseini H, Čada M, Hubička Z, Ünaldi S, Raadu M A, Brenning N, Gudmundsson J T, Lundin D 2019 Plasma 2 201

Google Scholar

Google Scholar

[7] Lin J L, Wang B, Sproul W D, Ou Y X, Dahan I 2013 J. Phys. D: Appl. Phys. 46 84008

Google Scholar

Google Scholar

[8] 王浩琦, 欧伊翔, 华青松, 邱马顺, 帅麒麟, 付薇 2022 北京师范大学学报(自然科学版) 58 775

Google Scholar

Google Scholar

Wang H Q, Ou Y X, Hua Q S, Qiu M S, Shuai Q L, Fu W 2022 J. Beijing Normal Univ. (Nat. Sci.) 58 775

Google Scholar

Google Scholar

[9] Sanekata M, Nakagomi Y, Hirayama M, Nishida H, Nishimiya N, Tona M, Yamamoto H, Tsukamoto K, Fuke K, Ohshimo K, Koyasu K, Misaizu F 2022 J. Appl. Phys. 131 243301

Google Scholar

Google Scholar

[10] Yokoyama E, Sanekata M, Nishimiya N, Tona M, Yamamoto H, Tsukamoto K, Fuke K, Ohshimo K, Misaizu F 2023 Jpn. J. Appl. Phys. 62 L1008

Google Scholar

Google Scholar

[11] 欧伊翔, 王浩琦, 庞盼, 罗军, 陈琳, 廖斌, 雷明凯, 欧阳晓平 2020 稀有金属材料与工程 49 2476

Ou Y X, Wang H Q, Pang P, Luo J, Chen L, Liao B, Lei M K, Ouyang X P 2020 Rare Metal Mat. Eng. 49 2476

[12] Oliveira J C, Fe Rnandes F, Fe Rreira F, Cavaleiro A 2015 Surf. Coat. Technol. 264 140

Google Scholar

Google Scholar

[13] Ferreira F, Cavaleiro A, Oliveira J 2021 J. Mater. Eng. Perform. 30 3912

Google Scholar

Google Scholar

[14] Belosludtsev A, Vlček J, Houška J, Haviar S, Čerstvý R 2020 Surf. Coat. Technol. 392 125716

Google Scholar

Google Scholar

[15] Gao J Y, Ferreira F, Lei M K 2024 J. Appl. Phys. 135 33301

Google Scholar

Google Scholar

[16] Gudmundsson J T, Fischer J, Hinriksson B P, Rudolph M, Lundin D 2022 Surf. Coat. Technol. 442 128189

Google Scholar

Google Scholar

[17] Ziegler J F, Ziegler M D, Biersack J P 2010 Nucl. Instrum. Methods Phys. Res. B 268 1818

Google Scholar

Google Scholar

[18] Gudmundsson J T 2020 Plasma Sources Sci. Technol. 29 113001

Google Scholar

Google Scholar

[19] Vlček J, Kudláček P, Burcalová K, Musil J 2007 Europhys. Lett. 77 45002

Google Scholar

Google Scholar

[20] Huo C, Raadu M A, Lundin D, Gudmundsson J T, Anders A, Brenning N 2012 Plasma Sources Sci. Technol. 21 45004

Google Scholar

Google Scholar

[21] Anders A, Čapek J, Hála M, Martinu L 2012 J. Phys. D: Appl. Phys. 45 12003

Google Scholar

Google Scholar

[22] Oliveira J C, Ferreira F, Anders A, Cavaleiro A 2018 Appl. Surf. Sci. 433 934

Google Scholar

Google Scholar

计量

- 文章访问数: 716

- PDF下载量: 37

- 被引次数: 0

下载:

下载: