-

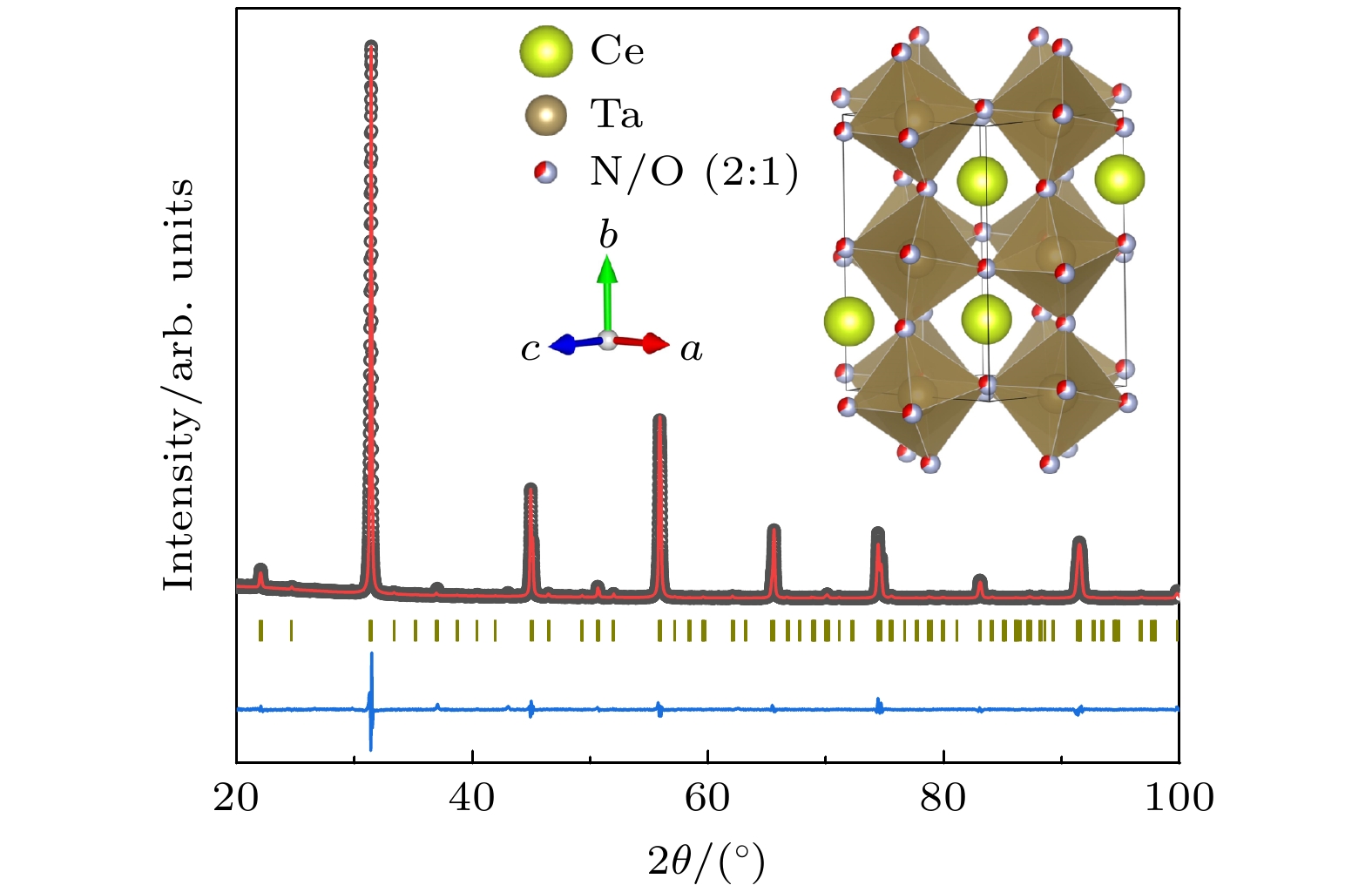

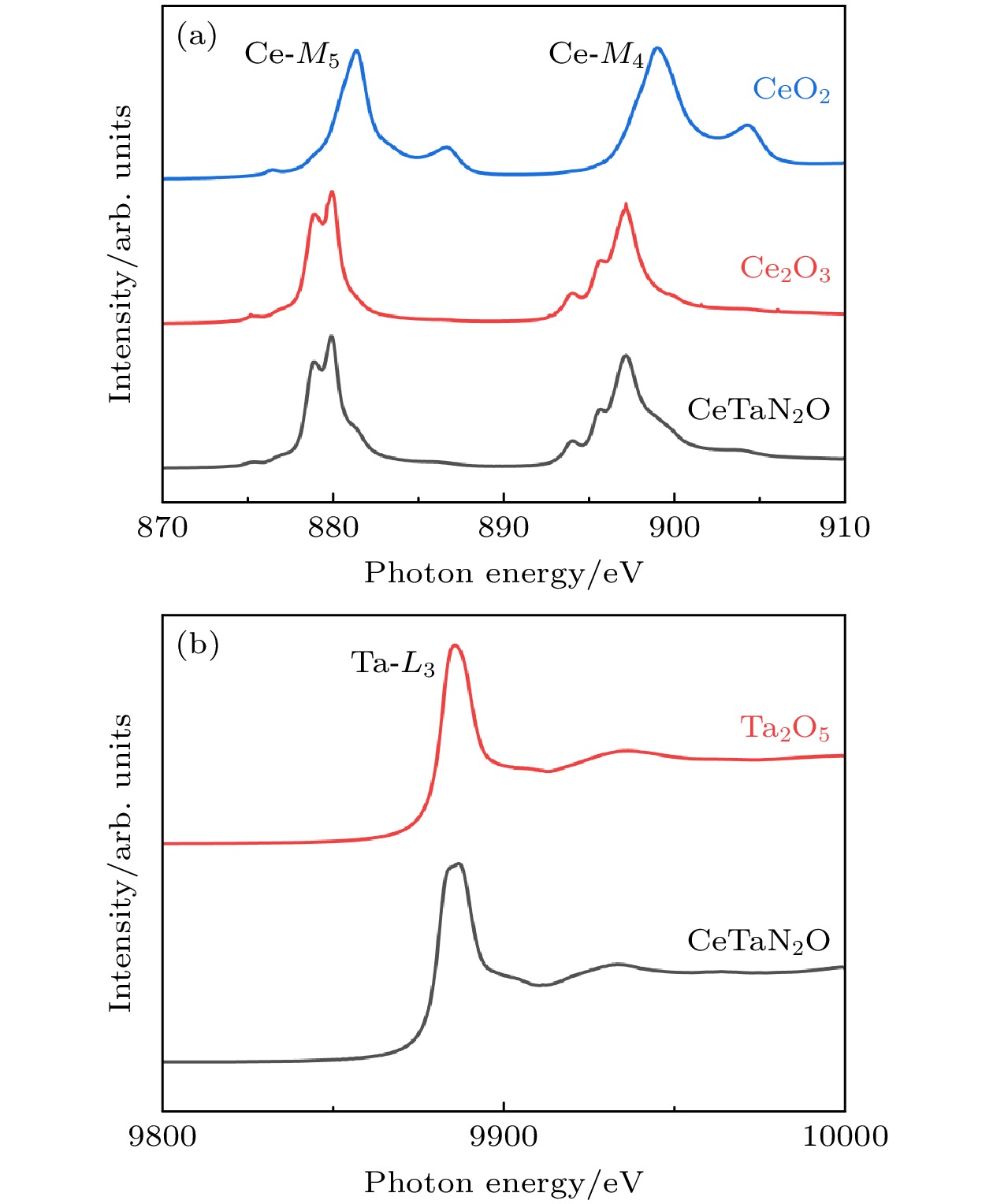

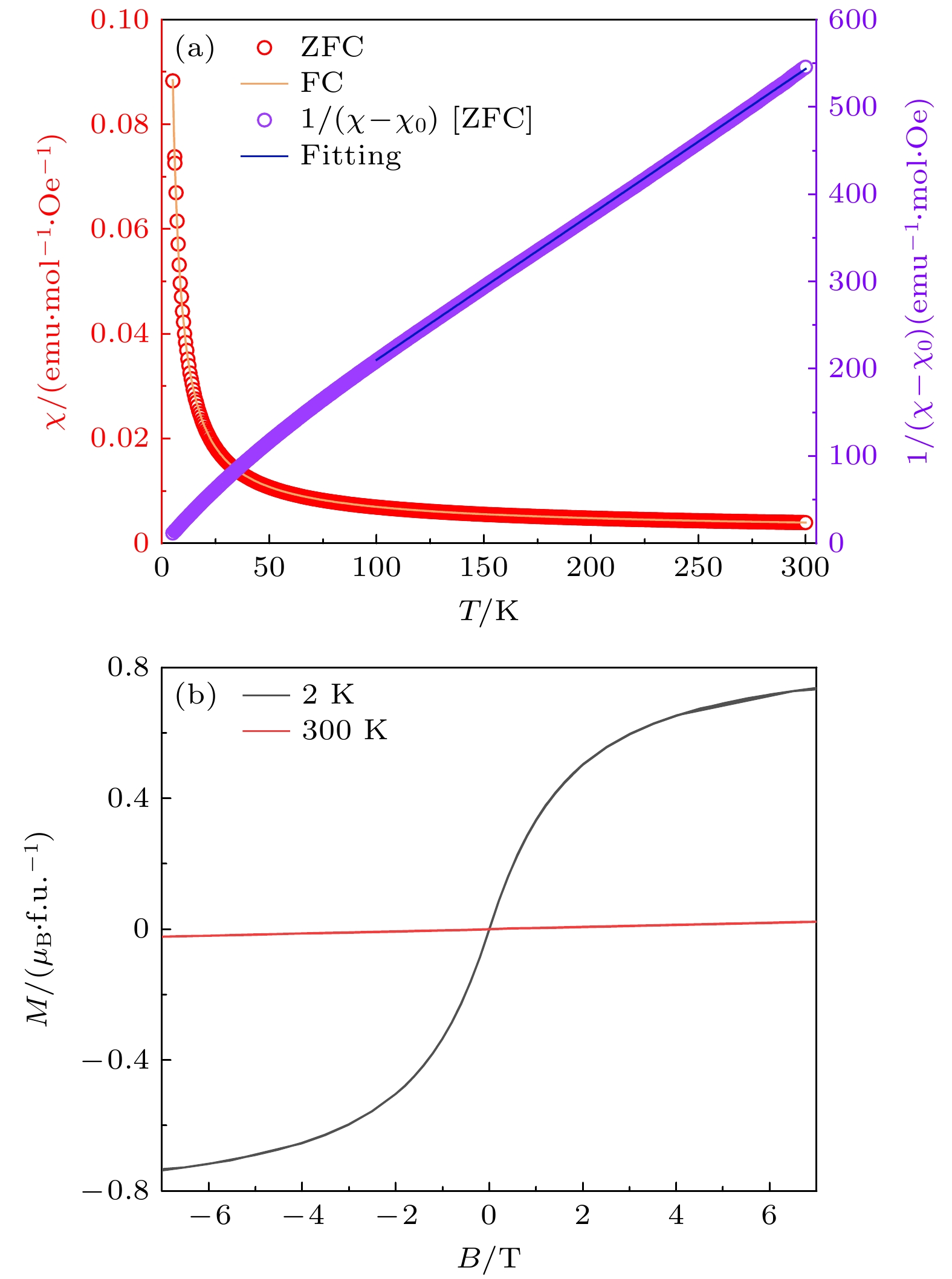

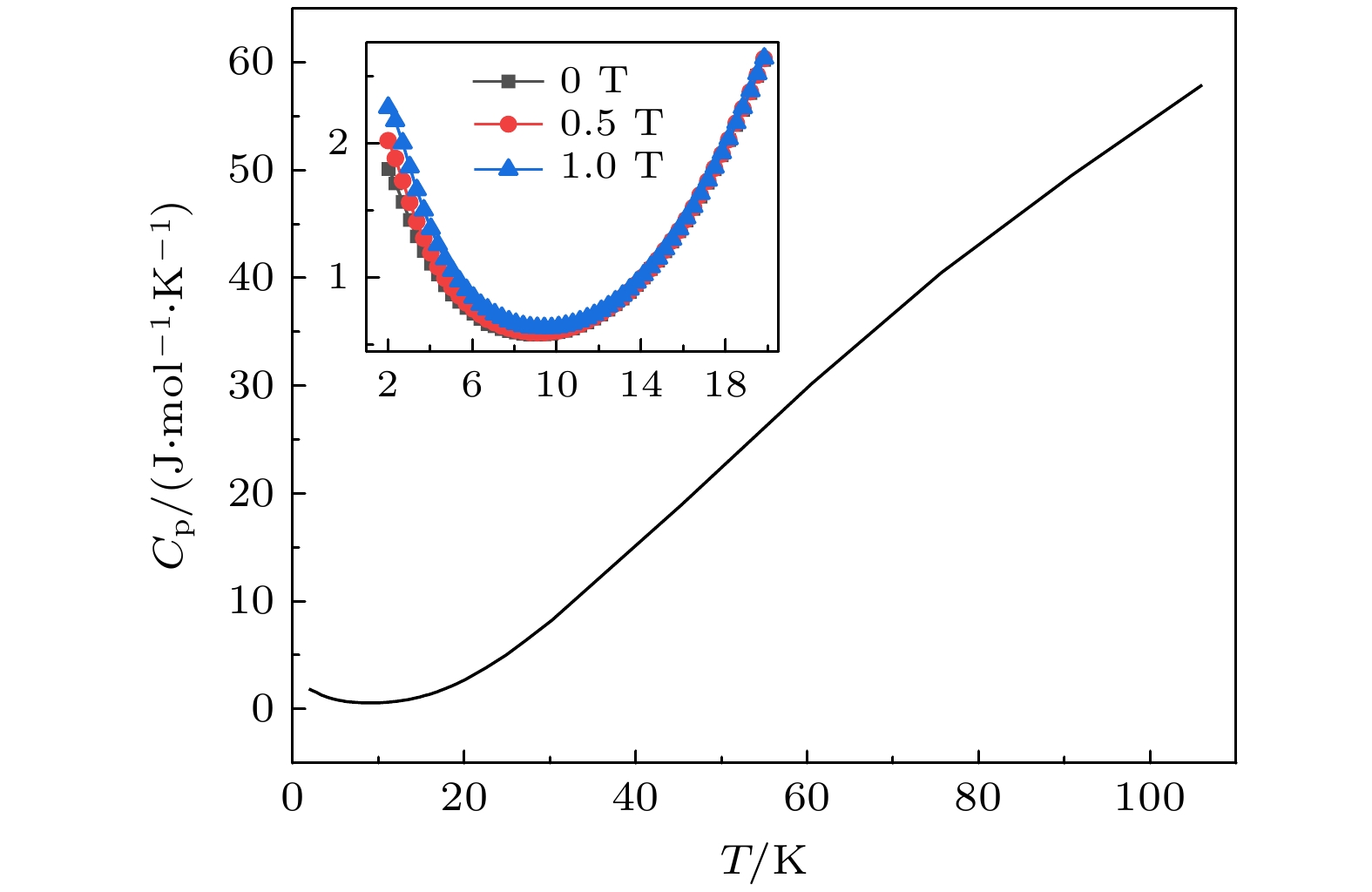

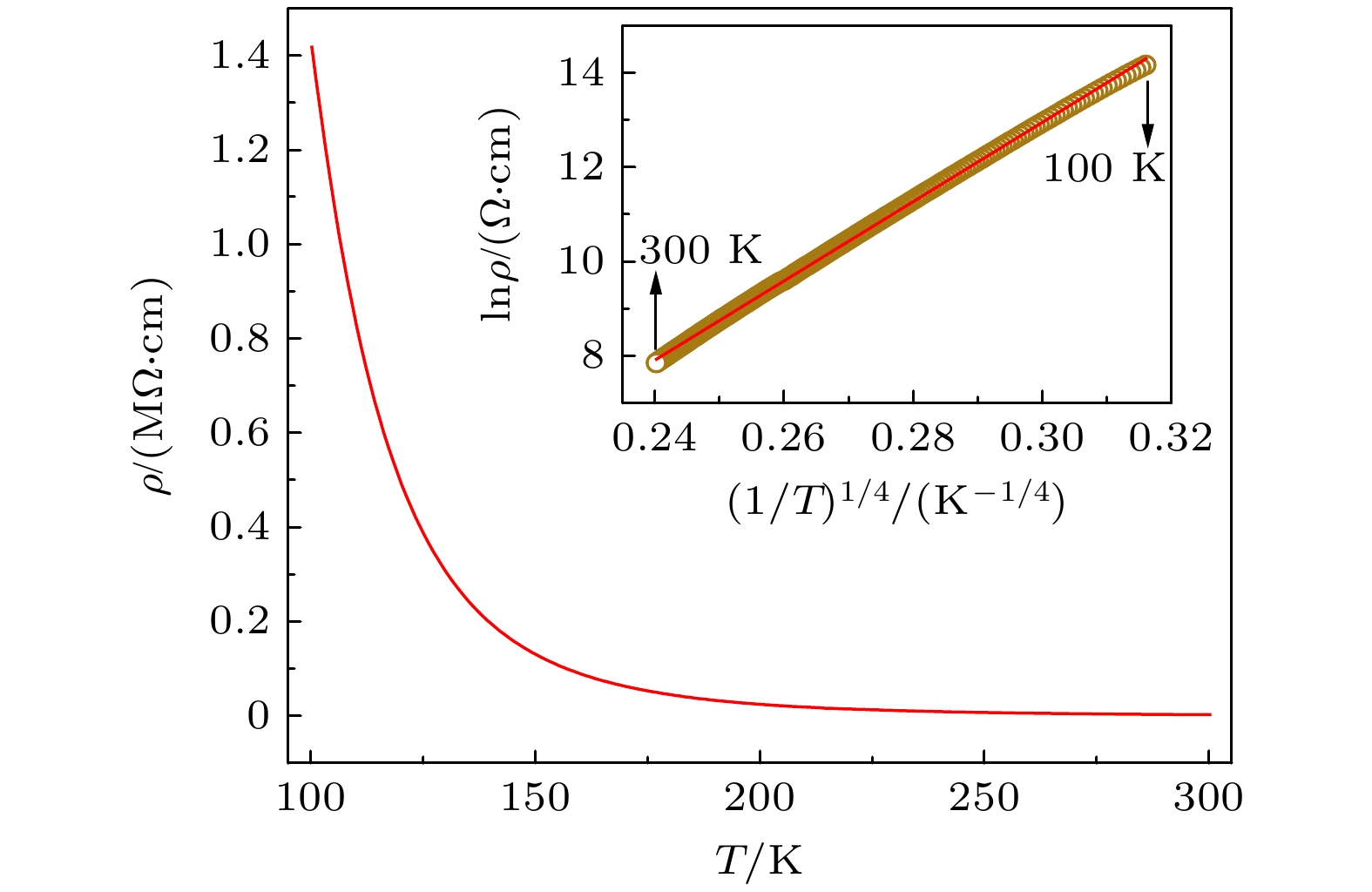

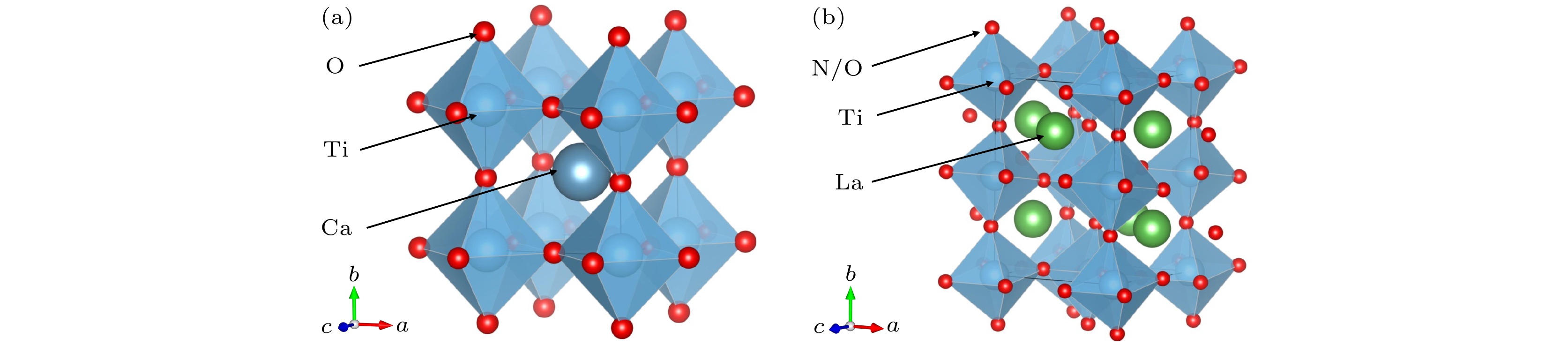

最近研究发现, AB(N,O)3型钙钛矿氧氮化物具有优异的介电、铁电、光催化等性能, 在光电子、能源存储和通信等领域展现出广阔的应用前景. 但是, 目前该类型材料的制备工艺耗时较长且产物纯度较低. 本文以氧化物为前驱体、以氨基钠为氮源, 利用六面顶压机设备所提供的高温高压环境成功制备了高纯度的钙钛矿型氧氮化物CeTaN2O块体材料, 并将制备时间缩短至1 h, 实现了快速合成. 并对其晶体结构以及物理性质进行了系统的研究. X射线粉末衍射实验和Rietveld精修结果表明, 所制备的样品属于正交晶系, 空间群为Pnma. X射线吸收谱测试确定了样品的电荷组态以及阴离子组合为Ce3+Ta5+N2O. 磁性和比热测试表明, 样品属于反铁磁物质, 磁相变温度低于2 K. 电学输运性能测试表明, 样品的电阻率呈现出典型的半导体行为, 且符合三维变程跳跃模型.Recently, it has been discovered that the AB(N,O)3-type perovskite oxynitrides exhibit excellent dielectric, ferroelectric, and photocatalytic properties, promising for applications in the fields of optoelectronics, energy storage, and communication. Due to the differences in charge, ionic radius, and covalent bonding between N3– ion and O2– ion, the N substitution for O enhances the B(N,O)6 octahedron tilting, giving rise to exotic properties and functionalities. However, the current fabrication process for this type of material is rather time-consuming, leading to products with an appreciable quantity of impurities. In this study, using oxide precursors and sodium amide as the nitrogen source, high-purity perovskite-type oxynitride CeTaN2O bulk materials are successfully synthesized under high-temperature and high-pressure conditions provided by a cubic-anvil press. The synthesis time decreases to 1 h, achieving rapid production. The lattice structure and physical properties of the obtained samples are comprehensively investigated. X-ray powder diffraction experiments and subsequent Rietveld refinement indicate that the title material shows an orthorhombic crystal structure with the space group of Pnma. The X-ray absorption spectra confirm the charge configuration and the anion composition as Ce3+Ta5+N2O. Magnetization and specific heat measurements reveal that the exchange interactions are mainly antiferromagnetic, with a potential magnetic transition below 2 K. The electrical transport data demonstrate typical semiconductor behaviors, which can be further explained by a three-dimensional variable-range hopping model. Our study paves the way for putting this exotic perovskite oxynitride into practical applications.

-

Keywords:

- high-pressure synthesis /

- perovskite-type nitride /

- antiferromagnetic /

- semiconductor

[1] Tobías G, Oró-Solé J, Beltrán-Porter D, Fuertes A 2001 Inorg. Chem. 40 6867

Google Scholar

Google Scholar

[2] Marchand R, Pors F, Laurent Y, Regreny O, Lostec J, Haussonne J M 1986 J. Phys. Colloques 47 C1

Google Scholar

Google Scholar

[3] Kim Y I, Woodward P M, Baba-Kishi K Z, Tai C W 2004 Chem. Mater. 16 1267

Google Scholar

Google Scholar

[4] Jorge A B, Oró-Solé J, Bea A M, Mufti N, Palstra T T M, Rodgers J A, Attfield J P, Fuertes A 2008 J. Am. Chem. Soc. 130 12572

Google Scholar

Google Scholar

[5] Yang M, Oró-Solé J, Kusmartseva A, Fuertes A, Attfield J P 2010 J. Am. Chem. Soc. 132 4822

Google Scholar

Google Scholar

[6] Maeda K, Domen K 2007 J. Phys. Chem. C 111 7851

Google Scholar

Google Scholar

[7] Li Y Q, Delsing A C A, de With G, Hintzen H T 2005 Chem. Mater. 17 3242

Google Scholar

Google Scholar

[8] Shannon R D 1976 Acta Crystallogr. Sect. A 32 751

Google Scholar

Google Scholar

[9] 叶施亚, 李端, 李俊生, 曾良, 曹峰 2021 人工晶体学报 50 187

Ye S Y, Li D, Li J S, Zeng L, F C 2021 J. Synth. Cryst. 50 187

[10] Porter S H, Huang Z, Woodward P M 2014 Cryst. Growth Des. 14 117

Google Scholar

Google Scholar

[11] Porter S H, Huang Z, Cheng Z, Avdeev M, Chen Z, Dou S, Woodward P M 2015 J. Solid State Chem. 226 279

Google Scholar

Google Scholar

[12] Page K, Stoltzfus M W, Kim Y I, Proffen T, Woodward P M, Cheetham A K, Seshadri R 2007 Chem. Mater. 19 4037

Google Scholar

Google Scholar

[13] Badding J V 1998 Annu. Rev. Mater. Sci. 28 631

Google Scholar

Google Scholar

[14] Brazhkin V V 2007 High Pressure Res. 27 333

Google Scholar

Google Scholar

[15] Rietveld H M 1969 J. Appl. Crystallogr. 2 65

Google Scholar

Google Scholar

[16] Roth R S, Negas T, Parker H S, Minor D B, Jones C 1977 Mater. Res. Bull. 12 1173

Google Scholar

Google Scholar

[17] Santoro A, Marezio M, Roth R S, Minor D 1980 J. Solid State Chem. 35 167

Google Scholar

Google Scholar

[18] 殷云宇, 王潇, 邓宏芟, 周龙, 戴建洪, 龙有文 2017 66 030201

Google Scholar

Google Scholar

Yin Y Y, Wang X, Deng H S, Zhou L, Dai J H, Long Y W 2017 Acta Phys. Sin. 66 030201

Google Scholar

Google Scholar

[19] Deminami S, Kawamura Y, Chen Y Q, Kanazawa M, Hayashi J, Kuzuya T, Takeda K, Matsuda M, Sekine C 2017 J. Phys. Conf. Ser. 950 042032

Google Scholar

Google Scholar

[20] Sekine C, Sai U, Hayashi J, Kawamura Y, Bauer E 2017 J. Phys. Conf. Ser. 950 042028

Google Scholar

Google Scholar

[21] Kabeya N, Takahara S, Satoh N, Nakamura S, Katoh K, Ochiai A 2018 Phys. Rev. B 98 035131

Google Scholar

Google Scholar

[22] Nakano T, Onuma S, Takeda N, Uhlířová K, Prokleška J, Sechovský V, Gouchi J, Uwatoko Y 2019 Phys. Rev. B 100 035107

Google Scholar

Google Scholar

[23] Matin M, Kulkarni R, Thamizhavel A, Dhar S K, Provino A, Manfrinetti P 2017 J. Phys Condens. Matter 29 145601

Google Scholar

Google Scholar

[24] Ajeesh M O, Kushwaha S K, Thomas S M, Thompson J D, Chan M K, Harrison N, Tomczak J M, Rosa P F S 2023 Phys. Rev. B 108 245125

Google Scholar

Google Scholar

[25] Ravot D, Burlet P, Rossat-Mignod J, Tholence J L 1980 J. Phys. 41 1117

Google Scholar

Google Scholar

[26] Mott N F 1969 Philos. Mag. 19 835

Google Scholar

Google Scholar

-

图 4 (a) 0.1 T磁场下磁化率和磁化率倒数随温度的变化关系, 其中蓝线代表100 K以上的居里-外斯拟合结果; (b) 不同温度下磁化强度随磁场的变化关系

Fig. 4. (a) Temperature dependence of magnetic susceptibility and the inverse susceptibility at 0.1 T. The blue line shows the Curie-Weiss fitting above 100 K; (b) field dependent magnetization measured at different temperatures.

表 1 CeTaN2O的精修结构参数

Table 1. Refined structure parameters of CeTaN2O.

Space group Pnma a/Å 5.69575(9) Rwp/% 3.28 b/Å 8.03326(8) Rp/% 2.30 c/Å 5.70427(8) χ2 2.71 Atomic position(s) atom site x y z occ Uiso/Å2 Ce 4c 0.01792(8) 0.25 0.99101(2) 1 0.0086(5) Ta 4b 0.5 0 0 1 0.0055(9) N/O 4c 0.49062(2) 0.25 0.14377(9) 0.67/0.33 0.01 N/O 8d 0.26950(2) 0.03833(9) 0.76871(6) 0.67/0.33 0.01 -

[1] Tobías G, Oró-Solé J, Beltrán-Porter D, Fuertes A 2001 Inorg. Chem. 40 6867

Google Scholar

Google Scholar

[2] Marchand R, Pors F, Laurent Y, Regreny O, Lostec J, Haussonne J M 1986 J. Phys. Colloques 47 C1

Google Scholar

Google Scholar

[3] Kim Y I, Woodward P M, Baba-Kishi K Z, Tai C W 2004 Chem. Mater. 16 1267

Google Scholar

Google Scholar

[4] Jorge A B, Oró-Solé J, Bea A M, Mufti N, Palstra T T M, Rodgers J A, Attfield J P, Fuertes A 2008 J. Am. Chem. Soc. 130 12572

Google Scholar

Google Scholar

[5] Yang M, Oró-Solé J, Kusmartseva A, Fuertes A, Attfield J P 2010 J. Am. Chem. Soc. 132 4822

Google Scholar

Google Scholar

[6] Maeda K, Domen K 2007 J. Phys. Chem. C 111 7851

Google Scholar

Google Scholar

[7] Li Y Q, Delsing A C A, de With G, Hintzen H T 2005 Chem. Mater. 17 3242

Google Scholar

Google Scholar

[8] Shannon R D 1976 Acta Crystallogr. Sect. A 32 751

Google Scholar

Google Scholar

[9] 叶施亚, 李端, 李俊生, 曾良, 曹峰 2021 人工晶体学报 50 187

Ye S Y, Li D, Li J S, Zeng L, F C 2021 J. Synth. Cryst. 50 187

[10] Porter S H, Huang Z, Woodward P M 2014 Cryst. Growth Des. 14 117

Google Scholar

Google Scholar

[11] Porter S H, Huang Z, Cheng Z, Avdeev M, Chen Z, Dou S, Woodward P M 2015 J. Solid State Chem. 226 279

Google Scholar

Google Scholar

[12] Page K, Stoltzfus M W, Kim Y I, Proffen T, Woodward P M, Cheetham A K, Seshadri R 2007 Chem. Mater. 19 4037

Google Scholar

Google Scholar

[13] Badding J V 1998 Annu. Rev. Mater. Sci. 28 631

Google Scholar

Google Scholar

[14] Brazhkin V V 2007 High Pressure Res. 27 333

Google Scholar

Google Scholar

[15] Rietveld H M 1969 J. Appl. Crystallogr. 2 65

Google Scholar

Google Scholar

[16] Roth R S, Negas T, Parker H S, Minor D B, Jones C 1977 Mater. Res. Bull. 12 1173

Google Scholar

Google Scholar

[17] Santoro A, Marezio M, Roth R S, Minor D 1980 J. Solid State Chem. 35 167

Google Scholar

Google Scholar

[18] 殷云宇, 王潇, 邓宏芟, 周龙, 戴建洪, 龙有文 2017 66 030201

Google Scholar

Google Scholar

Yin Y Y, Wang X, Deng H S, Zhou L, Dai J H, Long Y W 2017 Acta Phys. Sin. 66 030201

Google Scholar

Google Scholar

[19] Deminami S, Kawamura Y, Chen Y Q, Kanazawa M, Hayashi J, Kuzuya T, Takeda K, Matsuda M, Sekine C 2017 J. Phys. Conf. Ser. 950 042032

Google Scholar

Google Scholar

[20] Sekine C, Sai U, Hayashi J, Kawamura Y, Bauer E 2017 J. Phys. Conf. Ser. 950 042028

Google Scholar

Google Scholar

[21] Kabeya N, Takahara S, Satoh N, Nakamura S, Katoh K, Ochiai A 2018 Phys. Rev. B 98 035131

Google Scholar

Google Scholar

[22] Nakano T, Onuma S, Takeda N, Uhlířová K, Prokleška J, Sechovský V, Gouchi J, Uwatoko Y 2019 Phys. Rev. B 100 035107

Google Scholar

Google Scholar

[23] Matin M, Kulkarni R, Thamizhavel A, Dhar S K, Provino A, Manfrinetti P 2017 J. Phys Condens. Matter 29 145601

Google Scholar

Google Scholar

[24] Ajeesh M O, Kushwaha S K, Thomas S M, Thompson J D, Chan M K, Harrison N, Tomczak J M, Rosa P F S 2023 Phys. Rev. B 108 245125

Google Scholar

Google Scholar

[25] Ravot D, Burlet P, Rossat-Mignod J, Tholence J L 1980 J. Phys. 41 1117

Google Scholar

Google Scholar

[26] Mott N F 1969 Philos. Mag. 19 835

Google Scholar

Google Scholar

计量

- 文章访问数: 5112

- PDF下载量: 239

- 被引次数: 0

下载:

下载: