-

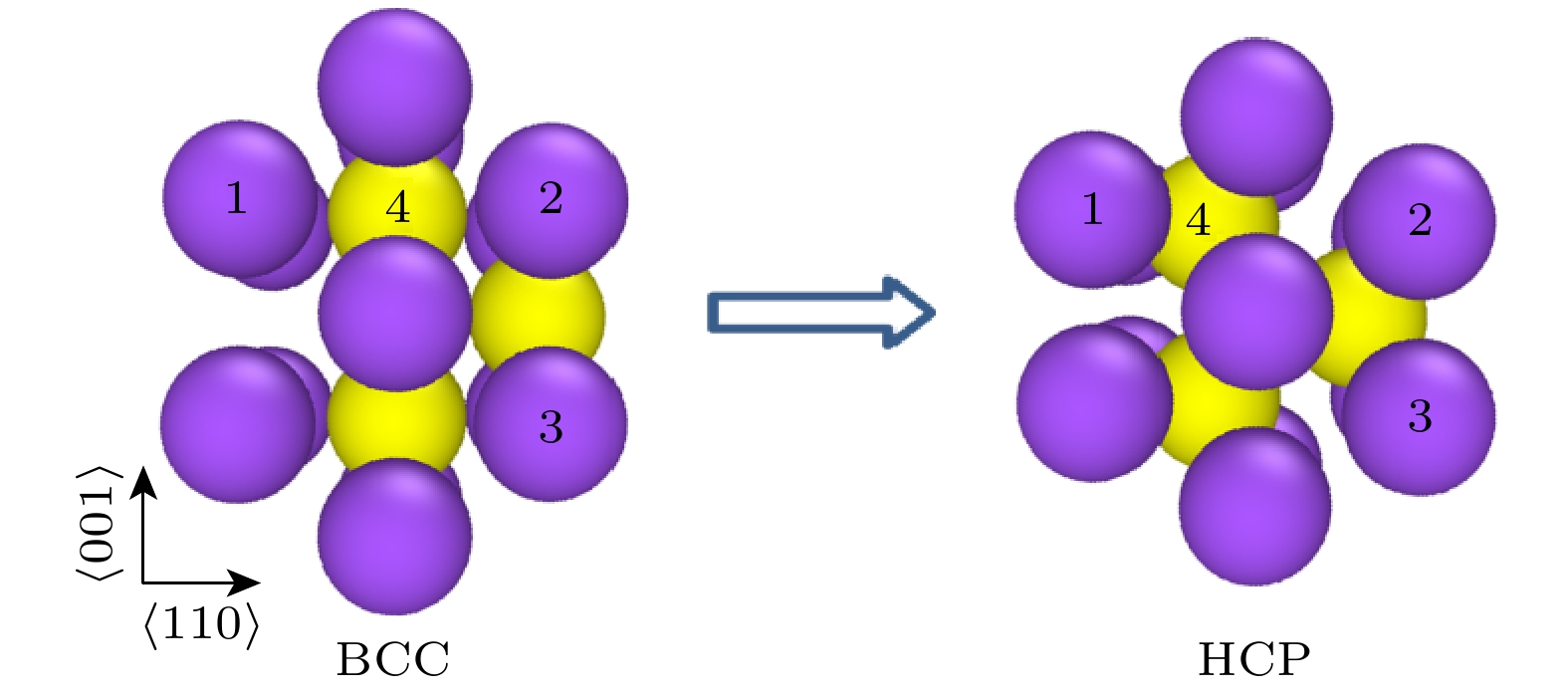

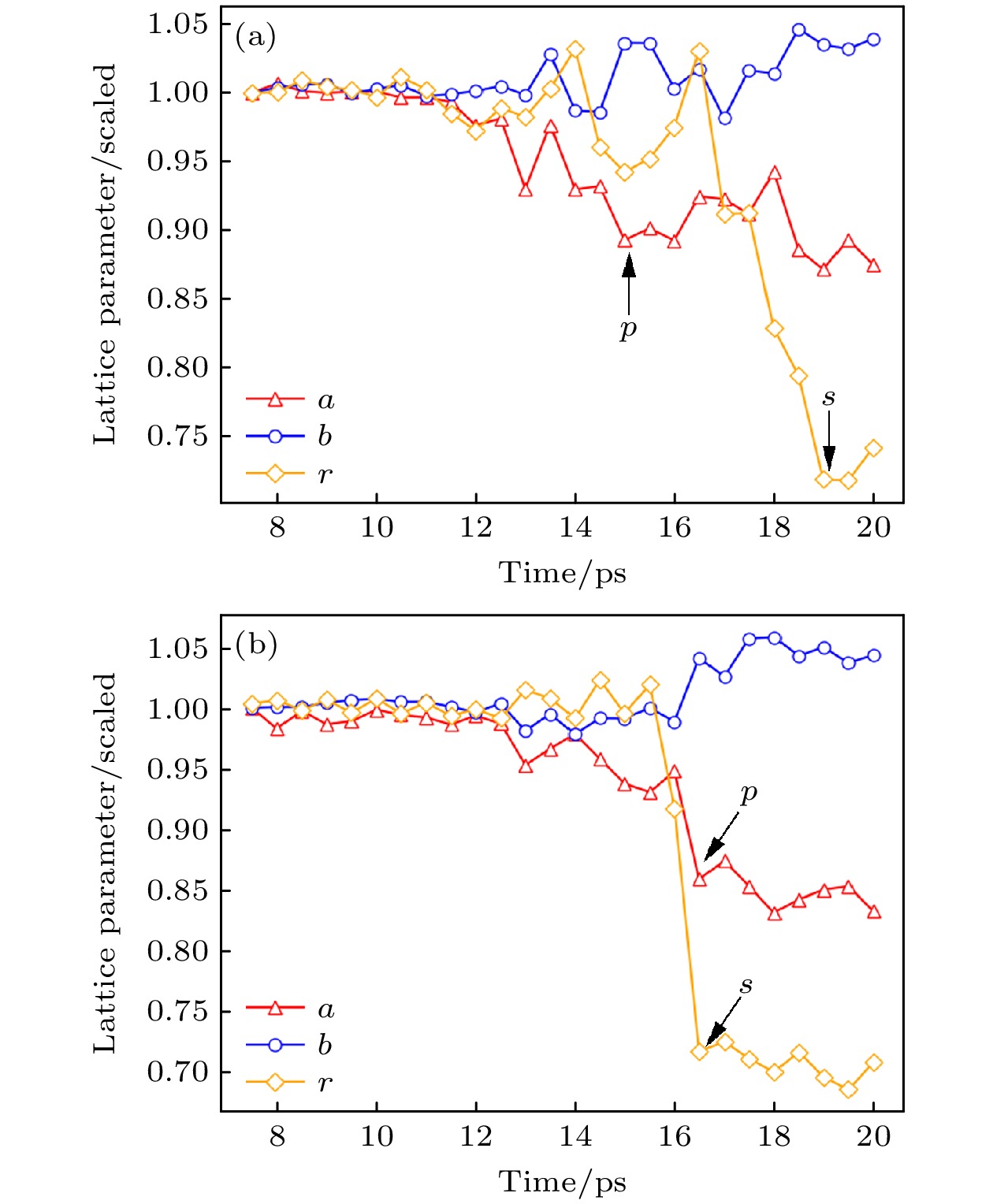

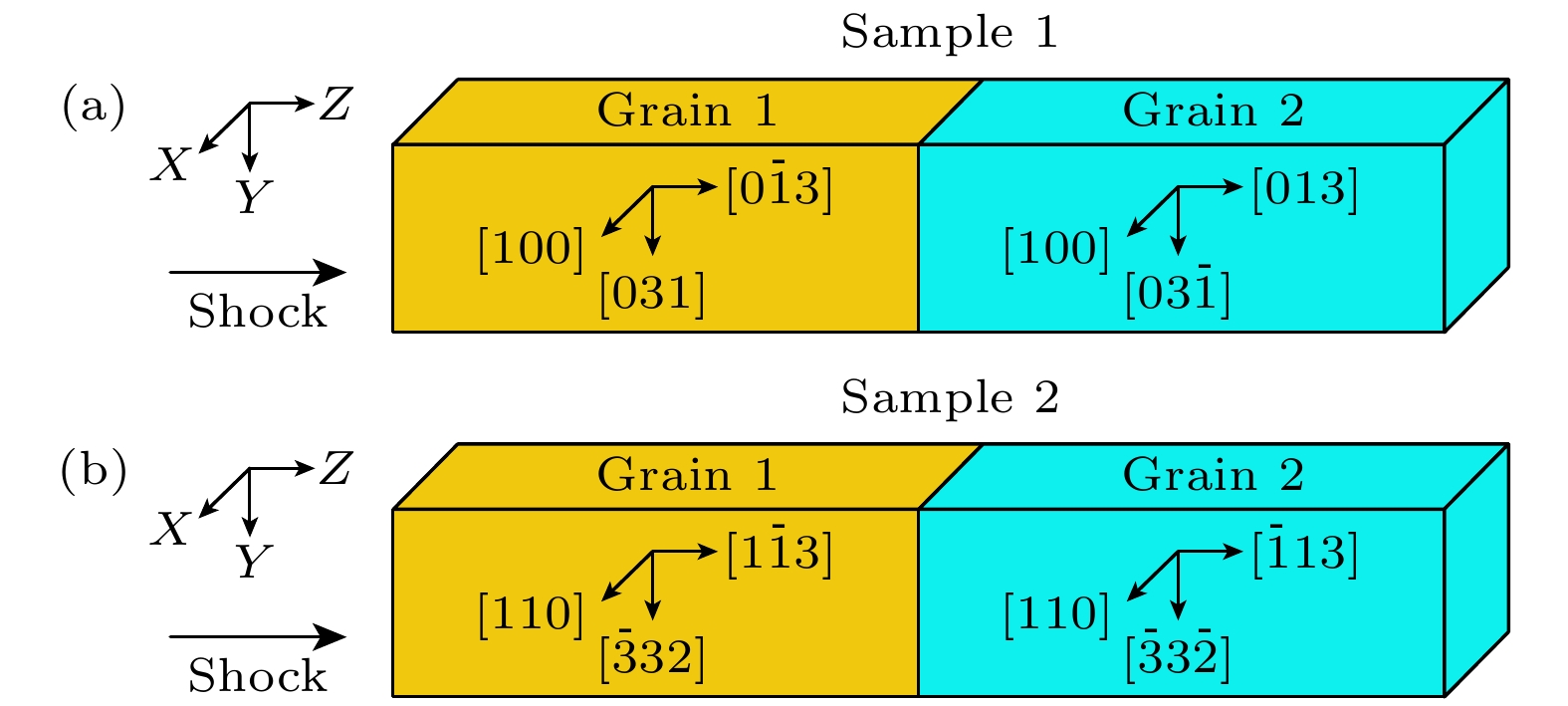

由于铁在国防和工业领域扮演着重要的角色, 因此研究其动态高压下的行为有着重要的意义. 本文拟采用大规模非平衡分子动力学方法研究冲击加载下铁的各向异性在双晶铁中对相变的影响, 通过追踪模型的局域结构、剪切应力分布和冲击后的形貌特点, 分析影响晶界两侧冲击响应的因素. 研究表明, 沿非中心对称晶向冲击可造成对称晶界两侧的相变阈值、相变路径和相变模式出现较大的差异, 考虑到该类型晶界两侧微观结构的对称性, 这种不对称的冲击响应与人们的惯性认知存在着偏差. 本文揭示了晶格的各向异性对冲击加载下晶界两侧的相变有重要的影响, 可以为多晶金属和合金的冲击实验提供一定的理论支持.As is well known, iron plays an important role in the fields of national defense and industry, so it is of great significance to study its behavior under dynamic high pressure. As one of the most common defects in metals in nature, grain boundaries have an important influence on the mechanical properties and deformation of materials under shock. This work intends to use large-scale non-equilibrium molecular dynamics simulation to study the influence of iron anisotropy on the phase transition in bicrystal under shock loading. By tracking the local structure, shear stress distribution and morphology characteristics after shock on both sides of the grain boundaries, the factors affecting the response on both sides of the grain boundary are analyzed. Our research result shows that shocking along the non-centrosymmetric grain direction can cause significant differences in the phase transition threshold, path and mode on both sides of the symmetric grain boundary. Especially, the different phase transition dynamic processes on both sides of the sigma11 grain boundary are discussed in detail in this work, which have been rarely discussed in previous studies. Considering the symmetry of the microstructure on both sides of this type of grain boundary, the result of asymmetric shock response is different from people’s inertial cognition. Finally, it is found that the atoms in both models will shift along the direction perpendicular to the shocked direction under shock, indicating that the shock wave generated by the piston method should no longer be simply regarded as one-dimensional when shocked along the non centrosymmetric crystal direction, and the displacement of atoms along the direction perpendicular to the shocked direction is closely related to the symmetry of the crystal, which causes significant differences in shear stress on both sides of the grain boundary and ultimately affects the shock response. This study reveals that the anisotropy of lattice has an important effect on the phase transition on both sides of grain boundaries under shock loading, which can provide theoretical support for the experimental studies of polycrystalline metals and alloys under shock.

-

Keywords:

- non equilibrium molecular dynamics /

- phase transition /

- grain boundary

[1] Bancroft D, Peterson E L, Minshall S 1956 J. Appl. Phys. 27 291

Google Scholar

Google Scholar

[2] Barker L M, Hollenbach R E 1974 J. Appl. Phys. 45 4872

Google Scholar

Google Scholar

[3] Smith R F, Eggert J E, Bolme C A, Collins G W 2011 J. Appl. Phys. 110 123515

Google Scholar

Google Scholar

[4] de Rességuier T, Hallouin M 1998 J. Appl. Phys. 84 1932

Google Scholar

Google Scholar

[5] Levitas V I, Javanbakht M 2015 J. Mech. Phys. Solids 82 287

Google Scholar

Google Scholar

[6] Javanbakht M, Levitas V I 2015 J. Mech. Phys. Solids 82 164

Google Scholar

Google Scholar

[7] Talonen J, Hänninen H 2007 Acta Mater. 55 6108

Google Scholar

Google Scholar

[8] Nagy E, Mertinger V, Tranta F, Sólyom J 2003 Mater. Sci. Eng. , A 378 308

Google Scholar

Google Scholar

[9] Li N, Wang Y D, Liu W J, An Z N, Liu J P, Su R, Li J, Liaw P K 2014 Acta Mater. 64 12

Google Scholar

Google Scholar

[10] Levitas V I, Ozsoy I B 2009 Int. J. Plast. 25 239

Google Scholar

Google Scholar

[11] Zarechnyy O M, Levitas V I, Ma Y 2012 J. Appl. Phys. 111 023518

Google Scholar

Google Scholar

[12] Hawreliak J A, Eldasher B, Lorenzana H, Kimminau G, Higginbotham A, Nagler B, Vinko S M, Murphy W J, Whitcher T, Wark J S 2011 Phys. Rev. B 83 144114

Google Scholar

Google Scholar

[13] Magee C L 1970 Phase Transformations (Metals Park, Ohio: American Society for Metals

[14] Wu L, Wang K, Xiao S, Deng H, Zhu W, Hu W 2016 Comput. Mater. Sci. 122 1

Google Scholar

Google Scholar

[15] Huang Y, Xiong Y, Li P, Li X, Xiao S, Deng H, Zhu W, Hu W 2019 Int. J. Plast. 114 215

Google Scholar

Google Scholar

[16] 马文, 祝文军, 张亚林, 经福谦 2011 60 066404

Google Scholar

Google Scholar

Ma W, Zhu W J, Zhang Y L, Jing F Q 2011 Acta Phys. Sin. 60 066404

Google Scholar

Google Scholar

[17] 张军, 陈文雄, 郑成武, 李殿中 2017 66 070701

Google Scholar

Google Scholar

Zhang J, Chen W X, Zheng C W, Li D Z 2017 Acta Phys. Sin. 66 070701

Google Scholar

Google Scholar

[18] Zong H, Ding X, Lookman T, Sun J 2016 Acta Mater. 115 1

Google Scholar

Google Scholar

[19] Gunkelmann N, Bringa E M, Kang K, Ackland G J, Ruestes C J, Urbassek H M 2012 Phys. Rev. B 86 144111

Google Scholar

Google Scholar

[20] Gunkelmann N, Bringa E M, Urbassek H M 2015 J. Appl. Phys. 118 185902

Google Scholar

Google Scholar

[21] Gunkelmann N, Tramontina D R, Bringa E M, Urbassek H M 2014 New J. Phys. 16 093032

Google Scholar

Google Scholar

[22] Wang K, Xiao S, Deng H, Zhu W, Hu W 2014 Int. J. Plast. 59 180

Google Scholar

Google Scholar

[23] Wang K, Chen J, Zhang X, Zhu W 2017 J. Appl. Phys. 122 105107

Google Scholar

Google Scholar

[24] Wang K, Zhu W, Xiao S, Chen K, Deng H, Hu W 2015 Int. J. Plast. 71 218

Google Scholar

Google Scholar

[25] Gunkelmann N, Bringa E M, Tramontina D R, Ruestes C J, Suggit M J, Higginbotham A, Wark J S, Urbassek H M 2014 Phys. Rev. B 89 140102

Google Scholar

Google Scholar

[26] Zhang X, Wang K, Zhu W, Chen J, Cai M, Xiao S, Deng H, Hu W 2018 J. Appl. Phys. 123 045105

Google Scholar

Google Scholar

[27] Zhang X, Chen J, Hu W, Zhu W, Xiao S, Deng H, Cai M 2019 J. Appl. Phys. 126 045901

Google Scholar

Google Scholar

[28] Germann T C, Holian B L, Lomdahl P S, Ravelo R 2000 Phys. Rev. Lett. 84 5351

Google Scholar

Google Scholar

[29] Zhakhovsky V V, Migdal K P, Inogamov N A, Anisimov S I 2015 19th Biennial American-Physical-Society (APS) Confe rence on Shock Compression of Condensed Matter (SEEM) Tampa, FL, USA, June 14–19, 2017 p070003

[30] Zong H, He P, Ding X, Ackland G J 2020 Phys. Rev. B 101 144105

Google Scholar

Google Scholar

[31] Zhang X, Deng Y, Chen J, Hu W 2021 Mater. Today Commun. 29 1028932

Google Scholar

Google Scholar

[32] Plimpton S 1995 Comput. Mater. Sci. 4 361

Google Scholar

Google Scholar

[33] Stukowski A 2010 Modell. Simul. Mater. Sci. Eng. 18 015012

Google Scholar

Google Scholar

[34] Thompson A P, Plimpton S J, Mattson W 2009 J. Chem. Phys. 131 154107

Google Scholar

Google Scholar

[35] Luo S N, An Q, Germann T C, Han L B 2009 J. Appl. Phys. 106 253

Google Scholar

Google Scholar

-

图 2 冲击加载下含sigma5晶界的模型1在24 ps时刻的(a)微观结构图, 红色表示HCP结构的原子, 蓝色表示BCC结构的原子, 绿色表示FCC结构的原子, 白色代表无序原子, 晶界的位置可以通过观察白色原子的位置得到; (b)剪切应力分布图; (c) 温度分布图

Fig. 2. (a) Microstructure figures of the model 1 containing sigma5 grain boundaries under shock loading at 24 ps, where red represents HCP structure atoms, blue represents BCC structure atoms, green represents FCC structure atoms, and white represents disordered atoms, the position of the grain boundaries can be obtained by observing the position of white atoms. (b) The shear stress distribution; (c) the temperature distribution.

图 3 冲击加载下含sigma11晶界的模型2在20 ps时刻的(a) 微观结构图, 颜色标示同图2(a); (b) 剪切应力分布图; (c) 温度分布图

Fig. 3. (a) Microstructure of the model 2 containing a sigma11 grain boundary under shock loading at 20 ps, and the color marking is the same as that of Figure 2(a); (b) the shear stress distribution of the model 2; (c) the temperature distribution of the model 2.

-

[1] Bancroft D, Peterson E L, Minshall S 1956 J. Appl. Phys. 27 291

Google Scholar

Google Scholar

[2] Barker L M, Hollenbach R E 1974 J. Appl. Phys. 45 4872

Google Scholar

Google Scholar

[3] Smith R F, Eggert J E, Bolme C A, Collins G W 2011 J. Appl. Phys. 110 123515

Google Scholar

Google Scholar

[4] de Rességuier T, Hallouin M 1998 J. Appl. Phys. 84 1932

Google Scholar

Google Scholar

[5] Levitas V I, Javanbakht M 2015 J. Mech. Phys. Solids 82 287

Google Scholar

Google Scholar

[6] Javanbakht M, Levitas V I 2015 J. Mech. Phys. Solids 82 164

Google Scholar

Google Scholar

[7] Talonen J, Hänninen H 2007 Acta Mater. 55 6108

Google Scholar

Google Scholar

[8] Nagy E, Mertinger V, Tranta F, Sólyom J 2003 Mater. Sci. Eng. , A 378 308

Google Scholar

Google Scholar

[9] Li N, Wang Y D, Liu W J, An Z N, Liu J P, Su R, Li J, Liaw P K 2014 Acta Mater. 64 12

Google Scholar

Google Scholar

[10] Levitas V I, Ozsoy I B 2009 Int. J. Plast. 25 239

Google Scholar

Google Scholar

[11] Zarechnyy O M, Levitas V I, Ma Y 2012 J. Appl. Phys. 111 023518

Google Scholar

Google Scholar

[12] Hawreliak J A, Eldasher B, Lorenzana H, Kimminau G, Higginbotham A, Nagler B, Vinko S M, Murphy W J, Whitcher T, Wark J S 2011 Phys. Rev. B 83 144114

Google Scholar

Google Scholar

[13] Magee C L 1970 Phase Transformations (Metals Park, Ohio: American Society for Metals

[14] Wu L, Wang K, Xiao S, Deng H, Zhu W, Hu W 2016 Comput. Mater. Sci. 122 1

Google Scholar

Google Scholar

[15] Huang Y, Xiong Y, Li P, Li X, Xiao S, Deng H, Zhu W, Hu W 2019 Int. J. Plast. 114 215

Google Scholar

Google Scholar

[16] 马文, 祝文军, 张亚林, 经福谦 2011 60 066404

Google Scholar

Google Scholar

Ma W, Zhu W J, Zhang Y L, Jing F Q 2011 Acta Phys. Sin. 60 066404

Google Scholar

Google Scholar

[17] 张军, 陈文雄, 郑成武, 李殿中 2017 66 070701

Google Scholar

Google Scholar

Zhang J, Chen W X, Zheng C W, Li D Z 2017 Acta Phys. Sin. 66 070701

Google Scholar

Google Scholar

[18] Zong H, Ding X, Lookman T, Sun J 2016 Acta Mater. 115 1

Google Scholar

Google Scholar

[19] Gunkelmann N, Bringa E M, Kang K, Ackland G J, Ruestes C J, Urbassek H M 2012 Phys. Rev. B 86 144111

Google Scholar

Google Scholar

[20] Gunkelmann N, Bringa E M, Urbassek H M 2015 J. Appl. Phys. 118 185902

Google Scholar

Google Scholar

[21] Gunkelmann N, Tramontina D R, Bringa E M, Urbassek H M 2014 New J. Phys. 16 093032

Google Scholar

Google Scholar

[22] Wang K, Xiao S, Deng H, Zhu W, Hu W 2014 Int. J. Plast. 59 180

Google Scholar

Google Scholar

[23] Wang K, Chen J, Zhang X, Zhu W 2017 J. Appl. Phys. 122 105107

Google Scholar

Google Scholar

[24] Wang K, Zhu W, Xiao S, Chen K, Deng H, Hu W 2015 Int. J. Plast. 71 218

Google Scholar

Google Scholar

[25] Gunkelmann N, Bringa E M, Tramontina D R, Ruestes C J, Suggit M J, Higginbotham A, Wark J S, Urbassek H M 2014 Phys. Rev. B 89 140102

Google Scholar

Google Scholar

[26] Zhang X, Wang K, Zhu W, Chen J, Cai M, Xiao S, Deng H, Hu W 2018 J. Appl. Phys. 123 045105

Google Scholar

Google Scholar

[27] Zhang X, Chen J, Hu W, Zhu W, Xiao S, Deng H, Cai M 2019 J. Appl. Phys. 126 045901

Google Scholar

Google Scholar

[28] Germann T C, Holian B L, Lomdahl P S, Ravelo R 2000 Phys. Rev. Lett. 84 5351

Google Scholar

Google Scholar

[29] Zhakhovsky V V, Migdal K P, Inogamov N A, Anisimov S I 2015 19th Biennial American-Physical-Society (APS) Confe rence on Shock Compression of Condensed Matter (SEEM) Tampa, FL, USA, June 14–19, 2017 p070003

[30] Zong H, He P, Ding X, Ackland G J 2020 Phys. Rev. B 101 144105

Google Scholar

Google Scholar

[31] Zhang X, Deng Y, Chen J, Hu W 2021 Mater. Today Commun. 29 1028932

Google Scholar

Google Scholar

[32] Plimpton S 1995 Comput. Mater. Sci. 4 361

Google Scholar

Google Scholar

[33] Stukowski A 2010 Modell. Simul. Mater. Sci. Eng. 18 015012

Google Scholar

Google Scholar

[34] Thompson A P, Plimpton S J, Mattson W 2009 J. Chem. Phys. 131 154107

Google Scholar

Google Scholar

[35] Luo S N, An Q, Germann T C, Han L B 2009 J. Appl. Phys. 106 253

Google Scholar

Google Scholar

计量

- 文章访问数: 3604

- PDF下载量: 91

- 被引次数: 0

下载:

下载: