-

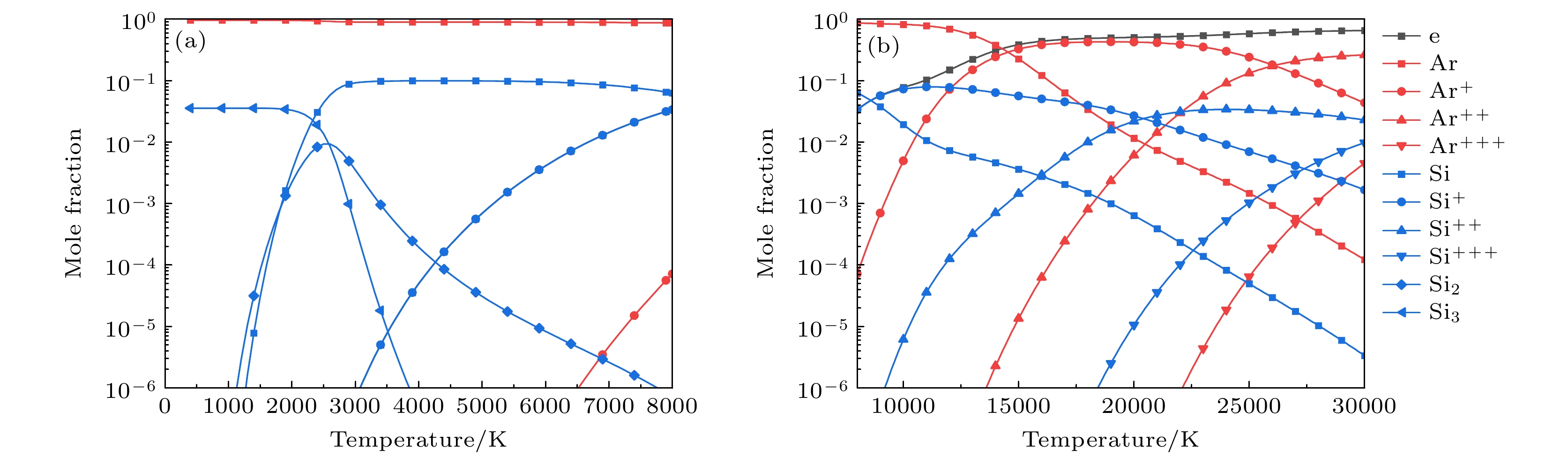

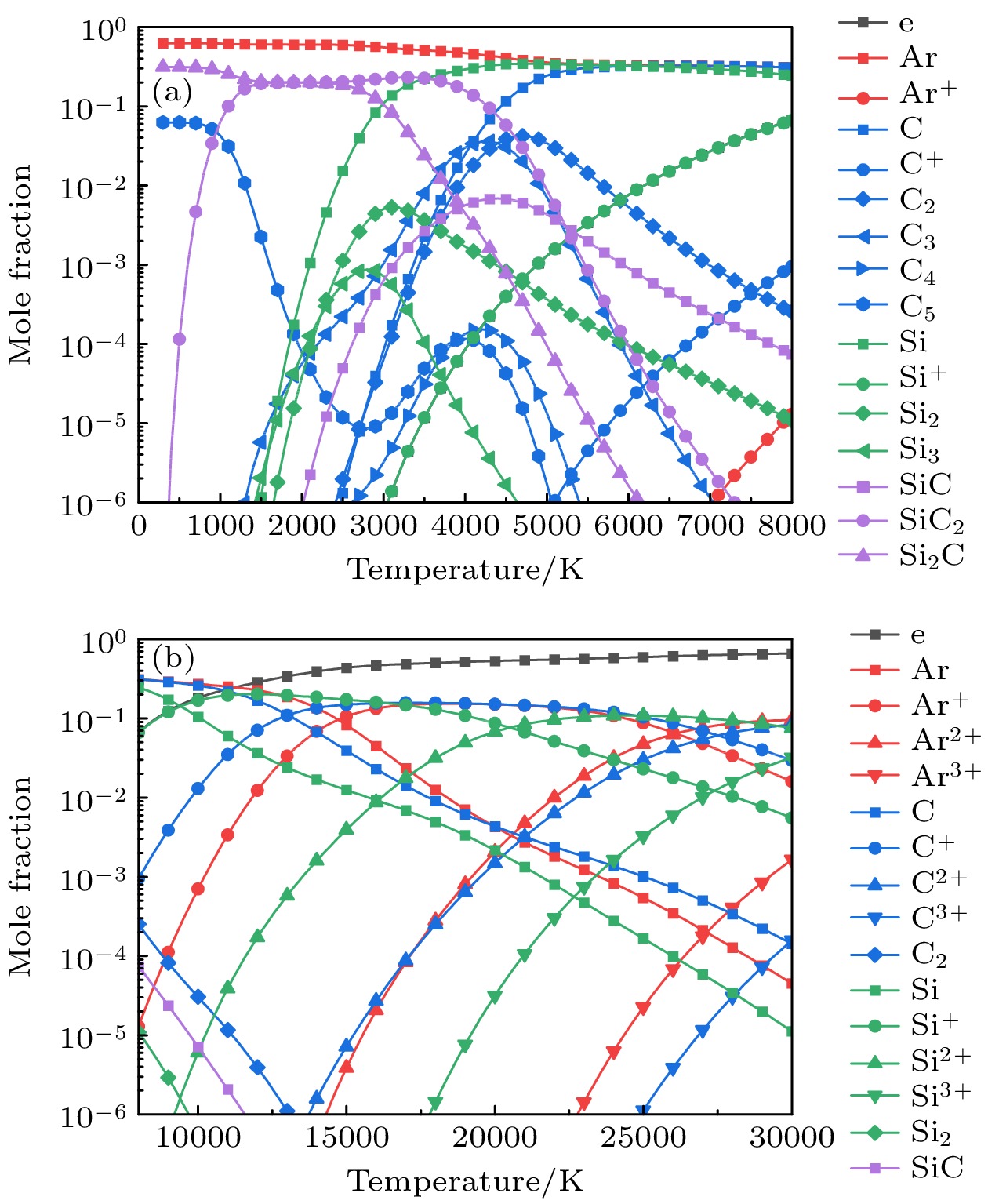

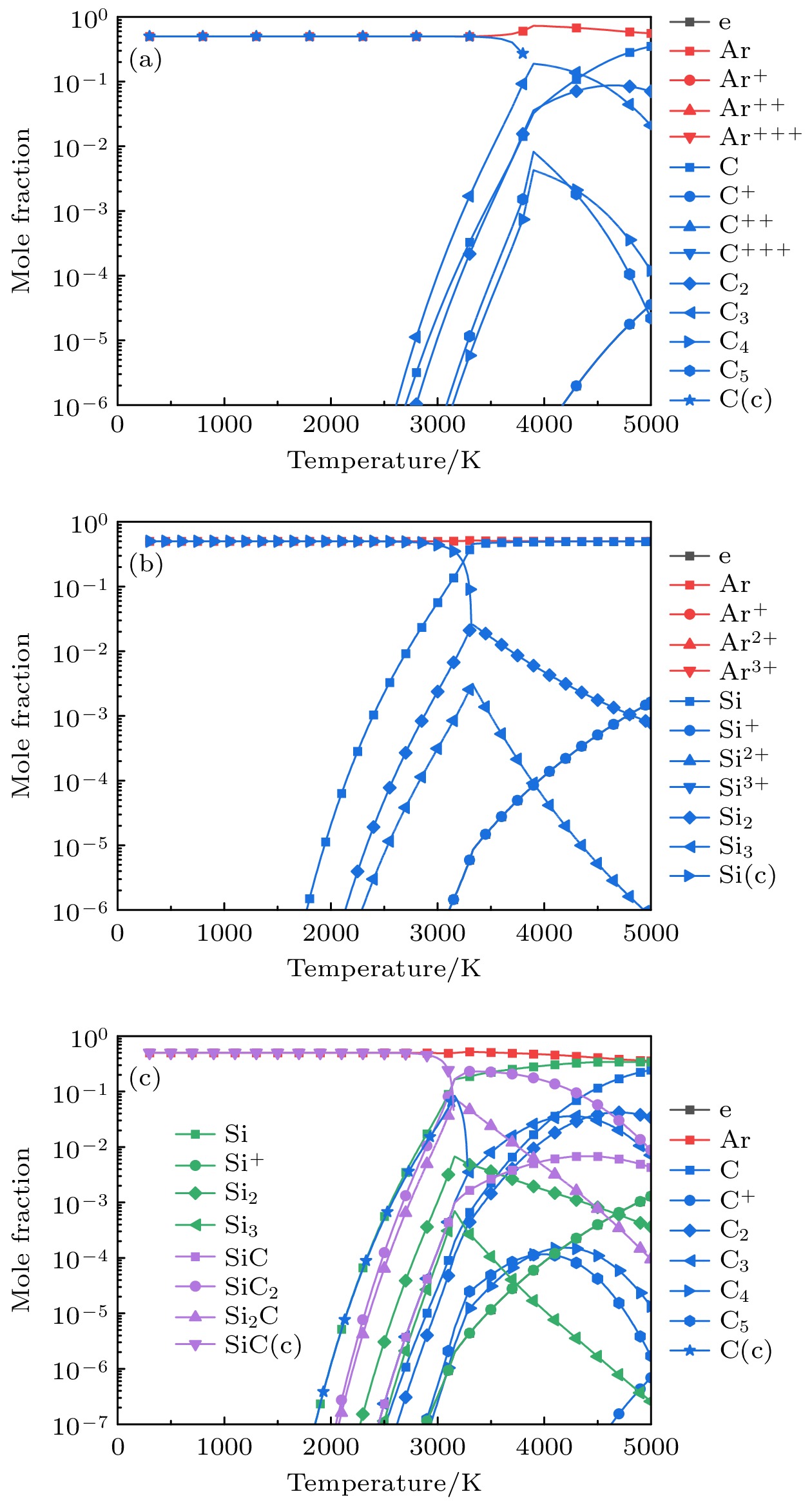

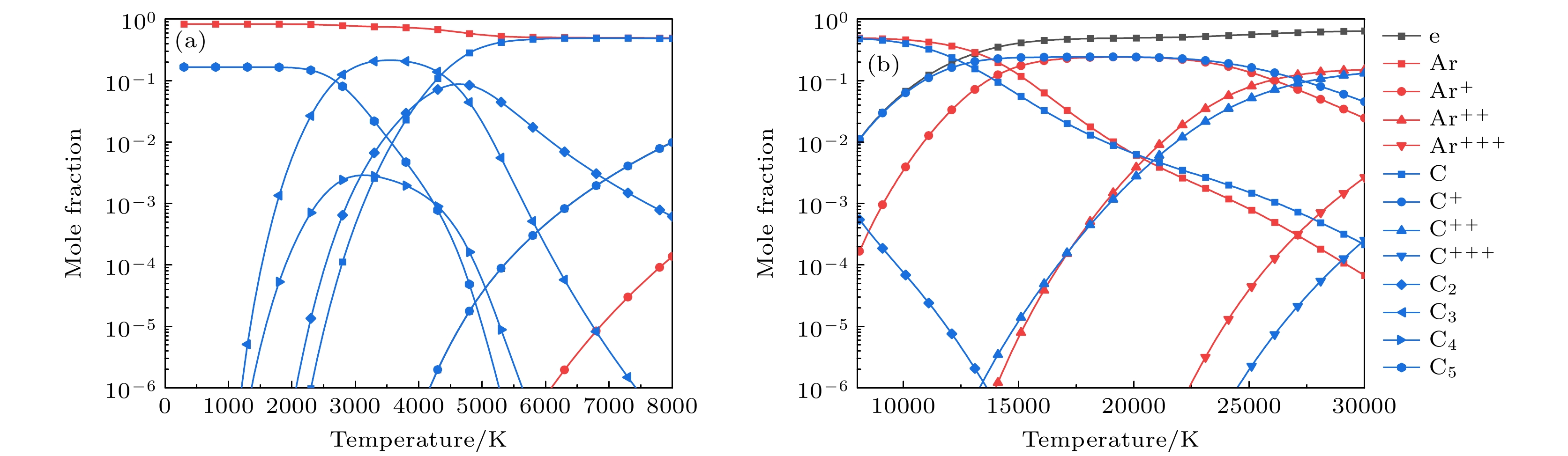

计算了广温度范围(300—30000 K)和广压力范围(0.1—10 atm, 1 atm=101.325 kPa)下, 不同混合物比例、碳和硅蒸气浓度的局域热力学平衡(LTE)和化学平衡(LCE)的氩-碳-硅等离子体组分、热力学性质和输运系数. 等离子体气相平衡组分使用质量作用定律计算, 同时凝聚相组分采用相平衡的方法计算. 输运系数的计算包括黏度、电导率和热导率, 使用拓展到高阶近似的Chapman-Enskog方法. 采用文献中较新的数据得到了较为准确的碰撞积分, 导出了Ar-C-Si等离子体的输运系数. 结果表明, 在相变温度以下, 凝聚态物种的引入导致Ar-C-Si等离子体的热力学性质、输运系数与纯Ar等离子体接近, 在相变温度点则会产生不连续点. 压力、碳/硅蒸气浓度和比例对等离子体热力学性质和输运系数具有较大影响. 最终计算值与文献数据对比符合良好, 有望为氩-碳-硅等离子体传热流动数值模拟提供基础数据.The compositions, thermodynamic properties and transport coefficients of the argon-carbon-silicon plasma at local thermodynamic equilibrium and local chemical equilibrium in temperatures range of 300-30000 K and pressure range of 0.1 to 10 atm and are different mixture ratios are investigated in this work. The condensed phases and Debye-Hückel corrections are both taken into account. The equilibrium component in gas phase is calculated by mass action law (Saha’s law and Gulberg-Waage’s law), Dalton’s partial pressure law, conservation of the elements and charge quasi-neutral equation, and at the same time the condensed species is calculated under the assumption of local phase equilibrium. Thermodynamic properties including density, enthalpy and specific heat are evaluated through a classical statistical mechanics approach. The transport coefficient calculations including viscosity, electrical conductivity, and thermal conductivity are carried out by using a third-order approximation (second-order for viscosity) of the Chapman-Enskog method. Collision integrals are obtained by using the relatively new data. The results show that the concentration and ratio of blend of C vapor and Si vapor can greatly affect the properties of the Ar plasma owing to the introduced C and Si vapor’ s own properties and their new reactions. While the pressure influences those properties through the shift of chemical equilibrium and the change of total number density. In addition, the introduction of condensed species leads the thermodynamic properties and transport coefficients of the lower temperature plasma to become almost the same as those of pure argon, and causes discontinuous points at phase-transition temperature. The final calculation results are in good agreement with those in the literature, and the slight difference in transport coefficient between them can be explained by the different selection of interaction potentials. The results are expected to provide reliable basic data for the numerical simulation of argon-carbon-silicon plasma.

-

Keywords:

- argon-carbon-silicon plasma /

- thermodynamic properties /

- transport coefficients /

- local thermodynamic equilibrium

[1] Kim T H, Oh J H, Kim M, Hong S H, Choi S 2020 Appl. Sci. Converg. Technol. 29 117

Google Scholar

Google Scholar

[2] Wang C, Zhou J, Song M, Chen X, Zheng Y, Yang C, Xia W, Xia W 2022 Ceram. Int. 48 632

Google Scholar

Google Scholar

[3] Zhou J W, Wang C, Song M, Chen X H, Xia W D 2021 Mater. Lett. 299 130072

Google Scholar

Google Scholar

[4] Choi S, Lee H, Park D W 2016 J. Nanomater. 2016 5849041

Google Scholar

Google Scholar

[5] Okuyama H, Saito S, Uda M, Nakata T, Sakka Y 2012 J. Alloys Compd. 520 127

Google Scholar

Google Scholar

[6] Qadri S B, Imam M A, Feng C R, Rath B B, Yousuf M, Singh S K 2003 Appl. Phys. Lett. 83 548

Google Scholar

Google Scholar

[7] Rai P, Kim Y S, Kang S K, Yu Y T 2012 Plasma Chem. Plasma Process. 32 211

Google Scholar

Google Scholar

[8] Wan X H, Fan Y K, Ma W H, Li S Y, Huang X, Yu J 2018 Mater. Lett. 220 144

Google Scholar

Google Scholar

[9] Zhang X Y, Hayashida R, Tanaka M, Watanabe T 2020 Powder Technol. 371 26

Google Scholar

Google Scholar

[10] Zhang X Y, Liu Z S, Tanaka M, Watanabe T 2021 Chem. Eng. Sci. 230 116217

Google Scholar

Google Scholar

[11] Mendoza Gonzalez N Y, El Morsli M, Proulx P 2008 J. Therm. Spray Technol. 17 533

Google Scholar

Google Scholar

[12] Kim K S, Moradian A, Mostaghimi J, Soucy G 2009 Plasma Chem. Plasma Process. 30 91

Google Scholar

Google Scholar

[13] Atsuchi N, Shigeta M, Watanabe T 2006 Int. J. Heat Mass Transf. 49 1073

Google Scholar

Google Scholar

[14] Pan Z H, Chen X H, Yuan X, Wang C, Xia W D 2021 Plasma Chem. Plasma Process. 41 1183

Google Scholar

Google Scholar

[15] Colombo V, Ghedini E, Gherardi M, Sanibondi P 2013 Plasma Sources Sci. Technol. 22 035010

Google Scholar

Google Scholar

[16] Wang W Z, Rong M Z, Murphy A B, Wu Y, Spencer J W, Yan J D, Fang M T C 2011 J. Phys. D Appl. Phys. 44 355207

Google Scholar

Google Scholar

[17] Wang W Z, Yan J D, Rong M Z, Murphy A B, Spencer J W 2012 Plasma Chem. Plasma Process. 32 495

Google Scholar

Google Scholar

[18] Wu Y, Chen Z X, Rong M Z, Cressault Y, Yang F, Niu C P, Sun H 2016 J. Phys. D Appl. Phys. 49 405203

Google Scholar

Google Scholar

[19] 王海兴, 孙素蓉, 陈士强 2012 61 195203

Google Scholar

Google Scholar

Wang H X, Sun S R, Chen S Q 2012 Acta Phys. Sin. 61 195203

Google Scholar

Google Scholar

[20] Akashi K, Tanaka Y, Nakano Y, Furukawa R, Ishijima T, Sueyasu S, Watanabe S, Nakamura K 2021 Plasma Chem. Plasma Process. 41 1121

Google Scholar

Google Scholar

[21] Colonna G 2019 Rend. Lincei Sci. Fis. Nat. 30 537

Google Scholar

Google Scholar

[22] Colonna G, D'Angola A, Pietanza L D, Capitelli M, Pirani F, Stevanato E, Laricchiuta A 2018 Plasma Sources Sci. Technol. 27 015007

Google Scholar

Google Scholar

[23] Devoto R S 1966 Phys. Fluids 9 1230

Google Scholar

Google Scholar

[24] Devoto R S 1967 Phys. Fluids 10 2105

Google Scholar

Google Scholar

[25] Godin D, Trepanier J Y 2004 Plasma Chem. Plasma Process. 24 447

Google Scholar

Google Scholar

[26] Kramida A, Ralchenko Y, Reader J, NIST ASD Team https://www.nist.gov/pml/atomic-spectra-database [2022-12-1]

[27] Chase M W, Davies C A, Downey J R, Frurip D J, McDonald R A, Syverud A N https://janaf.nist.gov/ [2022-12-1]

[28] André P, Bussière W, Rochette D 2007 Plasma Chem. Plasma Process. 27 381

Google Scholar

Google Scholar

[29] André P, Brunet L, Bussière W, Caillard J, Lombard J M, Picard J P 2004 Eur. Phys. J. Appl. Phys. 25 169

Google Scholar

Google Scholar

[30] Capitelli M, Cappelletti D, Colonna G, Gorse C, Laricchiuta A, Liuti G, Longo S, Pirani F 2007 Chem. Phys. 338 62

Google Scholar

Google Scholar

[31] Colonna G, Laricchiuta A 2008 Comput. Phys. Commun. 178 809

Google Scholar

Google Scholar

[32] Stallcop J R, Partridge H, Pradhan A, Levin E 2000 J. Thermophys Heat Transfer 14 480

Google Scholar

Google Scholar

[33] Aubreton J, Bonnefoi C, Mexmain J M 1986 Phys. Appl. Rev. 21 365

Google Scholar

Google Scholar

[34] Laricchiuta A, Bruno D, Capitelli M, Catalfamo C, Celiberto R, Colonna G, Diomede P, Giordano D, Gorse C, Longo S, Pagano D, Pirani F 2009 Eur. Phys. J. D 54 607

Google Scholar

Google Scholar

[35] Sourd B, Aubreton J, Elchinger M F, Labrot M, Michon U 2006 J. Phys. D Appl. Phys. 39 1105

Google Scholar

Google Scholar

-

图 5 1 atm下, 带有不同SiC浓度的Ar-SiC等离子体的焓值 (a) 300—5000 K的焓值, 考虑凝聚态物种(折线图), 忽略凝聚态物种(散点图); (b) 300—30000 K下的焓值(不考虑凝聚态物种)

Fig. 5. Enthalpy of Ar-SiC plasma with different SiC concentrations at 1 atm: (a) Enthalpy at 300–30000 K, (solid lines) considering condensed species, (dotted lines) neglecting condensed species; (b) results at 300–30000 K (neglecting condensed species).

图 10 1 atm下, 50%Ar和50%不同碳硅比混合物的等离子体的定压比热 (a) 300—5000 K的焓值, 考虑凝聚态物种(折线图), 忽略凝聚态物种(散点图); (b) 300—30000 K下的结果(不考虑凝聚态物种)

Fig. 10. Specific heat at constant pressure of 50%Ar and 50% mixture with different C/Si ratios at 1 atm: (a) Results at 300–5000 K, (solid lines) considering condensed species, (dotted lines) neglecting condensed species; (b) results at 300–30000 K (neglecting condensed species).

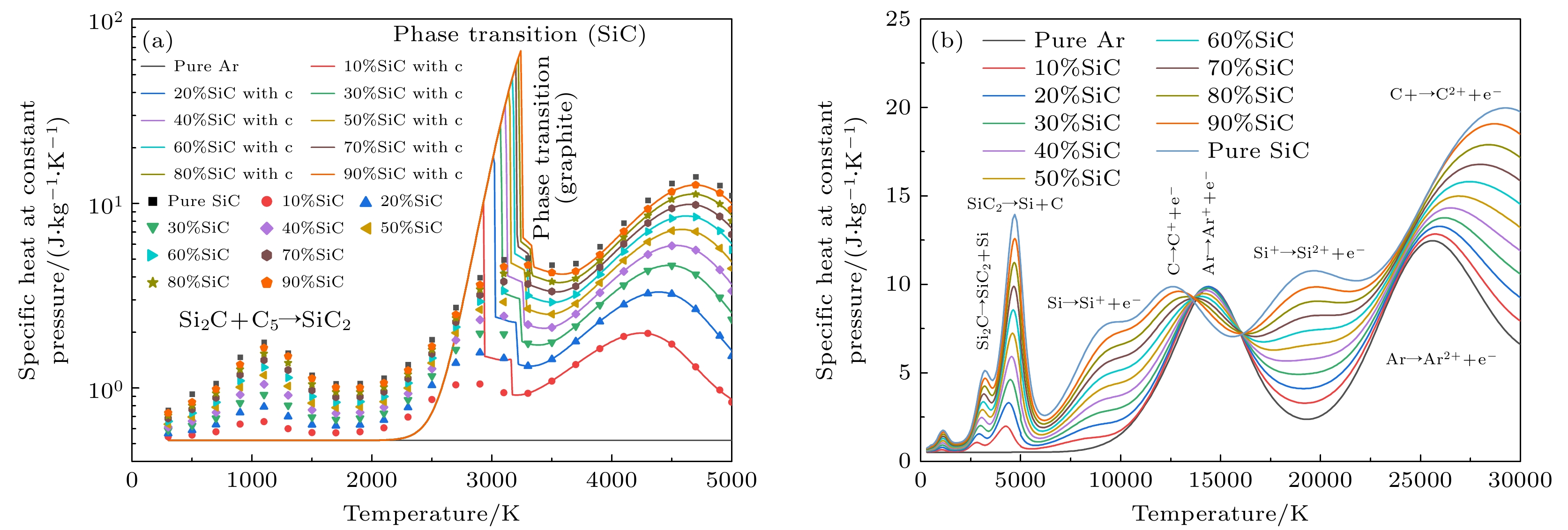

图 6 1 atm下, 带有不同SiC浓度的Ar-SiC等离子体的定压比热 (a) 300—5000 K的定压比热, 考虑凝聚态物种(折线图), 忽略凝聚态物种(散点图); (b) 300—30000 K下的结果(不考虑凝聚态物种)

Fig. 6. Specific heat at constant pressure of Ar-SiC plasma with different SiC concentrations at 1 atm: (a) Results at 300–5000 K, (solid lines) considering condensed species, (dotted lines) neglecting condensed species; (b) results at 300–30000 K (neglecting condensed species).

图 7 不同气压下50%Ar-50%SiC等离子体的焓值变化曲线 (a) 300—5000 K的焓值, 考虑凝聚态物种(折线图), 忽略凝聚态物种(散点图); (b) 300—30000 K下的焓值(不考虑凝聚态物种)

Fig. 7. Enthalpy of 50%Ar-50%SiC plasma at different pressures: (a) Results at 300–5000 K, (solid lines) considering condensed species, (dotted lines) neglecting condensed species; (b) results at 300–30000 K (neglecting condensed species).

图 8 在不同气压下50%Ar-50%SiC等离子体的定压比热Cp (a) 300—5000 K的定压比热, 考虑凝聚态物种(折线图), 忽略凝聚态物种(散点图); (b) 300—30000 K下的结果(不考虑凝聚态物种)

Fig. 8. Specific heat of 50%Ar-50%SiC plasma at different constant pressure: (a) Results at 300–000 K, (solid lines) considering condensed species, (dotted lines) neglecting condensed species; (b) results at 300–30000 K (neglecting condensed species).

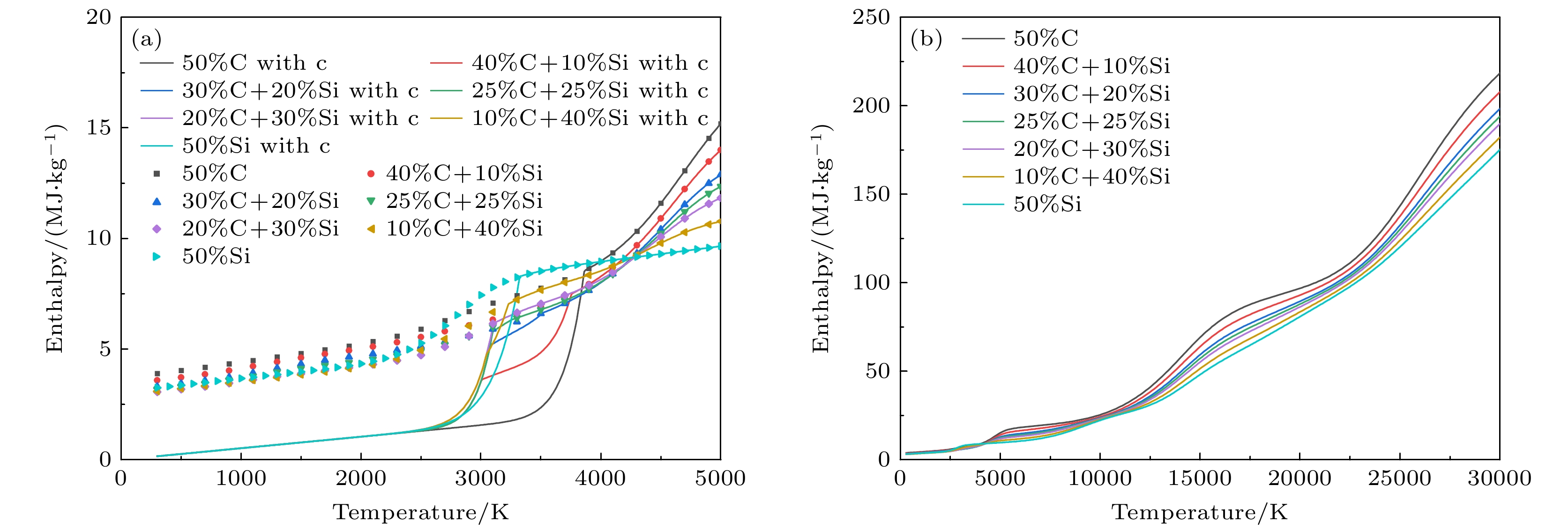

图 9 1 atm下, 50%Ar和50%不同碳硅比混合物的等离子体的焓值 (a)300—5000 K的焓值, 考虑凝聚态物种(折线图), 忽略凝聚态物种(散点图); (b) 300—30000 K下的结果(不考虑凝聚态物种)

Fig. 9. Enthalpy of 50%Ar and 50% mixture with different C/Si ratios at 1 atm: (a) Results at 300–5000 K, (solid lines) considering condensed species, (dotted lines) neglecting condensed species; (b) results at 300–30000 K (neglecting condensed species).

图 11 电导率随温度变化曲线 (a)不同压力下50%Ar+50%SiC的曲线; (b) 1 atm下不同SiC浓度的曲线; (c) 50%Ar和50%不同碳硅比混合物的曲线

Fig. 11. Temperature dependence of electrical conductivity: (a) Curves of 50%Ar and 50%SiC under different pressures; (b) curves of different SiC concentrations at 1 atm; (c) curves of 50%Ar and 50% mixtures with different C/Si ratios

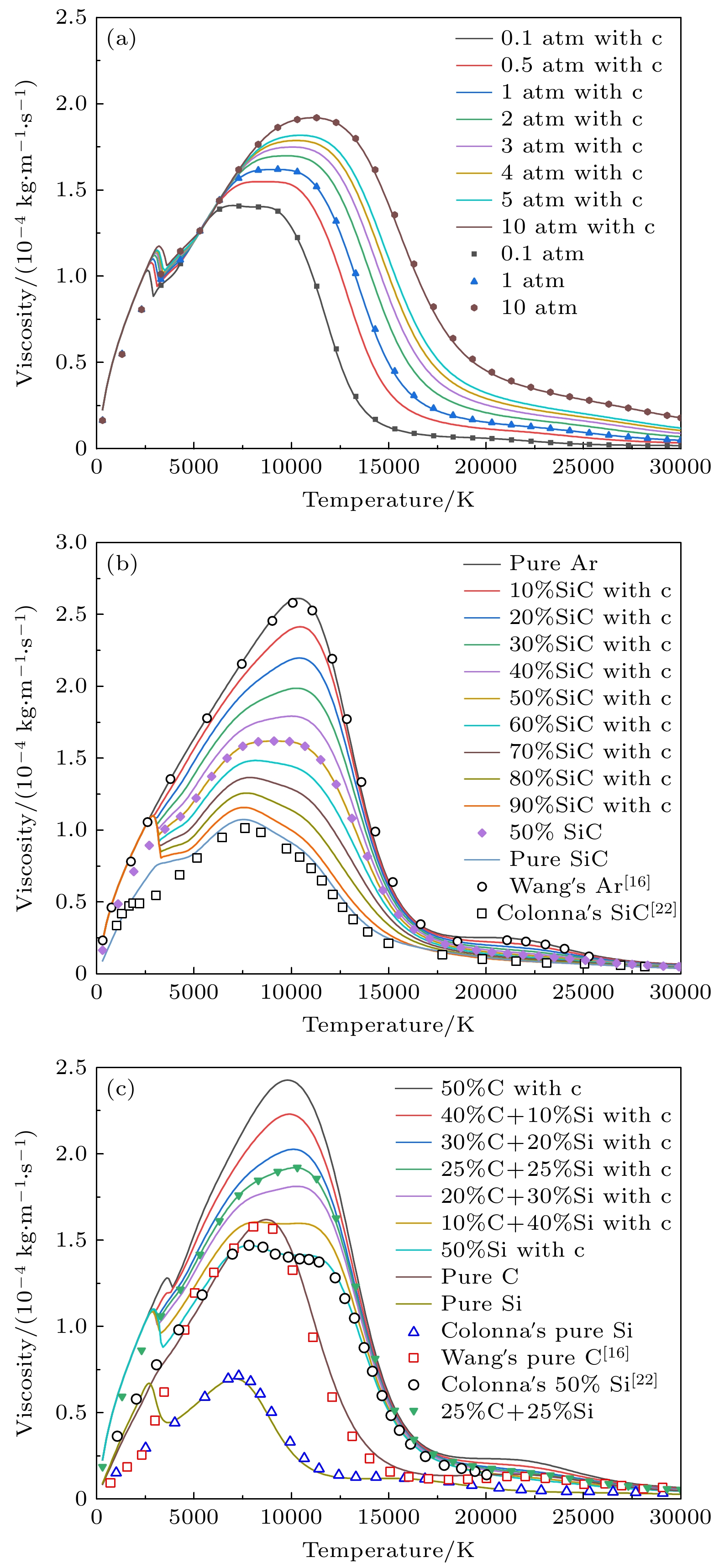

图 12 黏度随温度变化曲线 (a)不同压力下50%Ar+50%SiC的曲线; (b) 1 atm下不同SiC浓度的曲线; (c) 50%Ar和50%不同碳硅比混合物的曲线

Fig. 12. Temperature dependence of viscosity: (a) curves of 50%Ar and 50%SiC under different pressures; (b) curves of different SiC concentrations at 1 atm; (c) curves of 50%Ar and 50% mixtures with different C/Si ratios.

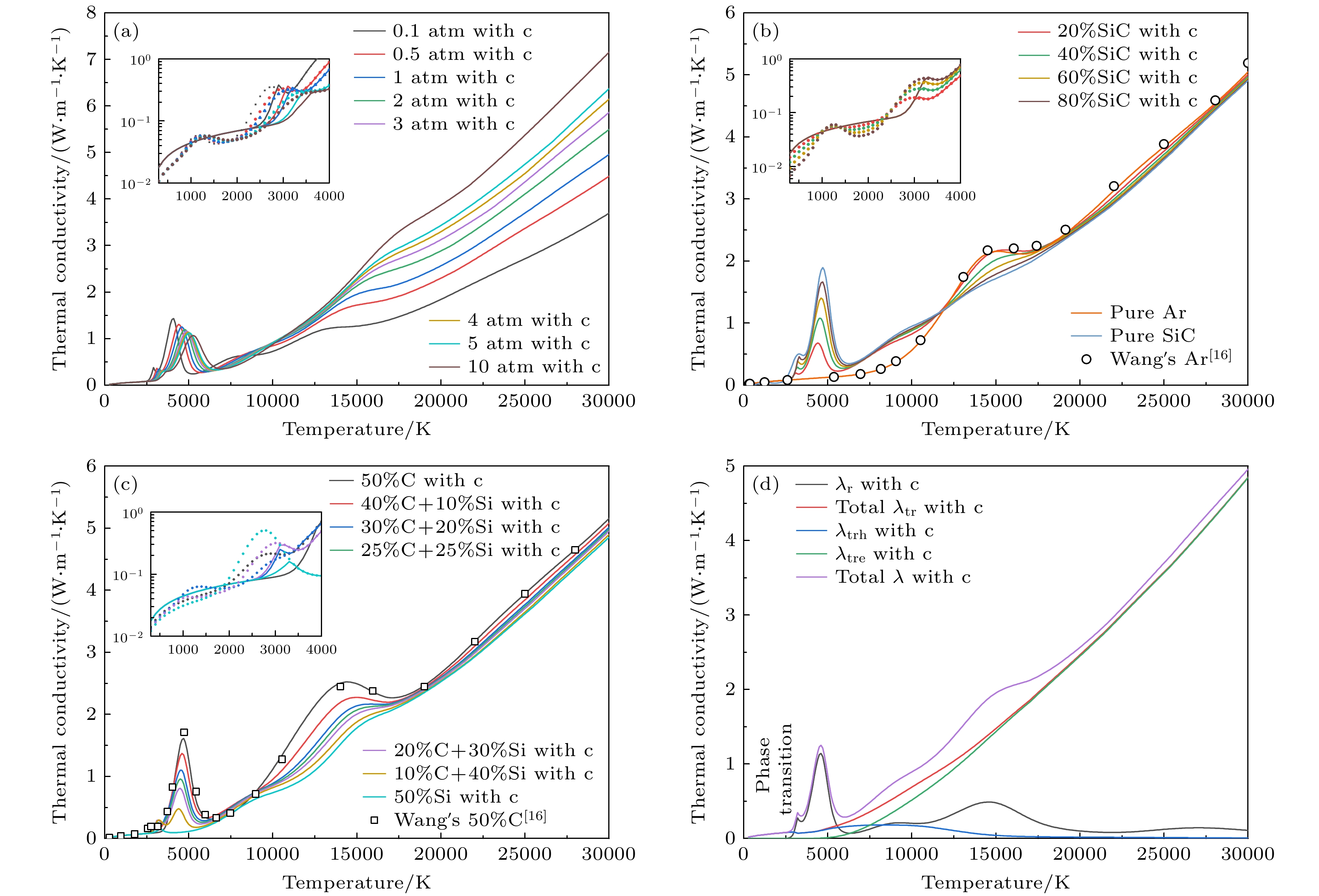

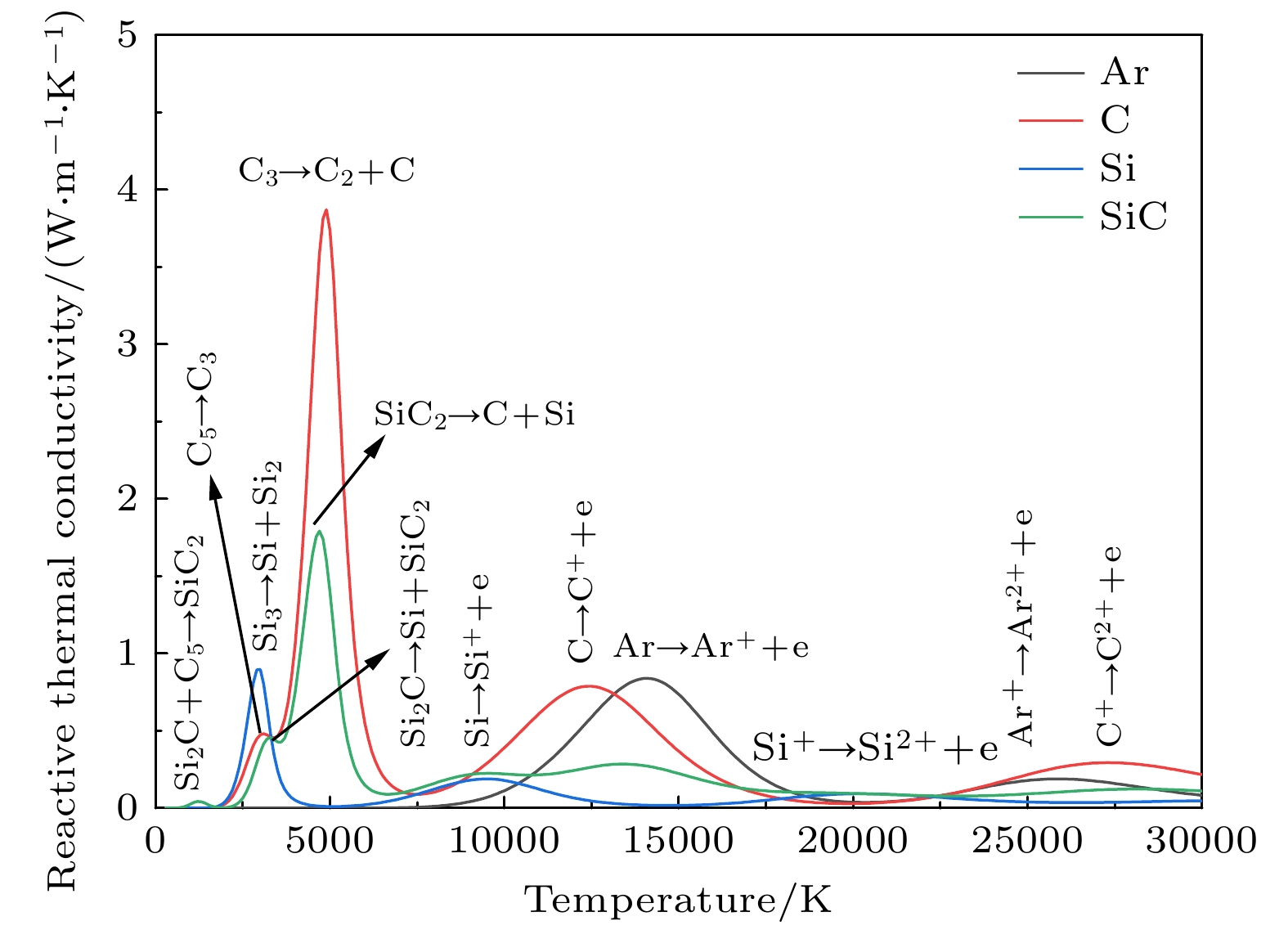

图 13 热导率随温度变化曲线 (a)不同压力下50%Ar+50%SiC的曲线; (b) 1 atm下不同SiC浓度的曲线; (c) 50%Ar和50%不同碳硅比混合物的曲线; (d)总热导率(total λ)、电子平动热导率(λtre)、重粒子平动热导率(λtrh)、总平动热导率(total λtr)、反应热导率(λr)随温度变化曲线

Fig. 13. Temperature dependence of thermal conductivity: (a) Curves of 50%Ar and 50%SiC under different pressures; (b) curves of different SiC concentrations at 1 atm; (c) curves of 50%Ar and 50% mixtures with different C/Si ratios; (d) curves of Temperature dependence of total thermal conductivity (total λ), electron translational thermal conductivity (λtre), heavy species translational thermal conductivity (λtrh), total translational thermal conductivity (total λtr) and reactive thermal conductivity (λr).

表 1 计算考虑的物种

Table 1. Species considered in calculations.

元素 物种 Ar Ar, Ar+, Ar2+, Ar3+ C C(g), C+, C2+, C3+, C2, C3, C4, C5, C(c) Si Si(g), Si+, Si2+, Si3+, Si2, Si3, Si(c) C, Si SiC(g), SiC2, Si2C, SiC(c) 表 2 部分二体相互作用势选取

Table 2. Partial selection of interaction.

-

[1] Kim T H, Oh J H, Kim M, Hong S H, Choi S 2020 Appl. Sci. Converg. Technol. 29 117

Google Scholar

Google Scholar

[2] Wang C, Zhou J, Song M, Chen X, Zheng Y, Yang C, Xia W, Xia W 2022 Ceram. Int. 48 632

Google Scholar

Google Scholar

[3] Zhou J W, Wang C, Song M, Chen X H, Xia W D 2021 Mater. Lett. 299 130072

Google Scholar

Google Scholar

[4] Choi S, Lee H, Park D W 2016 J. Nanomater. 2016 5849041

Google Scholar

Google Scholar

[5] Okuyama H, Saito S, Uda M, Nakata T, Sakka Y 2012 J. Alloys Compd. 520 127

Google Scholar

Google Scholar

[6] Qadri S B, Imam M A, Feng C R, Rath B B, Yousuf M, Singh S K 2003 Appl. Phys. Lett. 83 548

Google Scholar

Google Scholar

[7] Rai P, Kim Y S, Kang S K, Yu Y T 2012 Plasma Chem. Plasma Process. 32 211

Google Scholar

Google Scholar

[8] Wan X H, Fan Y K, Ma W H, Li S Y, Huang X, Yu J 2018 Mater. Lett. 220 144

Google Scholar

Google Scholar

[9] Zhang X Y, Hayashida R, Tanaka M, Watanabe T 2020 Powder Technol. 371 26

Google Scholar

Google Scholar

[10] Zhang X Y, Liu Z S, Tanaka M, Watanabe T 2021 Chem. Eng. Sci. 230 116217

Google Scholar

Google Scholar

[11] Mendoza Gonzalez N Y, El Morsli M, Proulx P 2008 J. Therm. Spray Technol. 17 533

Google Scholar

Google Scholar

[12] Kim K S, Moradian A, Mostaghimi J, Soucy G 2009 Plasma Chem. Plasma Process. 30 91

Google Scholar

Google Scholar

[13] Atsuchi N, Shigeta M, Watanabe T 2006 Int. J. Heat Mass Transf. 49 1073

Google Scholar

Google Scholar

[14] Pan Z H, Chen X H, Yuan X, Wang C, Xia W D 2021 Plasma Chem. Plasma Process. 41 1183

Google Scholar

Google Scholar

[15] Colombo V, Ghedini E, Gherardi M, Sanibondi P 2013 Plasma Sources Sci. Technol. 22 035010

Google Scholar

Google Scholar

[16] Wang W Z, Rong M Z, Murphy A B, Wu Y, Spencer J W, Yan J D, Fang M T C 2011 J. Phys. D Appl. Phys. 44 355207

Google Scholar

Google Scholar

[17] Wang W Z, Yan J D, Rong M Z, Murphy A B, Spencer J W 2012 Plasma Chem. Plasma Process. 32 495

Google Scholar

Google Scholar

[18] Wu Y, Chen Z X, Rong M Z, Cressault Y, Yang F, Niu C P, Sun H 2016 J. Phys. D Appl. Phys. 49 405203

Google Scholar

Google Scholar

[19] 王海兴, 孙素蓉, 陈士强 2012 61 195203

Google Scholar

Google Scholar

Wang H X, Sun S R, Chen S Q 2012 Acta Phys. Sin. 61 195203

Google Scholar

Google Scholar

[20] Akashi K, Tanaka Y, Nakano Y, Furukawa R, Ishijima T, Sueyasu S, Watanabe S, Nakamura K 2021 Plasma Chem. Plasma Process. 41 1121

Google Scholar

Google Scholar

[21] Colonna G 2019 Rend. Lincei Sci. Fis. Nat. 30 537

Google Scholar

Google Scholar

[22] Colonna G, D'Angola A, Pietanza L D, Capitelli M, Pirani F, Stevanato E, Laricchiuta A 2018 Plasma Sources Sci. Technol. 27 015007

Google Scholar

Google Scholar

[23] Devoto R S 1966 Phys. Fluids 9 1230

Google Scholar

Google Scholar

[24] Devoto R S 1967 Phys. Fluids 10 2105

Google Scholar

Google Scholar

[25] Godin D, Trepanier J Y 2004 Plasma Chem. Plasma Process. 24 447

Google Scholar

Google Scholar

[26] Kramida A, Ralchenko Y, Reader J, NIST ASD Team https://www.nist.gov/pml/atomic-spectra-database [2022-12-1]

[27] Chase M W, Davies C A, Downey J R, Frurip D J, McDonald R A, Syverud A N https://janaf.nist.gov/ [2022-12-1]

[28] André P, Bussière W, Rochette D 2007 Plasma Chem. Plasma Process. 27 381

Google Scholar

Google Scholar

[29] André P, Brunet L, Bussière W, Caillard J, Lombard J M, Picard J P 2004 Eur. Phys. J. Appl. Phys. 25 169

Google Scholar

Google Scholar

[30] Capitelli M, Cappelletti D, Colonna G, Gorse C, Laricchiuta A, Liuti G, Longo S, Pirani F 2007 Chem. Phys. 338 62

Google Scholar

Google Scholar

[31] Colonna G, Laricchiuta A 2008 Comput. Phys. Commun. 178 809

Google Scholar

Google Scholar

[32] Stallcop J R, Partridge H, Pradhan A, Levin E 2000 J. Thermophys Heat Transfer 14 480

Google Scholar

Google Scholar

[33] Aubreton J, Bonnefoi C, Mexmain J M 1986 Phys. Appl. Rev. 21 365

Google Scholar

Google Scholar

[34] Laricchiuta A, Bruno D, Capitelli M, Catalfamo C, Celiberto R, Colonna G, Diomede P, Giordano D, Gorse C, Longo S, Pagano D, Pirani F 2009 Eur. Phys. J. D 54 607

Google Scholar

Google Scholar

[35] Sourd B, Aubreton J, Elchinger M F, Labrot M, Michon U 2006 J. Phys. D Appl. Phys. 39 1105

Google Scholar

Google Scholar

计量

- 文章访问数: 4707

- PDF下载量: 105

- 被引次数: 0

下载:

下载: