-

液滴在织构基底上的自驱动对于理解一些生物表面水的定向运输和自清洁具有重要意义. 本文提出了一种楔形铜基底-单层石墨烯覆层结构, 实现了水滴从楔形基底尖端向宽端的定向快速自驱动. 运用分子动力学方法研究了液滴在织构基底上的自驱动行为, 结果表明, 受基底表面润湿梯度和Young-Laplace压力梯度驱动的水滴最大速度可达73.8 m/s. 能量变化规律表明, 液滴势能和液滴与基底之间的相互作用能存在竞争关系, 使得液滴与基底之间的相互作用能有部分转化为液滴势能, 部分作用于液滴驱动. 从理论上给出了楔形基底上液滴的最大位移与楔形基底角度、基底润湿性和液滴表面张力之间的关系, 通过分析微纳尺度楔形基底宽度的非连续线性增加对液滴自驱动的影响, 解释了液滴最大位移的理论值与模拟值的差异. 此外, 发现了尺寸较小的液滴更易获得较大的自驱动速度, 分析了高速运动的小液滴在无润湿梯度基底上的长距离减速运动对液滴位移规律的影响, 明确了楔形基底两侧悬浮状态的石墨烯对增强液滴输运效率的作用机制. 研究结果将对实现液滴自驱动的单层石墨烯覆盖的功能织构表面设计具有理论指导意义.The self-driving of water droplets on textured substrate is momentous for understanding the directional transport of water on biological surface. In this paper, a novel design of monolayer graphene-covered wedge-shaped copper substrate (GWCS) is put forward to realize the directional and ultrafast spontaneous driving of water droplets from the tip of the wedge-shaped substrate to the wide end. The self-driving behaviors of water droplets on GWCS are studied by classical molecular dynamics. The results show that the maximum spontaneous driving velocity of water droplet driven by surface wetting gradient and Young-Laplace pressure gradient can reach 73.8 m/s. The law of energy variation during the whole droplet self-driving on GWCS indicates that there is a competitive relationship between the potential energy of water droplet and the interaction energy between the droplet and GWCS, i.e. the interaction energy between water droplet and GWCS is partially converted into the potential energy of water droplet. The relationship of the maximum displacement of water droplet with the wedge angle, wettability of GWCS and the droplet surface tension is proposed in theory, and the influence of the discontinuous linear increase of the wedge-shaped substrate width on a nanoscale on the self-driving is analyzed and used to explain the little difference between the theoretical and simulation results. Furthermore, a smaller droplet is easier to obtain larger spontaneous driving velocity, and the influence of long-distance decelerating motion of high-speed small droplet on the non-wetting gradient substrate on the droplet displacement law is clarified. Finally, the mechanism of graphene suspended on both sides of the wedge-shaped copper structure to enhance the droplet transport efficiency is determined. The results will have theoretical significance in designing the functional texture surface covered by monolayer graphene to realize droplet self-driving.

[1] Parker A R, Lawrence C R 2001 Nature 414 33

Google Scholar

Google Scholar

[2] Zhang S N, Huang J Y, Chen Z, Yang S, Lai Y K 2019 J. Mater. Chem. A 7 38

Google Scholar

Google Scholar

[3] Ju J, Bai H, Zheng Y M, Zhao T Y, Fang R C, Jiang L 2012 Nat. Commun. 3 1247

Google Scholar

Google Scholar

[4] Yi S Z, Wang J, Chen Z P, Liu B, Ren L, Liang L, Jiang L L 2019 Adv. Mater. Technol. 4 1900727

Google Scholar

Google Scholar

[5] Yang X, Zhuang K, Lu Y, Wang X 2021 ACS Nano 15 2589

Google Scholar

Google Scholar

[6] Dai H Y, Gao C, Sun J H, Li C X, Li N, Wu L, Dong Z C, Jiang L 2019 Adv. Mater. 31 1905449

Google Scholar

Google Scholar

[7] Daniel S, Chaudhury M K, Gennes P G 2005 Langmuir 21 4240

Google Scholar

Google Scholar

[8] Habenicht A, Olapinski M, Burmeister F, Leiderer P, Boneberg J 2005 Science 309 2043

Google Scholar

Google Scholar

[9] Ang B T W, Zhang J, Lin G J, Wang H, Lee W S V, Xue J M 2019 ACS Appl. Mater. Interfaces 11 27464

Google Scholar

Google Scholar

[10] Lin Y C, Hu Z Y, Gao C L, Guo Z Y, Li C, Zheng Y M 2018 Adv. Mater. Interfaces 5 1800962

Google Scholar

Google Scholar

[11] Ju J, Zheng Y M, Jiang L 2014 Acc. Chem. Res. 47 2342

Google Scholar

Google Scholar

[12] Wang Q B, Yao X, Liu H, Quere D, Jiang L 2015 Proc. Natl. Acad. Sci. U. S. A. 112 9247

Google Scholar

Google Scholar

[13] Liu C R, Sun J, Li J, Xiang C H, Che L F, Wang Z K, Zhou X F 2017 Sci. Rep. 7 7552

Google Scholar

Google Scholar

[14] Hu B B, Duan Z F, Xu B J, Zhang K J, Tang Z X, Lu C, He M J, Jiang L, Liu H 2020 J. Am. Chem. Soc. 142 6111

Google Scholar

Google Scholar

[15] Zhou H, Jing X S, Guo Z G 2020 Langmuir 36 6801

Google Scholar

Google Scholar

[16] Wang F C, Wu H A 2013 Soft Matter 9 5703

Google Scholar

Google Scholar

[17] Yuan Q Z, Huang X F, Zhao Y P 2014 Phys. Fluids 26 092104

Google Scholar

Google Scholar

[18] Verho T, Bower C, Andrew P, Franssila S, Ikkala O, Ras R H A 2011 Adv. Mater. 23 673

Google Scholar

Google Scholar

[19] Chen H W, Zhang L W, Zhang P F, Zhang D Y, Han Z W, Jiang L 2017 Small 13 1601676

Google Scholar

Google Scholar

[20] Li J Q, Zhou X F, Li J, Che L F, Yao J, McHale G, Chaudhury M K, Wang Z K 2017 Sci. Adv. 3 eaao3530

Google Scholar

Google Scholar

[21] Vakarelski I U, Patankar N A, Marston J O, Chan D Y C, Thoroddsen S T 2012 Nature 489 274

Google Scholar

Google Scholar

[22] Liu M J, Li J, Zhou X F, Li J Q, Feng S L, Cheng Y Q, Wang S, Wang Z K 2020 Adv. Mater. 32 1907999

Google Scholar

Google Scholar

[23] Rafiee J, Mi X, Gullapalli H, Thomas A V, Yavari F, Shi Y F, Ajayan P M, Koratkar N A 2012 Nat. Mater. 11 217

Google Scholar

Google Scholar

[24] Xie Q, Alibakhshi M A, Jiao S P, Xu Z P, Hempel M, Kong J, Park H G, Duan C H 2018 Nat. Nanotechnol. 13 238

Google Scholar

Google Scholar

[25] Huang Q J, Zhang Z Q, Liu Z, Zhang F J, Cheng G G, Ding J N 2021 Appl. Surf. Sci. 542 148666

Google Scholar

Google Scholar

[26] Ma M, Tocci G, Michaelides A, Aeppli G 2016 Nat. Mater. 15 66

Google Scholar

Google Scholar

[27] Zhang Z Q, Zhang F J, Huang Q J, Cheng G G, Ding J N 2020 Appl. Surf. Sci. 515 145976

Google Scholar

Google Scholar

[28] Zhang Z Q, Guo X F, Tang H Y, Ding J N, Zheng Y G, Li S F 2019 ACS Appl. Mater. Interfaces 11 28562

Google Scholar

Google Scholar

[29] Guo Y F, Guo W L 2006 Nanotechnology 17 4726

Google Scholar

Google Scholar

[30] Ye H F, Zheng Y G, Zhang Z Q, Zhang H W, Chen Z 2016 Nanotechnology 27 315702

Google Scholar

Google Scholar

[31] Papadopoulou E, Megaridis C M, Walther J H, Koumoutsakos P 2019 ACS Nano 13 5465

Google Scholar

Google Scholar

[32] Horn H W, Swope W C, Pitera J W, Madura J D, Dick T J, Hura G L, Head-Gordon T 2004 J. Chem. Phys. 120 9665

Google Scholar

Google Scholar

-

图 1 水纳米液滴在GWCS上定向运输模型 (a)楔形铜基底模型的俯视图和A-A方向剖视图, 楔形铜基底包括中间的楔形基底、楔形基底两侧的凹槽和凹槽底部底板; (b)水纳米液滴在GWCS上的俯视图和正视图. 粉色是铜基底, 黑色是单层石墨烯, 红白相间的球是水纳米液滴

Fig. 1. Uni-directional self-driving model of a water nanodroplet on GWCS: (a) Top view and A-A sectional view of wedge-shaped copper substrate, the wedge-shaped copper substrate includes wedge-shaped substrate in the middle, grooves on both sides of the wedge-shaped substrate and a copper plate at the bottom of the grooves; (b) top view and front view of water nanodroplet on GWCS. The pink is Cu substrate, the black is monolayer graphene, and the red and white sphere is water nanodroplet.

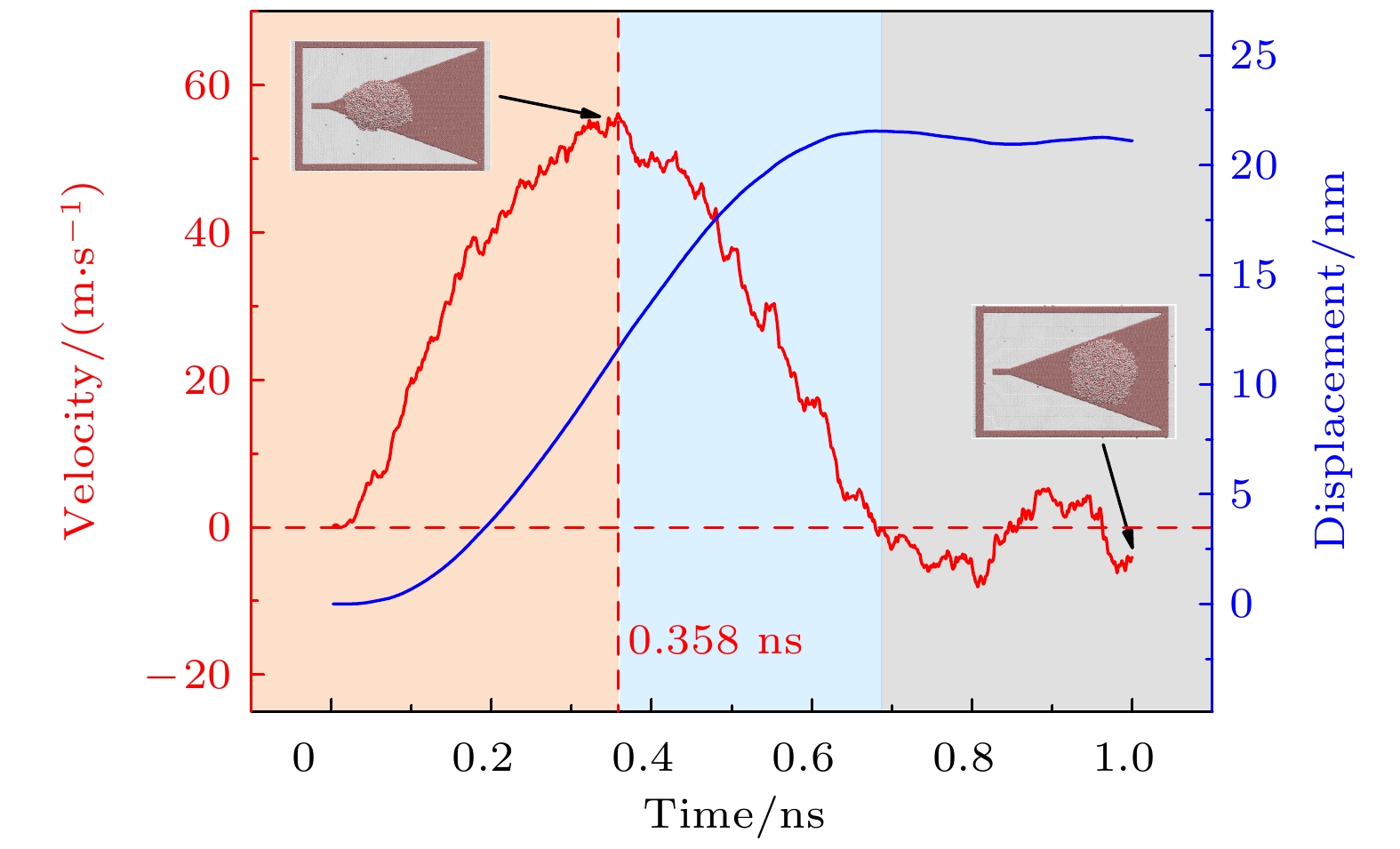

图 2 液滴自驱动的速度、位移与时间的关系, 液滴直径为8 nm, 楔形基底角度为40°, 插图分别为液滴在0.35和1.00 ns时的运动状态, 单层石墨烯模型设置为线条结构且未显示铜基底底板

Fig. 2. Velocity and displacement of the water droplet self-driving on GWCS. The diameter of the water nanodroplet is 8 nm, and the wedge angle of GWCS is 40°, the illustrations show the motion of the droplet at 0.35 and 1.00 ns, respectively. The monolayer graphene model is set to linear structure and the bottom plate of copper substrate does not show.

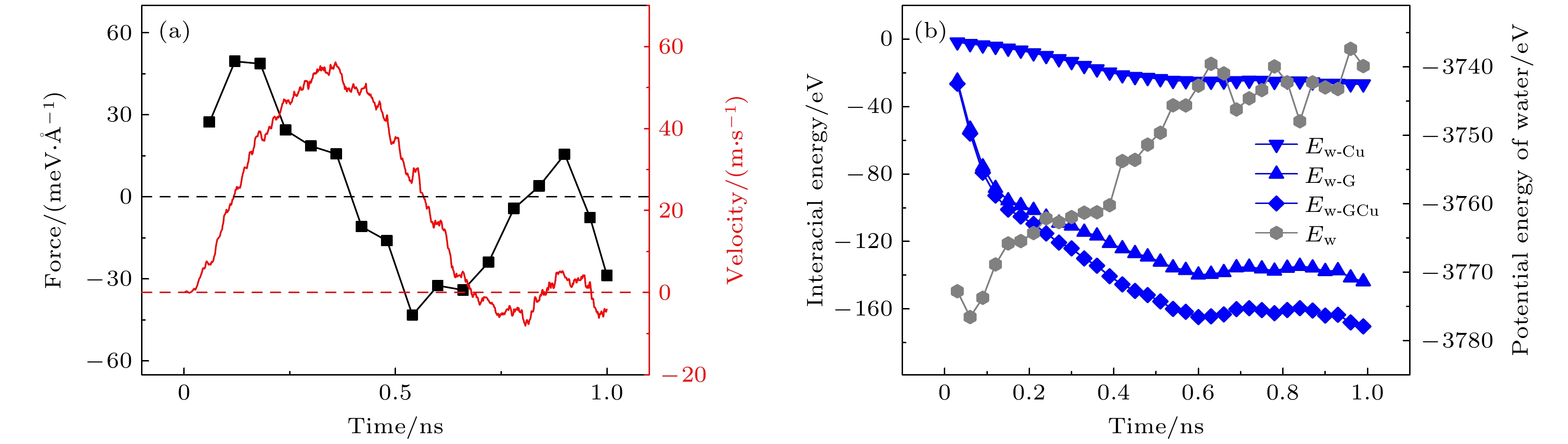

图 3 (a) 液滴前进方向所受的合力F和速度随时间的变化关系; (b) 液滴的势能、液滴与GWCS之间的相互作用能随时间的变化关系. Ew-Cu, Ew-G和Ew-GCu分别为液滴与铜基底、石墨烯、GWCS之间的相互作用能, Ew为液滴的势能

Fig. 3. (a) Resultant force F and velocity of the droplet in +x direction as a function of time; (b) potential energy of water droplet and the interfacial interaction energy between water droplet and GWCS versus time. Ew-Cu is the interaction energy between water droplet and copper substrate, Ew-G is the interaction energy between water droplet and graphene, Ew-GCu is the interaction energy between water droplet and GWCS, Ew is the droplet potential energy.

图 4 液滴自驱动过程中在GWCS上的两种接触状态的俯视图和正视图(未显示铜基底底板, 且俯视图中的单层石墨烯为线条结构) (a) 液滴在GWCS上的接触面包括楔形基底和沟槽正上方的单层石墨烯; (b) 液滴完全处于楔形基底上

Fig. 4. Top and front view of two contact states of the water droplet on GWCS in the self-driving process (the bottom plate of copper substrate is not shown, and the monolayer graphene in the top view is linear structure): (a) Contact area of the droplet on the substrate includes the wedge-shaped substrate and the graphene right above the groove; (b) droplet is completely on the wedge-shaped substrate.

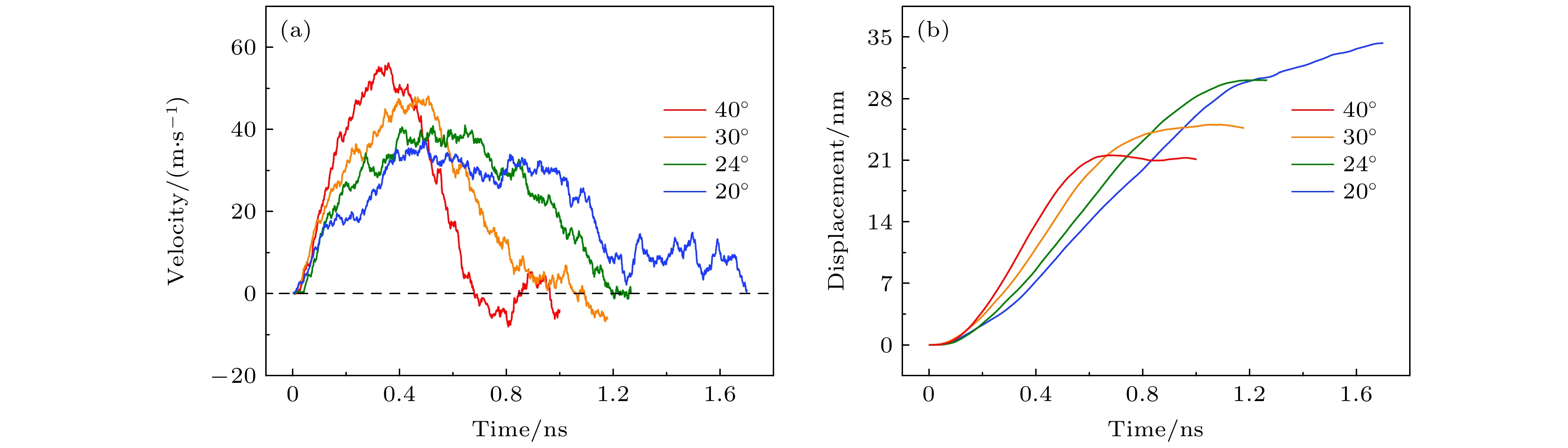

图 9 液滴直径在6−9 nm范围内时液滴尺寸对液滴自驱动的影响 (a) 液滴的速度和(b)液滴的位移随时间的变化关系, 插图为6 nm液滴的最终位置; (c) 液滴最大位移的模拟值与理论值随液滴直径的变化关系和模拟值与理论值的差值相对于液滴直径的比率

Fig. 9. Influence of water droplet size on the droplet self-driving behaviors when the droplet diameter in the range of 6−9 nm: (a) Velocity and (b) displacement versus time, the illustration is the final position of the 6 nm droplet; (c) simulated and theoretical values of the droplet displacement versus droplet diameter, and the ratio of the difference between the simulated value and the theoretical value to the droplet diameter.

图 10 楔形铜结构两侧凹槽深度对液滴自驱动的影响 (a) 液滴的速度和(b)液滴的位移随时间的变化关系; (c) 8 nm直径液滴在凹槽深度为0.904 nm的GWCS上最终运动状态

Fig. 10. Influence of groove depth on both sides of wedge-shaped copper structure on the droplet self-driving: (a) Velocity and (b) displacement of droplet versus time; (c) final motion state of 8 nm diameter droplet on GWCS with 0.904 nm groove depth.

表 1 不同原子之间的LJ势能参数

Table 1. Parameters of LJ potential between different atoms.

Atomic pairs σ ε/meV O-C 3.280 5.13 O-Cu 2.737 34.34 C-Cu 2.857 24.96 -

[1] Parker A R, Lawrence C R 2001 Nature 414 33

Google Scholar

Google Scholar

[2] Zhang S N, Huang J Y, Chen Z, Yang S, Lai Y K 2019 J. Mater. Chem. A 7 38

Google Scholar

Google Scholar

[3] Ju J, Bai H, Zheng Y M, Zhao T Y, Fang R C, Jiang L 2012 Nat. Commun. 3 1247

Google Scholar

Google Scholar

[4] Yi S Z, Wang J, Chen Z P, Liu B, Ren L, Liang L, Jiang L L 2019 Adv. Mater. Technol. 4 1900727

Google Scholar

Google Scholar

[5] Yang X, Zhuang K, Lu Y, Wang X 2021 ACS Nano 15 2589

Google Scholar

Google Scholar

[6] Dai H Y, Gao C, Sun J H, Li C X, Li N, Wu L, Dong Z C, Jiang L 2019 Adv. Mater. 31 1905449

Google Scholar

Google Scholar

[7] Daniel S, Chaudhury M K, Gennes P G 2005 Langmuir 21 4240

Google Scholar

Google Scholar

[8] Habenicht A, Olapinski M, Burmeister F, Leiderer P, Boneberg J 2005 Science 309 2043

Google Scholar

Google Scholar

[9] Ang B T W, Zhang J, Lin G J, Wang H, Lee W S V, Xue J M 2019 ACS Appl. Mater. Interfaces 11 27464

Google Scholar

Google Scholar

[10] Lin Y C, Hu Z Y, Gao C L, Guo Z Y, Li C, Zheng Y M 2018 Adv. Mater. Interfaces 5 1800962

Google Scholar

Google Scholar

[11] Ju J, Zheng Y M, Jiang L 2014 Acc. Chem. Res. 47 2342

Google Scholar

Google Scholar

[12] Wang Q B, Yao X, Liu H, Quere D, Jiang L 2015 Proc. Natl. Acad. Sci. U. S. A. 112 9247

Google Scholar

Google Scholar

[13] Liu C R, Sun J, Li J, Xiang C H, Che L F, Wang Z K, Zhou X F 2017 Sci. Rep. 7 7552

Google Scholar

Google Scholar

[14] Hu B B, Duan Z F, Xu B J, Zhang K J, Tang Z X, Lu C, He M J, Jiang L, Liu H 2020 J. Am. Chem. Soc. 142 6111

Google Scholar

Google Scholar

[15] Zhou H, Jing X S, Guo Z G 2020 Langmuir 36 6801

Google Scholar

Google Scholar

[16] Wang F C, Wu H A 2013 Soft Matter 9 5703

Google Scholar

Google Scholar

[17] Yuan Q Z, Huang X F, Zhao Y P 2014 Phys. Fluids 26 092104

Google Scholar

Google Scholar

[18] Verho T, Bower C, Andrew P, Franssila S, Ikkala O, Ras R H A 2011 Adv. Mater. 23 673

Google Scholar

Google Scholar

[19] Chen H W, Zhang L W, Zhang P F, Zhang D Y, Han Z W, Jiang L 2017 Small 13 1601676

Google Scholar

Google Scholar

[20] Li J Q, Zhou X F, Li J, Che L F, Yao J, McHale G, Chaudhury M K, Wang Z K 2017 Sci. Adv. 3 eaao3530

Google Scholar

Google Scholar

[21] Vakarelski I U, Patankar N A, Marston J O, Chan D Y C, Thoroddsen S T 2012 Nature 489 274

Google Scholar

Google Scholar

[22] Liu M J, Li J, Zhou X F, Li J Q, Feng S L, Cheng Y Q, Wang S, Wang Z K 2020 Adv. Mater. 32 1907999

Google Scholar

Google Scholar

[23] Rafiee J, Mi X, Gullapalli H, Thomas A V, Yavari F, Shi Y F, Ajayan P M, Koratkar N A 2012 Nat. Mater. 11 217

Google Scholar

Google Scholar

[24] Xie Q, Alibakhshi M A, Jiao S P, Xu Z P, Hempel M, Kong J, Park H G, Duan C H 2018 Nat. Nanotechnol. 13 238

Google Scholar

Google Scholar

[25] Huang Q J, Zhang Z Q, Liu Z, Zhang F J, Cheng G G, Ding J N 2021 Appl. Surf. Sci. 542 148666

Google Scholar

Google Scholar

[26] Ma M, Tocci G, Michaelides A, Aeppli G 2016 Nat. Mater. 15 66

Google Scholar

Google Scholar

[27] Zhang Z Q, Zhang F J, Huang Q J, Cheng G G, Ding J N 2020 Appl. Surf. Sci. 515 145976

Google Scholar

Google Scholar

[28] Zhang Z Q, Guo X F, Tang H Y, Ding J N, Zheng Y G, Li S F 2019 ACS Appl. Mater. Interfaces 11 28562

Google Scholar

Google Scholar

[29] Guo Y F, Guo W L 2006 Nanotechnology 17 4726

Google Scholar

Google Scholar

[30] Ye H F, Zheng Y G, Zhang Z Q, Zhang H W, Chen Z 2016 Nanotechnology 27 315702

Google Scholar

Google Scholar

[31] Papadopoulou E, Megaridis C M, Walther J H, Koumoutsakos P 2019 ACS Nano 13 5465

Google Scholar

Google Scholar

[32] Horn H W, Swope W C, Pitera J W, Madura J D, Dick T J, Hura G L, Head-Gordon T 2004 J. Chem. Phys. 120 9665

Google Scholar

Google Scholar

计量

- 文章访问数: 7068

- PDF下载量: 116

- 被引次数: 0

下载:

下载: