-

具有不同组成和形态的聚合物颗粒近来受到越来越多的关注, 它们的表面粗糙度显著影响着其理化性能, 尤其在调节生物材料与生物系统间的相互作用中发挥着重要作用. 本文设计了一种具有表面可调褶皱结构的聚苯乙烯微球. 首先通过微流控装置产生尺寸均一的含有疏水聚合物和助表面活性剂的液滴. 在有机溶剂的挥发过程中, 不断收缩的液滴出现界面不稳定现象. 表面面积自发增大, 固化后得到表面具有褶皱的微球. 研究结果表明, 调节助表面活性剂的浓度以及溶剂挥发速率均可以有效调控微球表面粗糙程度. 循环肿瘤细胞捕获实验表明, 这种褶皱结构能明显增强细胞黏附力, 提高细胞捕获量. 以上这些特征表明这种表面褶皱微球将在生物医学分析领域具备良好的应用前景.Polymer microparticles with various compositions and morphologies have recently received much attention. Their surface-roughness significantly affects the physical and chemical properties, which especially counts in regulating the interaction between biological materials and living systems. In this paper, we design a polystyrene microsphere with controllable surface textures. At first, a microfluidic device is used to generate droplets with uniform size containing the hydrophobic polymer and a co-surfactant. During the volatilization of the organic solvent, the shrinking droplets appear to be unstable at the interface. Thus, the surface area increases spontaneously, and microspheres with wrinkles on the surface are obtained after being solidified. The results show that tuning the concentration of the co-surfactant and the rate of solvent evaporation can effectively regulate the surface roughness of the microspheres. Circulating tumor cell capture experiments reveal that this textured structure can facilitate the cell adhesion and increase the number of the captured cells. These features indicate that the coarse microspheres possess a promising application prospect in the field of biomedical analysis.

-

Keywords:

- interfacial instability /

- microfluidics /

- surface-texture /

- microspheres /

- cell capture

[1] Jo Y K, Lee D 2019 Small 16 1903736

[2] Wang H, Liu Y X, Chen Z Y, Sun L Y, Zhao Y J 2020 Sci. Adv. 6 eaay1438

Google Scholar

Google Scholar

[3] Shang L R, Cheng Y, Zhao Y J 2017 Chem. Rev. 117 7964

Google Scholar

Google Scholar

[4] Iwai Y, Uchida Y, Nishiyama N 2016 Adv. Opt. Mater. 4 1961

Google Scholar

Google Scholar

[5] Visaveliya N, Köhler J M 2015 J. Mater. Chem. C 3 844

Google Scholar

Google Scholar

[6] Zhang X X, Zhao Y J 2019 Sci. Bull. 64 1472

Google Scholar

Google Scholar

[7] Zhang H, Liu Y X, Wang J, Shao C M, Zhao YJ 2019 Sci. China Chem. 62 87

Google Scholar

Google Scholar

[8] Koh L B, Rodriguez I, Venkatraman S S 2010 Biomaterials 31 1533

Google Scholar

Google Scholar

[9] Scopelliti P E, Borgonovo A, Indrieri M 2010 PloS One 5 e11862

Google Scholar

Google Scholar

[10] Campos E, Branquinho J, Carreira A S, Carvalho A, Coimbra P, Ferreira P, Gil M H 2013 Eur. Polym. J. 49 2005

Google Scholar

Google Scholar

[11] Wang Y T, Shang L R, Chen G P, Shao C M, Liu Y X, Lu P H, Rong F, Zhao Y J 2018 Appl. Mater. Today 13 303

Google Scholar

Google Scholar

[12] Wang B J, Pepijn P, Wang H Z, Bai Z H, Wang H L, Luque R, Xuan J 2017 Chem. Soc. Rev. 46 855

Google Scholar

Google Scholar

[13] Zhao C X, Middelberg A P J 2013 RSC Adv. 3 21227

Google Scholar

Google Scholar

[14] Hao N, Nie Y, Zhang J X J 2018 Int. Mater. Rev. 63 461

Google Scholar

Google Scholar

[15] Liu S Q, Deng R H, Li W K, Zhu J T 2012 Adv. Funct. Mater. 22 1692

Google Scholar

Google Scholar

[16] Hussain M, Xie J, Hou Z 2017 ACS Appl. Mater. Interfaces 9 14391

Google Scholar

Google Scholar

[17] 赵凯歌, 薛创, 王立锋, 叶文华, 吴俊峰, 丁永坤, 张维岩, 贺贤土 2018 67 214209

Google Scholar

Google Scholar

Zhao K G, Xue C, Wang L F, Ye W H, Wu J F, Ding Y K, Zhang W Y, He X T 2018 Acta Phys. Sin. 67 214209

Google Scholar

Google Scholar

[18] 夏同军, 董永强, 曹义刚 2018 62 214702

Google Scholar

Google Scholar

Xia T J, Dong Y Q, Cao Y G 2018 Acta Phys. Sin. 62 214702

Google Scholar

Google Scholar

[19] 李东阳, 张远宪, 欧永雄, 普小云 2019 68 054203

Google Scholar

Google Scholar

Li D Y, Zhang Y X, Ou Y X, Pu X Y 2019 Acta Phys. Sin. 68 054203

Google Scholar

Google Scholar

[20] 陈强, 漆小波, 陈素芬, 刘梅芳, 潘大伟, 李波, 张占文 2017 66 046801

Google Scholar

Google Scholar

Chen Q, Qi X B, Chen S F, Liu M F, Pan D W, Li B, Zhang Z W 2017 Acta Phys. Sin. 66 046801

Google Scholar

Google Scholar

[21] Yu Y R, Guo J H, Sun L Y, Zhang X X, Zhao Y J 2019 Research 2019 1

[22] Macosko E Z, Basu A, Satija R, Nemesh J, Shekhar K, Goldman M, Tirosh I, Bialas A R, Kamitaki N, Martersteck E M 2015 Cell 161 1202

Google Scholar

Google Scholar

[23] Zhu P, Wang L 2017 Lab Chip 17 34

Google Scholar

Google Scholar

[24] Li Y Q, Chandran B K, Lim C T 2015 Adv. Sci. 2 1500118

Google Scholar

Google Scholar

[25] Luan C X, Wang H, Han Q, Ma X Y, Zhang D G, Xu Y S, Chen B A, Li M L, Zhao Y J 2018 ACS Appl. Mater. Interfaces 10 21206

Google Scholar

Google Scholar

-

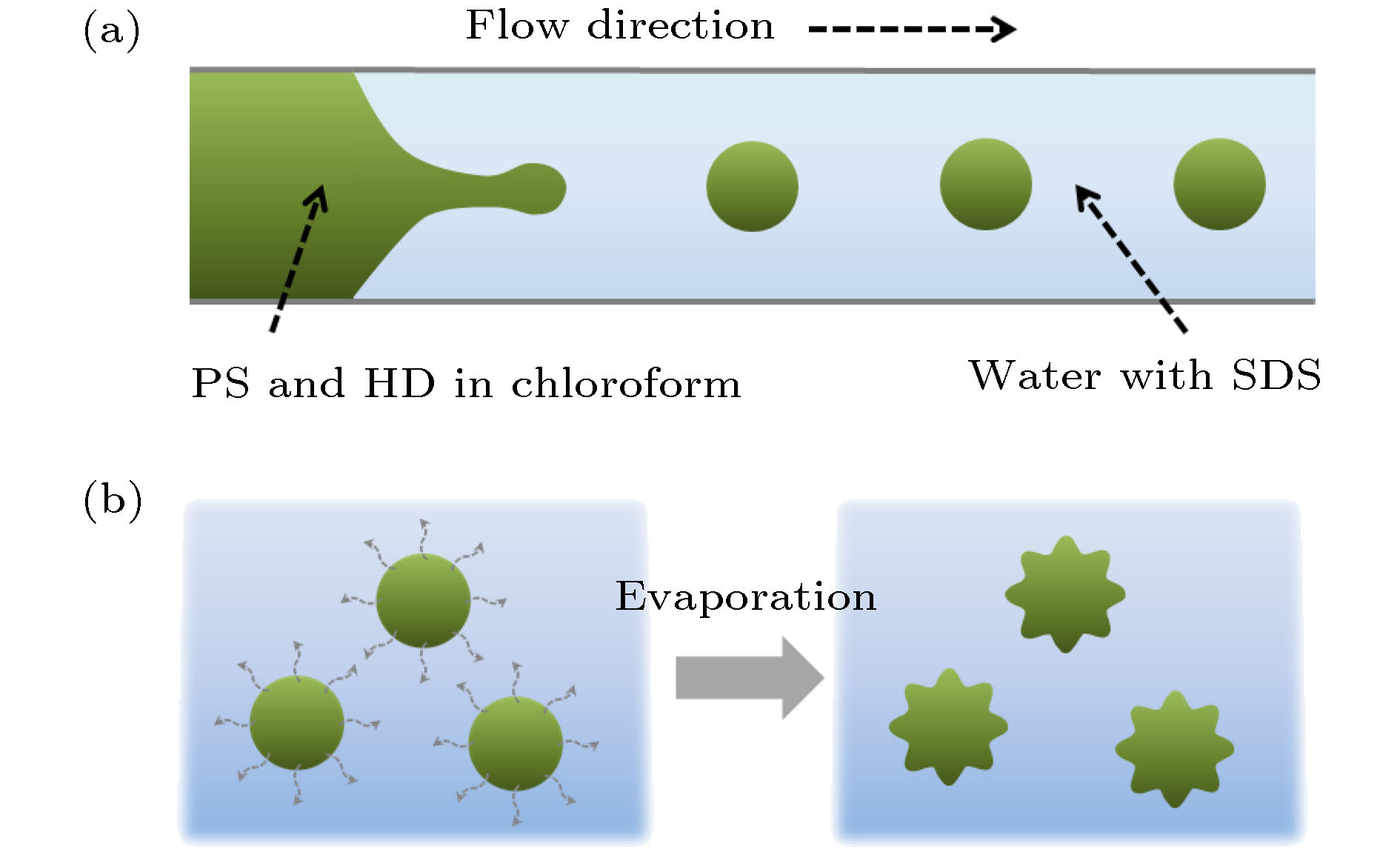

图 1 表面粗糙聚苯乙烯微球的制备示意图 (a) 均匀乳液液滴的微流控生成示意图; (b) 具有表面褶皱的固体微球的形成过程示意图, 在收集皿中, 液滴内氯仿的挥发触发了界面不稳定性现象, 随之产生表面的褶皱

Fig. 1. Schematic illustration of the fabrication of polystyrene microspheres with rough surface: (a) Schematic representation of generating uniform emulsion droplets from microfluidic devices; (b) schematic diagram of the formation process of solidified microspheres with surface wrinkles. In the collection dish, the volatilization of chloroform from droplets triggers the interface instability phenomenon, then the surface wrinkles are generated.

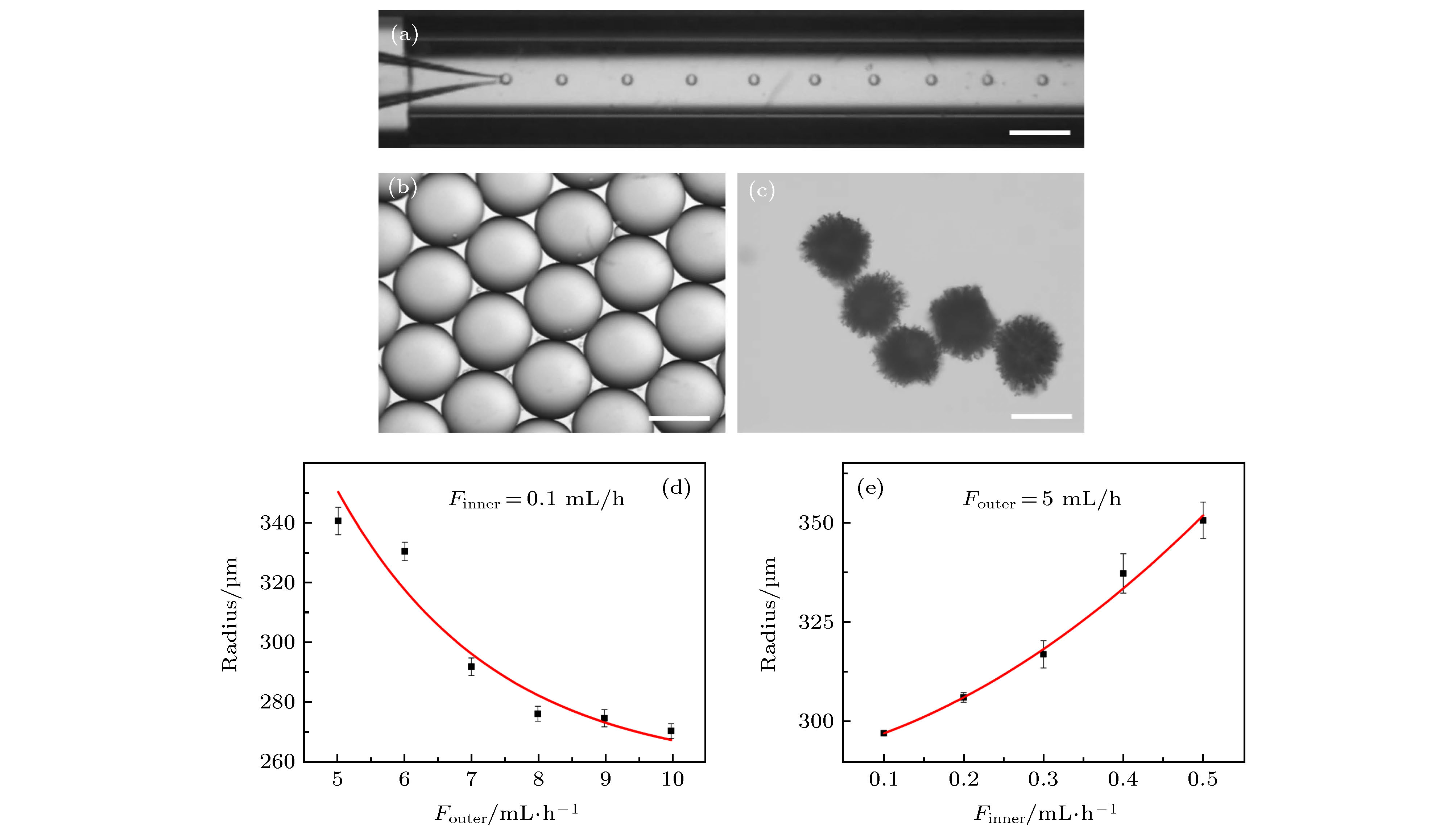

图 2 (a) 微流控通道内液滴的实时生成图像, 比例尺为600 μm; (b), (c) 液滴及其相应PS微球的光镜图片, 比例尺分别为200 和80 μm; (d), (e) 液滴直径和内外相流速之间的曲线关系图: (d) 当内相流速保持在0.1 mL/h不变时, 液滴直径与外相流速间呈负相关; (e) 当外相流速保持在5 mL/h不变时, 直径与内相流速呈正相关

Fig. 2. (a) Real-time images of droplets generated in the microfluidic device, the scale bar is 600 μm; (b), (c) microscope photographs of the (b) droplets and (c) the resultant PS microparticles. The scale bars are 200 μm in (b) and 80 μm in (c), respectively; (d), (e) Relationships of the droplets radius with (d) the same inner flow rate and (e) the same outer flow rate, respectively. Error bars represent standard deviations.

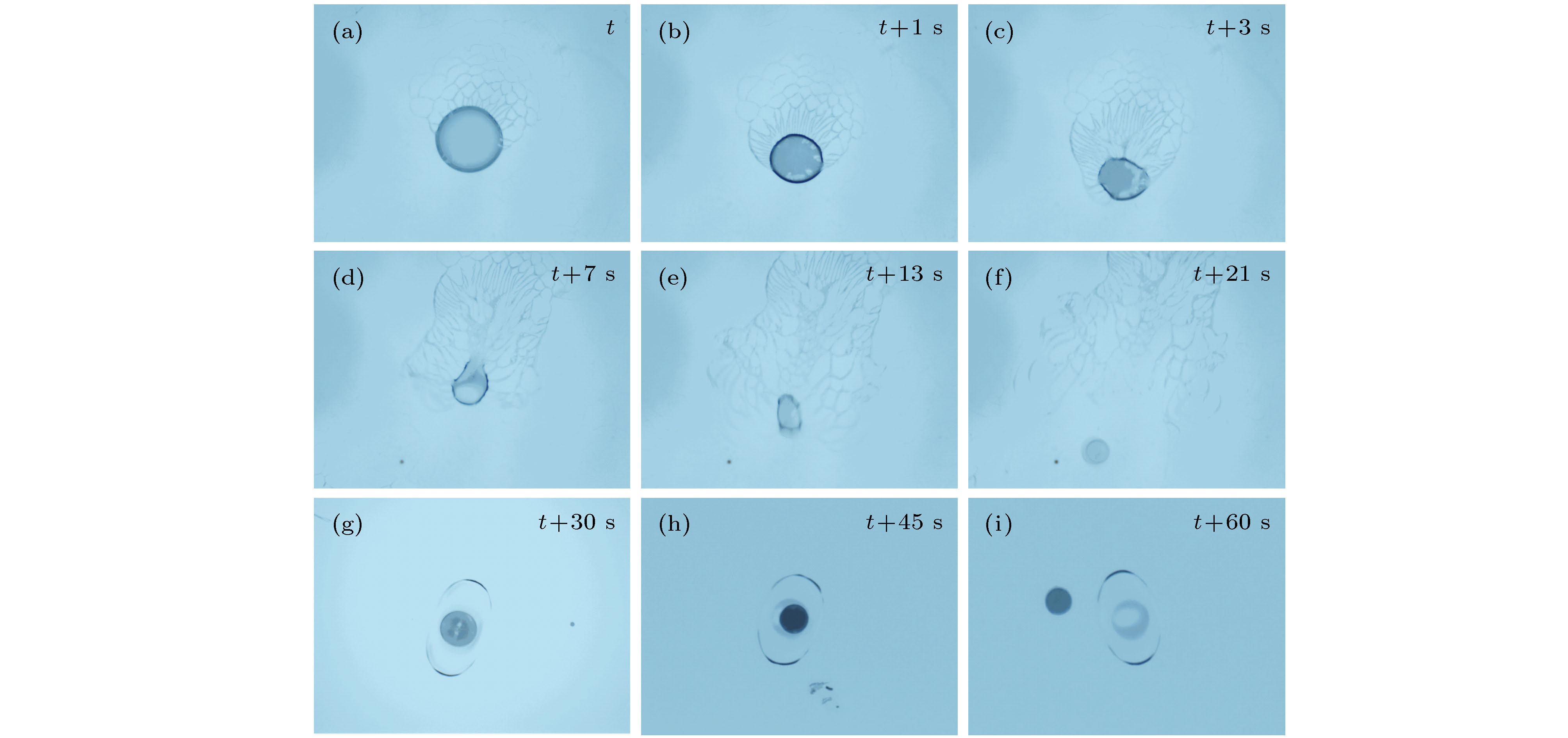

图 3 体式显微镜下观察到的具有褶皱表面的微球的生成过程. 随着氯仿的蒸发, 乳液液滴不断缩小, 同时产生“涟漪状”物质, 最后PS玻璃化形成固化微球, 此过程在常温下约持续1 min. 图(a)−(f)的比例尺为300 μm, 图(g)−(i)的比例尺为250 μm

Fig. 3. Formation process of microspheres with wrinkled surface observed under the microscope. With the evaporation of chloroform, the droplets continue to shrink, and meanwhile, the "ripple-like" substance is produced. Finally, the PS vitrifies to form solidified microspheres. This process lasts about 1 minute at the room temperature. The scale bars are 300 μm in (a)−(f) and 250 μm in (g)−(i), respectively.

图 4 具有不同表面褶皱度的聚苯乙烯微球的光镜和电镜表征. 这些微球是由含有相同浓度PS和不同浓度HD的液滴模板固化得到, 其对应的HD浓度如下: (a), (d) 0 mg/mL; (b), (e) 0.5 mg/mL; (c), (f) 1 mg/mL; (g), (j) 1.5 mg/mL; (h), (k) 2 mg/mL; (i), (l) 3 mg/mL. 光镜图片((a)−(c), (g)−(i)) 和电镜图片((d)−(f), (j)−(l)) 的比例尺分别为45和30 μm

Fig. 4. The optical microscopy and SEM images of the PS microparticles with different surface-roughness. They are obtained from microfluidic droplet templates containing 10 mg/mL PS and varied concentrations of HD: (a), (d) c = 0 mg/mL; (b), (e) c = 0.5 mg/mL; (c), (f) c = 1 mg/mL; (g), (j) c = 1.5 mg/mL; (h), (k) c = 2 mg/mL; and (i), (l) c = 3 mg/mL. The scale bars are 45 μm in ((a)−(c), (g)−(i)) and 30 μm in ((d)−(f), (j)−(l)), respectively.

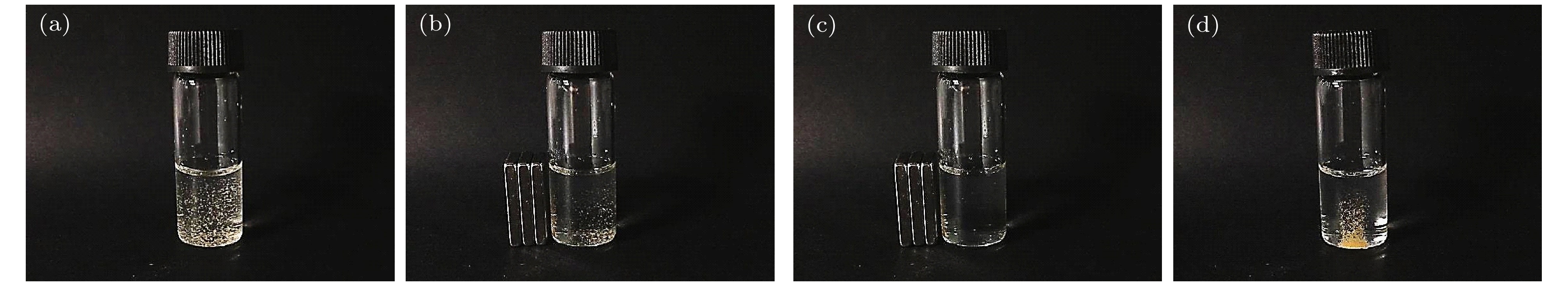

图 5 表面包覆有四氧化三铁纳米粒子的聚苯乙烯褶皱微球被赋予较强的磁响应性. 在永磁铁的引导下, 微球被吸引到靠近磁铁的瓶壁一侧. 图中比例尺为1.5 cm

Fig. 5. Strong mangnetic responsiveness of the highly textured PS microparticles coated with Fe3O4 nanoparticles. Under the gui-dance of the permanent magnet, the microspheres are attracted to the side of the bottle wall near the magnet. The scale bar is 1.5 cm.

图 6 被捕获在微球表面的循环肿瘤细胞的共聚焦激光扫描显微镜图像 (a) 横截面荧光图像; (b) 明场图像; (c) (a)和(b)合并后的图像; (d) 细胞捕获数量与微球表面褶皱度的关系

Fig. 6. The CLSM images of CTC captured onto the surface of the PS microparticles: (a) The cross-section fluorescent images; (b) the white-light images, and (c) the merged images. The scale bar is 30 µm; (d) the relationships of the number of captured cells with the extents of surface wrinkles.

-

[1] Jo Y K, Lee D 2019 Small 16 1903736

[2] Wang H, Liu Y X, Chen Z Y, Sun L Y, Zhao Y J 2020 Sci. Adv. 6 eaay1438

Google Scholar

Google Scholar

[3] Shang L R, Cheng Y, Zhao Y J 2017 Chem. Rev. 117 7964

Google Scholar

Google Scholar

[4] Iwai Y, Uchida Y, Nishiyama N 2016 Adv. Opt. Mater. 4 1961

Google Scholar

Google Scholar

[5] Visaveliya N, Köhler J M 2015 J. Mater. Chem. C 3 844

Google Scholar

Google Scholar

[6] Zhang X X, Zhao Y J 2019 Sci. Bull. 64 1472

Google Scholar

Google Scholar

[7] Zhang H, Liu Y X, Wang J, Shao C M, Zhao YJ 2019 Sci. China Chem. 62 87

Google Scholar

Google Scholar

[8] Koh L B, Rodriguez I, Venkatraman S S 2010 Biomaterials 31 1533

Google Scholar

Google Scholar

[9] Scopelliti P E, Borgonovo A, Indrieri M 2010 PloS One 5 e11862

Google Scholar

Google Scholar

[10] Campos E, Branquinho J, Carreira A S, Carvalho A, Coimbra P, Ferreira P, Gil M H 2013 Eur. Polym. J. 49 2005

Google Scholar

Google Scholar

[11] Wang Y T, Shang L R, Chen G P, Shao C M, Liu Y X, Lu P H, Rong F, Zhao Y J 2018 Appl. Mater. Today 13 303

Google Scholar

Google Scholar

[12] Wang B J, Pepijn P, Wang H Z, Bai Z H, Wang H L, Luque R, Xuan J 2017 Chem. Soc. Rev. 46 855

Google Scholar

Google Scholar

[13] Zhao C X, Middelberg A P J 2013 RSC Adv. 3 21227

Google Scholar

Google Scholar

[14] Hao N, Nie Y, Zhang J X J 2018 Int. Mater. Rev. 63 461

Google Scholar

Google Scholar

[15] Liu S Q, Deng R H, Li W K, Zhu J T 2012 Adv. Funct. Mater. 22 1692

Google Scholar

Google Scholar

[16] Hussain M, Xie J, Hou Z 2017 ACS Appl. Mater. Interfaces 9 14391

Google Scholar

Google Scholar

[17] 赵凯歌, 薛创, 王立锋, 叶文华, 吴俊峰, 丁永坤, 张维岩, 贺贤土 2018 67 214209

Google Scholar

Google Scholar

Zhao K G, Xue C, Wang L F, Ye W H, Wu J F, Ding Y K, Zhang W Y, He X T 2018 Acta Phys. Sin. 67 214209

Google Scholar

Google Scholar

[18] 夏同军, 董永强, 曹义刚 2018 62 214702

Google Scholar

Google Scholar

Xia T J, Dong Y Q, Cao Y G 2018 Acta Phys. Sin. 62 214702

Google Scholar

Google Scholar

[19] 李东阳, 张远宪, 欧永雄, 普小云 2019 68 054203

Google Scholar

Google Scholar

Li D Y, Zhang Y X, Ou Y X, Pu X Y 2019 Acta Phys. Sin. 68 054203

Google Scholar

Google Scholar

[20] 陈强, 漆小波, 陈素芬, 刘梅芳, 潘大伟, 李波, 张占文 2017 66 046801

Google Scholar

Google Scholar

Chen Q, Qi X B, Chen S F, Liu M F, Pan D W, Li B, Zhang Z W 2017 Acta Phys. Sin. 66 046801

Google Scholar

Google Scholar

[21] Yu Y R, Guo J H, Sun L Y, Zhang X X, Zhao Y J 2019 Research 2019 1

[22] Macosko E Z, Basu A, Satija R, Nemesh J, Shekhar K, Goldman M, Tirosh I, Bialas A R, Kamitaki N, Martersteck E M 2015 Cell 161 1202

Google Scholar

Google Scholar

[23] Zhu P, Wang L 2017 Lab Chip 17 34

Google Scholar

Google Scholar

[24] Li Y Q, Chandran B K, Lim C T 2015 Adv. Sci. 2 1500118

Google Scholar

Google Scholar

[25] Luan C X, Wang H, Han Q, Ma X Y, Zhang D G, Xu Y S, Chen B A, Li M L, Zhao Y J 2018 ACS Appl. Mater. Interfaces 10 21206

Google Scholar

Google Scholar

计量

- 文章访问数: 13842

- PDF下载量: 312

- 被引次数: 0

下载:

下载: